Back to the Future: Active Aeroelastic Wing Flight Research

NASA’s Armstrong Flight Research Center in Edwards, California, formerly Dryden, in cooperation with the U.S. Air Force Research Laboratory (AFRL) and Boeing Phantom Works, researched a high-tech adaptation of the Wright Brothers rudimentary “wing-warping” approach to aircraft flight control in the Active Aeroelastic Wing (AAW), also known as X-53, flight research project. The focus of AAW research was on developing and validating the concept of aircraft roll control by twisting a flexible wing on a full-size aircraft. The test aircraft chosen for the AAW research is a modified F/A-18A obtained from the U.S. Navy in 1999.

The aerodynamic forces acting on the F/A-18s traditional aircraft control surfaces, such as ailerons and leading-edge flaps, were used to twist a more-flexible wing to provide aircraft roll maneuvering control.

Historical Background

When Orville Wright first took to the air on Dec. 17, 1903, he didn’t have ailerons or flaps to control his airplane. Instead, the Wright brothers had chosen to twist or “warp” the wingtips of their craft to control its rolling or banking motion. Rather than using one of the craft’s two control sticks to make the wingtips twist, they had devised a “saddle” in which the pilot lay. Cables connected the saddle to the tips of both wings. By moving his hips from side-to-side, the pilot warped the wingtips either up or down, providing the necessary control for the Wright Flyer to make turns.

Status

Comparison drawing of conventional and active aerolastic wings. Begun in 1996, the AAW flight research project was completed in the spring of 2005. After completion of detailed design and wing modifications required for the program in the late 1990s, the test aircraft was extensively instrumented and reassembly was completed by early 2001. Over the course of the year, the AAW test aircraft was subjected to extensive structural loads, wing stiffness and vibration tests, installation of the initial control software into the aircraft’s research flight control computer, systems checkout, and flight simulation activity.

These flights were used to measure the forces available from each surface to twist the wing and control the aircraft. That was followed by a year-long period of data analysis and control software redesign to optimize the performance of the flexible wing. The final phase of flight tests to evaluate the AAW control laws and evaluate the handling and performance qualities available from the flexible wing concept began in late 2004 and concluded in March 2005. About 25 research missions were flown in the second phase, covering 18 test points ranging from speeds of Mach .85 to Mach 1.3 and altitudes ranging from 5,000 to 25,000 feet. Several additional flights were flown to re-evaluate several test points with different gains in the control laws and to evaluate the ability of the system to alleviate structural loads on the wing before AAW flights concluded. Analysis of flight data and preparation of technical reports is expected to continue for some time into the future as staff time is available.

Goals and Results

The AAW project’s goal was to demonstrate improved aircraft roll control through aerodynamically induced wing twist on a full-scale high-performance aircraft at transonic and supersonic speeds. Data was obtained to develop design information for blending flexible wing structures with control law techniques to obtain the performance of current day aircraft with much lighter wing structures. The flight data included aerodynamic, structural, and flight control characteristics that demonstrated and measured the AAW concept in a comparatively low-cost, effective manner. The data also will provide benchmark design criteria as guidance for future aircraft designs.

Over the course of the second phase of flight tests, roll rates adequate for lateral control, or within 15 to 20 percent of that obtained by a production F/A-18, were obtained by use of active control of wing flexibility alone, without use of the differential rolling horizontal tail used by standard F/A-18s at transonic and supersonic speeds. Roll rates at 15,000 feet were highest at Mach .85 and Mach 1.2, and lowest at Mach .95, similar to a conventional F/A-18.

Aircraft Modifications

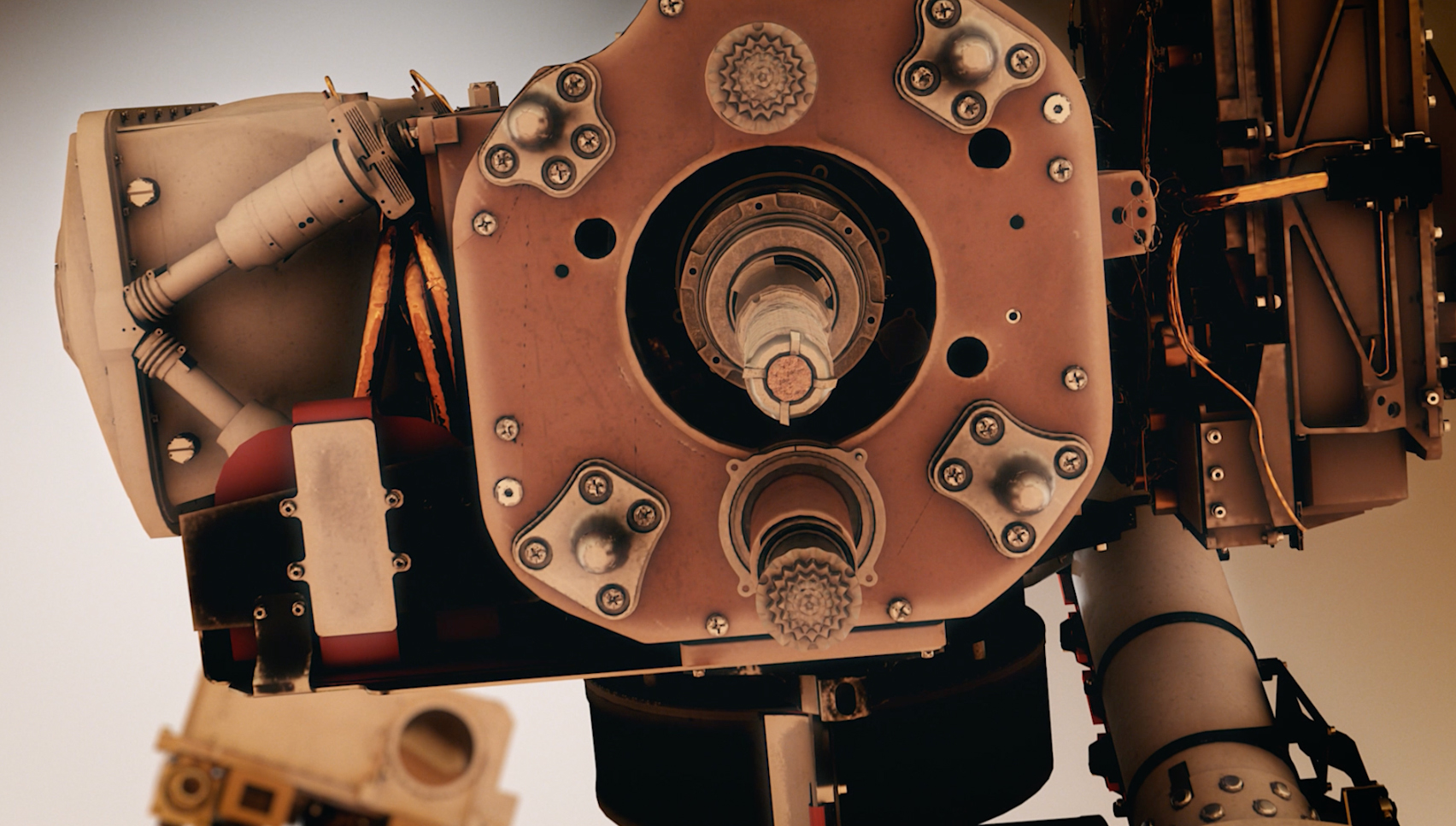

The wings from NASA’s now-retired F/A-18 #840, formerly used in the High-Alpha Research Vehicle (HARV) project, were modified for the AAW flight research project and installed on the AAW test aircraft. Several of the existing wing skin panels along the wing box section of the wing just ahead of the trailing-edge flaps and ailerons were replaced with thinner, more flexible skin panels and structure, similar to the prototype F/A-18 wings.

Original F-18 wing panels were comparatively light and flexible. During early F-18 flight tests, however, the wings were observed to be too flexible at high speeds for the ailerons to provide the specified roll rates. This was because the high aerodynamic forces against a deflected aileron would cause the wing to deflect in the opposite direction.

In addition, the F/A-18’s leading-edge flap was divided into separate inboard and outboard segments, and additional actuators were added to operate the outboard leading-edge flaps separately from the inboard leading-edge surfaces. By using the outboard leading-edge flap and the aileron to twist the wing, the aerodynamic force on the twisted wing provided the roll forces desired. With AAW control technology, a flexible wing will now have a positive control benefit rather than a negative one.

In addition to the wing modifications, a new research flight control computer was developed for the AAW test aircraft, and extensive research instrumentation, including more than 350 strain gauges, was installed on each wing.

Funding

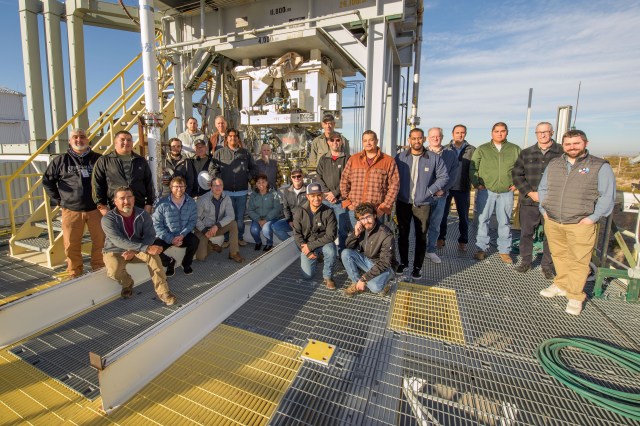

The AAW project received its funding from NASA’s Aeronautics Research Mission Directorate, as well as from the U.S. Air Force Research Laboratory. The Boeing Company’s Phantom Works division in St. Louis, MO, performed the AAW wing modifications, installed portions of the wing instrumentation and assisted in software development under contract with the Air Force Research Laboratory and NASA. Lockheed Martin and BAE Systems developed the AAW research flight control computer, while Moog developed the actuators for the outboard leading-edge flaps. The total budget for the entire AAW project was approximately $45 million, including about $29 million in direct monetary outlay and about $16 million for in-kind support, spread over eight years.

Technology Commercialization

With the successful demonstration of actively controlled “wing warping” techniques for aircraft roll control at transonic speeds in the Active Aeroelastic Wing project, engineers will now have more freedom in designing more efficient, thinner, higher aspect-ratio wings for future high-performance aircraft while reducing the structural weight of the wings by 10 to 20 per cent. This will allow increased fuel efficiency or payload capability, along with potentially reduced radar signature. The technology also has application to a variety of other future aircraft, such as high-altitude, long-endurance unmanned aircraft, transports, and airliners.