Advancing the efficiency of aircraft engines can be improved significantly by increasing the temperature at which they operate. Engine components today are made of super alloys, but operating conditions take these materials to their fundamental limits. In order to further improve fuel efficiency, a new class of ceramic materials made from silicon carbide, are being incorporated into engines. These materials are lighter and can withstand higher temperatures than the super alloys being used today. However, these ceramics erode in combustion environments due to the presence of water vapor.

To solve this problem, scientists and engineers at NASA’s Glenn Research Center have pioneered a process that applies thin, smooth ceramic coating materials to protect the silicon carbide parts.

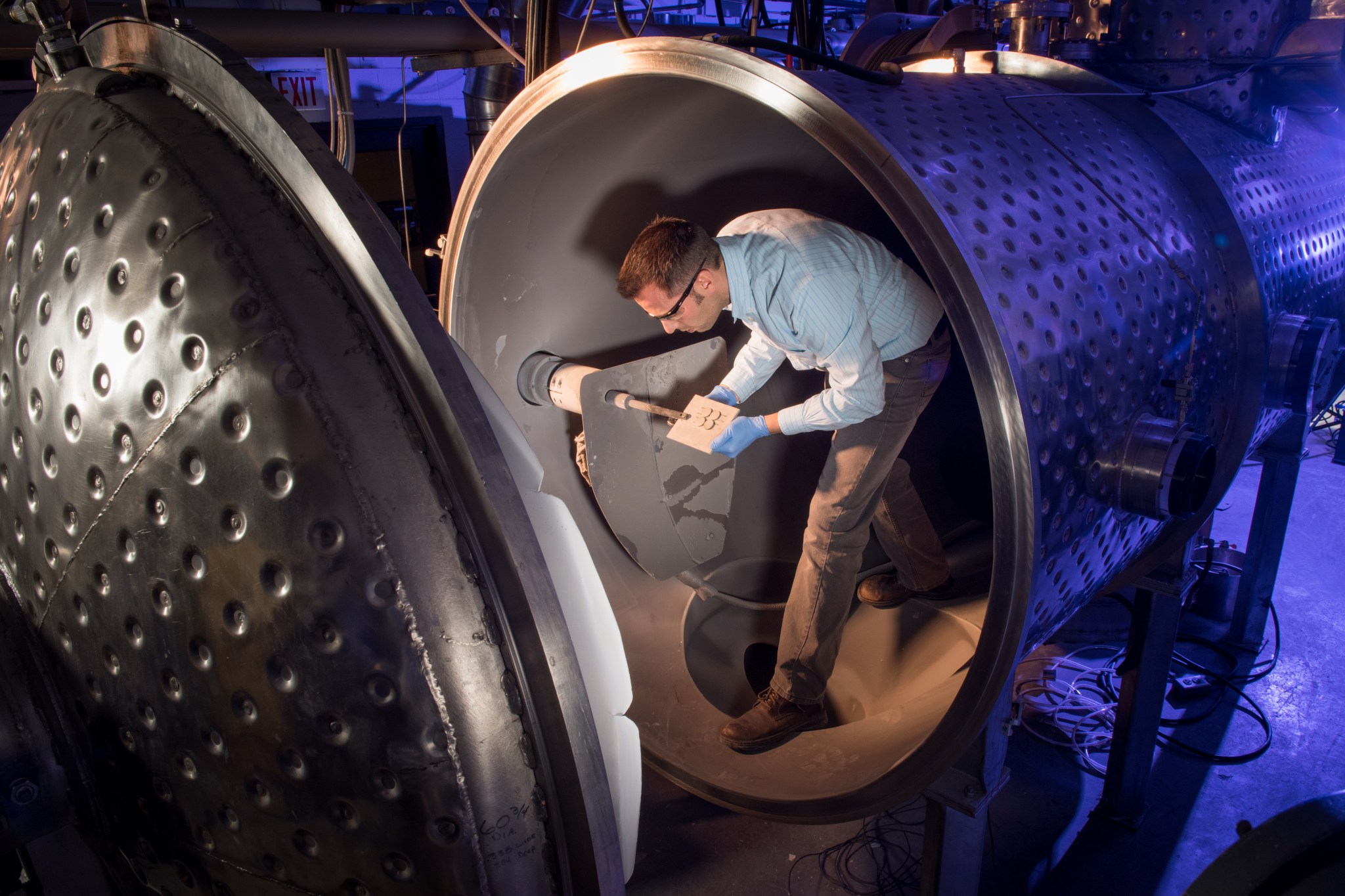

It all happens in the Plasma Spray-Physical Vapor Deposition Rig, a 10 by 6 foot stainless steel chamber. Materials Research Engineer Bryan Harder explains how it works. “The torch creates a high-powered plasma that vaporizes ceramic material and deposits it onto parts very precisely to create durable, long-lasting coatings to protect the components from environmental attack.”

Harder and a team of materials researchers and engineers at NASA Glenn are currently developing the next generation of coatings to allow for operation of turbine engine components up to 2700°F and beyond.

The applications of this game-changing technology are far reaching according to Harder. “Using this high temperature process, we can potentially create coatings rapidly with varied architecture and composition for fuel cells, batteries and sensors, as well as a host of other technologies including space applications,” he says.

NASA Glenn is maturing and developing this technology while making direct contributions to NASA’s aeronautic mission.

Nancy Smith Kilkenny, SGT Inc.

NASA’s Glenn Research Center