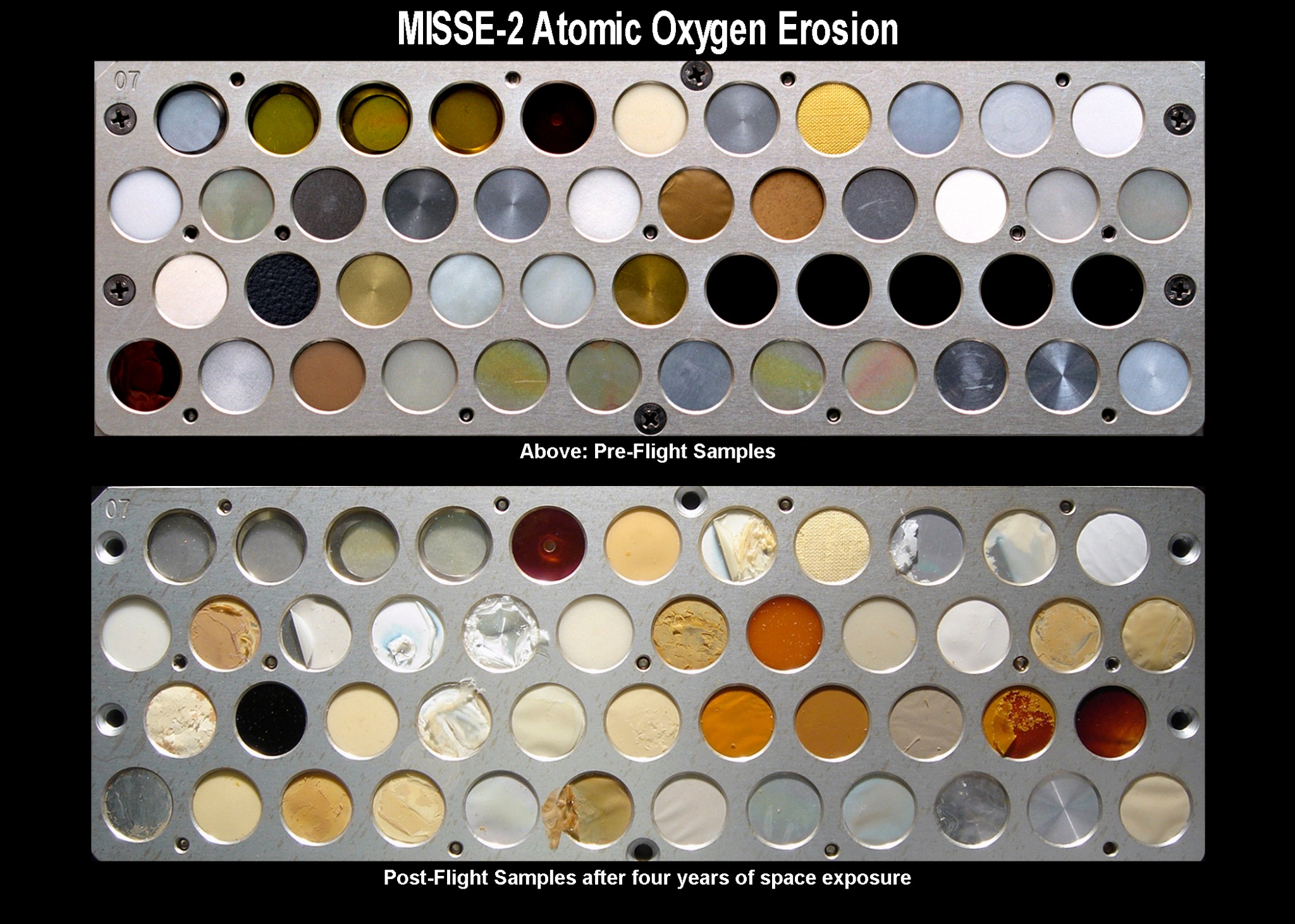

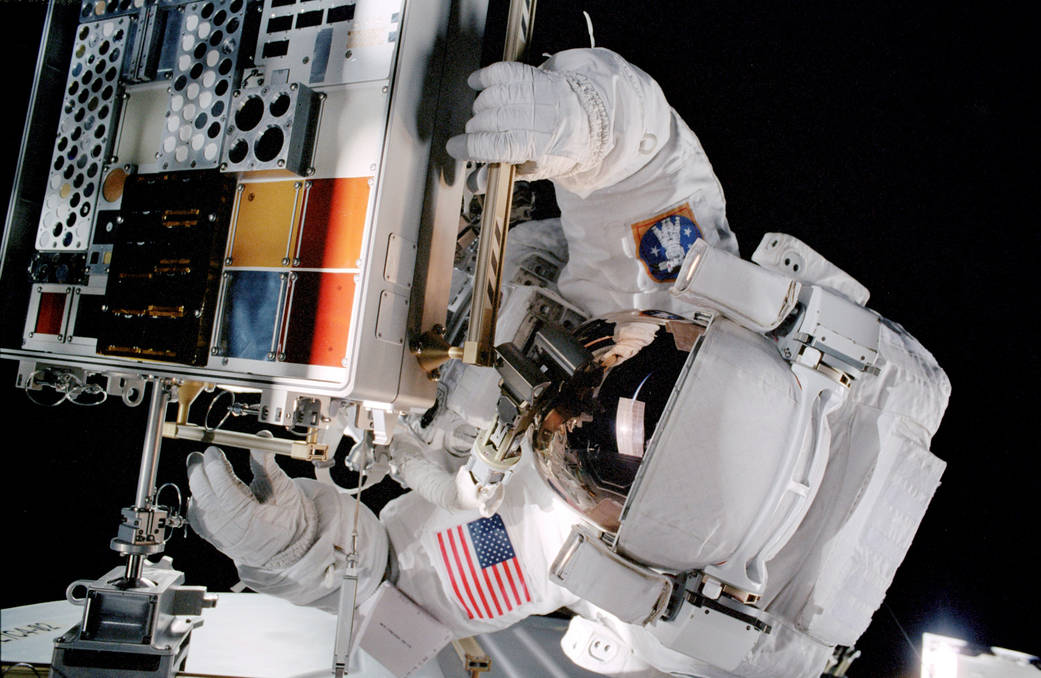

Since 2001, NASA’s Materials International Space Station Experiment (MISSE) series has tested some 4,000 material samples and specimens — from lubricants and paints to fabrics, container seals and solar cell technologies — to demonstrate their durability in the punishing space environment.

Flown 220 miles above Earth, fixed to the exterior of the International Space Station for periods of up to four years, these innovative experiments endured extreme levels of solar and charged-particle radiation, atomic oxygen, hard vacuum, temperature extremes and contamination, giving researchers unprecedented insight into developing durable materials for spacecraft, flight hardware and even astronaut clothing.

Because such research is difficult to simulate effectively in Earth-based laboratories, the MISSE series provided NASA and its partners with crucial insight into the challenges of protecting astronaut health and establishing a permanent human presence in space.

An enhanced version of the MISSE series dubbed MISSE-X, a NASA Technology Demonstration Mission led by NASA’s Langley Research Center in Hampton, Virginia, was a collaborative effort among NASA centers, the U.S. Department of Defense, academia and private industry. By pooling resources, these partners reaped the rewards of collaborating on advanced materials-science research while minimizing individual investment costs.

The MISSE-X concept included new enhancements, such as near real-time experiment monitoring, daily photographing of samples in flight and expanded accommodations to house more, and more complex, experiments. The MISSE-X team also developed plug-and-play mechanical and avionics systems to enable the cost-effective and timely replacement of completed experiments. The concept also included new models to correlate ground- and space-based data, and to compare results in low-Earth orbit with anticipated results in other space environments.

MISSE-X was designed to be robotically mounted and serviced on the station’s exterior. Individual experiments could be placed in modular experiment containers, which would be installed in larger, portable experiment containers. The concept accommodated both active experiments — those receiving space station power and data collection — and passive experiments.

The modular containers could be removed and replaced with other experiments after various periods of space exposure, from six months to three years. Passive experiments and some active experiments could be returned to Earth, where scientists could analyze the materials and devices to see how they fared. That information will be used in the development of new space materials and devices critical to future space exploration missions.

The MISSE-X project was transferred in 2012 from the Technology Demonstration Missions Program to the International Space Station Program. NASA continues to pursue a variety of space-based materials studies supporting future long-duration exploration missions.

NASA’s Technology Demonstration Missions are sponsored by the agency’s Space Technology Mission Directorate in Washington.