The Commercial Infrastructure for Robotic Assembly and Services (CIRAS) project has reached an important milestone in advancing technologies to build large structures in space.

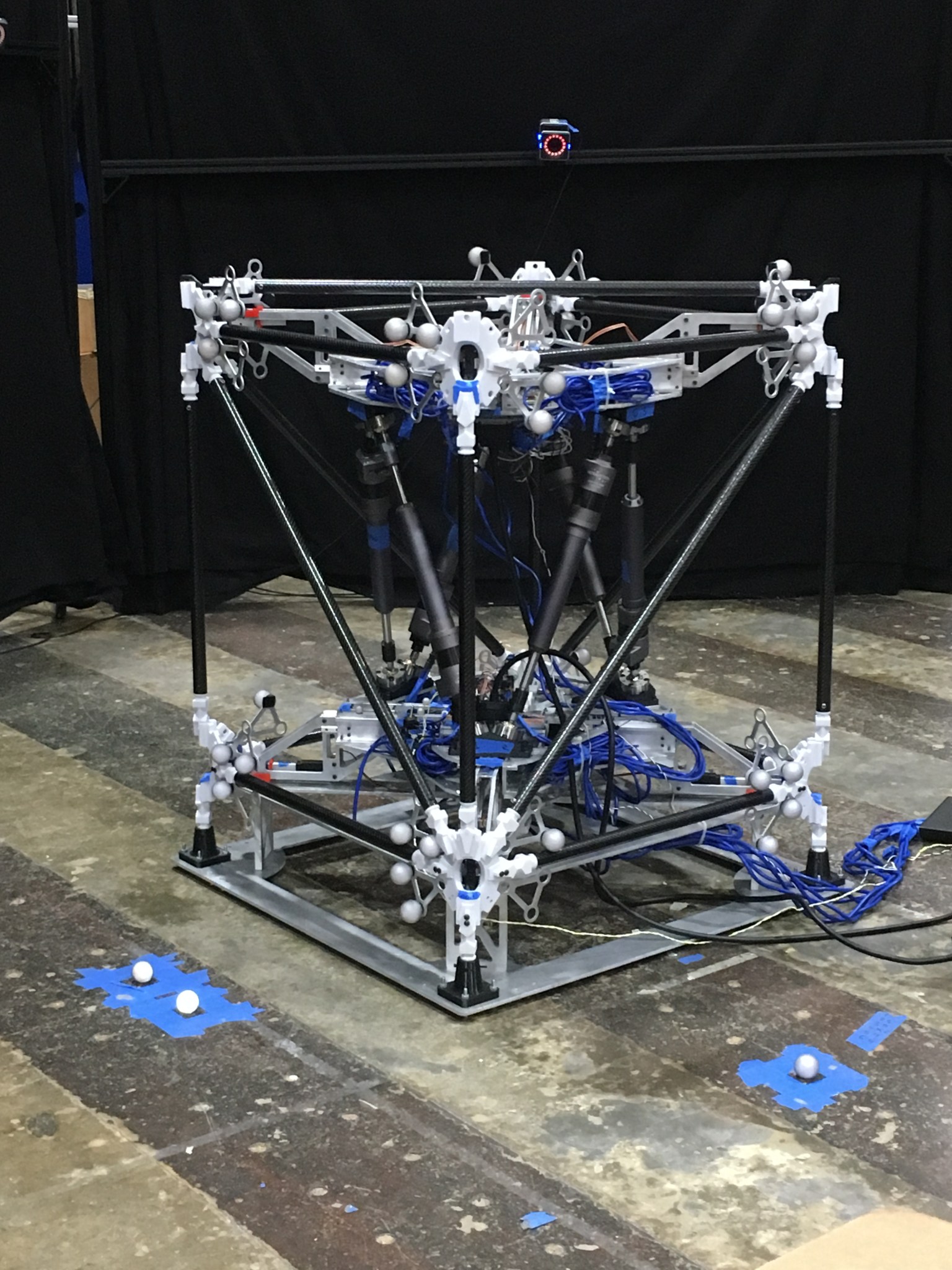

Ground demonstration of the CIRAS component, NASA Intelligent Jigging and Assembly Robot (NINJAR) 2.0, was conducted July 20 in the Structures and Materials Test Laboratory at NASA’s Langley Research Center in Hampton, Virginia.

The objective of the demonstration, in collaboration with industry partner Orbital ATK of Dulles, Virginia, was to assemble a square bay truss made of individual struts and nodes using the NINJAR 2.0. The robotic capability showcased in this demonstration was the NINJAR 2.0’s ability to position and hold the struts into a perfectly aligned square bay truss for the future robotic welder to permanently secure in place. In orbit, these joints will be secured by an electron beam welder.

“The NINJAR 2.0 has refined capabilities to hold pieces of framework together with very high precision to form a perfect cube,” said Dave Moore, project lead for NASA’s Technology Demonstration Missions program. “CIRAS is like a portable workshop. Once it builds the truss out, it can add capabilities such as installation of solar arrays to provide more power to the payload.”

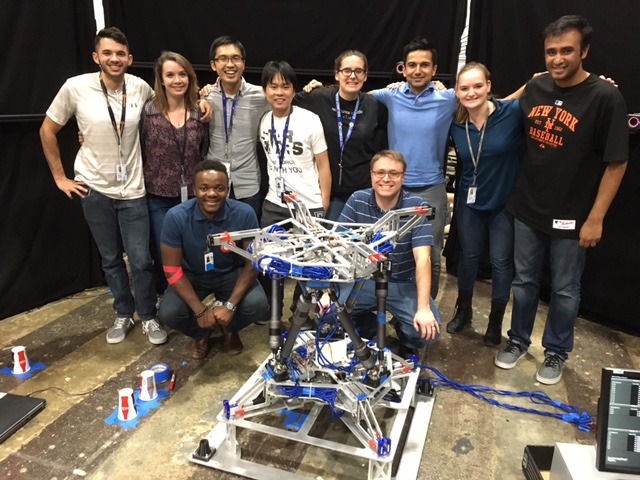

“We are very happy with the performance of the NINJAR 2.0 during this demonstration,” said Charles Taylor, NASA project manager for CIRAS. “All 10 runs conducted were not only within the criteria of success for this demonstration, but were very close to the more stringent criteria for next year’s ground test.”

Dr. Erik Komendera, a research engineer at NASA Langley, and his team of interns have spent the last 10 months working on taking this technology from concept to reality. Komendera and his team’s next focus will integrate the Strut Assembly, Manufacturing, Utility & Robotic Aid (SAMURAI) into the assembly process to pass the struts to NINJAR 3.0 and will develop a state estimation system to use in orbit that will visualize where the struts are and measure the preciseness of the angles. The fully functional CIRAS robotic manufacturing system is set for ground demonstration at NASA Langley in the second quarter of 2018.

The square bay trusses built by CIRAS will serve as the backbone on which space structures are anchored. Currently, structures sent to space are limited by the size of the payload that can fit on the launch vehicle. The advent of practical, robotic in-space assembly and manufacturing will mitigate the need for deployment mechanisms which will greatly reduce the weight of the payload and enable assembly using materials delivered by multiple launch vehicles. This will lead to simplified common architectures of any size, enabling interchangeable parts and driving down costs.

CIRAS, one of three projects awarded under the NASA Technology Demonstration Missions Program’s “Utilizing Public-Private Partnerships to Advance Tipping Point Technologies” solicitation, will help NASA meet its goals for robotic in-space assembly and manufacturing by using existing NASA technologies and building on the capabilities of Orbital ATK’s first Mission Extension Vehicle (MEV-1), scheduled to launch in 2018. The final version will use NASA’s Tendon-Actuated Lightweight In-Space Manipulator (TALISMAN) — originally developed to capture asteroids — to demonstrate the ability to assemble and deploy modular truss structures as well as install and reposition solar arrays on-orbit.

“We are excited by the progress, results and promise of a number of key technologies being developed by the CIRAS team,” said Tom Wilson, president of Space Logistics LLC, a subsidiary of Orbital ATK. “We are making significant progress on our MEV-1, and we look forward to building on to its existing capabilities with the robotic and other technologies developed in the CIRAS program.”

CIRAS is a part of the In-Space Robotic Manufacturing and Assembly project portfolio, managed by NASA’s Technology Demonstration Missions Program and sponsored by NASA’s Space Technology Mission Directorate. The CIRAS team includes prime contractor Orbital ATK, supported by its wholly owned subsidiary, Space Logistics, LLC; along with NASA Langley, NASA’s Glenn Research Center in Cleveland, Ohio, NASA’s Goddard Space Flight Center in Greenbelt, Maryland, and the U.S. Naval Research Laboratory in Washington, D.C.

To learn more about NASA’s Space Technology Mission Directorate, visit: