Plum Brook Station Director David Stringer discusses world-unique test facilities at the NASA station in Ohio.

David Stringer: Seems to me it makes much more sense to spend a small fraction — 2 percent or less of a space launch — to find out whether it’s going to work or not. You can find it out on the ground, before you go into low-Earth orbit or higher and try to fix it.

The thing we’re proudest of is most, if not all, our facilities allow you to test at full scale under operational conditions.

Even for the folks with The Avengers, it’s the “wow” of being able to step inside the world’s biggest space chamber.

Deana Nunley (Host): Welcome to Small Steps, Giant Leaps, a NASA APPEL Knowledge Services podcast that taps into project experiences to share best practices, lessons learned and novel ideas.

I’m Deana Nunley.

Plum Brook Station is a remote testing facility for NASA’s Glenn Research Center. Located in Sandusky, Ohio, Plum Brook Station is home to world-class test facilities that perform complex and innovative ground tests for the international space community.

Plum Brook Station Director David Stringer is our guest today. Welcome to the podcast.

Stringer: Glad to be here.

Host: How would you describe Plum Brook Station to someone who hasn’t seen the facility?

Stringer: Well, Plum Brook Station is 10 square miles, 6,400 acres of land with four world-unique test facilities in it. It’s a secure site with securable data and facilities, and we’re fortunate to have 125 people who are trained and equipped for large-scale frozen gas tests in harsh conditions, and we will describe later, but extreme temperatures, pressures, noise, and vibrations. And we can also do explosives and hazardous materials storage on site.

We further have a hundred megawatt power grid, that is engineered so that it doesn’t impinge on the civil grid, which means that we can do big power generation experiments, or buy power in high demand without affecting the customers outside the Plum Brook Station grid. We have large-scale access to gas, water and sewer.

And we’re 50 miles or less from large airports, Mansfield, Ohio, where the Orion capsule and service module came in, and from Cleveland Hopkins, and seven miles from a deep water Lake Erie port of Huron, Ohio. So those are what make Plum Brook unique, and that’s a little bit about the facility. It’s very easy to see on Google Maps. It looks like a Texas-shaped slice of land between the Ohio Turnpike and Ohio Route 2.

Host: Could you tell us about the different facilities at Plum Brook?

Stringer: Sure. Plum Brook Station has four unique facilities. The first one actually is an aeronautic facility, called the Hypersonic Test Facility. It has the ability to run high temperature, 3,000 degree Fahrenheit, non-combusted, so-called clean air, for about five minutes in a test section that is three and a half feet wide and 15 feet long. So that makes it useful for propulsion portions of big hypersonic aircraft, or small missiles that you could put on an airplane. So, with fixed nozzles, we can run at Mach 5 or 6 or 7, but the facility is also capable of handling devices that are hooked up directly, so called direct-connect, and then we can handle from Mach 1.4 up to about Mach 4.5.

So right now, that facility is hosting the NASA Electric Aircraft Testbed, which is a way to increase voltage for aeronautic use. And if you do that, you can really lower the mass of the lines that distribute that power around an airplane. That means weight savings, that means increased payload, or easier fuel consumption, all good things. We’re about three years into our test series to see what the effects of that are.

The altitude chamber, that’s also part of the Hypersonic Test Facility, gives us the ability to find out whether those new electronic devices are susceptible to arcing, and so it’s a nice illustration of a facility built for something, being used for many other things, and actually hypersonics is its second incarnation. Originally, it was designed to test, in a non-nuclear way, a rocket nozzle for a nuclear-powered spacecraft. It’s amazing that the facilities don’t care how they’re used. It’s up to us to look at safe, effective, reliable ways to use them, and so HTF — the abbreviation for the Hypersonic Test Facility — is one of those.

The next facility we’ll talk about is the Combined Effects Chamber. It’s a 25-foot stainless steel diameter sphere, with a removable liquid hydrogen cold wall, so that we can get it a hundred degrees colder than most other facilities on Earth, including the other two that we have, that we’ll talk about next. That’s useful if you’re talking about permanently shadowed craters on the Moon or Mars. It’s also useful because we can put solids, like soil simulant or regolith, in the NASA jargon, so that if you want to ruggedize equipment that humans or robots use, this would be a perfect place to do that. That same plate in the bottom can handle liquid, so it’s a great place to be able to test things like hydrogen and methane in liquid form, if you needed to have a device that would have to survive in those conditions, like space probes that are going out to the liquid moons of the outer planets.

It also has an aeronautic application that’s perfect for explosive decompression. So, this facility is currently mothballed, but we expect as the NASA In-Situ Resource Utilization Program blossoms, we expect this chamber to be activated, and do quite a bit of work for us.

The third facility is our In-Space Propulsion Facility, and this is a very interesting place because it’s the only thermal vacuum chamber. Thermal accounts for hot and cold in the vacuum of space, because the side facing the sun is 300 degrees above zero, the side away from the sun is minus 300 degrees from zero. And so we can put an upper stage or a rocket engine or any other device in and get it acclimated to the cold and vacuum of space, and then within several minutes, bring the pressure up to about 100,000 foot equivalent altitude and fire that engine or upper stage. So having that cold-soaked, in our jargon, and then being able to fire it, is a unique capability in the world.

So, we’re very proud of its use. We’ve also been able to test payloads for the NASA balloon payload program, which gives teams of colleges and universities about one to $2 million, so that the next generation of scientists and engineers can get actual practice by flying their balloons, usually watching from Australia and orbiting the naturally occurring ozone hole over Antarctica to be able to look into Deep Space very cheaply and affordably. So we’re proud of our ability to do that. We’ve also tested the Morpheus Mars Hopper, invented by engineers at Johnson Space Center, in 2017. And so that was our first rocket firing since 1998. We’re heavily into facility preparation for another customer, coming at the end of this year or early next year, to do a upper stage rocket test. So we’re very happy with that.

The In-Space Propulsion Facility is one of the two places where the Crew Dragon, the first Crew Dragon vehicle, was tested. We tested it in the cold and vacuum of space there, and then took it over to our last facility, the Space Environments Complex, where we have four capabilities under one roof. We have the biggest thermal vacuum chamber in the world, a hundred feet in diameter and 122 feet tall. It can get to space conditions in eight hours or less, we’ve done that reliably, which is extraordinary for that volume. We can also test in that same facility, electromagnetic interference and compatibility testing, as we did for Orion. We did both thermal vacuum testing and electromagnetic interference and compatibility testing for Orion.

Then, on the other side of that space chamber, through another set of big concrete doors, we have the most powerful mechanical vibration shaker system in the world, and the most powerful reverberate acoustic test facility. That’s one that mimics the aerodynamic loads that spacecraft feel as they go up through the atmosphere and out of the atmosphere. So when you hear, as we just heard in Crew Dragon’s flight, the point of maximum aerodynamic pressure, that’s what, among other things, this facility can emulate, so that we can make sure that the structures aren’t affected by those incredible stresses of going aloft.

Host: What are your thoughts on the importance of testing?

Stringer: Well, I think it’s interesting to see that you don’t have to test, none of us do, but we also know from our time in elementary school, that if we get tested, it’s a great way for us to check what we know and what we don’t know. If you don’t have enough time to test, or for whatever reason, don’t, that’s fine, but you want to know what your options are so you can make an appropriate decision. You could do flight tests with telemetry, or a return data package. You could do ground testing of the kind that’s available at Plum Brook. And the thing we’re proudest of is most, if not all, our facilities allow you to test at full scale under operational conditions. And we would also suggest that you want to be in a construct that leverages test points and data correlations so that you can minimize the repetitive testing that you would otherwise undertake.

So you want to define that testing upfront when you design a program, because you’ll like it better if both the users and the people who acquire systems understand the possible trades, some on technology cost and timeline, and test capabilities like ours are often very slow to bring online. Most of the time, if people don’t think about it ahead of time, they’ll simply live with risk, and that can either be good or bad as the program unfolds.

It’s much cheaper to test early on than it is later on, and one of the things I’ve noticed, both in the military and in NASA, is we teach experimental methods well, but we don’t teach people where test facilities are. So part of what you’re helping me do is explain Plum Brook to people who might be interested to use it. There’s no reason why you can’t compare various test facilities and their capability, price and availability, versus each other, or on flight tests, but you want to take a look at the facility you’re talking about before you make a final decision. There’s plenty of data out there, but nothing tells you about a facility like putting your eyes on it. So, if we made such relationships among each other, we’d be much better off, we’d be a stronger NASA. We’d be a stronger nation. And that’s some of what we’re trying to do at Plum Brook.

Host: Could you fill us in on the history of Plum Brook Station?

Stringer: Sure. Plum Brook was a farming community, actually, in the days of the first Europeans showing up where Native Americans had been. The area in Plum Brook was part of the Firelands, which was a section of land given to the state of Connecticut as reparations for the British having burned out coastal Connecticut towns in 1780. So early settlements, farming, started in the early 1800s, and that’s what it stayed until early 1941, when, as part of President Roosevelt’s program to develop the arsenal of democracy, the Army Corps of Engineers took 41 farmers’ lands and built a TNT facility that was producing TNT within three days of the attack at Pearl Harbor, and it operated just that way until August of 1945, when everyone walked away.

It stayed that way for 10 years, until the ancestor of NASA, NACA, the National Advisory Committee for Aeronautics, came and broke ground for a nuclear reactor at Plum Brook, which operated from 1961 to 73. The reactor was eventually cleaned up, and is returned as a greenfield. That finished in September of 2013, but in 1959 the first NASA test facility was built at Plum Brook, and so the facilities I described elsewhere were built under NASA supervision and leadership at that time. So quite an interesting place, and it’s a great way of showing, for example, the power grid comes from the TNT days, and it’s a great way of seeing citizen money used and used again, to save money and do more things for future generations.

Host: Such an interesting history. And trivia buffs may know that the Space Power Facility was transformed into a set for filming segments of Marvel Studios’ The Avengers Movie back in 2011. Could you tell us more about that?

Stringer: Certainly. I arrived at Plum Brook in 2007, and by 2008, we had a brief video, which you can find on YouTube, if you Google, “YouTube Plum Brook Station video,” you’ll see it. That video I sent to, among other people, the head of the Greater Cleveland Film Commission in 2009. Didn’t hear anything from him, or anyone else, for about a year and a half, and then we started to get phone calls about, “Could we take pictures? A movie might want to come.”

So, in spring 2011, the director, Joss Whedon, and 33 of his closest personal friends, toured Plum Brook, loved it and said, “We’d like to come here in August and film.” So we did that. In one week in August, we had 500 people. What they prized about Plum Brook, besides the striking nature of the sets, and you’ll see this in the opening scenes of The Avengers. This is the place where Loki emerges and Nick Fury gets shot. What they’ve liked was the striking nature of the facilities, and the fact that we have a guarded perimeter 24/7, which meant that fan photography wouldn’t leak out, so they could have a surprise for people.

So they were wonderful to work with, and that was part of the process for us of being able to witness what Plum Brook is to people who might not otherwise know it, because of the 500 people who came, at least 450 are people just like you and me. So, those movie folks will mostly go back to Southern California, where there’s lots of aerospace friends and neighbors. And so they left with a bit of the data that you’re passing to your people in this podcast, and that helped us tell our story. So that was a win-win for both them and for us.

Host: Dave, what are some of the reactions you see when people visit Plum Brook for the first time?

Stringer: They’re usually stunned, and we’ll take people on the tour from small to big. So the Hypersonic Facility first. We’ll pass the Combined Effects Chamber. We will often take them inside the In-Space Propulsion Facility, and then finish in the Space Environments Complex. What this allows us to do is give our visitors the opportunity to get an increased wow factor. And so even for the folks with The Avengers, it’s the “wow” of being able to step inside the world’s biggest space chamber, the thermal vacuum chamber, called the Space Power Facility. That’s stunning. It’s the same experience as when you go into a big cathedral, and you’re right there, close to the altar. So one of the reasons that architects make churches so big, in the cathedral class, is that they want you to get a sense of awe, and you can get a similar sense of awe inside our facilities. If you take them to the biggest one first, they can’t get the biggest one out of their minds, and so we’ve found, from a teaching and learning standpoint, it’s much better to go small to big than it is to go from big to small.

Host:

So many superlatives are accurately used to describe Plum Brook facilities and capabilities — world’s largest, most powerful, highest capacity, and the list goes on. What does it take to maintain operations?

Stringer: Well, actually we have about 24 civil servants, and around a hundred contractors who operate this facility, and so it’s about 40 acres per person, if you took the acreage into account. So if you’re looking for the urban experience, Plum Brook is not for you. But if you’re looking for a place that does unique things, it’s great. Our baseline budget is about $12 million a year, split between different funding pots in NASA. So that’s not very expensive for what you get out of it, which is the ability to fix things on the ground before you put them in the air, or in our four word motto, it’s, “Save money, test first,” or if you’re talking astronauts like for Crew Dragon and for Orion, it’s, “Save lives, test first.” So, seems to me, it makes much more sense to spend a small fraction — 2 percent or less of a space launch — to find out whether it’s going to work or not. You can find it out on the ground, before you go into low-Earth orbit or higher and try to fix it.

The Hubble Space Telescope comes to mind. The program in those days saved three months and $2 million by not doing a thermal vacuum test of the optics, and it took us about a billion dollars, two shuttle flights and four years to get it fixed so that it’s doing some of the path-breaking work it’s doing even today. So those are lessons, if we choose to learn them, and we think these facilities offer us citizens a very affordable way to make sure things work well, and work reliably.

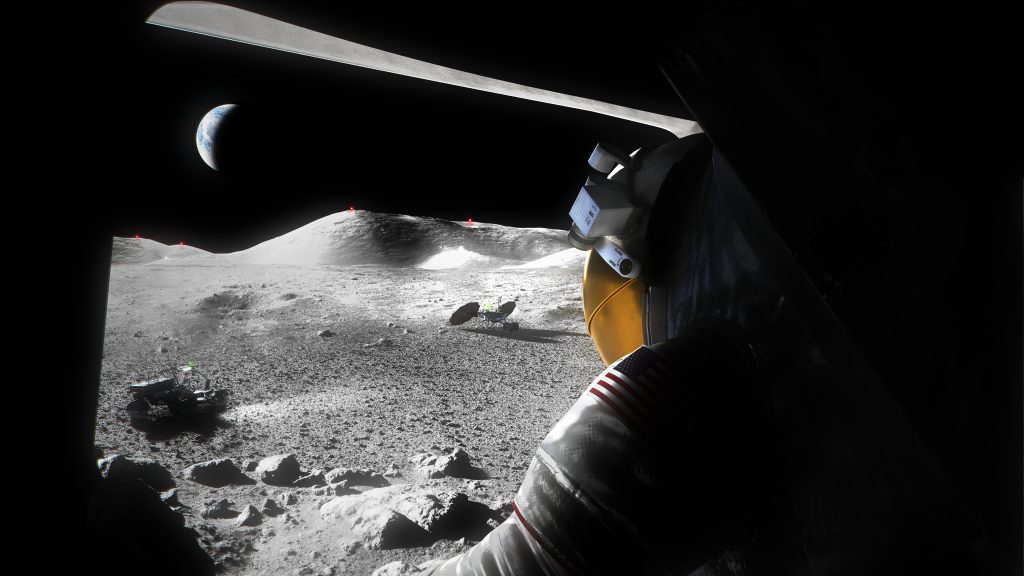

Host: How is Plum Brook supporting the Artemis Program?

Stringer: Well, we’ve done the first round of testing with Artemis from Thanksgiving 2019 through the end of March of this year. We were able to test it in the cold and vacuum of space, and then electromagnetic compatibility and interference. Earlier, in 2016, we had done the tests of the service module. That’s the power pack that’s underneath where the crew sit. That module was built by European Space Agency, and they brought a structural test article, which means not fully flight-worthy, but close enough, that we were able to test in the Mechanical Vibration Facility and the Reverberant Acoustic Test Facility. So we expect to see Artemis again. We’d also done for Orion, tests of the Launch Abort System and the Reverberant Acoustic Test Facility. So we’re delighted to continue to help whenever we can be useful.

Host: What role can we expect Plum Brook Station to have in the future of global space exploration?

Stringer: Well, I think certainly from a commercial space standpoint, Space X has certainly helped to tell people, “This is what Plum Brook Station can do for you.” I think our experience with Artemis, Orion, has done that very well on NASA. I think we’ll also see increasing use by defense activities, and all of those things are ways for citizens to get the most use out of their taxpayer dollars. The nice part about it, again, is we’re not very expensive. Again, 125 people and about $12 million in baseline funding says this is beautifully leveraged so that we can get lots out of it to help people find answers to make sure that their space vehicles are reliable.

Host: Many thanks to David Stringer for sharing the highlights and history of Plum Brook Station. You’ll find links to related resources along with David’s bio and a transcript of today’s episode on our website at APPEL.NASA.gov/podcast.

If you haven’t already, we invite you to take a moment and subscribe to the podcast, and tell your friends and colleagues about it.

As always, thanks for listening to Small Steps, Giant Leaps.