Artemis will take humans from Point A to Point B: from Earth, to a permanent presence at the Moon. And from there, eventually Point C: Mars.

But the question is: How do we get from Point A, to B, to C?

“Data tells you where the gaps are: there are capabilities we need and there are capabilities we have, and the gap is the difference in between,” explains Dr. Kathleen Boggs, the Systems and Technology Demonstration Manager in the International Space Station Division of the Human Exploration and Operations Mission Directorate (HEOMD) at NASA Headquarters in Washington. “And then we ask, ‘where do we need to do a technology demonstration or an operational test to prove that we’ve closed that gap?’”

Alongside colleague Kandyce Goodliff, an aerospace engineer at NASA’s Langley Research Center in with the Space Mission Analysis Branch, Boggs has been spearheading the effort to develop plans to demonstrate capabilities critical for long-duration deep space missions envisioned as part of NASA’s Moon to Mars plans.

In regard to working with Goodliff, as well as Robyn Gatens, International Space Station Division and System Capability Leader for Environmental Control and Life Support Systems at NASA Headquarters, Boggs says, “I’ve had some really great relationships with some of the women at NASA. Our collaboration is one of the best I’ve had in my career.”

The project started in early 2017, when she was asked to provide an update for HEOMD about how the agency can use the space station and the Gateway, a lunar outpost that will provide access to more of the lunar surface than ever before, to test the technologies needed to land humans on the Moon and onto Mars.

Dr. Boggs and Goodliff contacted the agency’s best technical experts in various system areas, and started to collect the data. Once the plans to return to the Moon were recently accelerated for a target of 2024, the team revamped the information to encompass the new timeline.

The knowledge that we gain during each step of the process throughout the Artemis program builds increasingly on the previous steps. Much of what we know about habitation comes from knowledge gained on board the space station. Once the Gateway is built, it will continue to operate during times when astronauts are not present, and we will be able to learn more about spacecraft that operate without a crew on board. In addition to gaining experience using Gateway, testing systems on the lunar surface will also prepare us for systems for the Martian surface.

In order to consolidate all of the data from different organizations throughout the agency, Dr. Boggs often ensures that technical experts are communicating effectively with each other.

“Everyone breaks the problem down a little differently,” Dr. Boggs says. “We are getting better at developing a shared language between each other and learning how to ask the right questions.”

Once different areas of expertise begin talking, they sometimes realize that they were working on similar problems. Both Safety and Mission Assurance (SMA) and Life Support Systems realized that they both needed a system in place for microbe detection — albeit completely different reasons. SMA aims to ensure that future planets we land on are not contaminated by human microbes, while Life Support Systems aims to keep cabin air and water clean. Both decided to work together on requirements for a microbe detection system.

“In some cases, different teams were completely aligned,” says Dr. Boggs. “In other cases, there were opportunities for collaboration.”

Overall, Dr. Boggs is confident that we have developed a lot of the technology needed for a sustained lunar presence — we just maybe haven’t applied it in certain ways.

“The large majority of challenges is in that developmental category. Take autonomous spacecraft: We know how to write those algorithms, but we maybe haven’t applied them yet in a human-rated vehicle, because the space station has people on the ground who do that,” says Dr. Boggs. “We still have time to test those things.”

In regard to the process of consolidating data, Dr. Boggs admits that data science was one of her strengths. “You’ve probably already surmised I’m a bit of a data dog,” she laughs. “I’ve probably been doing data science since before people thought data science was a thing.”

She’s probably right. Dr. Bogg’s interest in science began at a very early age, when she worked on her first science fair project in the 8th grade. Her parents, who were both high school chemistry teachers when they met, felt it was important that she use the scientific method with her project. While other students presented research projects, Dr. Boggs created and ran a science experiment to test which cooking oil was most effective to cook popcorn.

“I made a lot of popcorn. My poor brothers had to eat it all. I measured all sorts of things…volume popped and how many kernels left unpopped and how well did it taste,” recalls Dr. Bogg. By the end of the science fair, she had won numerous awards for her rigorous work.

“My dad never said ‘girls can’t do this,’” Dr. Boggs remembers. “He would always ask, ‘Hey! Do you want to do a project?’ and it would never fail. Next thing I know, I’m laying flooring with my dad.”

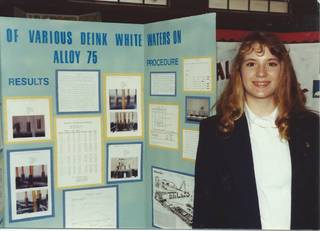

The flame for STEM was further ignited by a high school science teacher, who partnered with manufacturing laboratories in town to recruit students to work on real-world applications. Ms. Palmer recognized that Dr. Boggs had a keen interest in materials science, and sent her to a stainless steel foundry to find out why parts they manufactured for paper machines were corroding.

“It was the early 90s, so we were just starting to recycle paper,” Dr. Boggs explains. “Corrosive chemicals would be added to the mix to get the inks out of it…So I was simulating the chemical breakdowns in the laboratory and studying how these machines corrode.” For her work, Dr. Boggs earned first prize in the state-level science fair two years in a row — but more importantly, she was on track for her future career.

“It was all because of this teacher,” Dr. Boggs says. “I wouldn’t have known about material science if I hadn’t been exposed to it then.”

Prior to her graduate studies, Dr. Boggs worked in quality control for an iron foundry. “They would melt big buckets of iron in a huge furnace, and then they would pour it and it would be like a river,” recalls Dr. Boggs. Her eyes light up as she described how the magnesium pellets thrown into the river would make it spark.

Dr. Boggs laughs at the memory. “I still have my steel-toed shoes somewhere.”

Once she earned a Bachelor of Science in Materials Science and Engineering from Carnegie Mellon University, she began work on a Doctorate in Physics from Trinity College, Dublin, where her work focused on the development of ferromagnetic nanomaterials. “I loved making new alloys.”

Before joining NASA, Dr. Boggs completed a postdoctoral fellowship at the US Naval Research Laboratory and then served in several roles analyzing operations and technology issues for the Naval enterprise, with a focus on the application of simulation systems to train ground forces in complex combat operations.

Now that Dr. Boggs is at NASA, she compares her current work with her original love for materials science.

“Materials science is all about relationships — how you take atoms, combine them into molecules or compounds, and then process them to get your final material,” Dr. Boggs explains. “To me, it’s all the same. How do I take all of these different engineering disciplines and add it up to a plan to get us to Mars?”

Dr. Boggs’ message for people interested in working for NASA is this: “You don’t have to be a scientist to work in the space industry. We’re at a place right now where we need all career fields to achieve NASA missions. We need people who are communicators or artists, we need people who can do finance. If you love space but are not a scientist or engineer, we still have a place for you.”

By Thalia Patrinos