As NASA sets its sights on launching deep space missions to the Moon and other destinations, Stennis Space Center, near Bay St. Louis, Mississippi, is developing advanced component designs that could more accurately test the engines needed to power such journeys.

Subscale testing on the E-3 Test Stand at Stennis has validated innovative new diffuser designs to help test rocket engines at simulated high altitudes, helping to ensure the engines will fire and operate on deep space missions as needed.

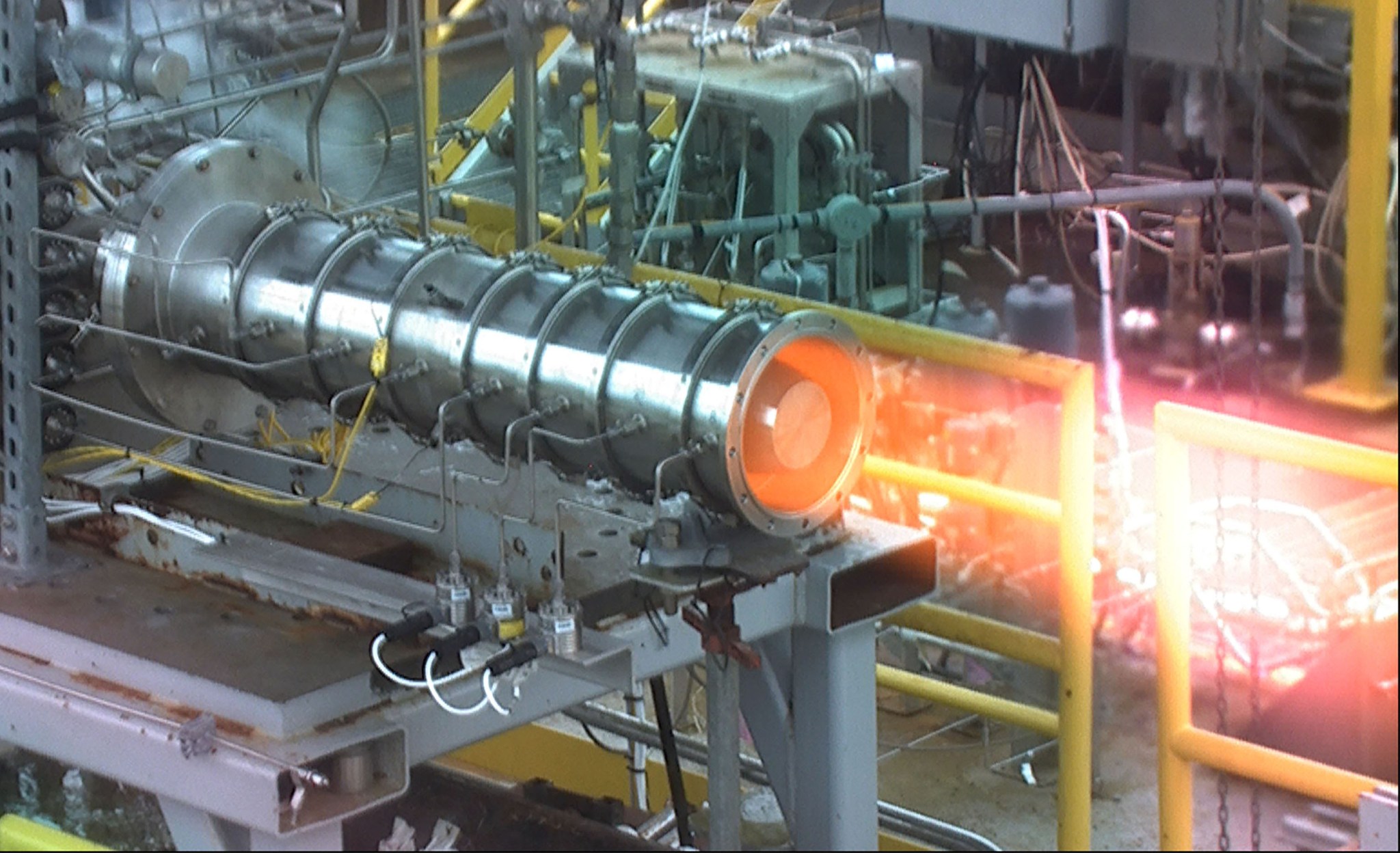

The experimental testing has demonstrated the effectiveness of a previously untested diffuser design and a new innovative design developed two years ago by Stennis engineers. The test team has compared supercomputer simulations to actual test measurements collected from hot fires of a subscale 3D-printed rocket engine and diffuser models.

A diffuser is a critical component for testing high-altitude engine designs. High pressure around the engine nozzle interferes with the way high-altitude engines are designed to perform and could damage the nozzle itself. A diffuser helps reduce the damage by harnessing the power of a rocket’s own exhaust gases to pull a vacuum around the nozzle during a test. It allows the test facility to simulate conditions closer to the low-pressure operating environments found high in the atmosphere and evaluate how a rocket engine will perform during near- or in-space missions.

The diffuser project began as NASA originally planned to conduct simulated high-altitude testing of its Exploration Upper Stage (EUS) unit on the B-2 Test Stand at Stennis. The EUS is being built as a large second stage for use on future missions of the agency’s Space Launch System (SLS) rocket. The EUS will be powered by four RL10 engines and will undergo a series of Green Run systems tests, including a hot fire of its four engines, at Stennis prior to its maiden launch.

Stennis engineers began working on a traditional second-throat diffuser design to simulate high altitudes for the test series and hot fire. The traditional design is based on hand calculations developed prior to the 1980s. However, computers and their new Computational Fluid Dynamics (CFD) capabilities have helped engineers better calculate the effectiveness of such designs and consider more complex and efficient approaches. In this instance, preliminary CFD calculations showed the traditional second throat design would perform poorly for EUS testing.

“Some out -of-the-box thinking was required,” said Nick Nugent, a project engineer in the Stennis Engineering and Test Directorate. “Our engineers designed several types of advanced supersonic diffusers to meet the program’s vacuum requirements.”

Stennis engineers used a center body design never before tested at Stennis and an innovative new spike design developed on site. Early CFD analysis showed both the center body and spike diffusers would perform better for EUS testing. However, the computer analysis needed to be tested.

By the time experiments began, EUS Green Run testing requirements had changed, and the program no longer needed state-of-the-art diffuser performance. However, Stennis engineers moved forward with a subscale project to test the new designs in the site’s versatile E Test Complex.

Testing posed its own set of challenges. First, the teams had to create subscale versions of the test articles, including the RL10 engine that will help power the EUS. Engineers additively manufactured (3D-printed) the subscale engine and used traditional machining methods to fabricate the scaled-down diffusers.

The center body diffuser design also posed a testing challenge. “Typically, a center body (design) in over 4000° Fahrenheit rocket engine exhaust presents a cooling challenge,” explained Nick Nugent, a project engineer in the Stennis Engineering and Test Directorate.

The concept itself is sound, but preventing overheating or melting during hot fire testing is crucial. To mitigate the risk, engineers planned hot-fire test durations lasting fewer than five seconds, preventing any overheating during the E-3 test series.

The Stennis team then put the new diffuser designs to the test, collecting data and comparing the performances of the second throat, center body and spike diffuser configurations. Following an early start, testing at the E-3 location experienced a one-year pause due to the COVID-19 pandemic that hit full force in March 2020. However, test operations resumed once more this year, allowing Stennis engineers to continue their analysis. Test results have been positive.

“This subscale test series has served to validate the aerodynamic performance of those designs,” Nugent said. “The type of innovative diffusers that were developed, then tested, will add to the overall knowledge base and significantly advance the diffuser field.”

Overall, the test series “has been a proving ground for Stennis’ homegrown innovations in hypersonics,” added Daniel Jones, a member of the Stennis Engineering and Test Directorate mechanical design and analysis team who served as the lead analyst and aerodynamic designer for the diffuser research project. “The spike diffuser in particular was the very first of its kind to be designed after Stennis engineers invented the technology.”

The spike diffuser data has shown the best margin during testing, followed by the center body and the traditional second throat designs. By one measurement, the spike design has shown a 51 percent improvement in performance.

The new data adds a fresh layer to the existing diffuser knowledge base, Jones said. “The series is living up to its ‘advanced diffuser testing’ label.”

Additionally, the additive technique used to create the subscale models is showing potential for manufacturing a full-scale version of the new diffuser designs. Engineers theorize that integration of a cooling network inside the large diffuser centerpiece could help prevent overheating damage during full-duration tests. They are hopeful the 3D-printing technique might overcome difficulties in manufacturing the full-scale integrated network and centerpiece.

In the meanwhile, engineers plan to continue testing of the diffuser designs at least through mid-December, continuing to collect data to learn even more about how the different configurations perform.

For information about NASA Stennis Space Center, visit:

C. Lacy Thompson

Stennis Space Center, Bay St. Louis, Miss.

228-363-5499

calvin.l.thompson@nasa.gov