Take a look at your current devices. Can you imagine swapping that smartphone for a gigantic cellphone from the 1980s? Surfing the Internet with dial-up speed? Working out to your favorite music with a cassette player?

Today’s technology is better, faster and more innovative. People have to keep up with the rapidly changing times, and so does the “brain” for the RS-25 rocket engine.

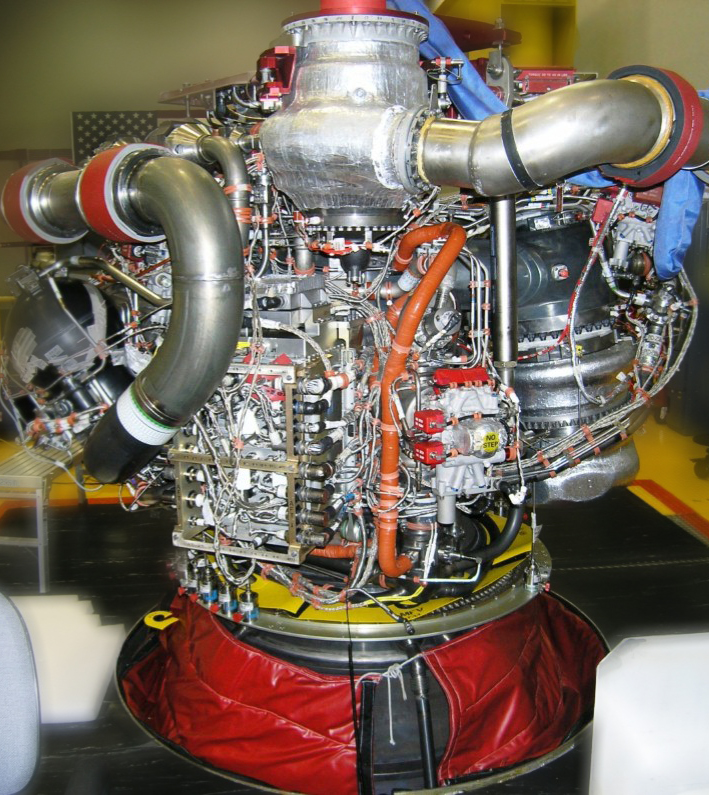

The engine controller unit on the RS-25 — formerly known as the space shuttle main engine — helped propel all of the space shuttle missions to space. It allows communication between the vehicle and the engine, relaying commands to the engine and transmitting data back to the vehicle. The controller also provides closed-loop management of the engine by regulating the thrust and fuel mixture ratio while monitoring the engine’s health and status.

Just like the ever-evolving computer, the engine controller unit needed a “refresh” to provide the capability necessary for four RS-25 engines to power the core stage of NASA’s new rocket, the Space Launch System (SLS), to deep space missions. The core stage, towering more than 200 feet tall with a diameter of 27.6 feet, will store cryogenic liquid hydrogen and liquid oxygen that will feed the vehicle’s RS-25 engines.

“You can’t put yesterday’s hardware on today’s engine, especially since many parts of the shuttle-era engine controller unit aren’t even made anymore,” said Russ Abrams, avionics subsystem manager in the SLS Liquid Engines Office at NASA’s Marshall Space Flight Center in Huntsville, Alabama. Marshall manages the SLS Program for the agency. “We need the most updated control systems for this engine to meet SLS specifications and take us to places we’ve never been before in space.”

Controller development is based heavily on the recent development experience with the J-2X engine controller. An engineering model RS-25 controller is being tweaked and tested at Marshall. At one of the center’s test facilities, engineers are simulating the RS-25 in flight, using real engine actuators, sensors, connectors and harnesses.

A second engineering model controller and RS-25 engine also recently were installed on the A-1 test stand at NASA’s Stennis Space Center near Bay St. Louis, Mississippi. Pending final preparation and activation work, the engine test series is anticipated to begin in 2015.

“NASA and its partners have been working very hard to evolve this crucial piece of hardware and software for the RS-25, and we look forward to seeing it tested on the A-1 stand very soon,” said Johnny Heflin, deputy manager of the SLS Liquid Engines Office at Marshall. “This is an exciting time for everyone involved with this project.”

The RS-25 and controller work are a collaborative effort between NASA and prime contractor Aerojet Rocketdyne of Sacramento, California.

The first flight test of the SLS will be configured for a 70-metric-ton (77-ton) lift capacity and carry an uncrewed Orion spacecraft beyond low-Earth orbit to test the performance of the integrated system. As the SLS evolves, it will be the most powerful rocket ever built and provide an unprecedented lift capability of 130 metric tons (143 tons) to enable missions even farther into our solar system.

For more information on SLS, visit: