If you’re fascinated by the idea of humans traveling through space and curious about how that all works, you’ve come to the right place.

“Houston We Have a Podcast” is the official podcast of the NASA Johnson Space Center from Houston, Texas, home for NASA’s astronauts and Mission Control Center. Listen to the brightest minds of America’s space agency – astronauts, engineers, scientists and program leaders – discuss exciting topics in engineering, science and technology, sharing their personal stories and expertise on every aspect of human spaceflight. Learn more about how the work being done will help send humans forward to the Moon and on to Mars in the Artemis program.

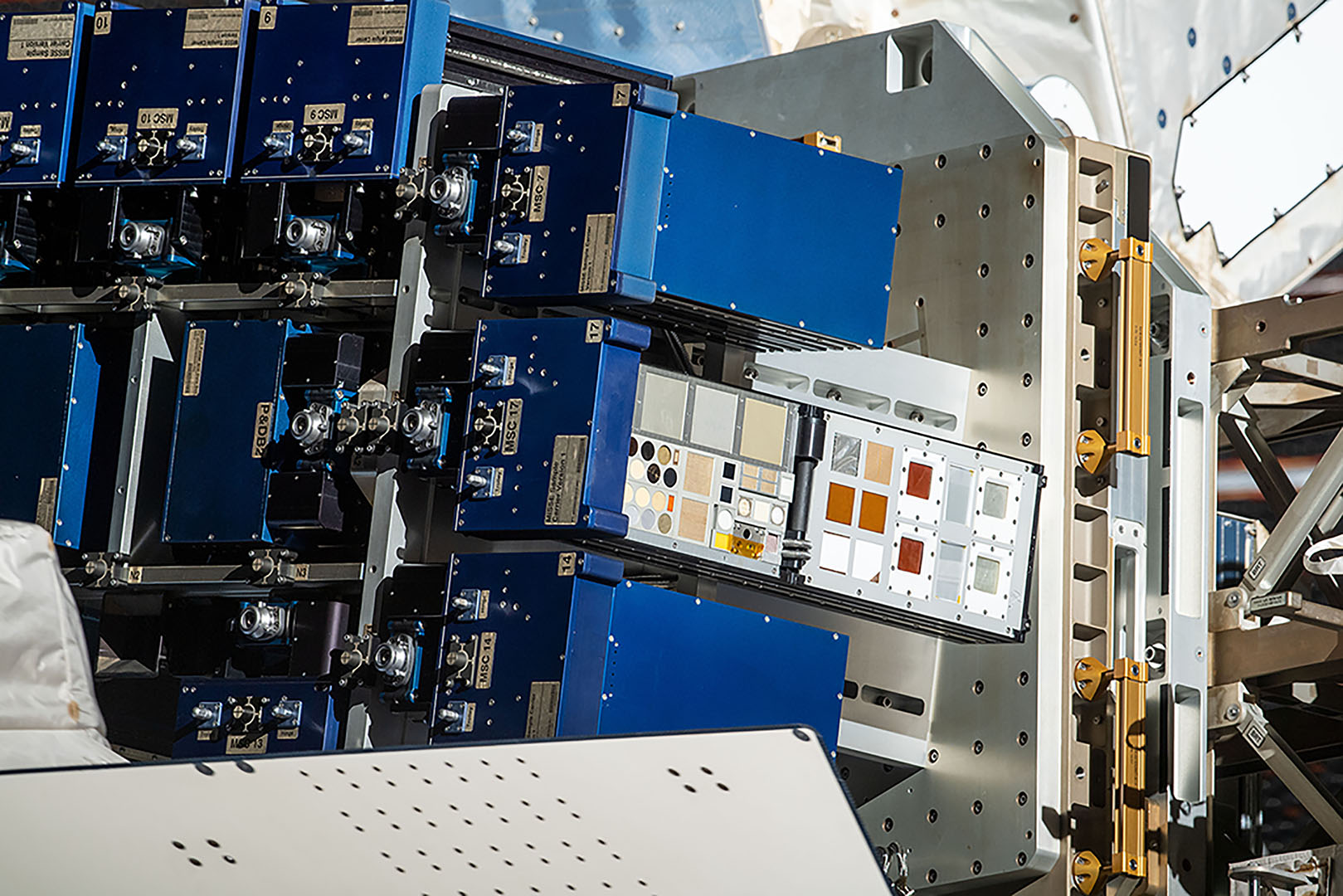

On Episode 150, Wesley Gordon, program manager at Alpha Space, highlights the facility aboard the International Space Station that provides the capability to test materials and technologies in the harsh environment of space. This episode was recorded on February 7, 2020.

Transcript

Gary Jordan (Host): Houston, we have a podcast. Welcome to the official podcast of the NASA Johnson Space Center, Episode 150, “Technology vs. Space.” I’m Gary Jordan, and I’ll be your host today. On this podcast, we bring in the experts, scientists, engineers, astronauts, all to let you know what’s going on in the world of human spaceflight. Space is a very harsh environment, intense temperatures of 200 °F in the sun and -200 °F in the shade. You hear about the vacuum of space and space radiation, micro gravity, debris, atomic oxygen. So, you have to ask yourself, what kinds of new technologies can hold up in an environment like this? Not just if they hold up, but how do they hold up and by how much and what exactly is happening to those materials and electronics, even solar cells? Just down the street from NASA’s Johnson Space Center in Houston is a small company called Alpha Space, and they manage a commercial R&D facility on the International Space Station called [Materials International Space Station Experiment] MISSE, M-I-S-S-E. This facility is mounted on the outside of the space station with pallets of hundreds of different technologies at a time. It’s exposed to the harsh environment of space in low-Earth orbit where the International Space Station flies. Materials, circuit cards, [Central Processing Unit] CPUs, solar cells, and more fly up to the station on a cargo craft. They’re brought inside by astronauts who, then, send these technologies outside through an airlock. They’re exposed to space for a while then brought back inside and put in a cargo vehicle for delivery back to Earth for analysis. We’ve learned a lot about how technologies hold up in space, and this can inform designs for future space missions, but can also improve products you buy on Earth like paints, coatings, and household electronics. So, here to tell us about this organization and commercial facility is Wesley Gordon. He goes by Wes. He’s the Program Manager for the MISSE facility at Alpha Space. Wes talks about the history of MISSE, the technologies that are flying right now, and the process of getting these technologies on the International Space Station. So, here we go. “Technology vs. Space” with Wes Gordon. Enjoy.

[ Music]

Host: Wes, thanks for coming on Houston, We Have a Podcast today.

Wes Gordon: Thank you, sir.

Host: So, you are the MISSE Project Manager?

Wes Gordon: The Program Manager for MISSE.

Host: Program Manager.

Wes Gordon: Yes, sir.

Host: Let’s start with a little bit of background. What is MISSE? What is this thing we’re going to be talking about today?

Wes Gordon: So, MISSE is a commercial science and product development R&D type platform to expose science to space. So, in doing so, what we have is a facility that sits on orbit where every six months, we interact and swap out payloads to put science and experiments, anything people want to research and do development work on and expose it to the various factors of the space environment for them.

Host: We’re talking outside the space station.

Wes Gordon: Yes, sir.

Host: OK.

Wes Gordon: Outside the space station, so there’s a lot of research and a lot of capabilities inside the space station. We provide capabilities for direct external exposure on the space station.

Host: OK. So, what is unique, what is interesting about that exposure? What are the things you, like, are we talking radiation? Are we talking vacuum? Are we talking extreme temperature swings?

Wes Gordon: Right. So, what you’re going to get on that activity is you get the extreme temperature.

Host: OK.

Wes Gordon: You get the extreme vacuum. You get the atomic oxygen.

Host: What’s that?

Wes Gordon: It’s a single molecule oxygen that you don’t get on Earth’s presence.

Host: We have O2.

Wes Gordon: Yes.

Host: OK.

Wes Gordon: And, you get a single molecule version of it, atomic oxygen, on orbit. The other thing, like you were mentioning, is you get the UV exposure unblocked and uninterrupted. We get the radiation exposure and expected radiation exposure that you wouldn’t get. So, you can see how that works. But, more importantly are those, just extreme temperatures. The combination of those temperatures and vacuum and all those factors in a single point for people to understand truly how their materials are going to react.

Host: Yeah.

Wes Gordon: You know, on the ground, we can simulate pieces. We can make something hot. We can make something cold, right. But we can’t bring everything together into one combined atmosphere to replicate space. And, that’s the value of the MISSE facility and what it brings to any product in any industry that’s out there.

Host: If you look at a picture of the MISSE facility, you can see it kind of looks like palettes, and there’s little circles of different colors. You know, for my untrained eye, they just look like pretty colors on the side. But I’m thinking what’s happening is these are different materials, these are different technologies that you’re putting in these little circles, and then that is just a little sample of the thing that you want to test.

Wes Gordon: Absolutely. So, what happens is we have about 200 square inches of exposure space on a facility, on each of the MISSEs, and there’s 12 exposure surfaces that we can put you on, ram, zenith, wake, and nadir. So, what happens is when you, when we put you up there, you provide, a lot of folks provide a one inch by one-inch square sample or a one-inch circular sample of what they would like to evaluate and test. And, that gives them sufficient material to see how the material’s going to react. And, using our facility for those material purposes and the photo capabilities that we have, we can give you visual results, which we provide you once a month by taking pictures, because the facility’s capable of taking pictures as you go through the flight. We give you health and science data, so we have the UV data, how much contamination we’ve had, what the solar exposure is, temperatures that you’re exposed to. So, that way, they can take that information, and then, when their science is returned, they can do further evaluation and testing combined with the data we gave to see if their material or their experiment reached the science point that they wanted to. There’s the other side of our facility, which people are starting to get into and starting to fully understand is the fact that we’re capable of providing data and power capability as well. So, we can do active experiments and do other testing for folks. One of the things that we get into that we’ve been doing is like an antenna system. If you wanted to evaluate a new antenna system out of a new material or you wanted to check its ability to transmit something via the ground. How does it respond in those kinds of conditions? You’re able to do that with our facility.

Host: So, we’re talking like, instead of just putting it out there and seeing what happens, are you sending commands to the antenna? Oh OK.

Wes Gordon: Yes, we have telemetry and command capability, right.

Host: Interesting.

Wes Gordon: The other thing is if you’ve got a particular circuit because the whole goal of a lot of the active experiments is can I get to TRL-8? Is it qualified for space, right? What is the way to do that? MISSE provides a really good, low cost, effective way to do it on a very fast cadence. And so, if you have a circuit card, or a module, or a new component, a new CPU, a new resistor, something you want to test, it’s really easy to integrate that into our deck so you get the exposure to space, the harshness of space, and what does your science do? So, we provide you power. We can provide you power and data, and you can interact with your science to get data and validate your experiment.

Host: When you were going over some of the details of how this works, one thing that kind of caught my ear was you talked about you can put the palette on different positions, facing different ways, as the International Space Station’s flying, whether it’s forward, whether it’s toward space, whether it’s more towards the Earth. What are the differences there? What are some things are valuable to point it a different way?

Wes Gordon: Yeah, it’s the existence of, for example, the UV exposure, whether they want direct exposure on zenith, where we put, for example, solar cells. We do a lot of solar cell testing. We have a solar cell test bed that we’ve developed and to test those solar cells that sits on zenith. It gets good zero beta exposure, good solar activity, no shading from the ISS. So, they get that exposure. If you’re just looking at your atomic oxygen, we can face you accordingly for that. If you just want space exposure, which some people just like, “Let me see how my exposure works in space,” right. We can expose you or even underneath our decks.

Host: Oh.

Wes Gordon: For that exposure as well.

Host: Wow. It’s a lot of, I’m already thinking about a lot of planning going on here because I’m visualizing this facility, right, and I’m thinking about every little dot, and all those dots is a different material, possibly a different client with different needs, and you have to figure it out. So, it’s like kind of a Tetris puzzle of where you want to put things.

Wes Gordon: Yeah. The trick in that is that’s the simplicity we provide for our clients and our customers, right, is they provide us exactly what they’re looking to achieve, and then we resolve the rest of the problems for them.

Host: Oh, very nice.

Wes Gordon: Right. So, we figure out how they’re placed, how they’re sorted, how they’re organized. You know, if they tell us what they’re looking to achieve or the science they’re looking to collect, we can tell them which face they need to be on and what would provide them the best results. Some of the PIs do know, right, our Principal Investigators and our clients do know what they’re looking at, but if they don’t, we provide that service. We design the holders. We design the decks that these units go on, and we do all the certification testing, all the environmental testing, and all of the activities that need to happen. So, once you’ve identified your material and you give us the information on the material or an active payload and science and we work to those technical aspects and we get it up there, we do the work and we bring you the results back. And, you can evaluate your science.

Host: OK.

Wes Gordon: We’ve really, Alpha Space has put significant effort into simplifying that process, right? When you look outside of, and you look at the science and the R&D and the technical community, there’s a very limited pool off people who know how to certify and fly hardware into space. And, cheaply and effectively, right, and that’s what we specialize in. When you’re looking at a low-cost way in the sub-10,000 range to fly one of your samples, we can do that. And, you don’t need to know what are the environmental exposures, what are the vibration requirements, what are any of the thermal activities. You know, you don’t have to know any of that. We do work with you and explain to you up front that your material’s going to be subjected to this, so we help them if we need to, to design it so that it will handle launch vibration. Because that’s part of our testing before we go up. So, we work very, very collectively with our clients and our investigators. But they key is making that as easy as possible and as simple as possible for them because the certification for flight process can be complicated if it’s not something you do on a day to day basis and you’re not configured to do so.

Host: You mentioned your business, Alpha Space.

Wes Gordon: Yes sir.

Host: This is where MISSE is going through. I want to take a little bit of history and set some context to why it is the way it is right now because, MISSE, as I was doing a little bit of research, is, has a lot of history with the International Space Station going back to its very beginnings. Let’s talk about the history of MISSE and then how that transitioned into becoming part of Alpha Space.

Wes Gordon: Yes, sir. So, for the first eight missions of MISSE starting back in 2001, so you’re talking back in ISS history.

Host: Yeah.

Wes Gordon: In 2001, the facility was owned and operated by NASA, and at that time, it was EVA serviceable. So, when they wanted to do work to it, it was EVA based. And, that’s how the activities occurred with it. Throughout the cycle of handling that work and going through that work, it was identified that easier serviceability and easier exchange method needed to be developed. And, that’s where Alpha Space came in. So, Miss Stephanie [Murphy] founded Alpha Space in 2015, right after [MEI Technologies, Inc.] MEIT was awarded a contract for building this facility. And, Alpha Space was launched. She launched the first minority female owned space company, commercial space company, actually, to assist in commercializing space in conjunction with NASA to put samples on orbit and to make this a robotically accessible and easily maintainable facility. That’s the pure essence of where, you know, Alpha Space started from. There was a need for that robotic and that rapid sample exchange, and access to science, right, access for the public to that science, which is one of the directions in the commercialization that’s going. And, Miss Stephanie has done a wonderful job in guiding a company to do and create just that whole purpose. You know, giving access. We have access, now, for universities, commercial companies. NASA’s always on our payloads and work with us, right. And so, you have access. Any industry that wants to get into space or evaluate their products in space, automotive industry. They evaluate parts using us to see just what extremes they can expose their parts to, right? Easy access. They don’t have to understand how it happens. They just know that it needs to go up. We certify it safely and bring them their data. And, that’s the key.

Host: I’m seeing it, because if it was, you know, from a NASA facility, what Alpha Space did was basically commercialize it. You’re talking about efficiency. You’re talking about bringing in more and different clientele. So, that’s the whole idea of the commercial space now owned and operated by you. You’re the ones going out and finding the commercial, finding partners or finding clients and helping them and guiding them through the process, working with NASA. You have a history of doing so. So, it seems like a very intertwined relationship to make that work.

Wes Gordon: Yeah, and establishment of a stronger cadence as to what we’ve been doing, right? You know, we launch carriers on orbit every six months. So, every six months, we are exchanging R&D experiments, science, any of those platforms and activities we carry, that’s the cadence we’re hitting. Every six months, we exchange something on orbit. And, it’s usually three to four of our carriers and the work that we’re doing. And, at the same time, we also are putting significant effort into focusing and upgrading, in enhancements and, you know, what can we aid and what data can we gather and what can we do to better service that science and that research. You know, because the biggest key is like you pointed out for the history of MISSE. MISSE originally was considered just a materials, research, and science facility. Right.

Host: M-I-S-S-E. I get it. Yeah, materials. OK.

Wes Gordon: So, we’ve taken that a step further because our carriers, it’s a universal platform, and it has the power. It has the data. It’s easily upgradable. It’s, I’ll call it fairly moldable to fit the needs, right. We do have a volume constraint in some instances, but we also have flexibility to adjust that even for what we’re doing to where we can use a whole carrier, if you need it. You can use a half a carrier, if you need it. Or, we get you down, like I mentioned, half an inch exposed or underneath the deck if you just want that space exposure. Then, we put you under the deck. And so, we’ve added such a huge, huge flexibility in that and a huge capability to a market that didn’t see or have the flexibility before.

Host: I want to better understand this terminology you’re saying. You’re talking about a carrier. Is a carrier one section of the whole facility, or is it a palette of materials? What’s a —

Wes Gordon: Yeah, so let’s explain the facility a little bit.

Host: OK.

Wes Gordon: I give everybody a good understanding. So, there’s a steel structure, the MISSE FF, the flight facility that’s on orbit.

Host: That’s the whole thing.

Wes Gordon: That’s the whole thing.

Host: OK.

Wes Gordon: In the center of the facility are what we call our two avionics boxes. That’s a switch box and the power and data box. That’s where the commanding and switching comes from pro to control the switching’s for our power on, power off, and those activities. The power and data box provides that power to each of those compartments. So, on each of the four faces, there’s three carriers. A lot of people consider them suitcases, if you will, right. And so, what we do is we send up this clamshell type device, the MISSE carrier. It’s an MSC, and it gets installed by robots. The robot, the Canadian robotic army goes out the gym to our transfer tray, out installed by the robot. Once it’s installed and locked in the facility, we do some initial testing. Then, we open the experiment. So, it’s about 19 inches long in a closed mode. Once we open the carrier, you have a 33-inch-long, 200 square inch exposed science surface. And, in that 200 inches, there’s a mount deck and a swing deck. The mount deck is the side that stays down, and the swing deck is the top of the clamshell. That comes out and gets further exposed. So, if you could picture folding a piece of paper in half and you’re holding it vertically, when you open the paper the rest of the way, that top piece of paper, that’s that swing deck portion of it.

Host: You basically have to put it out the airlock folded so it fits out that way.

Wes Gordon: Yeah. Yeah.

Host: And then, once you get it out and you’re about to install it on the facility, that’s when you can unfold it.

Wes Gordon: Yeah, the, when we go into the gym area, like we’re put onto an Alpha Space designed transfer tray.

Host: OK.

Wes Gordon: The [MISSE Transfer Tray] MTT, and we can carry up to eight carriers out there.

Host: Oh, wow.

Wes Gordon: Yeah, and eight of —

Host: And, three carriers per side.

Wes Gordon: Three carriers per side.

Host: OK.

Wes Gordon: So, we can take eight of them out there, and then install them and extract. And, they come back on the MTT as well. So, the full exchange activity happens by the robotic arm taking us out with the MTT. Then, we install and exchange and bring the units back. And, you know, that’s one of the key pieces if we want to upgrade the avionics, even the avionics, the power and data box and the switch box, they’re removable. We can upgrade. We can enhance. We can repair. The carriers, we swap them on a six-month to one-year cadence, right? They’re removable, easily removable and extracted. And, that’s the simplicity behind it for everybody else.

Host: So, for crew interaction, really the only thing they’re doing is they’re taking these carriers, these suitcases, and they’re just loading it into the transfer tray and sending that out. The robotic work does all the installation onto the facility, taking the carriers off and on from the facility, taking them back in. Then, once they’re back in the airlock, the crew is taking those suitcases and they’re putting them away for eventual return to Earth.

Wes Gordon: Absolutely, sir.

Host: Minimal crew time.

Wes Gordon: It’s minimum crew time.

Host: OK.

Wes Gordon: There’s a, you know, the robotics team and the crew have done a beautiful job coordinating and handling our crew time to where our crew time interaction and robotics has a really good understanding of how this works and the interaction. We interact with them on a regular basis to make that a very optimized and a very smoothly flowing system and operation. So, it’s a lot of coordination, you know, like you and I were talking before we started the show. You know, there’s a lot of unsung heroes and a lot of collaborations that happen in the background, and definitely that robotics work is critical to the work we do. But, also, the key to the simplicity of what we do.

Host: Yeah, yeah, yeah.

Wes Gordon: We don’t need the EVA. We don’t need that work, right. We need the robotics to do that, and it’s been designed as such.

Host: So, when we were talking about the history, you talked about MISSE as a materials experiment. It’s since included a lot of other technologies and, I don’t know, samples of whatever you want to put out on this facility. Let’s go through some of them. What are some of the materials that you’re testing, or the materials that you’ve tested in the past? What have we found out, and what are these other technologies?

Wes Gordon: So, we’ve done a lot of, like you said in the beginnings the materials work. We’ve done a lot of materials for different types of coating, new types of tapes, different types of fabrics, you know, what can we do. The space suit, for example, right. What can you expose that space suit to, and can we make a better fabric? Can we test a better fabric, right? What better way to test that fabric than to expose it to the environment? We’ve done some research and assisted with the research of lens coatings and protective coatings, right? What can survive and still be clear, right? What can you still see through and what survives? To be honest, we’ve had a few samples that just completely deteriorate, and that was because they just, that was the science, right? Is it designed to survive?

Host: The answer’s no, and that was the investigation.

Wes Gordon: The answer’s no, and that was the point of the investigation, right. You know, it’s always exciting when you’re seeing everything going on, and you’re seeing these samples, and you get the pictures every month. And, customers are like, you know, this is amazing. This is, you know, these pictures are very helpful. This data’s very useful, and that’s always exciting. That’s always positive because you’re like, I’m doing something good, and I’m doing something rewarding for everybody. But, that’s that material side. On the technology side, you know, that lone little company that has this new computer board that they want to fly in even a fighter, or they want to get it into the space program, that little shop can’t set up doing what we do and afford to do that, right? So, we’re able to go through and take their module or their new component, put it up there, apply power to it, pull data down, get them to a TRL-8, and prove that your unit is fine. It survives space. It survives the environment. It can handle the temperature swings. It handles the radiation. It handles all the things that space would do to that component in a raw, exposed form. Right.

Host: You talked about you want to get your clients to a TRL-8. Is that what it is? What’s that?

Wes Gordon: That’s the Technical Readiness Level. So, as you’re going through your Technical Readiness Levels, you go from a one to an eight. An eight means I’m qualified for space. I’m ready to go.

Host: Oh.

Wes Gordon: And, there’s varied interims in there, right? And, the best way to do that is pure exposure, rapidly. So, you could take yourself through the different TRLs by going, “I’m going to go into a thermal vac chamber, and I’m going to expose myself to the temperature swings in thermal. And, then I’m going to do it in a vacuum chamber, and then I’m going to try to expose it to this.” But cumulatively, what are those results, right? A lot of research time and a lot of lab time and a lot of testing time can happen where in our methodology, you know, we evaluate the materials and working with various groups on-site. And, like I said, there’s a huge army of people behind this science, OK. From materials groups to the safety groups to the engineering directorate that we work with on a regular basis, but once we evaluated these samples, experiments are safe for flight, safe for use, properly contained, you give it to us, and within six months, you’ve answered all the questions. You have all the answers. What does temperature do? What does vacuum do? What does the radiation do? What does UV do? What does any of it, what is the contamination? Do you survive the contaminations or excess contamination? You get all those answers in a six-month period.

Host: That’s it. So, is it ready to fly?

Wes Gordon: It’s ready —

Host: You’ve tested it on MISSE, and MISSEs providing, what’s happening here. Well, this is happening because we’ve gotten that data. Well, this is what’s happening because we’ve gotten that data.

Wes Gordon: Yeah, and you know, when you’re looking at the space program, what you want to do, you know, as NASA or other agencies, you want that high TRL, right. You want reassurance that if I pay you for this activity or this product that it survives, and it works in that environment. And, those small companies get that opportunity, and it’s there, right? And, that’s one of the wonders for that.

Host: So, some of the other technologies you were testing, you mentioned solar cells.

Wes Gordon: Yes.

Host: So, me as a regular person, I don’t know too much about solar cells. I just think, “oh, there’s a solar panel, and there it is.” What are you trying to figure out when it comes to solar cells? Maybe the power generation, maybe how it holds up in the vacuum of space. What is it about a solar cell you want to test?

Wes Gordon: It’s really about getting direct access to the solar activity without any environmental impact or anything around you and testing. They test different geometries, different circuitry, different lens materials, different reflectivities. So, they have a whole gamut of activities that these folks are testing, and we test them from anywhere from government agencies to commercial agencies to schools that are evaluating these in conjunction with other activities. So, it’s really good because there’s a huge research base out there right now of how can you make a more efficient, more robust solar cell. Right? And, it’s about not only the collecting of it, the reflectivity of it, how much of it can you reflect, at what angles can you reflect at. So, there’s a lot of science that goes into that that they get direct UV activity and solar exposure right at zero beta, optimal readings, and we provide that.

Host: That’s like almost industry level kind of data.

Wes Gordon: Yes.

Host: Improving the whole technology.

Wes Gordon: Yeah, and we’re constantly evolving that. You know, we flew the original prototype version of that on MISSE 12. We enhanced it for MISSE 13. We’re making another enhancement for 14. As we get better science, we get better as well, right? And so, once we understand the industry and we’re learning more ourselves because this is a constant learning activity, right? Once they do science, they’re like, you know, we need to see this or this, and then we adapt to learning what they’re looking at. And so, industry, in a way, teaches us as we teach industry and provide data. And, that’s the nice learning portion that I look forward to every day with my job, right? Every day is learning, right?

Host: Yeah.

Wes Gordon: It’s one thing to build the circuit. It’s one thing to build the control system and then collect the data but learning exactly what they’re looking for. What are your expectations? What are you looking to see? That’s where you need the army and the team because you can’t understand every technology, but you can definitely reach into the NASA resources and in this community get better expectations and understandings of the, what are good, expected results.

Host: Nice. You mentioned circuit boards and electronics as being some of the things you were testing out there. What would be interesting about doing that in space?

Wes Gordon: It’s really the survivability and exposure of a new circuit, new materials, new components. If somebody has a new type of integrated circuit, microprocessor that they want to test, will it survive? Did they make it out of good materials that would survive combined with the circuitry that they’ve built, right? That’s a really good exposure. We have a couple of clients who believe they’ve created new versions with new materials of existing types of capacitors relays for switching purposes that they believe are out of the right materials and everything. So, they fly them up passively, study their materials, the material results. Then, we’ll fly them again the next time, and if that’s the right materials and everything in an active mode. So, they get, then, the switching or the current drawls or the voltage drops that they’re looking for, right? And, at the cadence that we’re flying at, they have that design and development window to where they can buy low cost passive space, understand the passive and the physical characteristics of their device. Then, very quickly and easily transition to an active state easily on the next flight. To —

Host: Theoretically, you’re talking about a year of data.

Wes Gordon: Yeah. One-year development all the way through the process. And, that’s, you know, that’s huge reduction in data and science time because if you think about how long it would take for them to just evaluate the materials by going to the different labs and finding labs that could get them close but not exact results. Then, developing the active circuit. You can’t test that in those environments, right? How else do you do that? And, that’s what we provide.

Host: So, I heard a lot of examples, and we can even reiterate some of them of how testing these materials in space really helps to develop these technologies on Earth. I think there’s, there are already applications, but even stuff one that I read was paint. I thought that was pretty interesting. I don’t know how paint would — sending paint in the vacuum of space would help you with a bucket of paint painting your home on Earth.

Wes Gordon: You know, there’s, you have that UV exposure. You have those temperature adherences. You have harsh industrial environments that people are evaluating, and there’s no harsher environment than direct space, right? But, also, you know, you’ve got to think about it in spaceflight and space travel. Everything’s painted. Everything is painted. Right. I mean, we use a lot of stainless. We use a lot of steels. We use a lot of aluminums, magnesium, tungsten’s, we use a lot of surfaces that don’t need to be painted but they’re anodized or alodined. We do that a lot on space componentry and have for many, many, many years. But there are lots of companies also developing better coating, better painting processes, too, even for that survivability for painting of products, and you need that data. You need that science.

Host: So, it goes both ways, too. You’re talking about Earth benefits. It’s good in your bucket just for higher quality paint.

Wes Gordon: Yep.

Host: But, it’s also good on a spacecraft.

Wes Gordon: Absolutely. Right.

Host: OK.

Wes Gordon: That’s that evolution, and you get the answers like that.

Host: Very cool.

Wes Gordon: Real time.

Host: Alright. Say you’re a client, and you’re thinking this would, I really want to do this. I want to send up this little material, and I want to go up to space. What are, what do you expect the client to do? What do you expect them to do for you to help?

Wes Gordon: Actually, we’ve put a significant effort because this is what we do, into trying to simplify this process and make it really easy for our clients. So, when a client reaches out to us, when they’ve reached out to us and using Mark, currently Mark Shumbera who handles that on our Business Development side. When they reach out to him or a Principal Investigator at NASA, whoever this is, right. There’s two ways. We get them from commercial activity or the Principal Investigators through the NASA side. And, DOD and AFRL, so lots of agencies with that. We send them a questionnaire, and this questionnaire goes through and asks all the questions that we would need to answer all the questions for them to aid with the design, certification, safety approval, readying them for flight. We take that information and we create a design document that allows us to design that and do all that work internally. And then, we create, then from there, once they agree that, yes, this I agree this is how I like how you’ve packaged it. I like how you’re handling it, you know, all that information, then we start our entire process. And, you know, that’s the complicated portion behind the scenes, but to simplify that, it’s really, we do a design of your holder. That holder is then placed on a deck and that deck is what gets mounted into the MSC, the suitcase that we’ve been discussing.

Host: OK.

Wes Gordon: And so, that sample, the sample goes in a sample holder. Once the sample holder is designed, they’re fit onto a deck. So, we design the deck to fit all the samples that we’re trying to do. So, we do a lot of space planning, capacity planning, looking at how these things place, right?

Host: Yeah, your game of Tetris.

Wes Gordon: Exactly. It is. It’s a game of Tetris because we’re trying to maximize the number of samples that we can fly for that flight for everyone. So, we fit those pieces on. Then that deck is actually we have a thermal vac chamber at our facility. So, we’re able to put them through the thermal vac capability. We expose them to that, and also the key to that is getting rid of the contaminations. Because as people handle things every day and things go around, people don’t realize, but everything gets contaminated in some form or fashion.

Host: Which can lead to bad data.

Wes Gordon: Yes. So, we bake that off, and then we take that deck and we install it in a unit. And then, that unit goes to a series of environmental testing. I guess it’s important to mention to everybody folks, too, that we do that in a 10k clean room. That’s actually at our facility. So, we have a clean room in our facility, so we’re always handling their materials with care, and then integrating them with care within that 10k clean room. So, we then expose them to environmental testing. If it’s just a passive sample, it needs thermal cycling and it needs a vibration test. Because we’ve got to ensure that their material won’t break and won’t become a sharp edge or some other risk a safety factor on orbit, right? So, that’s the first step with that. If it’s an active experiment, we go through what’s called [Electromagnetic Interference] EMI testing, and what EMI testing is this ensures that we don’t induce any electronic noise to communication systems around the unit. For example, if we were transmitting, for some reason, at the same frequency as the astronaut’s headset, that would be very unfavorable to everybody.

Host: Yeah.

Wes Gordon: Right. So, we have a series of tests that we go through to ensure that everyone understands what noise I’m creating in space if any, what those levels are, and if there’s any impacts to systems around, the wireless system, headsets, you know, any of that, right. Because crew safety, critical, and when you’re doing an EVA, criticality, right. So.

Host: Is a lot of that written by NASA and set to Alpha Space, say, “hey, whatever you do, make sure your samples aren’t giving away this frequency because that’s going to mess with our stuff.”

Wes Gordon: We actually test it here at JSC.

Host: Oh, OK.

Wes Gordon: So, what we do is once we’ve integrated the units, we bring them to the facility here, and there’s an EMI lab, and we bring it actually to JSC and JSC in conjunction with us, we run the EMI test. They run that in a chamber over here right on-site, and so we go through. We bring our unit in. They connect the sensors and the filters. We power up our unit, and we know what the baseline noise levels are, and they see if we had any additional noise. Because, like I said, we’re flying antennas, circuit cards. So, we have to ensure that we haven’t added any additional noise that we’re not aware of. And, that report, then NASA generates that report, and we’ll either pass or fail. So, if we see failures during that, we have to make adjustments to our circuitry and our system, either our system or working with the client to try to reduce that noise so we’re in the proper area and test through.

Host: Seems like there’s a decent amount of work on the Alpha Space side where you already kind of have a good idea of what you, of what it takes to fly in space and you’re helping those clients. But then, you have to pass almost like go through the gauntlet of NASA tests, like almost the flights certification, making sure that this thing is safe and ready to fly.

Wes Gordon: Yes, sir.

Host: OK.

Wes Gordon: And, that’s, like I said, that was one of the key things I was mentioning early on is the value, right, the key thing that Alpha Space is making it easy for the customer. Once they deliver the sample, if nothing occurs, we don’t have to do anything for them other than form a, you’ve been integrated. You’ve passed environmental testing. You’ve been sent for stowage. You’re installed. Here’s your data, right. So, I mean, you know, those are really simple, easy steps for our client with all those little things we talked about happening in the background. And, it is. It’s a constant, you know, coordination, so you know, you really, it’s an efficient process and repeatable process. Right. That’s the key of understanding that portion.

Host: Now, that process, that’s happening here locally in Houston, right, you’re right down the street from us at the Johnson Space Center, but eventually, you got to fly. So, how does the stuff get from here in Houston over to where it’s going to launch from?

Wes Gordon: So, we deliver everything to the cargo management contract.

Host: OK.

Wes Gordon: Which is local to us here, and so we deliver the product to them and they package it up and get it transported with the other items that are going from JSC over. And, they get to the launch vehicle, get installed in the launch vehicle, and then launch. And, the same occurs, there is coordination here for even on the return. We know when the returning vehicle is going to be coming back. When the returning vehicle’s coming back within about two weeks, we get our carriers back.

Host: That was quick.

Wes Gordon: Well, because of the science we have, we can’t keep exposing them, we don’t want the additional exposure. We’re trying to get that science back to our customers and it not being on the ground any longer than necessary. So, from when the vehicle detaches and returns home, to when the client has the samples is right around less than 30 days.

Host: Wow.

Wes Gordon: Because we have a tight window there of the return within seven to ten days of splashdown. And then, we have a ten day turn on the science to get it shipped back to the customer. And, we’ve worked with customers on that. We have, you know, I think that’s the flexibility that you’d find with Alpha Space is that we do have some customers who actually come to our facility and directly integrate and directly de-integrate because they hand carry their samples. They take the samples directly from their lab. They bring them directly to us. We integrate them that day or a couple days, depending on what the samples are, and we schedule and coordinate with them to be available and return to de-integrate their samples and take those samples back with them and hand carry a return. So, we have that coordination as well, right. Just, it’s tailored around the science as what, you know, what they’re needing in terms of their handling and care and what needs to be done with their science.

Host: Yeah. I’m sure there is a significant amount of handling and care when it comes to investigating a sample that has now been returned from space and you’re the one saying, “Here you go.” But I’m sure there’s a lot that goes before that, before you finally say, “Here you go.”

Wes Gordon: Yeah, that’s why we, like I was mentioning before. We had the questionnaire because one of the key things we ask in the questionnaire is are there any special handling instructions. And, special handling instructions in terms of delivery, installation, de-integration. You know, it may come to me in the mail and may get returned in a hand carry. Right. So, some sample may be complex and, in such case, where you need our integration capability and their engineering knowledge to do the install, right? So, that flexibility and that, that’s interaction is what’s critical to making that science a success.

Host: Well, tell me about right at this very moment, in fact, earlier today, I was listening to some of the flight loops, and they were, they had MISSE on their to do list. Actually, working with trays and doing that. So, tell me what’s going on right now for MISSE.

Wes Gordon: Yeah, MISSE is actually an amazing place right now, actually. It really is. It’s an amazing time to be a member of the Alpha Space team because we’re actually in the process in March, we’ll be removing seven carriers and installing five others. That’ll be an exchange that happens, so they’ll be taking care of that. So, when they return, we’ll be going through that exact process we just talked about. But, at the same time, we’re preparing for the next launch and the next delivery. We have a delivery due in the first week of August for NG14, which is launching in October, and so we’re in the process right now of what I talked to you about. We already have the client questionnaires. We’ve already done the [Interface Definition Document] IDDs with them. We’ve done the sample deck layout. We’re getting ready to start cutting the metals and doing everything to get ready for their samples. First part of May, we start receiving samples to integrate and start that testing cycle. So, we’ve got units returning end of April. In the same time, we’re prepping for the next flight to go out in May. So, that’s, you know, de-integration, rolling right into integration of the next flight, you know. It’s a consistent rotation and process for everybody.

Host: Yeah, it’s busy.

Wes Gordon: That’s a six-month cadence, and it’s rolling.

Host: And, you talked about a Northrop Grumman, going up on a Northrop Grumman mission.

Wes Gordon: Yes.

Host: So, we did talk about returning samples, but are there some samples that don’t necessarily need to be returned to a customer? They have all the data that they need and so it gets put in the trash? Or, do they all come back?

Wes Gordon: No. They all come back.

Host: Oh, interesting.

Wes Gordon: So, we go up on an NG. We can go up on SpaceX or NG.

Host: OK.

Wes Gordon: Currently. There are, we’ve been assessed for other vehicles, but we currently go up on an NG or a SpaceX, and we return on SpaceX flights.

Host: Got it.

Wes Gordon: And, depending on what we’re doing, our cadence is go up on an NG, return on a SpaceX, or because of the ease of installation, we can go up on a SpaceX. They remove us, install us, extract the other units and install them back in SpaceX during that flight mission while they’re docked.

Host: Oh, wow.

Wes Gordon: So, they can do the full exchange, and that was the full transfer to MTT, bring them back in, get off of MTT, re-box, and put in SpaceX. So, it’s done. The last two flights that I’ve been part of, I’ve been with Alpha Space a year now. But, the last two flights I’ve been part of have gone up and been returned on a SpaceX flight in that docked window. That’s how fast that turnaround is in the, but that’s huge coordination with robotics, huge coordination with the crew, right. Because SpaceX is going up. They’ve got to empty SpaceX. They’ve got to get me transferred. They’ve got to do an install, bring everything back, and —

Host: Yeah. It’s kind of, it reminds me kind of like a logistics company.

Wes Gordon: Yeah.

Host: If the packages are coming and you’re like, “Go, go, go, go!” And then, you have to do the, all these switches and then shove them back in and deliver them back.

Wes Gordon: Absolutely. You know, and that’s why there was, you know, making a system that involved minimum crew time.

Host: Yeah.

Wes Gordon: It was critical, right. You know, you take it off the MTT, and you box it up and send it back home.

Host: Because anything can happen, right? Like, I’m sure you know the crew’s busy. You can be shoving a bunch of spacewalks in there or other science experiments. Some things they’re going to have their hands in like the glovebox, and you’re like, “Hey, we got to get these trays out.”

Wes Gordon: Yeah, that’s the huge coordination, you know.

Host: Yeah.

Wes Gordon: To give you an example of the coordination, you know, we’re working, we’ve been working with robotics team already for the 13 transition, and we’re preparing already starting next week for 14 which doesn’t happen until October. But so, they have that timeline and that understanding, that evaluation.

Host: Wow.

Wes Gordon: It’s making sure that coordination is set so they know. The nice feature of our system though is they know how long it takes to install. They know how long it takes to remove them. And so, they have that timeline, and they’ve worked that timeline now to where they have repeatability.

Host: Yeah. Having that precedence of having done it before.

Wes Gordon: Yeah.

Host: Makes it a little bit more predictable for the crew and easier to schedule.

Wes Gordon: Yes, sir.

Host: So, we talked about the genesis of MISSE being a materials experiment, and we’ve gone through a lot of different examples of different technologies and things that you can put on this facility to expose. What’s coming up? What’s the future for some of the things we can test outside?

Wes Gordon: You know, there’s a couple of them. One of the bigger ones we’re working on is understanding how to work with biology outside. You know, we’ve done materials. We can do componentry. We can do any number of physical devices, powered on power. What we’ve been approached with and the things we’re looking at is how to handle biology outside of the station. It’s a complicated process, but MISSE Provides a great platform. It’s very flexible, and so, you know, I think that’s going to be one of those next evolutions. Huge need for it in science. Huge exposure for it. But, I think even beyond that and sooner than that is one of the more, I think, exciting things we’ve been working on, too, is we’re in the process of partnering with a company whose able to take our data that we generate in the LEO area and analytically predict what it’s going to do in other orbits. What will this, given that we know this is how it reacts on Earth. Given that we know how it reacts in LEO, going to the Moon, they can analytically predict how it would respond going to that base using us as a calibration point.

Host: Oh, interesting.

Wes Gordon: And, we’re working on that, and that’s coming really soon for everybody. And, I think that’s exciting, right, because we’re providing you a platform now to understand and start evaluating the next step, right. You know, we’ve talked about the TRL previously.

Host: Yeah.

Wes Gordon: OK, well how do you TRL or approve yourself to be landing on the Moon, right? We’re giving you a platform and analytics to try to get to that point. And, I think that’s huge. Another evolution is we’re actually in the process right now and significant team effort and investment with Alpha Space, and we’re upgrading our avionics and our control systems to add more features for the clients. You know, the streaming will come, the better photos will come, better data management, more real time data management, faster data transmission, you know, enhancing reliability and, you know, we’ve learned a lot. Right. We have learned a lot, right, and we did. Alpha Space as a company did MISSE 9 and we’re prepping for 14 right now.

Host: Alright.

Wes Gordon: Right. In that timeframe, we’ve learned a lot, and technology, technologies we’ve even tested have advanced a lot, right? And so, leveraging all that, creating a more robust system for everyone is what we’re preparing in the background for everybody. You know, it’s that unseen by the client but better for the client.

Host: Yeah. Because I’m — the one that really stuck out to me was streaming. If you’re able to have real time data and track your experiment in space over time, just imagine. I mean, because, you know, if, for a material, I’m sure you’re providing a lot more data, but what I’m visualizing in my head is you send up a material, and you know how it was when it launched, and you know how it looked when it came back. I’m sure there’s data in between, but to have that live, continuous data.

Wes Gordon: You know, monthly, they just get a picture.

Host: Oh, wow.

Wes Gordon: It’s great, right. Every month, we give them a picture, so the facility, which I guess is a piece we didn’t cover. Currently, when the facility opens, when you open up one of the MSCs, we have a camera trolley that goes down the whole deck, and every month, we take photos. So, they get a monthly photo, right? But, a lot of our experiments don’t expect a lot of changes in a 30-day window. Right? But, if you need the streaming because you’re expecting the possibility of something rapid happening or occurring, bio-experiments right, the bio-experiments. Things are going to happen. You want to see that happening. You want to see that interaction, right? We see that need coming. When we see that we’re looking at those things, and it think that’s, you know, that’s your, the pinnacle of the next piece is the constant evolution to enhance the science and enhance the experiments.

Host: I could see that with the biology, that being so much more of a need to have that sort of monitoring because life is just. When we’re talking biology, what, I mean, are you thinking like microbiology? Are you thinking, like, plant life? Are you thinking?

Wes Gordon: We’re still evaluating a lot of that, working with folks on that, but we definitely see that evolution, and we’re evaluating it very strongly, yeah.

Host: You talked about analytics to understand the difference between low-Earth orbit and seeing how that might apply to other environments like the Moon. Are you thinking about maybe sending stuff right to the Moon and using that analytic software to compare what you thought was going to happen versus what actually happens?

Wes Gordon: Actually, we’ve taken it a little step further. We actually have won a contract that we call rack internally, and we are actually sending a MISSE type activity to the Moon. We’re part of one of the new lunar payloads.

Host: Wow.

Wes Gordon: So, Alpha Space was selected to perform that work as part of the new lunar payload work that’s going on. So, we’re working directly with everybody on the new lunar work to actually use our capabilities and what we’ve been doing for exactly that, the lunar work. Right. And so, that’s an amazing piece, right? When you look at where Alpha Space is sitting, we have LEO. We are enabling analytics and a whole other level of analytics for everybody and we’ve been selected, and we are going to the Moon.

Host: Wow. What’s — for Alpha Space, for maybe some of your clients, what is interesting about the Moon? What do you want to test on there? Are we talking circuits? Are we talking materials?

Wes Gordon: It’s open. It’s an open platform, just like, right. That’s the point, giving everyone access.

Host: Yeah.

Wes Gordon: And, we, you know, the market has to be evaluated, and we have to look at where the pieces are, but you know, we’ve been selected for a specific target and payload using our technology, and I think that’s a key, huge first step. And, proving that technology and those steps, and you know as NASA evolves and does more with that, it’s nice to know that we’re part of that evolution and working with them to create that step and move ourselves forward and doing that. And, you know, it’s quite an honor also at the same time for Alpha Space to be recognized for our capability of performing that work from what we’ve been doing with our facilities and our research for them to have the confidence in our product to be used as that device for the new lunar work.

Host: You say you’ve been at Alpha Space for a year. Were you in the space industry beforehand, or is this like a whole new world to you?

Wes Gordon: No, it’s not a whole new world. I actually was, I’ve been in the space industry, well, I was weapons and defense relative to the space industry since the late ’90s. Moved directly into the actual space program at JSC mid-2000s. At the end of shuttle, I did take a step out, and I went out, like several folks did, into the energies and oil and gas business to enhance some of my skillset, and I learned a lot about process optimization and the logistics and other things. But my true love was with the space program, and when I saw the opportunity at Alpha Space, I was given the opportunity to come back and play with this toy. You know. I mean, well, when you look at, I did, I did shuttle. I did station. I was a subsystem manager for several products on the space station and space shuttle. And, some of my gear even transferred from shuttle to station as swapped —

Host: Oh, cool.

Wes Gordon: And so, when you’ve done that, those things were fixed purpose. I had the laptops. I had the cameras. I had a radio. You know, they were fixed. But those were just assets and tools, right. That’s what I had at that time in my life in the space program. What Alpha Space has afforded me is the opportunity to work with the science and the R&D, and the engineering, right? And, that is something that is priceless because we need to evolve. We need to grow, and you know, it goes all the way back to right, Miss Stephanie opening a woman owned and the first female owned facility in-orbit, right? Setting those firsts. Opening up new windows. I mean, she started that in the beginning by opening female owned facility. Boom. Now, we’re doing science for everybody on a regular basis, every day and filling that hole that didn’t really exist, right? Where was the gap prior to us? Who filled it between the engineering mind and the space certification? Those scientists and those folks.

Host: Wow. Well, Wes, I want to thank you for coming on. Your passion is extremely contagious for all of this, but what I think was really fascinating about MISSE as a facility, and we’ve gone over a lot of just the, you know, how it works and everything, but what really excites me is just the amount of stuff you can test. Like, that’s a lot of data. That’s a lot of materials. That’s a lot of technologies. That’s a lot of things being exposed to space, and that’s good data for everyone. Because, ultimately, we’re talking about the commercialization of space. I think Alpha Space is a great example of that. Your commercial company operating in space, bringing on clients, working with NASA. It’s just, it’s a great example of how this all works, and there’s just so much data. Really exciting to be talking to you today, Wes, I really appreciate your time.

Wes Gordon: No, I appreciate your time, and you guys taking and giving us the opportunity to even talk about the facility. You know, it’s exciting. It’s there, and I hope the world sees everything that we’re bringing for science and the community.

Host: Alright. Thanks, Wes.

Wes Gordon: Thank you.

[ Music]

Host: Hey, thanks for sticking around. Really good conversation we had with Wes Gordon about MISSE and Alpha Space. If you liked this podcast, we have a lot of episodes that you can listen to in no particular order. Go to NASA.gov/podcasts to check out some of our other episodes as well as many other podcasts that are here at NASA. If you want to talk to us at Houston, We Have a Podcast, we are at the NASA Johnson Space Center pages of Facebook, Twitter, and Instagram. Use the hashtag #AskNASA on your favorite platform to submit an idea for the show. Just make sure to mention it’s for Houston, We Have a Podcast. This episode was recorded on February 7, 2020. Thanks to Alex Perryman, Pat Ryan, Norah Moran, Belinda Pulido, Jennifer Hernandez, and Mike Shumbera from Alpha Space. Thanks again to Wes Gordon for taking the time to come on the show. Give us a rating and feedback on whatever platform you’re listening to us on and tell us how we did. We’ll be back next week.