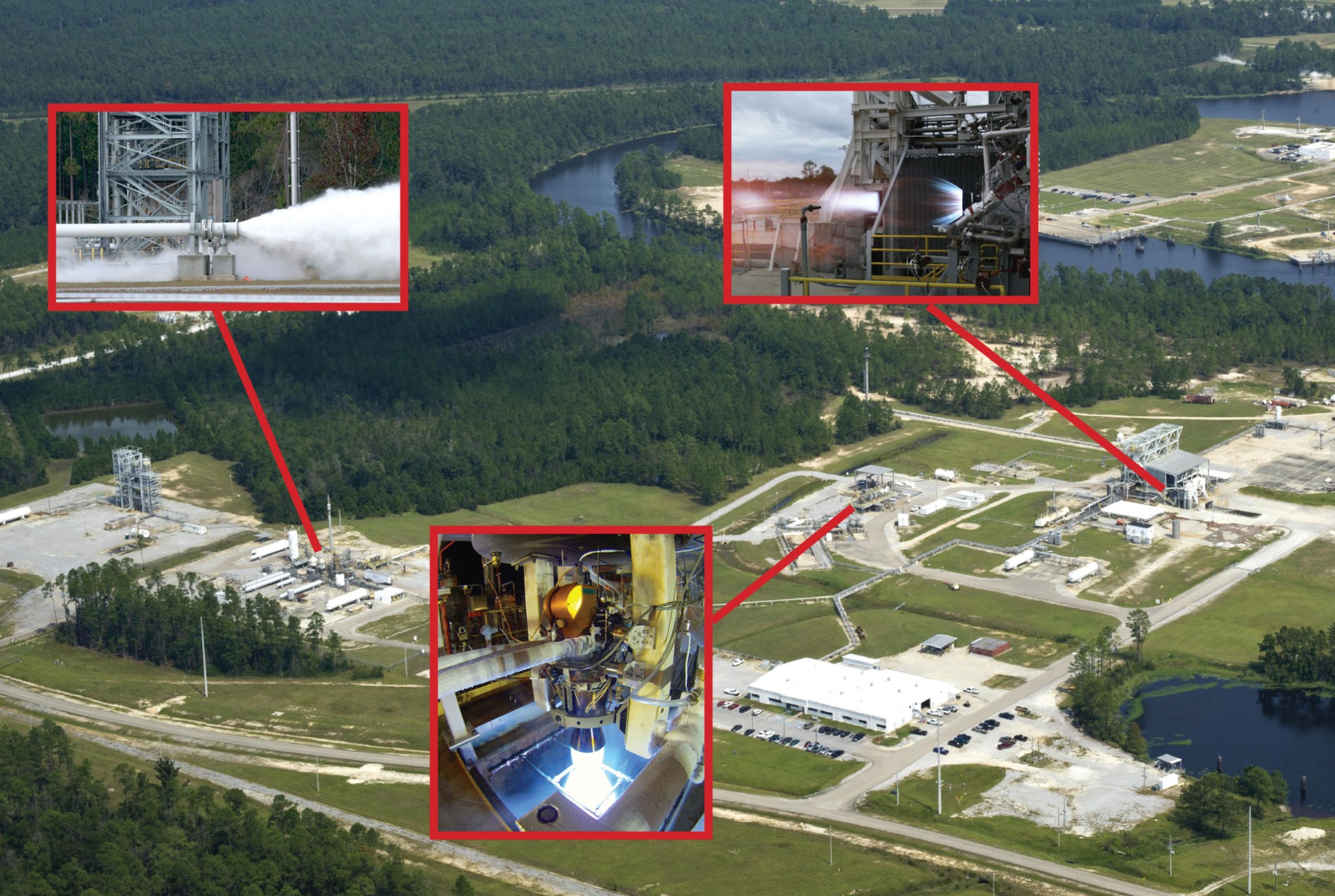

NASA’s Stennis Space Center operated much like a musical symphony at the site’s most versatile testing area – the E Test Complex – 10 years ago with high levels of coordination and a variety of tempos.

Over a three-day stretch the week of Nov. 5-9, 2012, test complex operators conducted 27 tests on three different rocket engines/components on three different test stands. The work demonstrated the flexibility of Stennis employees and their desire to fulfill NASA and commercial space company testing needs.

“This is not something just anybody can do,” then-NASA E-2/E-3 Test Director Craig Chandler said at the time.

The accomplishment involved conducting tests on a Blue Origin engine thrust chamber, a modified steam generator, and a prototype liquid oxygen, liquid methane engine. It also demonstrated the expertise of the Stennis test complex team and the unique capabilities of Stennis’ E Test Complex facilities.

The test team expertise and test complex capabilities have continued to grow since that historic week, operating as a valuable resource as NASA focuses on deep space missions to explore the secrets of the universe for the benefit of all and commercial space initiatives grow.

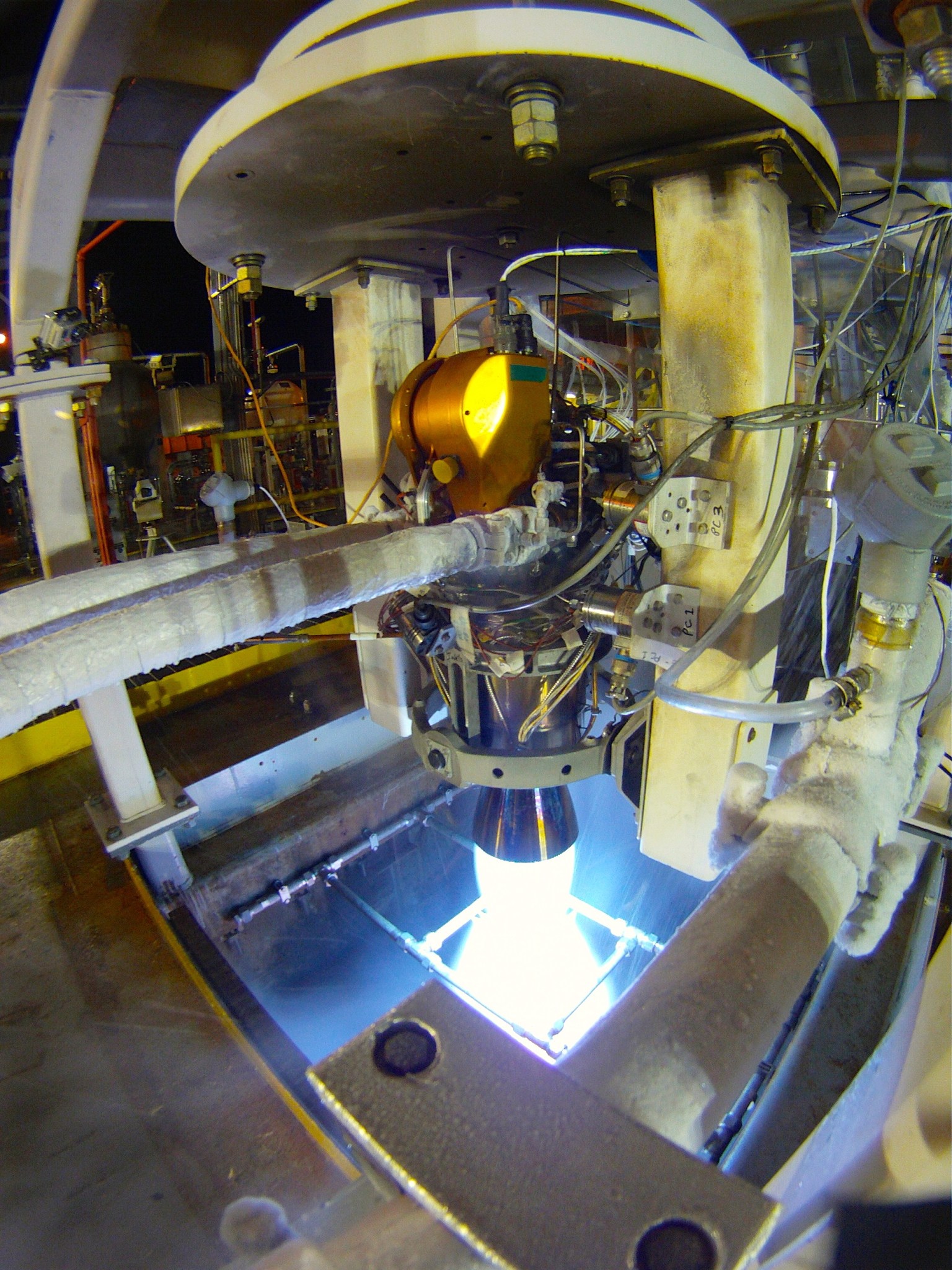

“What makes the E Test Complex unique is the pressures and flow rates it is capable of handling,” explained Stennis Chief of Test Operations Maury Vander.

The three-stand complex includes seven separate test cells that can support testing with ultra high-pressure gases and cryogenic fluids. The capability includes the delivery of liquid oxygen, liquid hydrogen, and liquid methane at pressures up to 8,500 pounds per square inch (PSI).

“There are all sorts of elevated pressures that are not available anywhere else at flow rates like that,” Vander said. “If you have a relatively large engine and are trying to validate a component, it takes high pressure and a high flow rate to do that. That is what really makes the E Test Complex unique, not just for the agency but for the world. There are not many places that can do that.”

In addition, the E-3 Test Complex offers its own unique capabilities. With slightly lower pressures, the E-3 facilities require less modifications to begin a project, meaning commercial partners can receive data in a quicker timeframe at Stennis.

Since the November 2012 record-setting week, Stennis personnel in the E Test Complex have worked with more and more commercial companies. Companies such as Relativity Space, Blue Origin, Launcher, SpaceX, Ursa Major, and Virgin Orbit have taken advantage of complex capabilities. Some of these are currently testing engines/components in the area with success.

SpaceX tested engine components on E-1 and E-2 test stands while developing its Raptor engine for the Starship spacecraft. In April 2021, NASA selected Starship for its human landing system.

In 2017, a California-based space company, Relativity Space, began its partnership with Stennis by testing on the E-3 Test Stand. The relationship soon expanded in 2018, allowing Relativity exclusive use of the E-4 Test Complex.

Relativity now tests on the E-2 and E-4 stands. Last month, it also announced plans for a major expansion of its rocket and engine test facilities at Stennis.

“That’s an example of a company that has a vision and came to Stennis, took advantage of some of our resources and facilities, and are headed toward a launch soon,” Vander said. “They are good example of the value of the E Test Complex.”

In addition to the complex being highly adaptable to meet customer needs, chief among the valuable resources at Stennis are the people working to help companies to be successful in their development and test efforts.

“It was that way 10 years ago and it is even more that way now,” Vander added. “We are getting more involved in the intimate details of our customers, and they are taking advantage of the resources and people who work here to do things we never thought they would do in the past. Our workforce is getting smarter, and our customers are getting smarter. It all leads to being the best we can be and to increasing the likelihood of success for our customers.”

For information about Stennis Space Center, visit:

C. Lacy Thompson

Stennis Space Center, Bay St. Louis, Mississippi

228-363-5499

calvin.l.thompson@nasa.gov