Harvesting Lessons Learned: NASA has studied past results from both fundamental and applied research, including early InSPA technology demonstrations, and developed a list of best practices to guide principal investigators (PIs) and payload developers (PDs) in future InSPA projects. Although in-space manufacturing is still in its early years, NASA hopes the following best practices aid in accelerating learning and shortening the time to market. Experienced PIs/PDs are invited to share their lessons learned with the NASA InSPA team.

Best Practices:

- Newcomers should select an implementation partner with expertise in NASA’s policies, processes, and procedures, and the associated documents as they apply to your payload. Implementation Partners offer Payload Hardware Development and/or Mission Integration and Operations (MI&O) services to assure the payload meets ISS interface and safety requirements. For more information, please reference the ISS National Lab list of Implementation Partners.

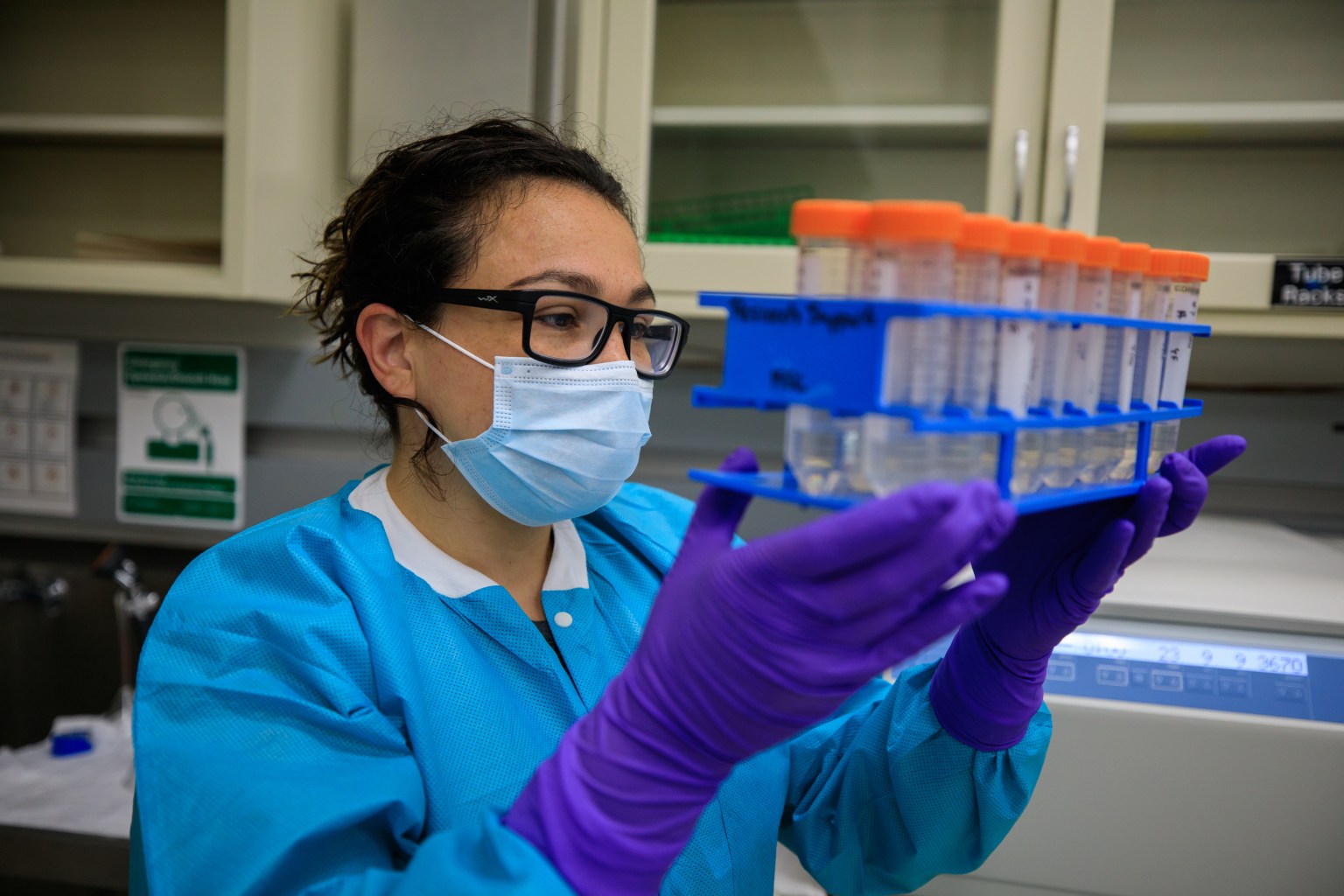

- Know what environments your payload will experience at every step of the flight process and ensure that they are appropriate for your goals. Consider storage characteristics and durations and launch and landing stresses, especially for living tissues, organisms, or environmentally sensitive materials. For more information on payload interface requirements, please refer to NASA technical document, “SSP 57000 – Pressurized Payloads Interface Requirements Document – International Space Station”.

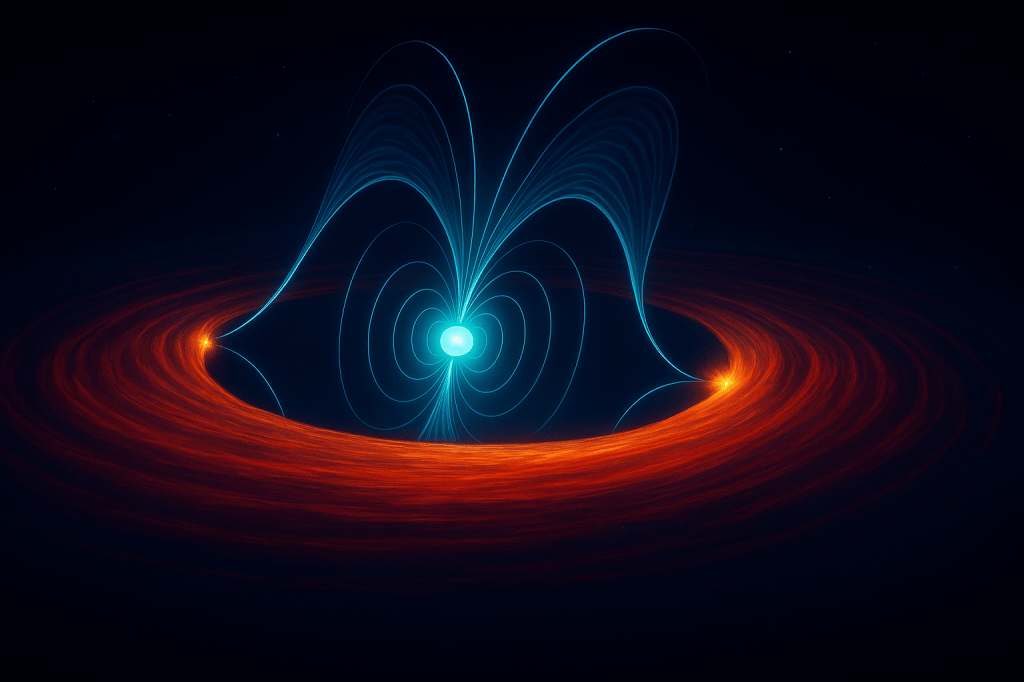

- Some features of microgravity can be enabling for an important outcome. However, other features (or the same ones in different situations) can give unexpected results, e.g., bubbles, Marangoni convection, thermal hot spots, galactic cosmic ray events, and off-gassing.

- Build a second flight unit or flight-like Engineering Development Unit (EDU). This process allows high-fidelity pre-flight tests, in-flight troubleshooting, and high-quality data collection to provide a ground unit for use in troubleshooting during flight as well as design confirmation.

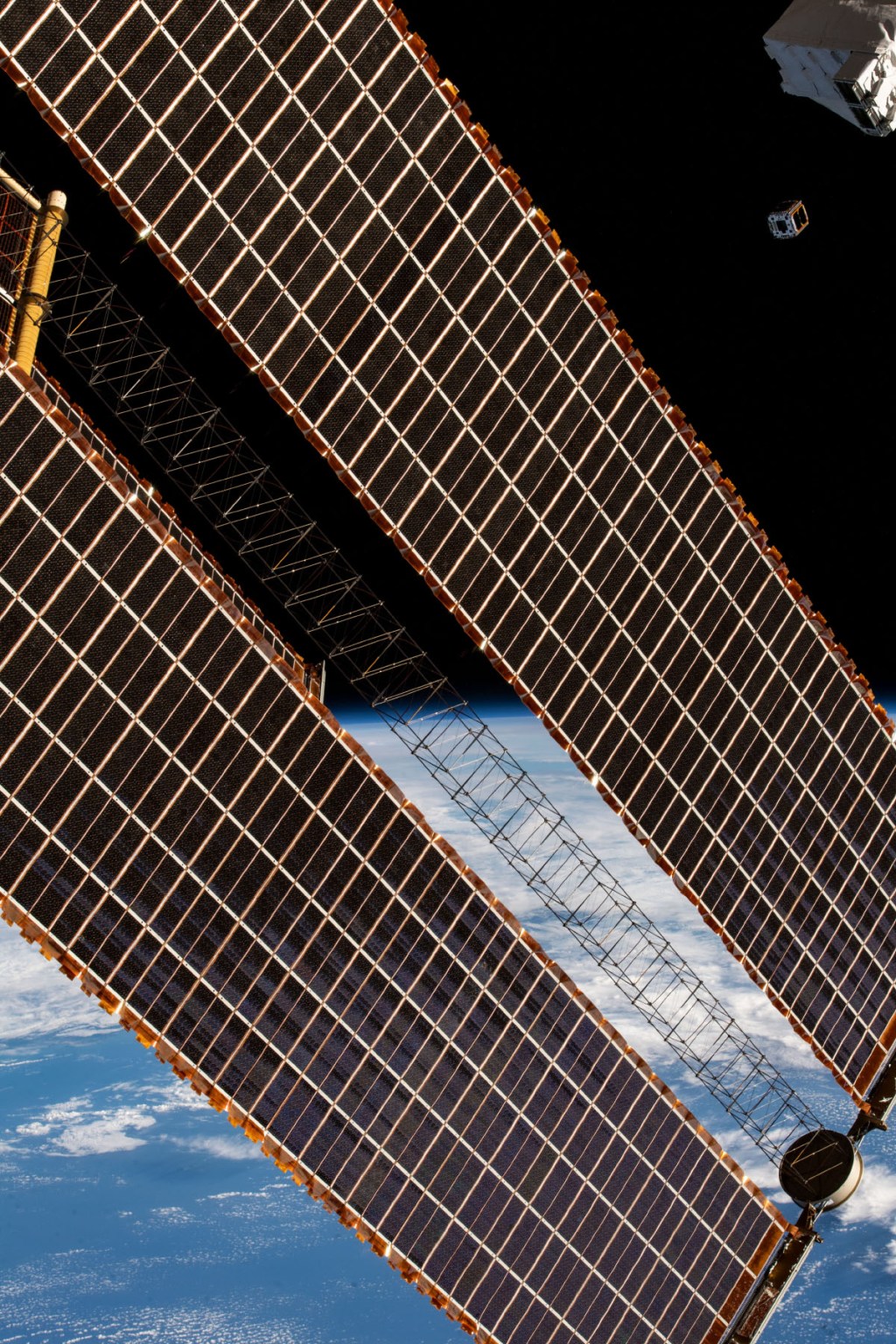

- Plan for video downlink and include adequate sensors to determine causal relationships post-flight. Most payloads have too few sensors and too many don’t have video. Plan to calibrate your sensors on the ground and in-flight. Many systems behave differently in space than they do on the ground and anything generating heat (e.g., furnaces, computers, integrated circuit boards, lights) may affect your payload in space differently than when tested on the ground.

- Prototype quickly and iterate to accelerate learning. The high-tech mantra applies to space: Fail fast, fail often = learn fast, learn often = breakthroughs and superior performance.

- Fly and test your experiment on a parabolic flight (or suborbital flights, if appropriate) to validate your hardware and mitigate risk prior to flying to the space station.

- Enable the astronauts to assist with in-space troubleshooting and iteration. Expect 10 Learning Cycles to be needed for meeting payload goals. More than one Learning Cycle can be achieved in a single flight and other assets, such as artificial intelligence and machine learning (AI/ML), vibration testing, and parabolic flight offer other Learning Cycle opportunities.

- We are seeing higher than expected failures in control and communication systems in some ISS payloads. This could be caused by galactic cosmic ray events frying a circuit, integrated circuit boards overheating because there is no convective cooling, or both. These failures could be caused by both, either, or neither. Providing cooling for electronics including computers is recommended; but for general hardware design, you should develop hardware designed to allow the crew to swap out boards and extra boards.

- Practice, practice, practice. Learn to operate your hardware like a virtuoso plays a violin before a performance at the White House. Make sure to practice with the exact preflight storage, launch, and flight conditions as often as possible, including vibration testing of your hardware under launch conditions. Try to emulate the power conditioning, the ambient environment, etc. on the ISS. Because of the age of some of the spacecraft systems and the nature of vehicle constraints, certain utilities are not the same as you would expect on Earth and will affect your hardware performance.

- Let the data talk to you. Be ruthlessly honest about what results are telling you. Bring in experts to help interpret the findings in real time during flight. Draw on the subject matter experts (SMEs) and guides, such as Space Hardware Experts for Research Production and Applications (SHERPAs). Involve them as early as possible in reviewing your experiment design and hardware, and have them provide support during inflight operations.

- First flights are usually hardware and handling shakedowns. If you have never flown hardware before, you’re in for an adventure! No one should expect the first flight of hardware -, or substantially redesigned hardware, – to work perfectly.

- Include time in your schedule to pack your experiment as you expect to do for the actual flight (with foam, bubble wrap, etc.) and use an available vibration table to see how well your hardware and materials (especially biologicals) can handle launch stresses.