Once dubbed “the man who could see air,” NASA engineer Richard T. Whitcomb used a combination of visualization and intuition to revolutionize modern aviation — by turning the shape of the airplane wing on its head.

For decades, Whitcomb had been working on getting aircraft to move faster and more efficiently. By the time he was 34, he had already won the most prestigious honor in aviation, the National Aeronautic Association’s 1954 Collier Trophy, for his critical work to overcome the aviation challenge of the day — the sound barrier.

Sixteen years later, he was working on improving flight efficiency at speeds just below that barrier.

“Most people have to see through testing how air moves on a model,” Roy Harris, former aeronautics director at NASA’s Langley Research Center, told the Washington Post in Whitcomb’s 2009 obituary. “But he had this uncanny ability to accurately sense how air molecules reacted over a surface before he even built the models.”

Conquering Drag

The problem facing aviation engineers was that, as an airplane approached the speed of sound, the air molecules around the wings created drag, forcing the plane to work harder to maintain its speed.

“As an object moves through air, it collides with the air molecules, creating a disturbance,” forming what are essentially sound waves, explains Robert Gregg, chief aerodynamicist for Boeing Commercial Airplanes. “As the object moves faster, approaching the speed of sound, these disturbances that travel at the speed of sound cannot work their way forward and instead coalesce to form a shock wave.”

That was the sound barrier, which aeronautical engineers figured out how to breach in 1947. However, flying near the speed of sound — around 660 mph at cruising altitudes, depending on air pressure and humidity — remained highly inefficient because of the drag caused by these standing shock waves.

Whitcomb set out to conquer the drag. And his bosses at NASA were eager to help him lend his particular brand of genius to the problem. “Though he had a conservative, shy personality, he was a radical in the laboratory,” NASA historian James Hansen wrote of Whitcomb in his history of Langley. “In some respects, management did not know exactly how to deal with him. The best idea any of his supervisors came up with was to leave him alone” and take care of any administrative details slowing him down.

Winging It

Obsessed with the aerodynamics of flight since his childhood, Whitcomb was famous for his single-track focus. He never married, and he often worked two shifts per day, sleeping on a cot at the high-speed wind tunnel facility. His nephew, David Whitcomb, told the New York Times that NASA accountants scolded his uncle more than once for letting his paychecks expire while he used them as bookmarks.

Unlike many engineers, Whitcomb skipped the calculations and went straight to a physical model.

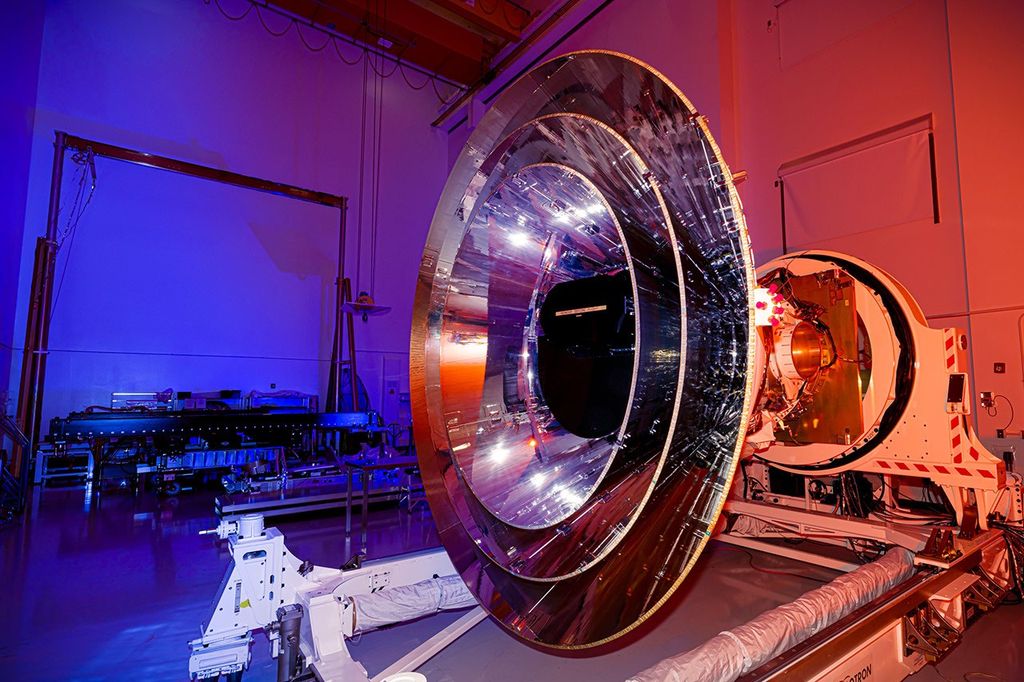

He started with a conventional wing design and, relying on intuition, used auto body putty to add bulk to some areas while filing away others, testing and retesting his models in Langley’s high-speed wind tunnel. He came up with something he called the “supercritical” airfoil. The end result almost looked upside-down compared with standard wings of the day, because it was nearly flat on top and rounded on the bottom. It was also thicker than the norm, especially on its blunt leading edge.

Around the speed of sound, the flatter top minimized the effect of the standing shock wave that formed on the wing, while a downward-curving underside compensated with additional lift. The added thickness also provided a sturdier attachment to the fuselage, allowing for less reinforcing structure and, hence, a lighter wing.

Early testing showed the supercritical wing increased a plane’s efficiency by as much as 15 percent. And it turned out that the wings were more efficient at subsonic speeds as well.

Today, Whitcomb’s supercritical wing design is the industry standard, used in commercial, business and military aircraft all over the world. Its increased efficiency has saved the airline industry billions of dollars in fuel every year, which also means significant reductions in greenhouse gas emissions.

To learn more about this NASA spinoff, read the original article from Spinoff 2015.

For more information on how NASA is bringing its technology down to Earth, visit http://technology.nasa.gov.