NASA’s Fiber Optic Sensing System (FOSS) collected temperature data during the agency’s recent Low-Earth Orbit Flight Test of an Inflatable Decelerator (LOFTID) mission, proving that it’s ready to monitor spacecraft systems for future missions.

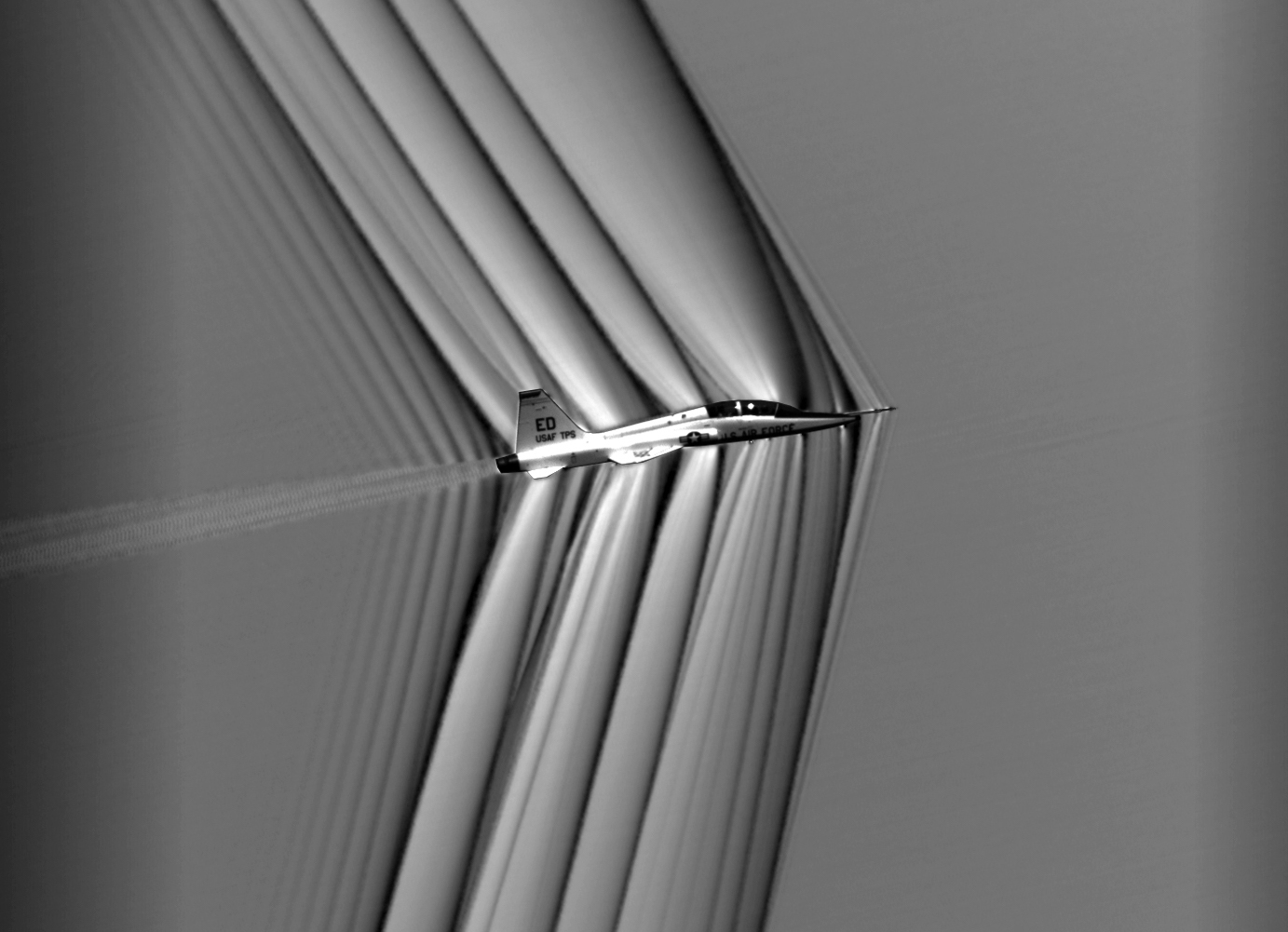

FOSS uses long strands of fiber optic wire about the thickness of a human hair to take thousands of measurements of temperature, strain, and other information critical to mission safety. In the past, collecting and transmitting such data required miles of wires, harnesses to keep those wires in place, and bulky sensors ‑ all of which add weight and complexity to aircraft systems. Originally developed for aircraft at NASA’s Armstrong Flight Research Center in Edwards, California, researchers adapted FOSS for spacecraft use.

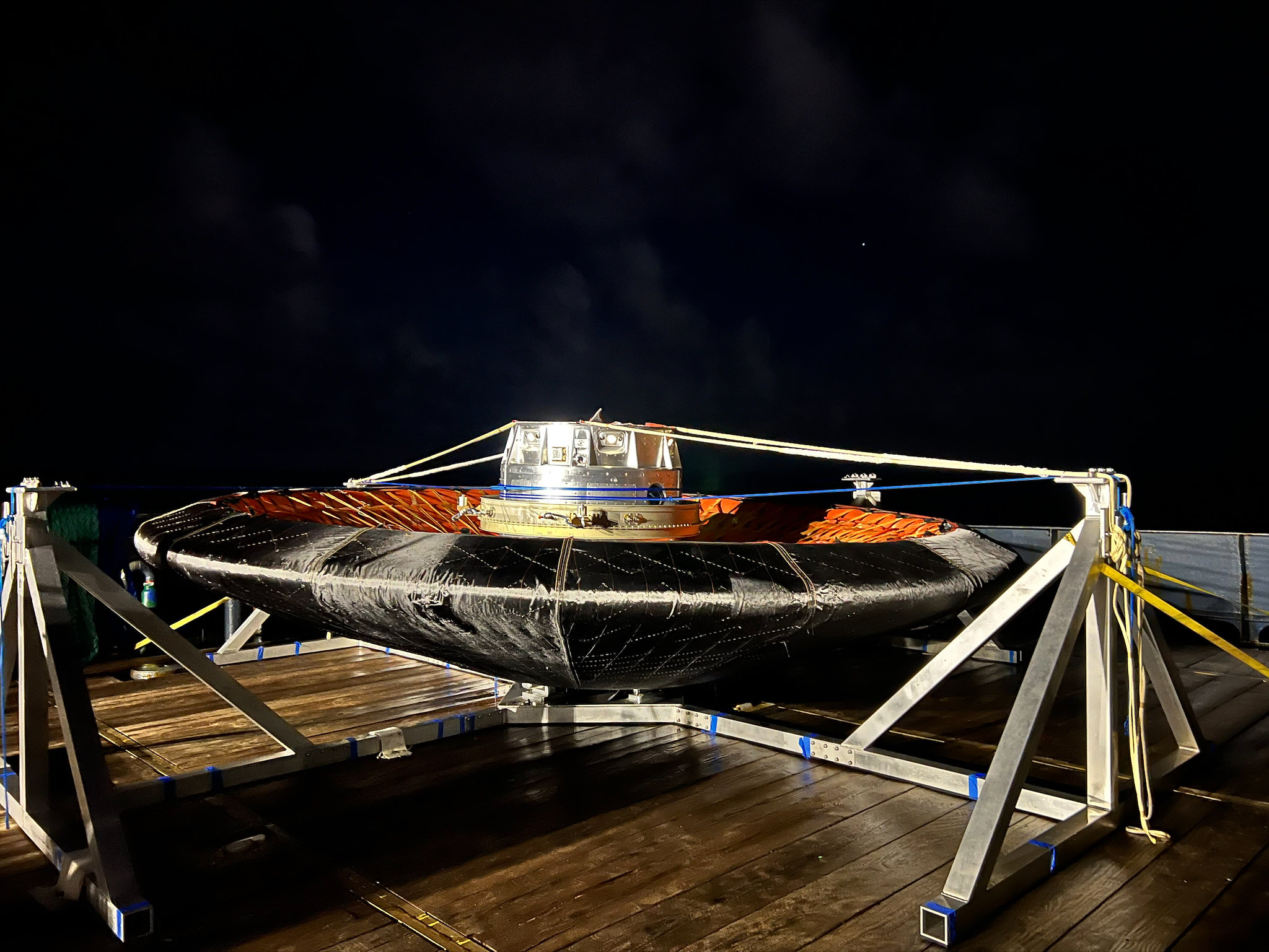

When LOFTID launched Nov.10 aboard a United Launch Alliance Atlas V rocket from California’s Vandenberg Space Force Base, it carried 1,400 FOSS sensors on three optic fibers totaling 60 feet in length, placed in spiral pattern on LOFTID’s nose, while the FOSS box was mounted in the LOFTID reentry vehicle’s midsection.

The LOFTID mission tested inflatable heat shield technology, showing how it could help spacecraft slow down and survive the heat of re-entry. Flying as an experiment within an experiment, FOSS provided a thermal map of the heat LOFTID was subjected to as it re-entered Earth’s atmosphere and landed in the Pacific Ocean. Not only did FOSS survive the rigors of spaceflight, it demonstrated its accuracy too: The temperature information it collected matched the numbers from another system on LOFTID.

“This was our first real opportunity to work on the space side of house in terms of building an avionics system for a launch vehicle,” said Allen Parker, FOSS principal investigator. “We learned a lot from this experience and proved that we have a viable system for space applications.”

Researchers at Armstrong continue to develop FOSS for new applications, including monitoring the health of spacecraft, as well as measuring levels and temperatures of liquid fuel tanks during spaceflight.

“Two private companies have adapted FOSS technology, one company for products to monitor structural integrity in bridges, auto parts, and rockets. The other company adapted FOSS to doctors to track instruments inside the human body with less harmful radiation.

FOSS was originally slated to make its space debut as a self-contained experiment on an uncrewed Blue Origin New Shepard launch in September 2022. FOSS was to take strain, temperature, and flex measurements of a metal beam that was pulled and distorted during the flight. That mission was shortened due to an anomaly shortly after launch. New Shepard’s crew capsule returned to Earth prior to reaching its intended altitude. However, despite this anomaly the team still obtained valuable data.

“We’ve tested the system to the vibration, shock and thermal requirements prior to the launch,” said aerospace engineer Jonathan Lopez.”To have the system actually go through the flight environment, survive, and produce good data was huge step for the FOSS technology.”

“Two space-ready FOSS systems are available for future missions, one at NASA’s Kennedy Space Center in Florida, and the other at the agency’s Langley Research Center in Hampton, Virginia. “We don’t know what those applications will be, but we look forward to supporting what’s coming,” Parker said.

FOSS has applications for commercial space use, such as monitoring structural health of spacecraft components. “A lot of project managers want something low risk, something that is off the shelf,” said Dr. Patrick Chan, Parker’s colleague. “We do have a technology proven to survive and work in space and we expect more interest.”

The FOSS team plans to take advantage of new technology and make the system smaller, simpler, and more robust. The researchers are also developing a new laser for the system and working towards making FOSS able to measure temperature and the levels of cryogenic fluids, such as those found in fuel tanks of space vehicles.

“FOSS can provide more information than conventional methods today. Whether it’s a launch vehicle, a satellite, or a station on the Moon or Mars – wherever you find yourself – there’s a need for system health monitoring,” Parker said. “This can be that technology.”

The Technology Demonstration Missions program in NASA’s Space Technology Mission Directorate manages and funds LOFTID.