Quick Facts

Year Built: 1940

Historic Eligibility: National Register Eligible

Important Tests: Aircraft Icing, Airfoils, X-1, F-100, F-111, F-14, F-15 C-5A, Saturn, Apollo, Space Shuttle

History

When the Langley Variable Density Tunnel (VDT) was put into operation in 1922, its unique capability to test in pressurized conditions up to 20 atmospheres provided unprecedented aerodynamic data and made Langley a world-class aerodynamic research laboratory.

This breakthrough facility could more accurately simulate flight conditions during tests of small-scale models than any other tunnel in the world. Langley quickly applied the tunnel to studies of the aerodynamic behavior of a variety of shapes including dirigibles, airplanes and airfoils. The airfoil research proved to be a particularly important contribution to the state of the art.

Unfortunately, while the VDT provided data in good agreement with flight test results for certain airfoil characteristics such as maximum lift, the levels of drag predicted by the tunnel testing were not in agreement with flight.

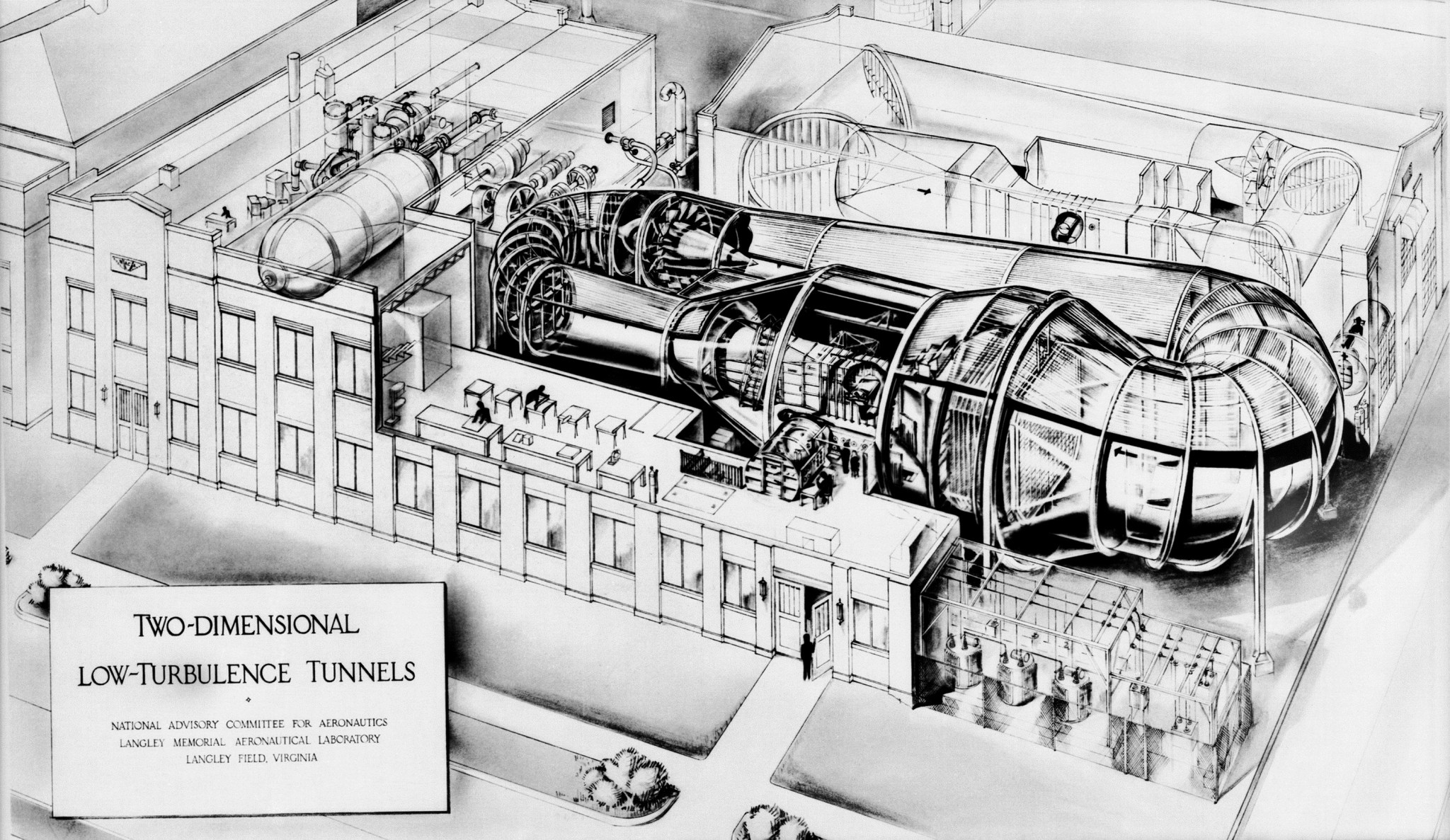

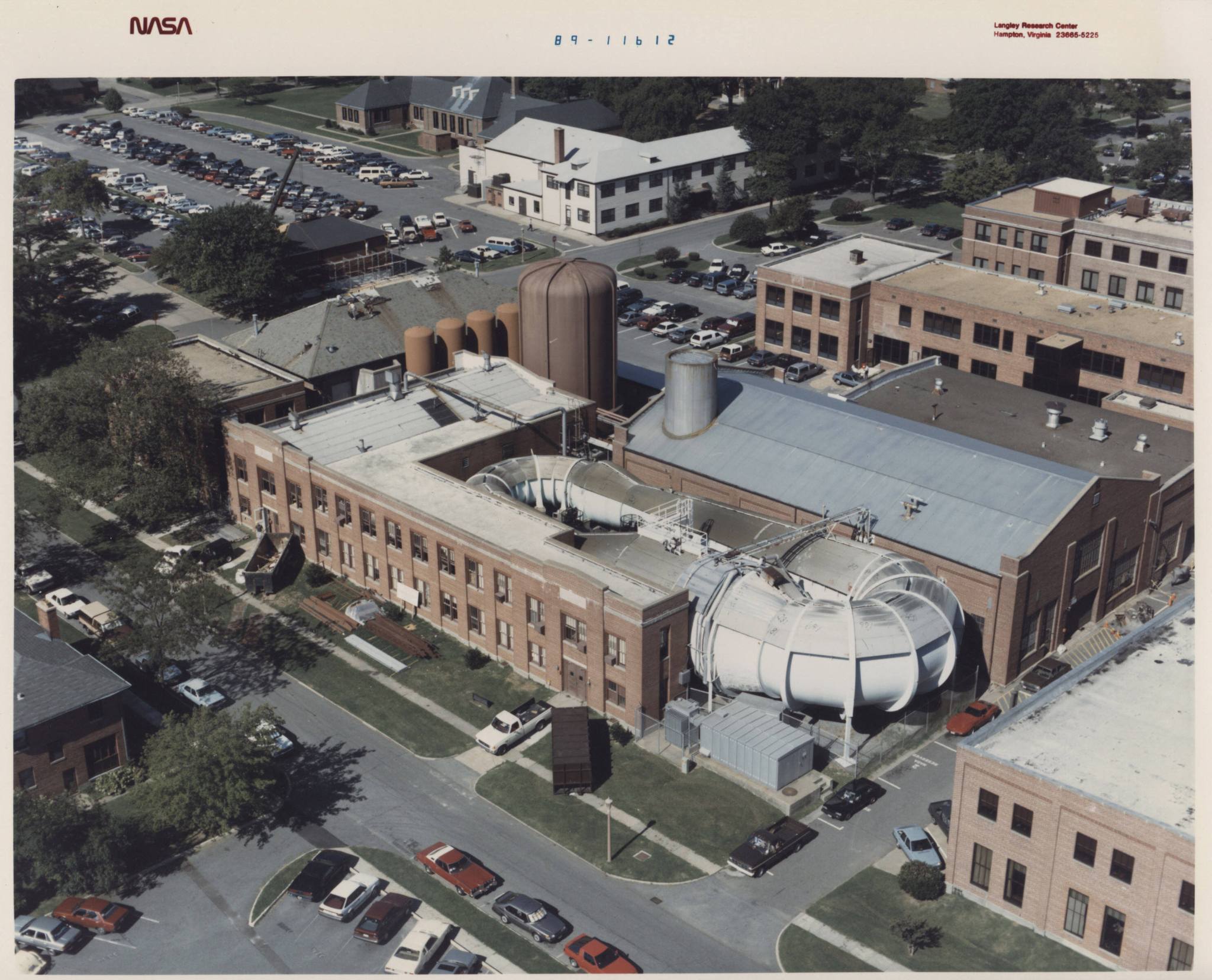

Authorization for the LTPT was granted in 1938 and the facility was constructed in Building 582A, becoming operational in May 1941. The tunnel had a test section 7.5 feet high by 3 feet wide and 7.5 feet in length. Its heavy steel plate structure could be pressurized to 10 atmospheres. The LTPT had a contraction ratio of 17.6-to-1, and 11 screen elements smoothed the airflow by breaking up eddies, providing unprecedented low levels of turbulence.

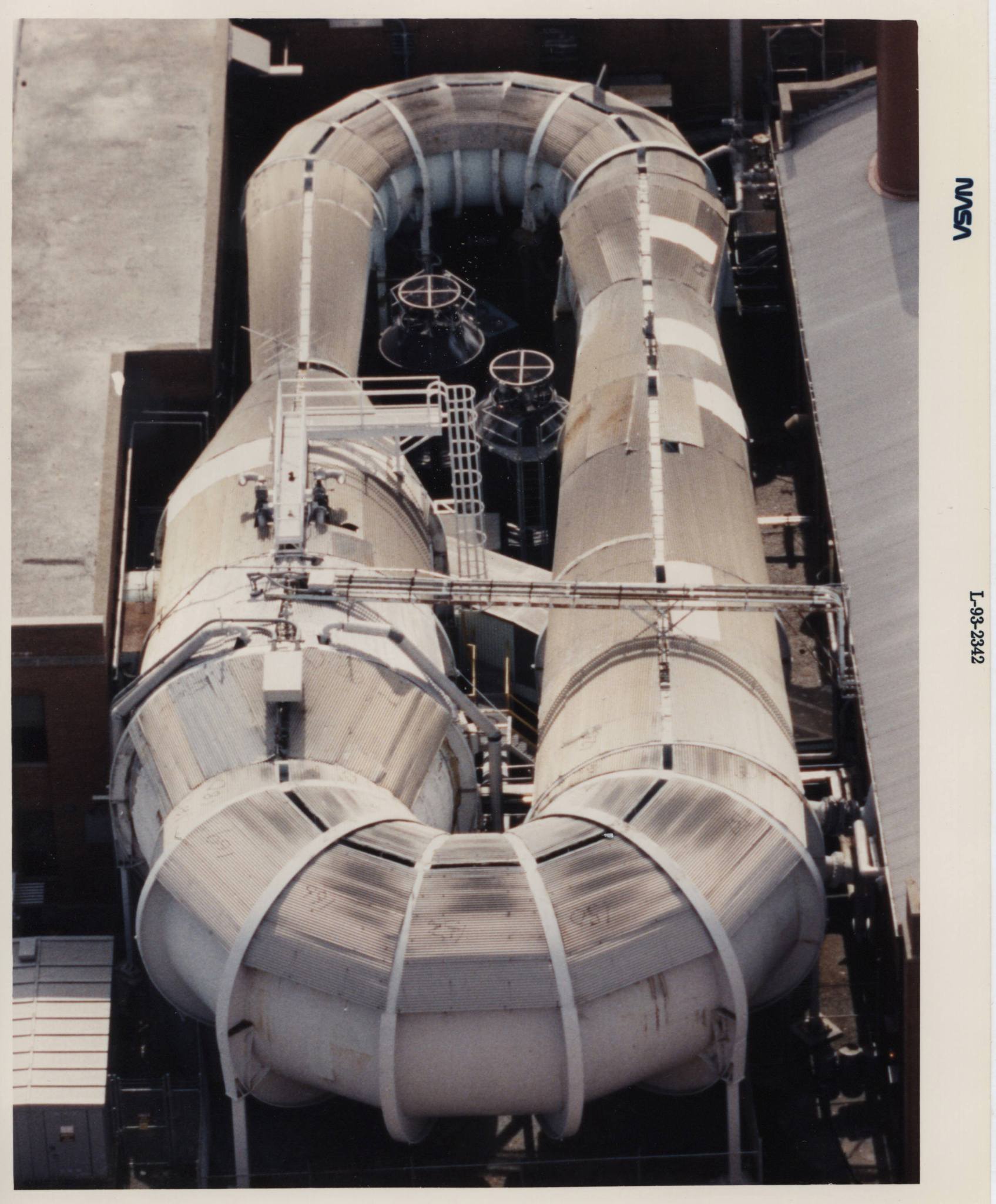

A 13-foot fan with 20 blades, driven by a 2,000-horsepower motor, provided test speeds up to about 380 mph (Mach 0.5). The flow circuit of the tunnel was built with curved sections rather than conventional 90-degree turns to minimize structural stress concentrations at the high air pressures used. Large splitter vanes were also used for structural reasons rather than flow control. Another unique feature of the tunnel was a metal sunshade over the top of the shell to reduce differences in temperatures between the upper and lower parts of the airstream due to solar heating. Differential heating of the airstream had been found to cause turbulence in preliminary testing of a smoke-flow tunnel. An airlock was provided to allow access to the test chamber and test section at pressures greater than atmospheric.

An interesting sidebar to the operation of the tunnel is the NACA Medical Recompression Chamber. The test crew working in this tunnel, as well as a few others, were subjected to high pressures during operations and had to go through a depressurization process.

During the war years, technicians wore diving bell suits while the tunnel was at alternate pressures. Before the high-pressure air connection from the West Side, it would take days to depressurize. Instead of waiting several days to do a model configuration change, a person would go through the air lock and into the pressurized test section to work on the model. Even data acquisition was by observation of gages and manometers while inside the pressure vessel. After the work was completed, the person would go through the air lock again and go to a decompression chamber.

The political and economic atmosphere during construction of the tunnel is apparent in the choice of some of the construction materials. Several parts from P-38 aircraft were utilized as components in the facility. One example is the use of P-38 propellers as fan blades. Originally, the NACA attempted to power the LTPT with unmodified P-38 propeller blades, but the original blades could not absorb the power of the drive system and added too much turbulence to the airflow. This turbulence was attributed to the rounded tips of the P-38, so the blades were modified by cutting the tips off. The solution was successful, and the modified blades continued to serve the tunnel until it was closed. The blades were removed for salvage as historic artifacts.

At the time of its introduction, the LTPT had the lowest turbulence levels of any wind tunnel in the world. Initially, test programs in the new facility focused on further development of low-drag airfoils (NACA 6-series airfoils) that were incorporated into many U.S. military aircraft during World War II (the first laminar-flow airfoil that was used by the P-51 Mustang had been based on earlier data from the LTT). Coupled with extensive results from other facilities including the VDT and LTT, data from the LTPT was cataloged by Abbott and Von Doenhoff in a publication which became the “bible” of airfoil information for many generations in the aeronautics community.

The LTPT was briefly converted for use with Freon in 1948, and in 1953 was modified with slotted walls to permit transonic testing, but neither of the modifications proved to be successful. After 1955, the LTPT served as a pressure vessel for the Langley 26-inch Transonic Blowdown Tunnel (TBT) located in nearby Building 583 (the previous site of the LTT). The TBT had been put into operation in 1950. The LTPT continued to be used as a pressure reservoir until the mid 1960s.

In the 1970s, Richard Whitcomb’s highly successful research on transonic supercritical airfoils and wings had stimulated the development of airfoils for low- and medium-speed vehicles such as business jets and general aviation aircraft. As part of a major Langley program on these topics, the LTPT was reactivated in the early 1970s when interest in the new airfoils peaked.

The LTPT underwent a major overhaul between December 1979 and March 1982. The two main objectives of the rehabilitation work were to restore and improve the flow quality required for laminar-flow research and to provide a two-dimensional model-support and force-balance for testing airfoils. During the overhaul activities, the original anti-turbulence screens and a cooling coil used to remove the heat put into the airstream during operations were replaced. In addition to the model support and balance modifications, a sidewall boundary-layer control system was added, as well as a remote-controlled survey apparatus and new data acquisition system.

After the modifications were completed, turbulence measurements made in the test section were about the same as measurements made after initial operations began in 1941.

Research applications in the LTPT included extensive contributions of new airfoil designs, more efficient high-lift flap systems, the first experiments with active laminar-flow-control concepts, and basic studies of flow phenomena at high Reynolds numbers.

Aerodynamic studies of specific aerospace vehicles contributed to the development of the X-1, F-100, F-111, F-14, F-15 and C-5A aircraft, as well as the Saturn, Apollo, and Space Shuttle spacecraft. Late research had focused on problems of efficiently integrating engines into airframes for better performance of commercial and military aircraft.

In 2006, the drive motor of the LTPT burned, resulting in termination of operations. With no funding to refurbish the tunnel, the decision was made to deactivate it. The LTPT Complex was demolished in 2014.

The NASA Technical Reports Server contains reports on additional examples of work done in the LTPT, including examples such as:

- Summary of Airfoil Data – NASA Technical Reports Server (NTRS)

- Drag and Cooling with Various Forms of Cowling for a “Whirlwind” Radial Air-Cooled Engine I – NASA Technical Reports Server (NTRS)

- The Langley Two-dimensional Low-turbulence Pressure Tunnel – NASA Technical Reports Server (NTRS)

Related Materials

1978 Floorplan

Langley Memorial Aeronautical Laboratory Description