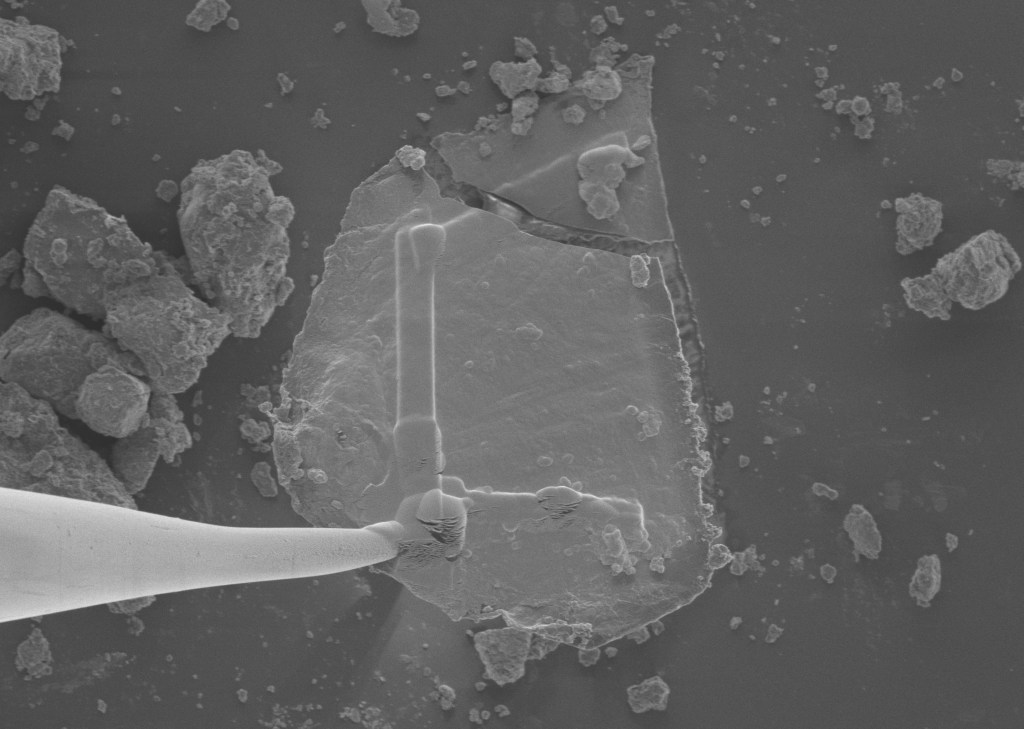

Ratana Meekham, a Qualis Corp. engineering technician at NASA’s Marshall Space Flight Center in Huntsville, Alabama, helps install approximately 5 miles of cable on a half-ring structure being used to test the avionics system that will guide the world’s most powerful rocket, the Space Launch System, on deep-space missions. Qualification testing began March 30 and is an important next step in ensuring the system is “go for launch” for the first flight of SLS in 2018. During testing, the avionics team can troubleshoot any problems with subsystems, and make sure the units communicate together as they are designed to do. The complex avionics system, housed in the SLS core stage, is made up of computers, software and related hardware systems. The avionics hardware units are arranged in flight configuration at Marshall’s Systems Integration and Test Facility, and with the flight software, will replicate what will actually fly the rocket. Engineers at Marshall’s Systems Integration and Test Facility will run simulations in which the flight software works with the avionics just like they will work together to control the SLS during its launch and flight. The initial developmental designs and first power-on testing, known as “first light,” were completed in 2014. It took technicians 11 months to assemble the avionics ring and install the cables for qualification testing, but watch this time-lapse video to see all that hard work happen in just 60 seconds.

Image Credit: NASA/MSFC/Fred Deaton