“Houston We Have a Podcast” is the official podcast of the NASA Johnson Space Center, the home of human spaceflight, stationed in Houston, Texas. We bring space right to you! On this podcast, you’ll learn from some of the brightest minds of America’s space agency as they discuss topics in engineering, science, technology and more. You’ll hear firsthand from astronauts what it’s like to launch atop a rocket, live in space and re-enter the Earth’s atmosphere. And you’ll listen in to the more human side of space as our guests tell stories of behind-the-scenes moments never heard before.

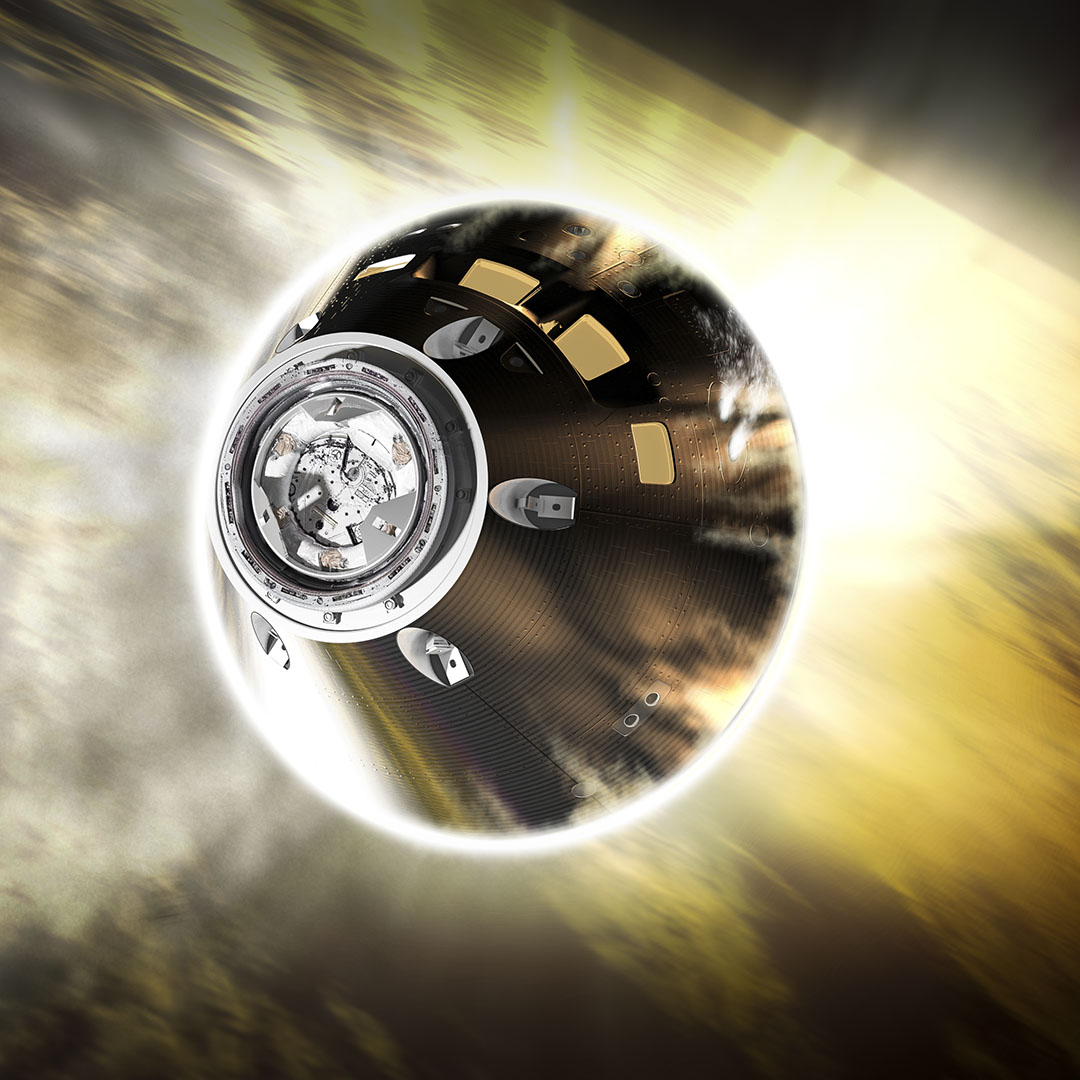

For Episode 66, Ronny Baccus, Orion structures and thermal protection system functional area manager, discusses how Orion deals with temperatures around 5,000°F when screaming back into Earth’s atmosphere at 25,000 miles per hour. This episode was recorded on August 28, 2018.

Transcript

Gary Jordan (Host): “Houston We Have a Podcast.” Welcome to the official podcast of the NASA Johnson Space Center, Episode 66, 5,000° Fahrenheit. I’m Gary Jordan and I’ll be your host today. On this podcast, we bring in the experts, NASA scientists, engineers, and astronauts, all to let you know the coolest information about what’s going on right here at NASA. So today, we’re discussing Orion, the vehicle that will take humans out into deep space. Specifically, we’re talking about how Orion deals with serious temperatures. It might not be super-apparent, but it has some serious swings out in space. In sunlight, structures can be exposed to temperatures as high as 500 degrees Fahrenheit, minus 150 in the shade. And that’s just out in space. When Orion comes screaming back into Earth’s atmosphere at 25,000 miles per hour, the heat shield will have to protect the spacecraft and, more importantly, the astronauts inside from temperatures around 5,000 degrees Fahrenheit. That’s twice as hot as molten lava and half as hot as the Sun. Discussing this topic is Ronny Baccus, Orion structures and thermal protection system functional area manager.

We go into how Orion is designed to handle all of this and keep the astronauts safe from intense heat. So with no further delay, let’s go light speed and jump right ahead to our talk with Mr. Ronny Baccus. Enjoy.

[ Music ]

Host: Well thank you for coming on the podcast today, Ronny. We really appreciate your time.

Ronny Baccus: Oh, thanks Gary. Glad to be on.

Host: So we’ve had guests that talked about Orion before but we haven’t gone specifically into this, into what it takes to withstand serious temperatures — I mean, high temperatures, especially during reentry, which we’ll get into, but also just temperature swings, of being in space and the difference that it takes with deep space travel. We talked a little bit about it on the Space Station, but Orion is kind of a different beast. So let’s just start with kind of just — kind of set the scene. Just overall, what do we know so far about the temperature of space? Because I don’t think it’s — you don’t really think of that, like if you’re watching a space movie, you see someone just kind of floating out in space, right? You don’t really realize the temperature swings, especially in and out of the Sun. So what do we know so far?

Ronny Baccus: Well, let’s see. So we’re talking about in space temperatures.

Host: Yeah.

Ronny Baccus: And the temperature swings that you get on orbit vary quite a bit, right? And really, what I’m talking about, the temperatures that you see in space, there’s kind of two phases that are important to consider. One is just the on-orbit environment. Once you get up, you know, out of the atmosphere and you’re in orbit around the Earth either on the way to the Moon or somewhere, then you’ve got a thermal management problem that you have to maintain, that you have to manage, okay? And there are a wide range of temperatures that you — that the spacecraft will see while it’s in orbit or in space. Then you also, of course, have the energy associated with the thermal environment for the reentry phase, right, at the end of the mission, which of course the Space Station doesn’t have to deal with. So those are kind of two distinct but related problems to solve, okay? And so, on our team, so in my role as the Orion manager of the structure of the spacecraft and also the thermal protection system, we deal with the heat shield primarily and then the backshell, which I’ll get into what that is.

But basically the external shielding to protect the spacecraft and the occupants, of course, from the reentry environment. But the larger spacecraft, in its entire mission, we have to manage that temperature obviously from start to finish. We have several teams that are engaged and work together, you know, to kind of hand off that responsibility depending on the mission phase. And so getting back to your question about, you know, once you get up into space, let’s take low Earth orbit, just as a starting point.

Host: Okay.

Ronny Baccus: And you will see, you know, when you’re on the side that’s — when you’re facing the Sun, obviously you’re getting all that thermal energy. The surface temperatures — we talk about the temperature of space but the really important thing is what the temperature of the spacecraft is getting when it’s exposed to that solar radiation. And so you can see temperatures as high as, you know, 500 degrees or so on the surface and then you come around on the backside or if you’re just in the shade, then there’s a very steep gradient where it drops down to, you know, minus 150 or so at the coldest point.

And temperature varies throughout the, you know, all over the spacecraft surface. It’s a distribution. It’s a function of what materials you choose, what the optical properties of the outer surface are and how much light and solar energy get reflected, how much gets absorbed — all of those are important design considerations in managing how much heat is coming into the spacecraft and also how much heat is going out of the spacecraft, right? In the terms of the crew inside, you know, we like to keep a nice room temperature, you know, short sleeve environment for them. And so it’s as much about making sure it doesn’t get too cold or too hot, right? So when you’re going in orbit, you have these temperature swings in low Earth orbit 16 times a day, you know? Every 90 minutes you’re going around.

Host: Yeah.

Ronny Baccus: And so that is a design consideration that has to be accounted for. Once you’re in transit to, let’s say talk about the missions to the Moon, upcoming EM missions for Orion for example or for Apollo, they didn’t have temperature swings that frequently but you had to account for the fact of which side is facing the Sun? Which side is in shadow? And account for what that does to the spacecraft in the design.

Host: Yeah, that’s right. So when you talk about orbital, you’re thinking about the Earth having one side mostly facing towards the Sun. That’s where you’re getting those positive temperatures, those really, really hot temperatures. It’s really the Sun and what maybe the lack of an atmosphere really that’s not protecting you against those extreme temperatures. So the sunshine’s.

Ronny Baccus: Right, you’re getting that direct radiation.

Host: Exactly. So the Sun is shining on the side of the structure. That structure is heating up to 500 degrees. And then on the shade side, yeah, pretty darn cold, negative 150. That’s not a brisk winter, that’s something else. So what — how do you — I guess we’ll start with what materials — what kind of materials you need to think about in the way that a spacecraft is designed to deal with that?

Ronny Baccus: So when you’re trying to manage the temperatures that you have in the spacecraft, you know, you have to look at, you know, maybe the surface temperature is one thing and it’s also the how does that temperature, that thermal energy, transmit inside to the components that you really care, right? The crew, obviously.

Host: Oh yeah.

Ronny Baccus: And any other components that are sensitive to temperature. And so that’s managed through, I mean, the primary structure of the spacecraft, typically the materials that we select for, you know, on-orbit temperatures aren’t primary drivers for the design of the structure itself. The materials can typically handle that. We have carbon composite materials. We have, you know, other high-temperature materials and metals in the spacecraft. Those are — those do have temperature limits. We have a layer — typically what we’ll do, like take for example the Orion crew module and Apollo had this as well. We put an external layer of basically it’s a Kapton tape or a film that has very specifically chosen optical properties so that you’re minimizing how much thermal energy is coming — you know, you’re reflecting a lot of that energy back out into space, or if it’s reaching a certain amount of energy or temperature, then it will emit some of that energy off just as part of its natural physical properties.

And so that’s a very important parameter that is defined. And then once the analysts who have done all of the thermal modeling and analysis — they’ve defined, well, here’s what we need so that we can maintain the environment that we need inside. Then that drove the decision for the specific material or the Kapton tape — basically like tape. It looks like aluminum foil and there’s different variations of it, and pick the one that works best for our mission.

Host: So really, it’s — when you say optical, that’s kind of the reflective component to it. Literally, if you want to get rid of some of the heat, you’re going to reflect it — reflect that sunlight.

Ronny Baccus: Right, right.

Host: Okay. So that actually has a serious effect then on getting rid of some of that heat from the Sun?

Ronny Baccus: Sure. And certainly, you still have those temperatures. Some of that heat will still conduct in. But actually, when you’re on orbit, the bigger challenge is cooling, right? Even though you may have one side that’s facing the Sun, like for the Orion crew module as the example, the real driver is making sure that the heat that’s inside the crew module doesn’t drop too much because that conduction path goes both ways. So you can have the heat start to conduct out to the surface and radiate out from those outer layers, so we had to kind of strike a balance between making sure we have the right range of temperatures inside. We control — we have systems that will monitor the temperature inside and will — you know, if we need to activate heaters to offset that to some amount, we will. That was part of a factor that drove the selection of the outer layer, for example.

This is an integrated problem where if it’s radiating too much out or if the — if it’s emitting or the emissivity is the primer that we’re interested in is too high, that can drive how much heater power that you have to provide to keep the temperature inside what you need. Well then that draws more power from the electrical system and then there’s a ripple effect, right? So we have to look at this from a systems engineering problem to make sure the choices that we make work for the vehicle as a whole.

Host: Yeah, it’s a chain reaction. So you’re talking about not only from the outside, thinking about the temperature of the Sun coming and hitting the spacecraft, now the inside, you want to maintain that temperature. So, as a summary, is it in the colder temperatures in the shade you have — you want to make sure that heat is more contained and that it’s not escaping? That’s really what it comes down to. Okay, so you’re constantly thinking about that.

Ronny Baccus: That actually turns out to be more of the design driver.

Host: Really?

Ronny Baccus: Yeah.

Host: Okay — well, the crew, right? You want to protect the crew.

Ronny Baccus: Right, absolutely.

Host: Do you find yourself fighting with the power guys who want to face the solar arrays a certain way but have thermal constraints on the structure of the vehicle?

Ronny Baccus: So we do consider, you know, what is the overall spacecraft pointing needs, the solar arrays can obviously point us in whatever direction is most favorable.

Host: Oh, there you go.

Ronny Baccus: Particularly when you’re in transit. For the most part, you’ll be tail to Sun. Like if you’re going from the Earth to the Moon on the Orion spacecraft, primarily you’re going from the Earth to the Sun. So you kind of have that study sunlight on one side and that’s — you know, we’re drawing power from the solar arrays and we’re able to have an integrated solution that doesn’t violate any thermal constraints that we have for the spacecraft while still generating the power that we need.

Host: There you go.

Ronny Baccus: And there are factors as you go. Depending on what phase of the mission you’re in, you may need to do an attitude adjustment to change how you’re pointing of the spacecraft or the solar arrays.

Host: Yeah. So we should probably go back and address the fact that this Orion spacecraft is — the first few missions, we’re planning on going to the Moon, right? We’re going to go around the Moon. That’s where the vehicle is going to be tested. We have some knowledge from going to the Moon before. The Apollo capsule had humans that went to the Moon and have kind of a similar profile, you know? You’re launching, you’re going around the Earth and then, bam! Translunar injection to the Moon. What do we know from some of those missions, learning from past experiences on how to deal with going to the Moon and the thermal constraints there? And then coming back too, especially with reentry?

Ronny Baccus: Right, right. Yeah, certainly the Orion spacecraft has — genealogy can trace back to [Apollo] in many areas. We definitely have looked at that design and the lessons learned and the leverage that experience base in informing the design choices that we make, what works best for Orion. There are some differences, certainly. Orion didn’t — I mean, pardon me, the Apollo had fuel cells on board to generate the electrical power rather than solar arrays, which Orion has.

Host: Ah, okay.

Ronny Baccus: There are pros and cons with that. The benefits of solar arrays is that basically the sustained power that you can get for long-duration missions. [Apollo] had fuel cells so they didn’t necessarily have the same attitude constraints that would be associated with solar array pointing than we would have for Orion. Just as one example, there were a number of lessons learned if we talk about reentry in particular. The heat shield that [Apollo] had, we did a lot of research in looking at the Orion design and determining what is the most — what would be the most effective and efficient heat shield for reentry for the missions that we’re looking at? Of course, we have this experience base with Apollo and the system that was developed during that program, and the material systems that were a part of that is a material called AVCOAT.

It was developed during the ’60s. We are maintaining a lot of that knowledge — corporate knowledge within the agency — and have applied that to the Orion spacecraft because it works very well.

Host: There you go.

Ronny Baccus: For lunar returns.

Host: So what’s AVCOAT?

Ronny Baccus: So AVCOAT is a material system that is used to — it’s basically the outer layer. So if you’re looking at the spacecraft, whether you’re looking at Apollo or the Orion crew module, basically the outer layer of the heat shield that you see before you put this thin film of Kapton on that I mentioned earlier is the AVCOAT material. That’s your primary barrier that protects the crew module from the hostile environment of the reentry trajectories that we’ll fly. It’s a material that will shed heat as you reenter the atmosphere. The temperature goes up, you get up to the surface temperature of about 5000 degrees Fahrenheit. On the back side, these — this is probably, depending on where you are on the heat shield, it’s an inch or two inches thick.

By the time you get to the layer where it’s attached to the internal structure, it’s no more than a few hundred degrees, right? So it’s very effective at isolating heat from the areas that you need to protect and not exceeding any temperature limits. And the way it works is, as the heating is increased, then you get these chemical reactions that happen at the surface that’s taking the brunt of the reentry environment. And you have these, basically these small particles that will start to be liberated from the surface as that heat increases. What that does is you’re taking — small amounts of mass are leaving or eroding off of the heat shield. It’s taking heat with it. And so that’s a way — it’s basically dumping the heat as it’s applied, or dumping it overboard into the wake of the spacecraft as it flies in the reentry and that is very effective at controlling how much remaining thermal energy makes its way into the spacecraft.

Host: Wow! So literally — you said it’s about an inch-thick, right? And it’s just — it’s meant to burn away?

Ronny Baccus: Right.

Host: And that’s how it protects? You’re literally — the heat comes and you just throw it off the back, huh.

Ronny Baccus: Right. I think at the hottest spot on the heat shield, it’s called the stagnation point, and that’s basically where you’re hitting the wind stream basically head-on, 90 degrees. That’s the taking the brunt of it. I think in that location it’s about two inches thick at its thickest.

Host: Okay

Ronny Baccus: And as you get to regions where the heating is reduced, that thickness will taper that down to only be as thick as it needs to be with the appropriate amount of margin.

Host: Right.

Ronny Baccus: So that was a system that was developed in the ’60s, just at the fundamental material level. We did a very extensive trade study at the beginning of the Orion program to evaluate a number of different candidate materials to determine which one would be the most effective for our use and AVCOAT was one of the contenders — and went through a lot of testing and analysis to determine what’s the best fit. And for our purposes, the physics are really the same as they were back then and it really is a robust system that is very effective at what we’re doing.

The shape of the crew module, certainly for those that are — have some familiarity with the Orion spacecraft, it looks very similar to the Apollo capsule design. It’s a larger spacecraft in general, but the shape is the same essentially.

Host: Yeah.

Ronny Baccus: So it flies through the atmosphere in the same way. The curvature of the heat shield is the same, just scaled up. And it’s the curvature of these blunt-body capsules inherently provides you an additional level of thermal control, if you will. And the way it does that is that as you’re pushing through the atmosphere, it creates this shockwave in front. There’s this bow wave in front. And as you get farther away from the heat shield and get into where that shock-layer is, the temperatures are much higher than 5,000 — we were talking about 5,000 degrees being very hot, they’re many thousands of degrees hotter than that.

You get to temperatures of the Sun kind of temperatures. You never want that flow to actually directly attach to the heat shield, right? You’ll immediately have a problem.

Host: Right.

Ronny Baccus: So the shape of the capsule is very important in keeping that shockwave offset from the spacecraft.

Host: Huh!

Ronny Baccus: And so then you have — and so the heating environment that’s inside that shockwave is much less. It’s “only” 5000 degrees on the surface. So that — so then we have to manage that surface temperature in terms of how the heat shield system itself will reject the heat and minimize heat conduction so that by the time you get to the bondline where the heat shield material is bonded to the structure, it’s at most allowed to get to about 500 degrees again like we talked about before, by the time you get to splashdown, right? And so then we just changed the thickness of the blocks depending on where you are so that you’re always protecting that temperature limit inside the structure.

Host: Yeah, wow! I didn’t think about that. Upon reentry, there are higher temperatures than 5,000 degrees, which is absurd to think about in the first place. But just the shape of the vehicle and the way that it’s designed protects the vehicle itself from those temperatures just based on physics.

Ronny Baccus: Right.

Host: Wow! Okay.

Ronny Baccus: Yeah, and you think about how much energy there is and you watch the vehicle, you know, a vehicle that’s bound for the Moon launch on a — it’s got to be on a big rocket. There’s a lot of energy that is expended to be converted into the kinetic energy or the velocity required to get all the way out to the Moon and all the way back. Well, we still have that energy, it’s in the system, it’s just in a different form. And we have to slow down to, you know, levels that are within the range of what the parachutes can take over from and all of that energy dissipation is done through just dissipating it through thermal dissipation, I guess from the heat shield primarily. And so you’ve got all this work that’s done. As you’re pushing through the atmosphere, you’re reducing the velocity as you’re pushing all these hot gases away and out in front of this shockwave. And then energy of just liberating this material from the AVCOAT system to carry the heat away and minimize how much heat is coming in.

Host: Yeah.

Ronny Baccus: And by the time you get down low enough, if we’ve done our job right, you’re nice and starting off let’s say 25,000 miles an hour at the start, and by the time you get down in the lower atmosphere, you’re maybe 1,000 miles an hour or so, a little bit less. You’re within range of where the parachute system would then start to take over.

Host: Okay, yeah. The atmosphere is a great kind of way to slow down.

Ronny Baccus: Right.

Host: So the heat shield — it’s designed, if you’re thinking about this capsule shape, it’s designed to take that heat. It’s designed to withstand the 5000 — or sort of withstand it. It’s supposed to kind of shed it and — but on the other side, that doesn’t have a heat shield as well and the reason is just because of the shape, because a lot of the heat is on this side. So what’s happening on the other side as the temperature’s within that 500 degree?

Ronny Baccus: So on the back side, where the conical portion of the capsule — so the temperatures are much lower back there because you’re in the wake of the spacecraft as it’s plowing through the atmosphere. But we still have to provide thermal protection back there. And this is a case where, for the Orion vehicle, we’ve leveraged our experience with shuttle and actually have an array of — very similar to the shuttle tile system back there. So the temperatures back there, you know, 1600 degrees Fahrenheit on the surface roughly, you know, it varies depending on location, but that’s within range of what a tile system could do. So we put these blocks on there in typical fashion and that provides the protection that we need for the back shell.

Host: And then you said there’s tape on top of that?

Ronny Baccus: Then on top of that, we put the layer of the Kapton tape, the shiny metallic, looks like aluminum foil. It’s the very thin layers on the outside and then that gets us back to the optical properties that we need to help manage the thermal environment when we’re in orbit. So it all ties together — the system.

Host: Yeah. So having the sort of reflective tape on top to — when you’re out in space, that’s going to be reflecting a lot of the heat because the tile itself is black, right? And you don’t want black tiles when you’re out in space, right? That’s going to absorb too much heat. So then what’s the heat shield made out of? If there’s these tiles up top, what’s underneath this AVCOAT?

Ronny Baccus: So underneath the AVCOAT, then you’re getting into the primary structure of the vehicle. And so the heat shield is basically a giant dish. It’s a composite — carbon-composite material. So it’s fabricated. You basically have these layers of these plies of material that you can lay — and think of like fiberglass in a boat, right? They will lay these layers in at different angles. The fibers come in these rolls of — it’s basically like a roll of — think of like a roll of carpet or something, two-feet wide or something. And you lay it down in these strips and you build up these layers, you know, 40, 50 plies thick. And then that goes into an oven or an autoclave and that cooks it. And then all the resin and everything that’s in that system will harden and then you’ve got a structure that’s stiff and strong and can handle the loads at splashdown, can handle the aerodynamic pressure during reentry and all the other load cases that we have to deal with.

So that’s the primary skin that the AVCOAT is bonded to. Then there’s some supporting members inside that made out of titanium that provide additional stiffness and then they attach points to the rest of the crew module.

Host: Oh, okay. Yeah, because the heat shield not only has to deal with heat but you’re talking about a lot of other factors too that you have to test.

Ronny Baccus: Right. Yeah, it’s an integrated problem for sure because, you know, the thermal environment — and obviously managing and discarding the heat as you’re coming into the atmosphere is a key part of it — but you do see temperature differences internal to the structure. You also have to consider this in space where, if you have materials that are made from — or if you have structural elements that are made of different materials, they may expand and contract a little bit differently from each other. And if they’re attached together, then that will induce some stresses in the structure that we have to make sure we design for and account for. So that’s all part of the analysis and testing that we do to ensure that we understand how the design works as an integrated system.

Host: That’s right. Because you have all these issues to solve so you just have to make sure that your solutions are going to not only solve them but then work together.

Ronny Baccus: Right, exactly.

Host: Wow! So this — it sounds like the heat shield this is just a solid piece, like you described it as a dish. Is that how the Apollo heat shield was as well?

Ronny Baccus: The Apollo design was a little bit different. The structure was different. They had a — it was basically a metallic honeycomb — they call it a honeycomb sandwich panel. So if you were to look at a cross-section of it, you’d see a very thin sheet of steel and then you’d have this honeycomb material in between. And then on the other side, you’d have another layer of steel is what they had for Apollo, at high-temperature capability. So that’s very stiff. The reason for the honeycomb structure is to take some of the weight out. If it was just a solid material, it would be very heavy. You wouldn’t be able to lift it off the pad. And so you can separate these two sheets, make them very thin, put this honeycomb material in between, and then you get a nice, stiff structure.

Host: Okay.

Ronny Baccus: We use similar versions of that design for, like, the backshell panels on the conical section. We use composites instead but we use — the sandwich construction is very efficient for handling load. It wasn’t the best fit for the Orion heat shield. The size of the dish made it more efficient for us to just basically make a single skin and then reinforce it with some metallic beams inside — stiffeners. That was a more efficient solution for our size. It’s one of those things — when you look at the Apollo design, the Apollo design is a 12 1/2 or so feet diameter heat shield. The Orion vehicle is larger. It’s 16 1/2 feet or so in diameter. It’s the largest heat shield of its kind. You can’t just take the old design and, you know, scale up everything as it was on the Apollo drawings and have it necessarily work, right? There are other things that come into play with scaling up. And so we made a decision to have a different structural configuration that worked better for the size that we were going to be using in terms of its ability to be manufactured. And so that drove the structural differences.

The AVCOAT material itself is very similar to Apollo. The biggest difference in the Orion design now is in how the architecture of the system — and what I mean by that is the — if you look at the Apollo design, if you’re familiar with the Apollo design, you have this — so you have this structure, the sandwich structure that I mentioned. And then bonded to the outside of that is another layer of honeycomb material. And it’s open cell. So if you were to — and you can go over — if you ever go over to Space Center Houston and look at the crew module that they’ve got over there of the Apollo 17 vehicle, you can see the individual cells. It looks like a honeycomb. I mean, you see these little cells — kind of the pattern is on the outer surface of the heat shield.

Host: Cool.

Ronny Baccus: Now there’s a lot of manual touch labor that’s involved with a design like that. So the way they did it was they had this honeycomb. It was open cell material and then they had a — think of like a — almost like a glorified caulking gun. And they had a technician manually inject every single little cell to cover the entire spacecraft with this AVCOAT material in its uncured form, so it’s like a paste.

Host: Okay.

Ronny Baccus: Okay and then, once they get every cell filled up, they put it in the oven and cook it. Then after it’s cured, fully cured, then it’s ready for flight. It’s got the properties that we need to then ablate. We started with that design for Orion as well. So in fact, the EFT-1 mission that flew back in December of 2014, we started with that design as well. So we had the, you know, much larger heat shield.

We had this honeycomb system and, same process basically, injected every single — so there’s like 300,000 of these individual cells.

Host: Ah, so fun!

Ronny Baccus: On the heat shield that was then cured. What we’ve learned from that is, as part of the scaling up process, is that there are some challenges in terms of manufacturing that design presented us with. So, once we cured the entire heat shield, we saw some cracks had formed in certain areas — not desirable to have cracks on a heat shield, right?

Host: No!

Ronny Baccus: And so the good news is we had repair methods that did have, you know, Apollo heritage that we could employ to basically fill those cracks. We had a series of plugs that were applied to fill in all of these cracks and we got a nice heat shield out of it, had a very successful flight and the heat shield performed beautifully. It was amazing.

Host: Cool.

Ronny Baccus: But it was an experience that kind of led us to think about, well maybe there’s an opportunity here to evolve the design a little bit. And so we were looking at other programs and other experiences that we had with block heat shield systems that have flown since Apollo. An example of this would be some of the Mars probes that have flown, like the MSL mission, you know, a few years ago. They had basically a block system that you cure the individual blocks of a blader into these chunks of maybe two inches or — I’m sorry, two feet by two feet or so in size.

And then you can — and then you basically bond those on a piece at a time. And so the advantages of that is that the amount of touch labor is reduced, so trying to be good stewards of the taxpayer dollar. The cost comes down in terms of production, but it also got us away from some of these failure modes that were kind of an inherent with this honeycomb system, to get some more reliability out of it. And the reason that that’s helpful is with the honeycomb design, you basically had to build the entire heat shield and then you cured it all at once. And then you kind of found out at the end, how did it turn out? You know, did the cake bake the way we planned? And with the block system now where if you can make these the AVCOAT in these individual pieces, you can cure them separately and you can do an inspection of each block and say, oh, this is a good block, let’s bond it onto the spacecraft.

Oh, this one’s got a flaw in it or this has an issue — throw it out, right? So it allows us to kind of screen out as we go and get some efficiency out of the system and get some confidence in that, as we are building up the heat shield, that we’re going to have a system that’s going to work for us. So there’s a combination of, you know, looking for ways to take what we’ve learned from Apollo and not lose that benefit because the material is very effective at what it does, but look for opportunities to enhance its performance and its ability to, you know, from a practical perspective, from manufacturing and getting costs down and other things that is working well for us now. That’s one of the key things looking forward that we’re going to be looking for on this EM-1 mission, which is our next flight, is a flight demonstration of this block version of the AVCOAT system.

Host: Okay. There you go. Well, that’s the wonderful thing about testing, right? So EFT-1 kind of revealed, well, maybe let’s reinvestigate this honeycomb thing, and now you’ve got the blocks. So we’re going to try that out. That’s wonderful.

Ronny Baccus: Exactly.

Host: Yeah, thinking about more efficient ways of doing things, I love that. So where is — I guess kind of along those lines, since we’re on the heat shield, you’re talking about these blocks being designed, where is everything happening? Where are the blocks being manufactured and tested and all that?

Ronny Baccus: So we have — so our team is — we’ve got facilities at multiple locations kind of across the country. The primary design center for the — with our partners, Lockheed Martin, that is developing the design and doing the fabrication for the spacecraft is in their facility in Denver, Colorado. All the design activity happens there. The primary structure is all fabricated there. It’s tested there for strength to verify that it’s going to perform the way we want. And then all of that hardware is delivered to the Kennedy Space Center. The AVCOAT system is manufactured — now that we’ve moved to this block architecture, we have the capability down at the NASA Michoud Facility down in New Orleans — so Lockheed Martin has got a team there as well and they’ve got production capability. And we’ve over the past few years built up the capability to build the heat shield material, thermal protection material, in these AVCOAT blocks at Michoud in New Orleans.

And all those blocks are delivered to Kennedy Space Center for installation onto the structure. And then of course the tile system that we have on the backshell, you know, we have maintained that production capability. Those tiles were, during the shuttle era, all fabricated at Kennedy Space Center and we’re maintaining that for our uses as well.

Host: There you go.

Ronny Baccus: We’ve got pieces everywhere and it all comes together at KSC and getting ready for flight.

Host: Awesome! So this is an interesting question because 5,000 degrees Fahrenheit is — that’s pretty hot — and even you said, there’s temperatures that are even higher than that but they’re not on the vehicle itself. How do you test the material to make sure it’s going to withstand those high temperatures?

Ronny Baccus: Right. So our biggest workhorse test facility for evaluating designs for how are they going to stand up to the reentry thermal environment is at Arc Jet Facility at Ames Research Center in California. There are — the Arc Jet Facility, there are several facilities there that can provide, depending on what environment that you’re targeting — you know, what kind of a heating duration and magnitude are you trying to get? Then that kind of determines, well, which facility will I go into? Primarily, our testing runs through our team members at Ames who perform those tests for us and we evaluate a lot of different design features. If we’re looking at just the basic performance of the material, is it recessing or ablating away at the rate that we predict? Are the temperatures following the predictions — all of those things that are important to validating the design.

We’ll take a sample of this AVCOAT material and put it in this chamber and then you’ve got this superheated plasma essentially, dissociated gas that will simulate the reentry environment. This arc heater will, basically like a big torch that can get up to very high temperatures.

Host: So cool.

Ronny Baccus: And then you define, well how long do I want to stay at this temperature and you define this profile, and then you can compare the results of the test with your analytical predictions and see how am I doing? Do I need to change the model and how I’m assuming how thick does it have to be, right? So we’ve gone through, you know, hundreds of tests, looking at different things that have gone through the Arc Jet Facility. We’ve also looked at — we’ve done some tests up at Wright-Patterson Air Force Base at our research lab there. They have a unique capability to apply a very high-energy thermal environment using lasers. Now it’s a different mode of getting heat in but you can get very hot and also put mechanical load, or you can basically bend the sample at the same time as you’re heating it. So you’re getting that sort of combined effect now, right?

Host: Right, there you go.

Ronny Baccus: Because you’re coming in. You’re entering the atmosphere, you know, all this heating on. But at the same time, you’ve got air pressure building up and so you’re flexing the heat shield at the same time as you’re heating it up. So that’s a way to kind of check the — sort of the combined effects of those two things at once.

Host: There you go.

Ronny Baccus: And so we’ve run quite a few tests through there. We’ve got testing capabilities at Johnson Space Center here. We’ve got a radiant test facility that we’ll put thermal energy in, depending on what we’re trying to do. Those are the main areas that we’ve done testing for and we’re — you know, in addition to just testing the material system itself, there are things like, well now we’ve got this block system. Well, what do you do at the interface from one block to the next, right? You’ve got a — you can’t have a crack. You can’t have a groove. So to fill it in, we have what’s called RTV, which stands for room-temperature-vulcanized — it’s a type of rubber, basically. And we put some special ingredients in the mix to make sure it preforms and stretches the way we want. But we have to make sure that there’s not some unique failure mode hiding in the design, you know, at these features or at these interfaces, right? So we spend a lot of time testing out the gap filler and how is it performing in these environments as well.

So that’s been a key part of our demonstration and getting confidence in this block system before we put it up in the air.

Host: Yeah. Because when you’re talking about testing — the reason I ask is I find this so fascinating is you talked about, you know, you go through all of these tests and then finally you fly EFT-1 and then find improvements, you know? You have this big test, the actual flight that reveals something. You just can’t — no matter how many times you test, once you do it, you still learn so much.

Ronny Baccus: Absolutely.

Host: So that’s one of the incredible things about testing, and that’s why I’m so looking forward to these upcoming tests, you know, EM-1, EFT-1. What are you looking forward to with these upcoming things to finding out?

Ronny Baccus: Well, certainly the EM-1 mission is going to be huge for the entire team of course but looking kind of from my knothole, how does the structure perform? And in particular, how does the thermal protection system perform? For EFT-1, we had a very high heating environment, you know, by design. We lofted the orbit up 3,000 miles up in apogee, I think it was, and then came in and really dug into the atmosphere to really try to put a stressing environment on the heat shield and learned a lot of things from how did it perform and how did it compare with our predictions? Well, for EM-1, that — we’re going out even further, right? We’re going out to the Moon and back. And by the time you get back, those velocities, you know, you’re back up to 25,000 plus miles an hour. How is the heating environment going to interact with our design, right? And so we’ve really done a lot of testing on the ground but it’s not a replacement for flying it.

You see it, you know, how is it going to do? We’ve made assumptions. There are certain things that we know you can’t test on the ground — certain corners of the design box, if you will, that we can’t duplicate on the ground. The only way you get it is if you fly. And so for those areas, you know, we may carry some additional uncertainty in our analysis and how we’re sizing the system to handle those loads. So we’re really looking forward to getting some real flight data on this system and we can go and compare. You know, maybe after I see how it flies a time or two, I can start to reduce those uncertainties in that area and confirm that there’s no hidden, you know, failure modes or something that we need to pay attention to, you know? There’s a lot of good things coming out of EM-1 and we’re really looking forward to getting that data and getting it in the hands of the engineers.

Host: Yeah, like an altered design, right? You’re testing it a lot, but really — it’ll be exciting to see that thing come through the atmosphere and deploy the parachutes, yay! You know? You did it.

Ronny Baccus: Absolutely.

Host: So that’s going to be pretty exciting. You know, this is where we’re talking about these test flights but then, beyond that, we’re talking about missions to the Moon, missions to Mars. What needs to change to make those successful, or is this something that we can apply to future deep space missions?

Ronny Baccus: Right. So we have — just from the very beginning of the design of the Orion vehicle — have purposely designed it to be as capable and as robust as we can so that we keep our options open as far as destinations, right? We want to make sure we’re providing ourselves with that latitude so that if, you know, if we’re doing lunar missions, right? So we’ve got these upcoming missions — EM-1 and EM-2. EM-1 will basically be our big shakedown flight, you know, coming back at lunar velocity — return velocities, obviously. EM-2, we’ll have crew on board, right? That’ll be huge. And then if you’re looking — and so we’ve designed the vehicle from the get-go for those environments. If you’re looking at the later missions, you know, we’re evolving to this gateway concept of having an outpost out on the other side of the Moon, those return velocities are still very similar, well within the capability of what the Orion heat shield can handle once we get — and we demonstrate that up front with these test flights.

And then, of course, off in the horizon, we’ve got our eye on Mars and, you know, there may be — day-to-day, we’re working the immediate problems but that’s — Mars is always there, right, in our minds. And so looking at the return velocities from Mars, there are a number of different ways you can go to and from Mars. Some of the return trajectories will be way too fast for really any material to handle, but there are a nice class of trajectories that our guidance and navigation control team can put us in that will be within reach of the current design that we have. And what’s interesting about the way this material works, you know, let’s say you’re coming back on a Mars mission. The typical class of trajectories that we would be looking at may be 10 or 15% higher in velocity, roughly. Okay, so it is faster but it’s not inordinately faster.

And so, at those kind of speeds, the surface temperature, just based on the physics of how the oblation works, is still at 5,000 degrees. It’s essentially the same temperature even though you’re coming in a little bit faster. But what’s happening is you still have more energy coming into the system. And so for that case as we evolve towards beyond the Moon and evolve towards Mars capability, we’re expecting that the thickness will have to increase a little bit so that we maintain that backside temperature limit is how we’ll manage that. So we do have some knobs we can turn to make sure we, even for Mars missions, that we are able to reenter safely and protect the spacecraft and the crew from a mission like that.

Host: I like that phrase, “just turning some knobs,” right? You’re working towards these deep space missions but really just, you know, a few tweaks based on the knowledge we have now and you can — you’re talking about a mission to Mars and even beyond. That’s really exciting. So Ronny, thank you so much for coming on the show today.

Ronny Baccus: You bet!

Host: And explaining this. I’ve never really gotten a chance to sit down and go this deep into just how a spacecraft is not only going to survive in space but then dealing with these insane temperatures. It’s pretty exciting stuff, so I appreciate you coming on.

Ronny Baccus: You bet!

[ Music ]

Host: Hey, thanks for sticking around. So today we talked with Mr. Ronny Baccus about the Orion and the temperatures that it’s going to have to withstand out in missions to the Moon and even beyond but then, more importantly, that 5,000 degrees Fahrenheit temperature screaming back into Earth’s atmosphere — that’s going to be wild. We’ve talked about Orion before on the podcast on a couple of episodes, so you can go back and listen to some of them. You don’t really have to do it in any particular order. But we do a nice overview for Episode 17. We talk about how the crew is going to operate inside on missions that can go up to three weeks for Episode 28. And then you can actually listen to Episode 35 and take a ride inside the capsule. We bring audio from EFT-1, the mission that we talked about during today’s episode, and bring it inside that episode and just — you can just sort of sit back and feel what it’s like to launch on Orion and reenter Earth’s atmosphere and even splashdown. I’ve been talking to a lot of Orion folks lately, so you can go to nasa.gov/orion and search for an article called “The Top Five Technologies Needed for a Spacecraft to Survive Deep Space.”

This heat shield is one of them and we’re going to address a lot of them just kind of scattered on this podcast. But you can go and read that right now, it’s a great article. You can follow Orion on Facebook, Twitter, and Instagram. Use the #AskNASA on your favorite platform to submit an idea for “Houston We Have a Podcast.” Make sure to mention that in the post so we can go look for it and maybe answer it on the show or bring in an expert to answer it for us. So this episode was recorded on August 28, 2018. Thanks to Alex Perryman, Bill Stafford, Pat Ryan, Laura Rochon, and Rachel Kraft. Thanks again to Mr. Ronny Baccus for coming on the show. We’ll be back next week.