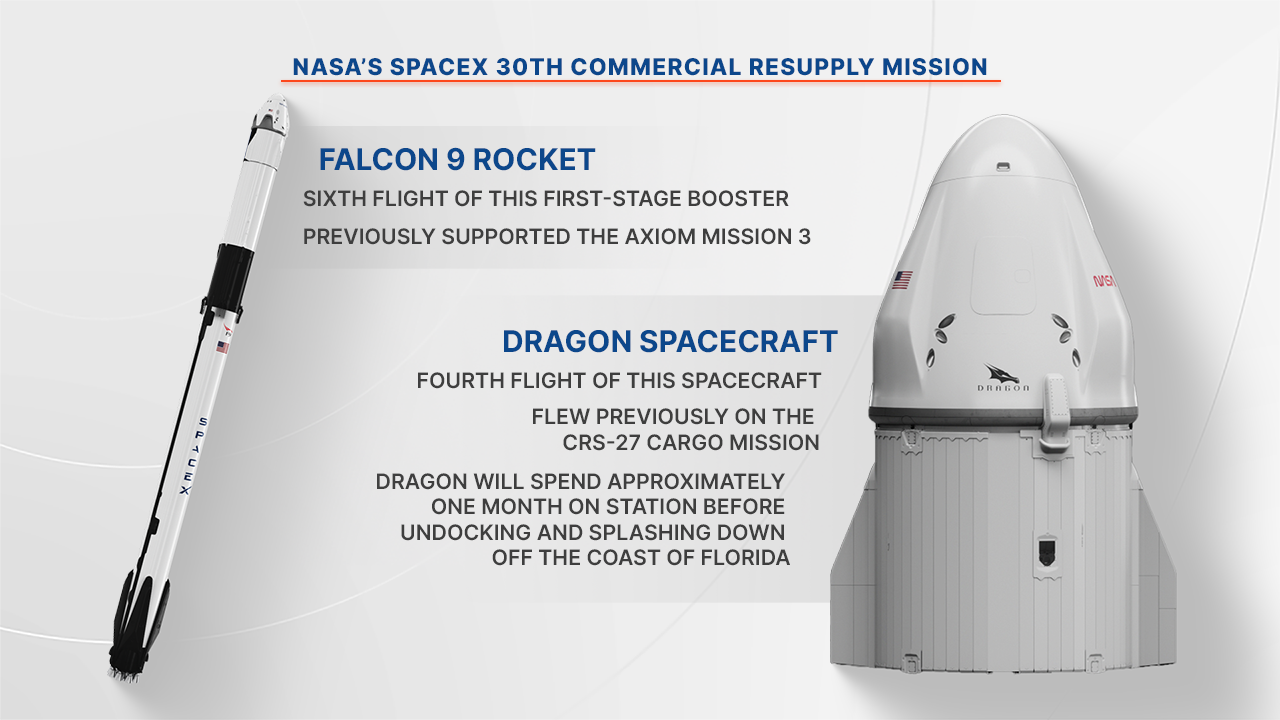

NASA, SpaceX 30th Commercial Resupply Mission Overview

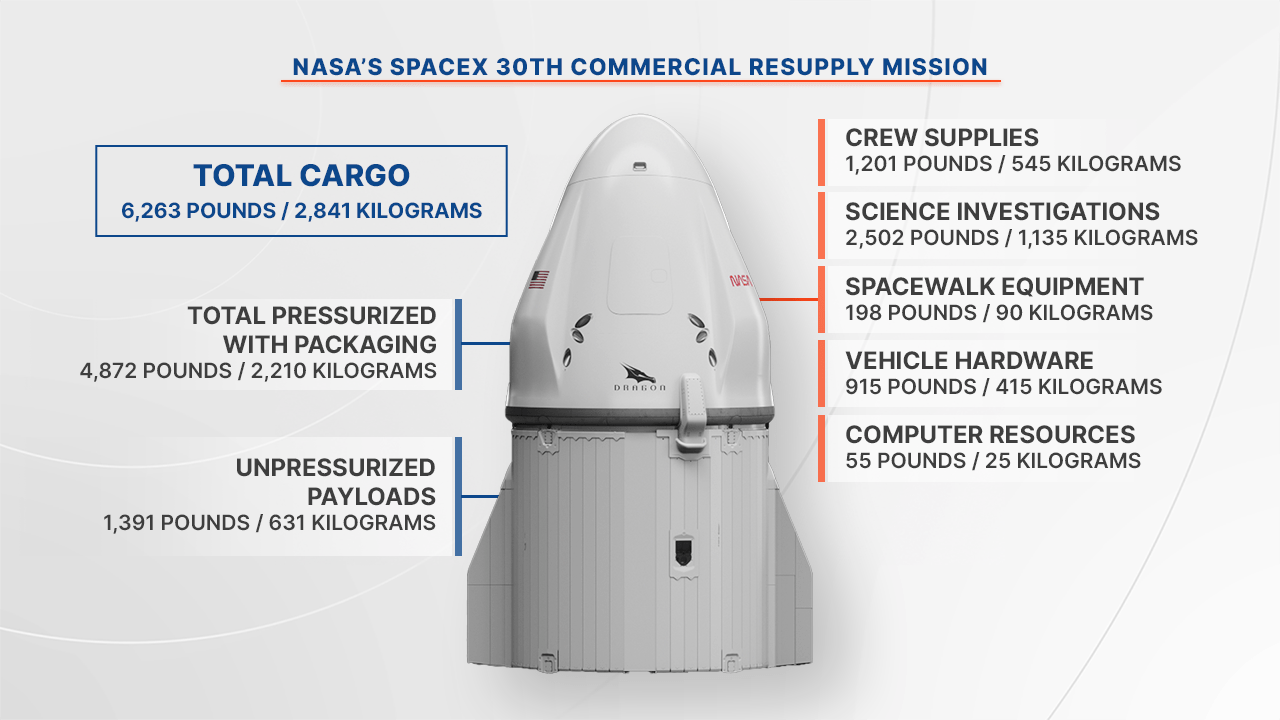

New research and technology demonstrations for NASA are set to launch aboard the agency’s SpaceX 30th commercial resupply services mission to the International Space Station. The SpaceX Dragon cargo resupply spacecraft will deliver more than 6,000 pounds of scientific research, supplies, and hardware to the orbiting laboratory.

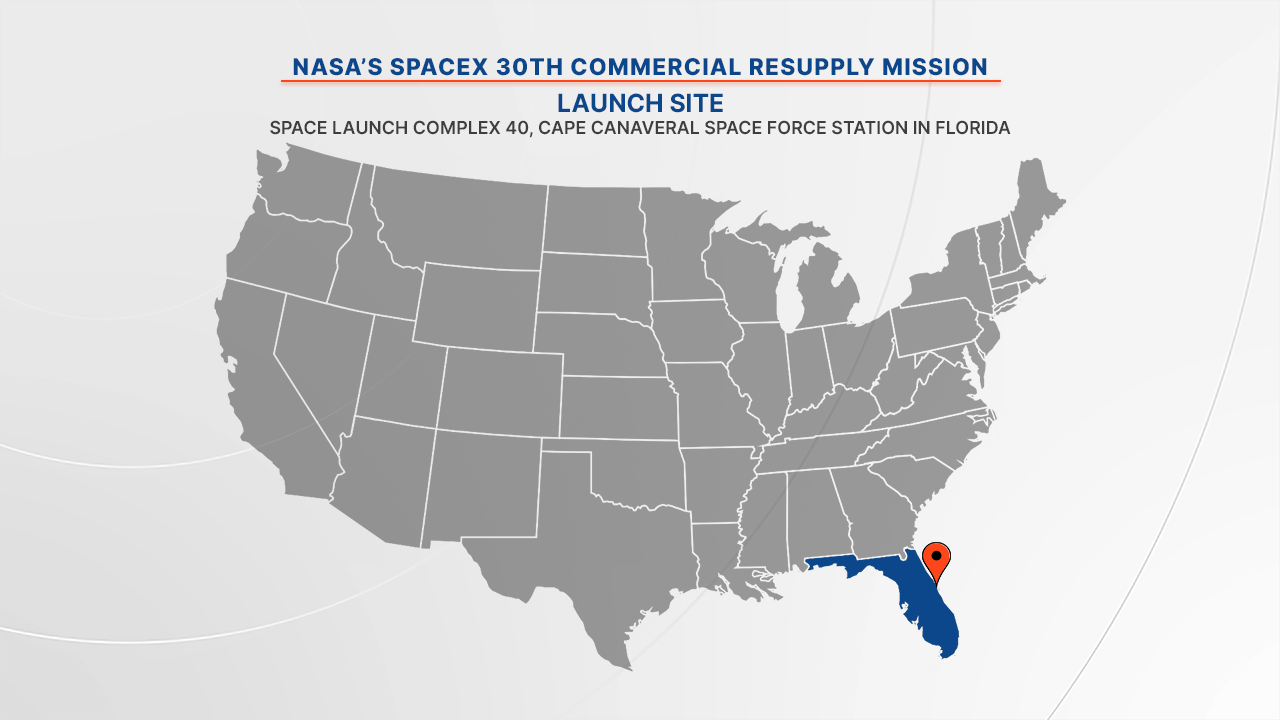

Launch is scheduled for at 4:55 p.m. EDT Thursday, March 21, from Space Launch Complex 40 at Cape Canaveral Space Force Station in Florida.

This is the 10th SpaceX launch under the Commercial Resupply Services-2 (CRS) contract, as the first 20 launches were under the original resupply services contract.

Jump To: Arrival & Departure | Research Highlights | Cargo Highlights | Watch & Engage

Arrival and Departure

The SpaceX Dragon spacecraft will arrive at the space station and dock autonomously to the zenith port of the station’s Harmony module at approximately 7:30 a.m. Saturday, March 23. Live coverage of the rendezvous and docking will begin at 5:30 a.m. NASA astronauts Loral O’Hara and Mike Barratt will monitor the arrival of the spacecraft, which will stay docked to the orbiting laboratory for about one month before splashing down and returning critical science and hardware to teams on Earth.

Research Highlights

Plants off the Planet

Plants can be used in regenerative life support systems, to provide food, and to contribute to the well-being of astronauts on future deep space exploration missions. The Photosynthesis in Space Advanced Plant Experiment examines how microgravity affects the mechanisms by which two types of grasses, known as C3 and C4, capture carbon dioxide from the atmosphere.

“Plants respond to stressful conditions based on their genetic makeup and the environment,” said Pubudu Handakumbura, principal investigator with the Pacific Northwest National Laboratory. “We aim to uncover the molecular changes involved in plants exposed to spaceflight stressors and develop an understanding of the mechanisms of photosynthesis in space.” Results could clarify plant responses to stressful environments and inform the design of bio-regenerative support systems on future missions, as well as systems for plant growth on Earth.

Sensing the Sea

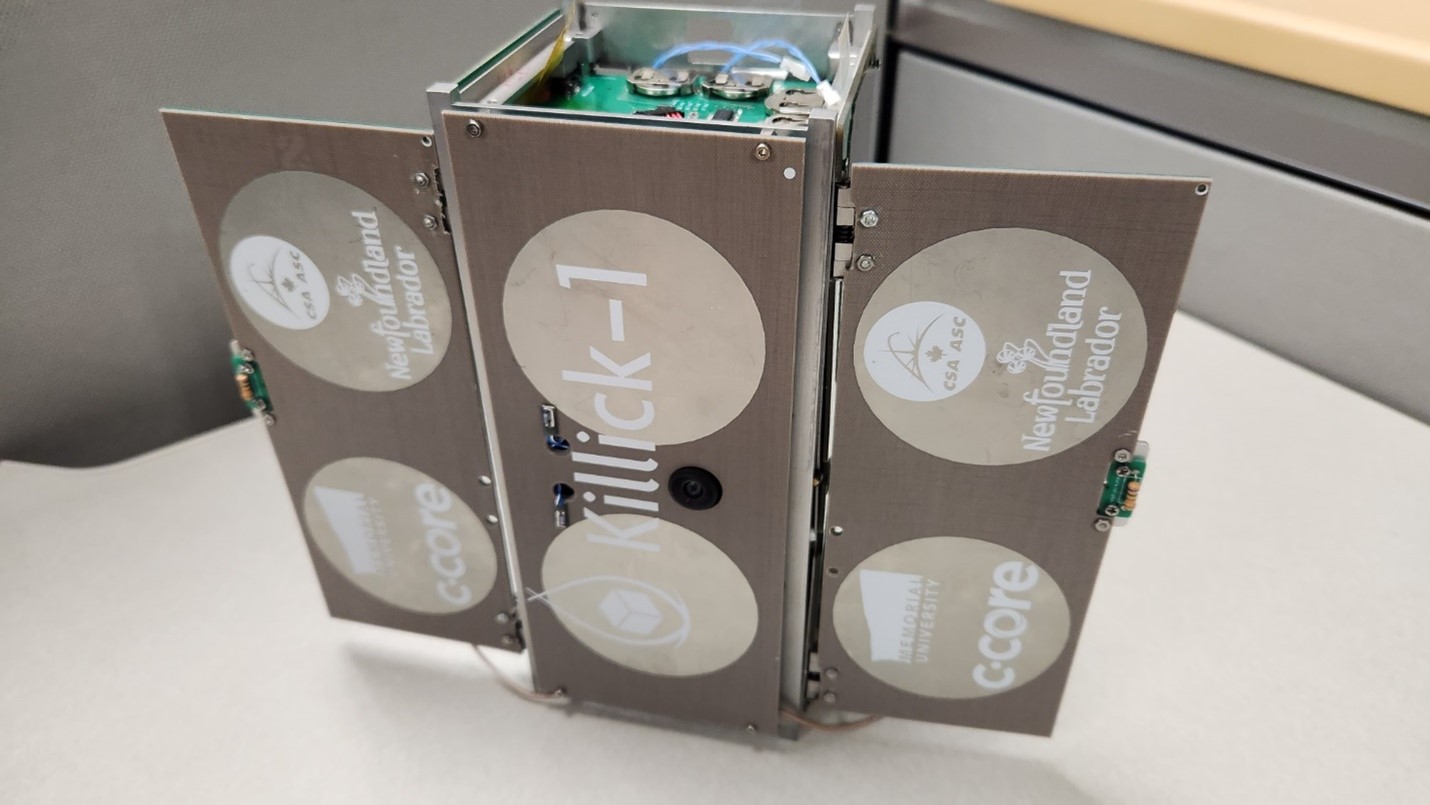

The ocean significantly affects the global climate. A technique called Global Navigation Satellite System reflectometry, which receives satellite signals reflected from the surface of Earth, shows promise as a way to monitor ocean phenomena and improve climate models. Killick-1: A Global Navigation Satellite System Reflectometry CubeSat for Measuring Sea Ice Thickness and Extent (Nanoracks KILLICK-1) tests using this technique to measure sea ice. The project supports development of space and science capabilities in Newfoundland and Labrador, Canada, by providing hands-on experience with space systems and Earth observation. More than 100 undergraduate and graduate engineering students participated in the project.

“The most exciting aspect of this project is that students have the opportunity to launch a mission into space,” said Desmond Power, a co-investigator with C-CORE of Canada. “It is also exciting to build a tiny satellite that does different things, including contributing to our knowledge of climate change.”

Reflectometry technology is low-cost, light, and energy efficient. Its potential applications on Earth include providing data for weather and climate models and improving the understanding of ocean phenomena such as surface winds and storm surge.

Automated Autonomous Assistance

The Multi-resolution Scanner (MRS) payload for Astrobee tests technology to automate 3D sensing, mapping, and situational awareness systems.

“Our MRS on an Astrobee free-flying robot will create 3D maps inside the space station,” said Marc Elmouttie, project lead with Australia’s national science agency, Commonwealth Scientific and Industrial Research Organization, which developed the technology with Boeing. “The scanner integrates technologies developed by our mining and robotics teams. By combining data from multiple sensors, we compensate for weaknesses in any one system. This provides very high-resolution 3D data and more accurate trajectory data to help us understand how the robot moves around in space.”

“The technology could be used to autonomously operate spacecraft with minimal or no human occupancy where robots must sense the environment and precisely maneuver, including the lunar Gateway space station,” said Principal Investigator Connie Miller of Boeing. “Other uses could be to inspect and maintain spacecraft and for autonomous vehicle operations on other celestial bodies. Results also support improvements in robotic technologies for harsh and dangerous environments on Earth.”

Placement of Particles

The Nano Particle Haloing Suspension investigation examines how nanoparticles and microparticles interact within an electrical field. A process called nanoparticle haloing uses charged nanoparticles to enable precise particle arrangements that improve the efficiency of quantum-dot synthesized solar cells, according to Stuart J. Williams, principal investigator with the University of Louisville Department of Mechanical Engineering.

Quantum dots are tiny spheres of semiconductor material with the potential to convert sunlight into energy much more efficiently. Conducting these processes in microgravity provides insight into the relationship between shape, charge, concentration, and interaction of particles.

The investigation is supported by NASA’s Established Program to Stimulate Competitive Research, which partners with government, higher education, and industry on projects to improve a research infrastructure and research and development capacity and competitiveness.

Cargo Highlights

Hardware

Launch:

- Oxygen Generation Assembly Pump – The assembly pump converts potable water from the water recovery system into oxygen and hydrogen. The oxygen is sent to the crew cabin and the hydrogen is either vented or used to produce more water. This pump will maintain sparing on orbit.

- Pump Module Assembly – The assembly provides coolant and regulated flow to the radiator in order to maintain proper temperature for the Direct Current to Direct Current Converter Unit, the Main Bus Switch Unit, and the interface heat exchanger. This unit will maintain sparing on orbit.

- ARED (Advance Resistant Exercise Device) Right Upper Stop Cable – A cable mechanism attached to ARED bar which will allow crew to rack and unrack equipment during exercise. The mechanism will maintain sparing in orbit.

- Hatch Handle Alignment Guide –The guide ensures the proper hatch handle configuration for return vehicle operations.

- Toilet Pretreatment Package (Dose Pump) – The toilet dose pump mixes water and alternate pretreat concentrate from separate sources, flows it through the toilet pretreat quality sensor, and injects it into the urine hose block. The toilet pretreat quality sensor measures the conductivity of the pretreat and water mixture. This installation will enable a new upgraded on-orbit toilet.

- Potable Water Dispenser Filter Assembly Unit – The filter unit, installed into the potable water dispenser on the station, will provide the capability to remove iodine from the water before the crew consumes it in food and drink packages. The unit contains two filters, a de-iodination filter and a 0.2-micron filter, which will be launched as a spare.

- Animal Enclosure Module – A next-generation design of the rodent habitat for the space station. The structure, an anodized aluminum enclosure with an internal stainless-steel cage, is a front breather with enhanced video, LED lighting, and sound reduction. An aluminum box provides water contained in pressurized bags to the specimens. The water can be refilled from the front quick disconnect and three-way valve. Inlet and outlet filters provide odor and waste containment. On orbit, the entire assembly is housed within a powered locker in the hardware storage rack.

- Animal Transporter – A powered animal module containing live rodents for ascent, return, and animal transfer operations on orbit. In a powered configuration, the module provides air exchange, food, water, and lighting. In a passive configuration, live animals are not in the enclosure. The transporter has foam strips mounted externally to provide vibration isolation and is the prime physical interface to the locker used in transport to the space station. The transporter will launch with water, food bars, and up to 20 rodents.

- Catalytic Reactor Startup Filter – The filter is used with the catalytic reactor installation to capture catalyst debris generated in the catalytic hardware during launch and before processing wastewater can begin. This will launch to maintain sparing.

- Vibration Isolation and Stabilization System Mass Tray –The tray supports the Vibration Isolation and Stabilization System on the European Enhanced Exploration Exercise Device. Two numbered trays each will house two tungsten plates when assembled. The trays will be stacked together to become the upper counter mass in support of the exercise device technology demonstration.

- Nitrogen Oxygen Recharge System Regulator –The regulator reduces pressure during transfer of oxygen to airlock supply systems. This will replace the existing unit noted to contain debris on the last restock and resupply of oxygen tanks.

- Crew Quarters Acoustic Blankets –The blankets are used in the crew quarters to provide noise mitigation. These blankets will replace blankets in all four crew quarters.

- Compatible Water Container-Iodine –The container, with a capacity approximately 45 pounds of fluid, stores iodinated water to be used in the coolant loop.

- Solid Fuel Ignition and Extinction Sample Spinner –A hardware insert for the combustion integration rack that enables a range of solid material combustion and fire suppression studies.

Return:

- Common Cabin Air Assembly Heat Exchanger – The exchanger performs heat-transfer functions and removes moisture from the ambient on-orbit air. This unit is being returned for analysis and repair and then returned on a later flight.

- Oxygen Generation Assembly Pump – The pump converts potable water from the water recovery system into oxygen and hydrogen. The oxygen is sent to the crew cabin and the hydrogen is either vented or used to produce additional water. The pump is being returned for repair and will return on a later flight.

- Air Quality Monitor – The monitor is intended to improve the air analysis aboard the space station by measuring volatile organic compounds. The monitor is being returned for potential refurbishment of some of its components.

- Water Separator Orbital Replacement Unit – The unit draws air and condensate mixture from a condensing heat exchanger and separates the two components. The air is returned to the cabin air assembly outlet air-flow stream and the water is delivered to the condensate bus. The unit is being returned for repair.

- Emergency Mask –This unit will be returned to replace retaining rings.

- Emergency Portable Breathing Apparatus O2 Reducer Cylinder Assembly – A cylinder tank that provides 15 minutes of oxygen to a crew member in case of an emergency and is used with a quick don mask. This unit has been depressed and will be inspected, placed in line for refill, and relaunched at a later date.

- Remote Power Controller Module – The module distributes 120 volts of direct current electrical power and provides current limiting and fault protection to secondary loads aboard the space station. Both units are degraded, returning for repair, and will be reworked.

- Separator Plumbing Assembly – Supporting the urine processor assembly, the separator plumbing assembly receives steam condensate from the pressure control and pump assembly and recovers water from the orbital replacement unit. The separator plumbing assembly also controls the flow of water to the fluids control and pump assembly and can detect a pressure regulator failure. It is being returned for refurbishment.

Watch & Engage

Live coverage of the launch will air on NASA+, NASA Television, the NASA app, and the agency’s website at 4:35 p.m. with liftoff at 4:55 p.m. Thursday, March 21.

Subscribe and get the latest NASA news with a weekly update in your inbox: