In 2014, NASA made important progress toward the in-space manufacturing necessary for deep space exploration by “printing” tools in space using a 3-D printer on the International Space Station.

In 2018, the nation’s space agency will take the next step toward a sustainable in-space manufacturing capability when it launches a machine that can not only print plastic parts, but can also recycle them back into reusable raw materials to make more and/or different parts.

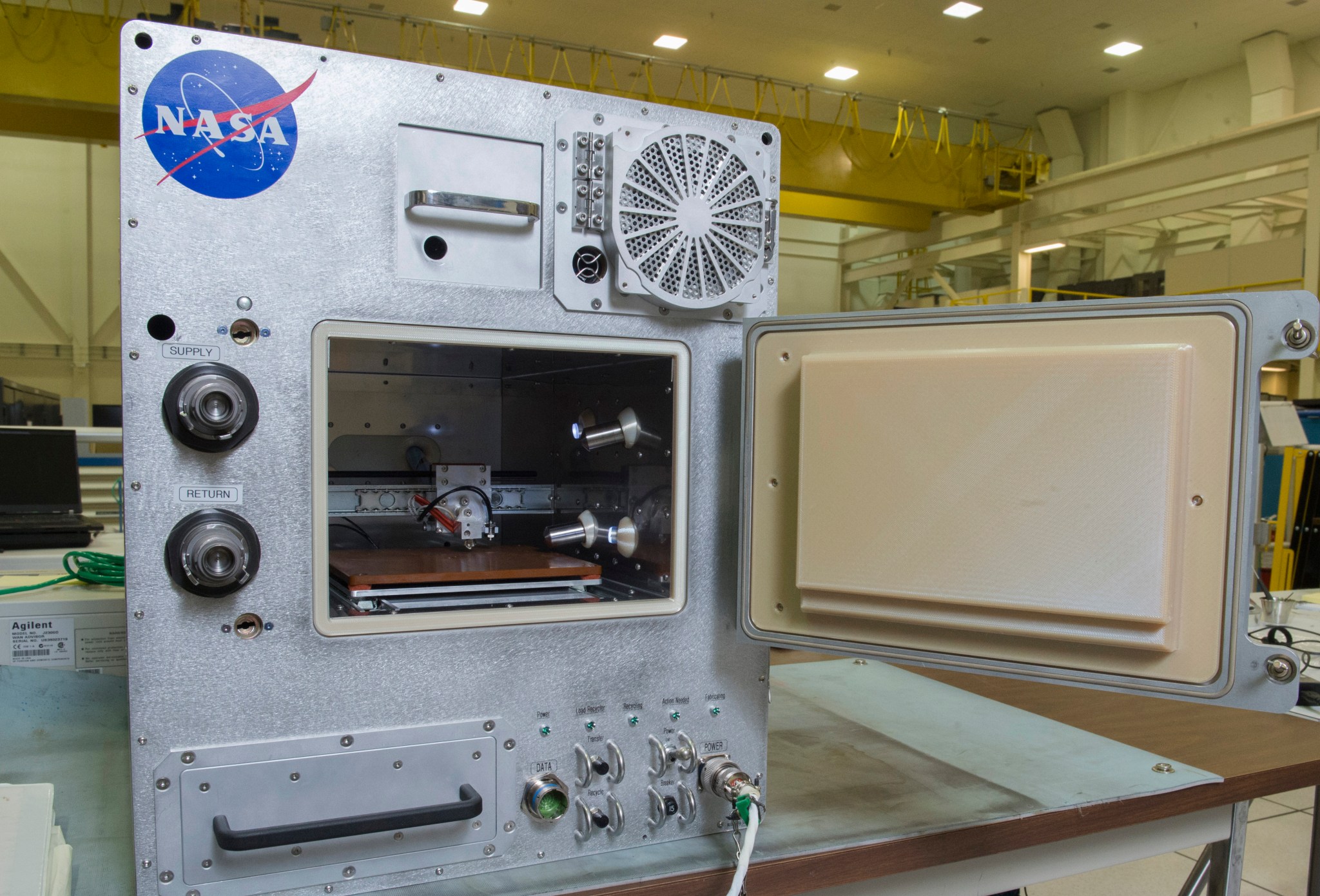

The machine, coined the “Refabricator,” is a device that will accept plastic materials of various sizes and shapes and turn them in to the feedstock used to 3-D print items. The whole process happens in a single automated machine about the size of a dorm room refrigerator.

“When we begin launching humans to destinations beyond low-Earth orbit, space will be at a premium,” said Niki Werkheiser, manager of In-Space Manufacturing at NASA’s Marshall Space Flight Center in Huntsville, Alabama, where the device will be thoroughly tested before launching to the space station. “It simply won’t be feasible to send along replacement parts or tools for everything on the spacecraft, and resupplying from Earth is cost and time prohibitive. The Refabricator will be key in demonstrating a sustainable logistics model to fabricate, recycle, and reuse parts and waste materials.”

NASA awarded a Small Business Innovation Research contract valued at approximately $750,000 to Tethers Unlimited Inc. of Seattle in April 2015, to build the recycling system.

“The Refabricator demonstration is a key advance toward our vision of implementing a truly sustainable, in-space manufacturing ecosystem,” said Rob Hoyt, CEO of TUI. “Astronauts could use this technology to manufacture and recycle food-safe utensils, and turn what is now inconvenient waste into feedstock to help build the next generation of space systems. We believe re-using the waste could reduce the cost and risks for NASA and private space exploration missions.”

The Refabricator will complete final flight certification testing at the Marshall Center in May 2018 and is slated to launch to station in November 2018. Almost all operations will be remotely commanded and controlled from Marshall’s Payload Operations Integration Center – mission control for science on the space station — and TUI. The ability to remotely manage the process can save astronaut time and provide greater autonomy for future spaceflight missions.

“The space station is the ideal proving ground for this important technology,” said Werkheiser. “Astronauts are already living and working in space, a mere 250 miles above Earth. Those crew members are helping make discoveries to benefit humans around the world while testing the important technology, life support systems and medical breakthroughs that will enable long-duration space exploration by humans.”

The Refabricator will be the first integrated recycler-manufacturer in orbit and may eventually be able to recycle and print, using metal as well as plastic, with very little monitoring from the station crew members. By 2020, NASA wants to create a Fabrication Laboratory, or FabLab, to test an integrated, multi-material, on-demand system.

“The FabLab would allow astronauts to select what they want or need from a catalogue of parts and then simply push a button to have it made,” said Werkheiser.

This project is an ideal example of how government and small businesses can effectively work together. In this example, NASA and TUI worked hand-in-hand in the rapid development of a brand new technology for in-space applications. NASA provided guidance and insight on how to design the system to successfully meet the stringent space flight certification, safety, and operations constraints.

NASA continues to leverage open competition, including crowd-sourcing, Small Business Innovation Research awards, Broad Agency Announcements, and challenge competitions, to collaborate and meet space needs for space exploration.

For more information about the Small Business Innovation Research program, visit: