In This Week’s Star

- NASA and Virgin Orbit 3D Print, Test Rocket Combustion Chamber

- What’s All the Buzz About? Marshall Builds Pollinator Habitat

- Human Exploration Development & Operations Team Highlights Newly Certified Members

- NASA Awards Occupational Health Services Contract

- New Bicycling Policies Now in Effect on Redstone Arsenal

- Winning Teams Design Systems to Convert Carbon Dioxide into Something Sweet

- This Week in NASA History: 1st Full-Thrust, Long-Duration F-1 Engine Test — May 26, 1962

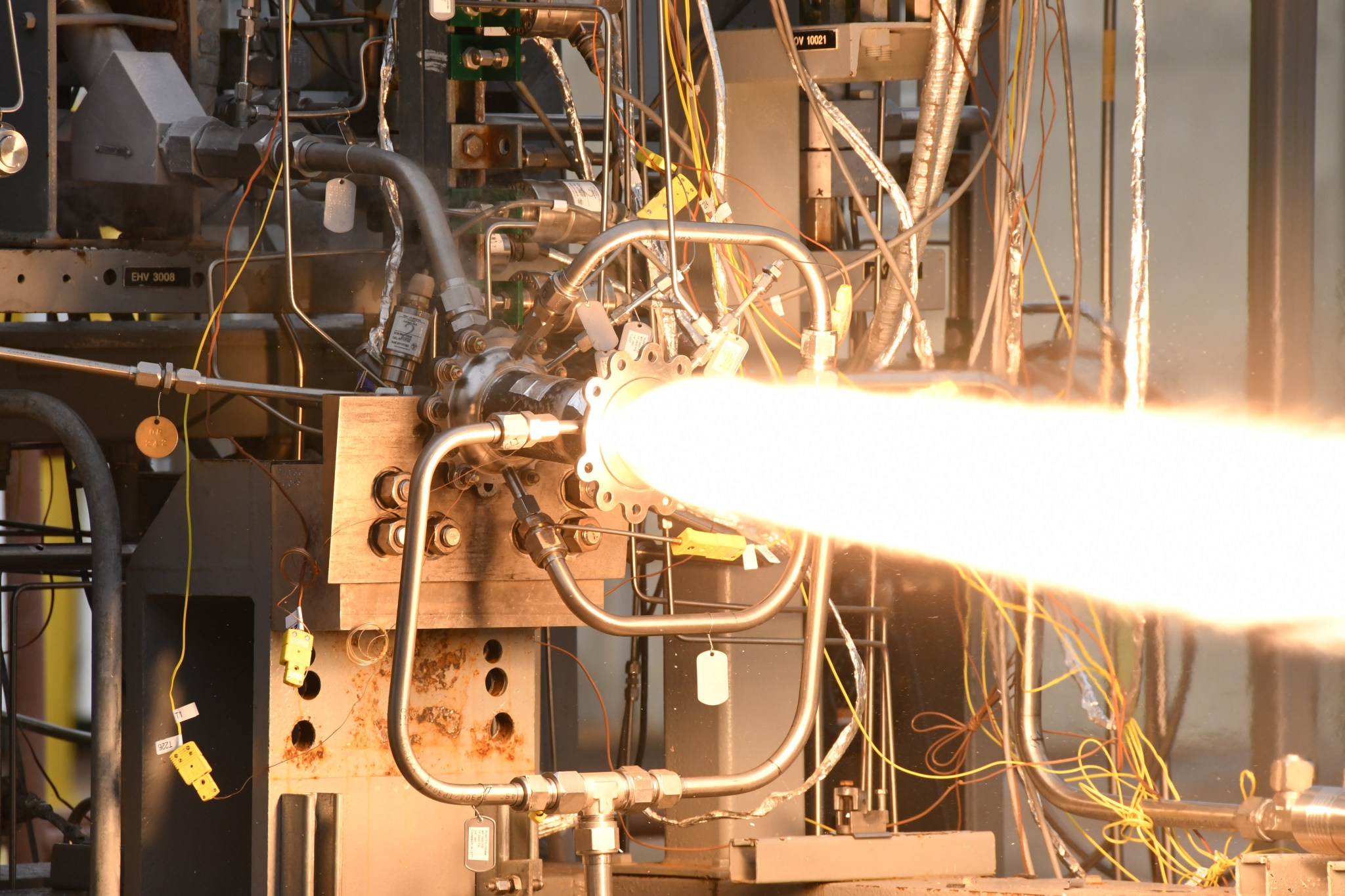

NASA and Virgin Orbit 3D Print, Test Rocket Combustion Chamber

By Rick Smith

At the heart of future rocket engines lifting off to the Moon or Mars could be a 3D-printed combustion chamber. NASA’s Marshall Space Flight Center was a key partner with Virgin Orbit in the development and testing of a uniquely manufactured rocket part.

Virgin Orbit air launches rockets carrying small satellites to space. The company enlisted support from NASA experts in combustion and additive manufacturing, or 3D printing, at Marshall, NASA’s Glenn Research Center and NASA’s Armstrong Flight Research Center. Their goal: Create a 3D-printed combustion chamber that combines multiple materials and takes advantage of cutting-edge manufacturing processes.

“Traditionally, it takes many months to manufacture, test and deliver a conventional combustion chamber. We can reduce that time considerably,” said NASA senior engineer Paul Gradl, who leads the joint project at Marshall. “Additive manufacturing is primed to augment and enhance traditional processes. With this partnership, we’re advancing that capability even further.”

The effort incorporates a proven NASA additive copper alloy, GRCop-84, which was developed at Marshall and Glenn in 2014 to successfully print and test the first full-scale, 3D-printed copper rocket engine part. To further strengthen the new combustion chamber, Virgin Orbit used its own hybrid additive/subtractive machine to apply a second bimetallic super-alloy jacket and precisely machine the part.

In late 2018 and early 2019, Marshall, in consultation with Glenn and Virgin Orbit engineers, tested the combustion chamber using high-pressure liquid oxygen/kerosene propellants. The test article delivered more than 2,000 pounds of thrust successfully in nearly two dozen, 60-second test firings.

“The combination of multiple optimized materials and additive manufacturing technologies we’ve employed represents a significant advancement from the compromises typically made in the production of 3D-printed combustion chambers,” said Kevin Zagorski, manager of propulsion advanced manufacturing at Virgin Orbit.

“Information gained from our partnership with NASA will be key in applying these technologies to further improve cost, performance and lead time of Virgin Orbit’s propulsion systems for the LauncherOne vehicle,” he added, referencing the company’s two-stage commercial orbital launch vehicle under development to launch smallsat payloads.

“NASA’s goal is to continue working with industry to advance technology and improve access to space by making launch technology safer, faster and more cost effective,” said Ed Hamlin, who manages the collaborative project agreement at Armstrong.

“Public-private partnerships like this one are instrumental to maturing critical technology and achieving the nation’s strategic goals in space for decades to come,” Hamlin said.

At Marshall, that means refining 3D printed combustion devices further by exploring even higher-performing copper alloys. In time, Gradl said, additive manufacturing solutions could support a variety of crewed or robotic deep space exploration missions, including lunar landers and advanced propulsion systems. Earth-based applications also may present themselves.

The collaborative partnership between NASA and Virgin Orbit was created via an Announcement of Collaborative Opportunity by NASA’s Space Technology Mission Directorate. The joint endeavor seeks to advance technology across the commercial sector and benefit future NASA missions, reducing launch costs and enabling more robust scientific exploration of the Moon and Mars.

Smith, an ASRC Federal/Analytical Services employee, supports the Office of Strategic Analysis & Communications.

What’s All the Buzz About? Marshall Builds Pollinator Habitat

By Will Bryan

Did you know that in addition to helping humans explore space, the team at NASA’s Marshall Space Flight Center also helps Earth-bound explorers of the insect and avian varieties? New to the south end of the walking trail behind Building 4315, the Marshall Wellness Center, is a home for pollinating bees, butterflies and hummingbirds.

“The habitat already hosts more than 150 plants that attract butterflies, hummingbirds and other pollinators,” Marshall Center Director Jody Singer said. “Supporting pollinators is not only fun, but it keeps a critical link in our biological system.”

Many of the plants in the habitat were grown from seeds planted by Marshall Green Team members Donna Leach and Lyndsey Winslette.

“Pollinators are necessary for three-quarters of Earth’s major food crops,” Leach said. “Without pollinators, our diets would be severely limited, and it would be harder to acquire the vitamins and minerals we need to stay healthy. We are helping ourselves when we do what we can to help pollinators.”

The habitat also serves as a waypoint for migrating monarch butterflies as they fly south for the winter and return north for the summer. It is the result of a 2014 Presidential Memorandum that instructed federal agencies to evaluate and use resources, facilities and land management to expand knowledge of pollinator health and to increase habitat quality and availability. The memorandum also established the Pollinator Health Task Force, which initiated specific actions for all federal agencies, including increasing pollinator-friendly vegetation and flower diversity.

The Green Team worked with the North Alabama Master Gardeners to develop the habitat, and with Scenic Hills Nursery in McMinnville, Tennessee, to acquire the right trees and shrubs. The variety of plants consists mostly of perennials that are drought resistant and require minimal upkeep.

“This habitat was created without any appropriated funds,” Leach said. “It still amazes me when I think about the teamwork that made it happen. I have people come by offering to help all of the time.”

Among planned additions are vines that will cover an arch to attract additional pollinators.

“Projects like these are proof that Marshall is focused on being a good steward of the environment while helping humanity explore beyond the ‘blue marble’ of Earth,” Singer said.

Additional sustainability efforts lead by the Green Team include single-stream recycling, building and operating of sustainable buildings, energy and water conservation and use of renewable energy.

To learn more about how you can be a part of Marshall’s efforts to help Earth while exploring space, visit the Sustainability page on ExplorNet.

Bryan, an ASRC Federal/Analytical Services employee, supports the Office of Strategic Analysis & Communications.

Human Exploration Development & Operations Team Highlights Newly Certified Members

Joseph Pelfrey, deputy manager of the Human Exploration Development & Operations Office at NASA’s Marshall Space Flight Center, addresses team members during a May 13 all hands meeting in Activities Building 4316. Office managers and branch chiefs briefed team members on organization goals and duties and introduced newly certified members of the payload operations team, which supports round-the-clock science and communications activities in the International Space Station Payload Operations Integration Center. (NASA/Fred Deaton)

Among the event participants are, from left, Nate Boclair, branch chief in HEDO’s Space System Operations Branch; and April McDaniels and Kelvin Nichols, ground data systems engineers in the Mission Systems Engineering & Operations Integration Branch. HEDO supports NASA’s Human Exploration and Operations Mission Directorate on numerous vital missions: partnering with industry to design launch vehicles for NASA’s Commercial Crew Program; leading propulsion development for the Orion crew capsule’s launch abort system; developing International Space Station hardware and managing the station’s round-the-clock science from Marshall’s Payload Operations Integration Center; and overseeing development of the U.S. habitation module and advanced life support systems for NASA’s lunar Gateway, a permanent human presence at the Moon to further scientific discovery and pave the way to Mars. (NASA/Fred Deaton)

NASA Awards Occupational Health Services Contract

Civil service employees and contractors at NASA’s Marshall Space Flight Center will have a new urgent-care clinic option on Redstone Arsenal beginning Oct. 1.

For Marshall team members that means making use of commercial, “doc-in-the-box” style services at the Marshall Medical Center, said Farley Davis, manager of Marshall’s Environmental Engineering and Occupational Health Office.

“If a civil servant or contractor at Marshall needs a physical, or if they’ve got the flu or have any other urgent-care requirement, they can walk in and be seen promptly using their own medical insurance,” he said.

InoMedic Health Applications of Hampton, Virginia, was awarded the occupational health services contract at Marshall in May. The performance-based contract covers occupational medicine, industrial hygiene, health physics and respiratory protection services. The contract also offers Occupational Safety and Health Administration, and NASA-specific work-related physical exams, health maintenance exams, non-occupational urgent care, a flu shot clinic and other medical services using private medical insurance or other methods of payment.

InoMedic’s contract includes a one-year base period followed by four one-year options which may be exercised at NASA’s discretion.

New Bicycling Policies Now in Effect on Redstone Arsenal

By Rick Smith

Amid new construction around Redstone Arsenal access points, increased traffic and a daily influx of more than 40,000 workers, officials have announced new safety policies to protect a vulnerable subset of the onsite workforce: bicyclists.

“Whether biking for sport, exercise or to save on fuel costs during their commute to work, bicyclists can be all seen across Redstone as summer nears”, said Rick Burt, director of Marshall’s Safety & Mission Assurance Directorate. “Marshall Space Flight Center is joining the rest of Team Redstone to help ensure they, like everyone on Redstone roads, exercise caution and remain safe as they cross the arsenal,” he said.

Motorists and cyclists are encouraged to familiarize themselves with the updated Redstone Arsenal Bicycle Traffic/Safety Policy 190-5. Key policy updates include:

- Cyclists are not permitted to enter Redstone Arsenal through Gate 9 weekdays between 5:30 a.m. and 5 p.m., except on federal holidays. Rideout Road from Gate 9 to Martin Road, and Martin Road between Rideout and Patton roads, also are off-limits to cyclists between 6 a.m. and 5 p.m. Monday through Friday, except on federal holidays.

- Cycling is authorized in the on-post housing area.

- During hours of darkness or limited visibility, cyclists are required to wear high-visibility or reflective outer apparel and equip their bicycles with personal protective equipment, including head lamps and tail lamps — making them easier for drivers to see in fog, rain or darkness.

- Wearing headphones, earphones or other listening devices while bicycling is deemed a safety hazard and is prohibited anywhere on Redstone Arsenal.

- When a pedestrian path or bike trail — in navigable condition — is provided adjacent to a roadway, cyclists are required to use those pathways instead of the main roads. Cyclists must ensure it is safe to transition from pedestrian paths or trails onto a roadway. Cyclists also must yield to pedestrians at crossings or on sidewalks.

- Cyclists may ride together in groups, with no more than two riding abreast, and must always ride in the direction of traffic on approved roadways. Groups must be limited to a maximum of 10 cyclists and must maintain a minimum distance of 300 meters between groups.

- Competitive racing is forbidden on the arsenal except during sanctioned events approved by the Garrison commander.

Burt encouraged motorists and cyclists to be particularly vigilant during early morning and late afternoon hours, when peak traffic poses increased risks to all drivers and riders. But any trip across post — or anywhere on open roads — is a good time to stay alert, he added.

“Good situational awareness is the cornerstone of road safety day or night,” he said.

The bicycling policy was updated at the direction of Redstone Army Garrison Commander Col. Kelsey Smith, who assigned a committee of safety and law enforcement personnel, gate guards and cyclists to assess the existing policy and recommend revisions and updates. The committee met with approximately 100 cyclists last September for a town hall discussion. With their inputs and a final review by Team Redstone leadership, the final policy was drawn up and is now in full effect across the installation.

“What we’re trying to do is set forth a policy … that protects all of us, our cyclists and our motorists,” Smith told the Redstone Rocket in December.

Redstone officials have suggested the new enforcement policy is crucial with so much growth and change expected here in coming years. The workforce is projected to grow to nearly 50,000 workers by 2025.

Smith, an ASRC Federal/Analytical Services employees, supports the Office of Strategic Analysis & Communications.

Winning Teams Design Systems to Convert Carbon Dioxide into Something Sweet

As NASA prepares to land humans on the Moon in 2024, the agency is keeping a keen eye on technologies needed for Mars missions that follow. NASA’s prize competitions and challenges engage the public in fostering innovative ideas.

NASA awarded a total of $250,000 to five teams in the initial phase of the CO2 Conversion Challenge. The purpose of the challenge is to convert carbon dioxide into glucose in order to eventually create sugar-based fuel, food, medicines, adhesives and other products. While sugar-based biomaterials are created on Earth by plants, this is not practical for space missions because of limited resources such as energy, water and crew time. This capability would let future Martian explorers manufacture products using carbon dioxide in the Red Planet’s atmosphere.

For this phase of the competition, teams submitted system designs, provided information on how the conversion would occur and explained how the system would work in space. Submissions also provided fabrication and testing plans.

The top five teams, each of which will receive $50,000, are:

- Dioxide Materials of Boca Raton, Florida

- Lotus Separations of Princeton, New Jersey

- Peidong Yang Group of Berkeley, California

- RenewCO2 LLC of Jersey City, New Jersey

- The Air Company of Brooklyn, New York

“A solution to this challenge could provide sustainable infrastructure for human exploration missions,” said Monsi Roman, manager of Centennial Challenges, the NASA program that conducted the competition. “Designing a system that can make this transformation is a big step, and we are excited to see teams build out these concepts.”

NASA is currently examining the possibility of opening Phase 2 of the competition, which would require system construction and demonstration and carry a prize purse estimated at $750,000.

Centennial Challenges, part of the Prizes and Challenges portfolio in NASA’s Space Technology Mission Directorate, bridges the innovation gap between NASA and the nation by stimulating research and technology solutions inside and outside of the traditional aerospace community. The competitions offer incentive prizes to generate revolutionary solutions to problems of interest to NASA and the nation, and to enable exploration of the Moon, Mars and beyond. Centennial Challenges is managed at NASA’s Marshall Space Flight Center. For information about the CO2 Conversion Challenge, visit here.

This Week in NASA History: 1st Full-Thrust, Long-Duration F-1 Engine Test — May 26, 1962

This week in 1962, the first full-thrust, long-duration F-1 engine test was successfully conducted. The F-1 engine was developed by Rocketdyne under the direction of NASA’s Marshall Space Flight Center and was propelled by a mixture of RP-1, a type of kerosene, and liquid oxygen. The engine was used in a cluster of five engines to propel the Saturn V rocket’s first stage, the S-IC stage. Each engine produced 1.5 million pounds of thrust. Here, the F-1 engine is test-fired at Test Stand 1-C at Edwards Air Force Base in California. Now through December 2022, NASA will mark the 50th anniversary of the Apollo Program that landed a dozen astronauts on the Moon between July 1969 and December 1972, and the first U.S. crewed mission — Apollo 8 — that circumnavigated the Moon in December 1968. The NASA History Program is responsible for generating, disseminating and preserving NASA’s remarkable history and providing a comprehensive understanding of the institutional, cultural, social, political, economic, technological and scientific aspects of NASA’s activities in aeronautics and space. For more pictures like this one and to connect to NASA’s history, visit the Marshall History Program’s webpage. (NASA)