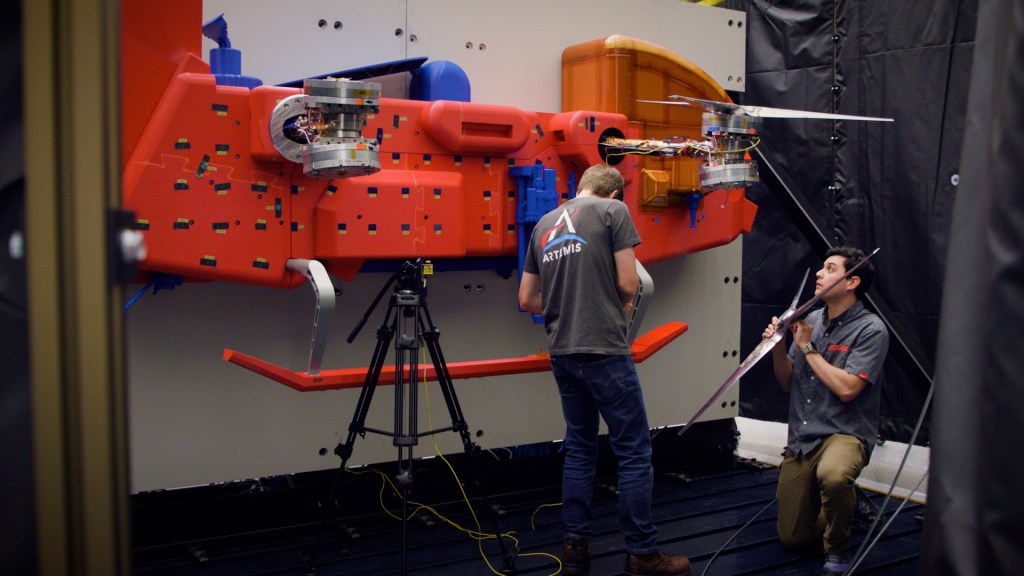

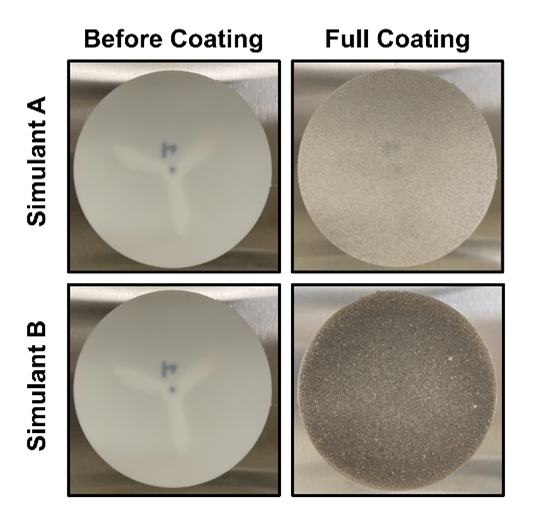

When astronauts live and work on the Moon during Artemis missions, the surface will be very different from Earth’s. Lunar dust is a very fine layer of regolith, or fragmented rock material, that is static and adheres to exposed surfaces. NASA engineers at Johnson Space Center in Houston, including a team of early-career engineers, have developed a device, called the Lunar Dust Distributor, that can evenly coat simulated lunar dust onto hardware for teams to study designs and develop mitigation strategies to keep lunar dust at bay.

Lunar soil is made up of different components, with the finest grains being referred to as lunar dust. This dust has been created over billions of years from the onslaught of meteors and atomic particles crashing onto the surface of the Moon. Once lunar dust sticks to a surface, it can impair hardware, create problematic temperature variations, and degrade solar array efficiency. As NASA teams and industry work to create the tools, hardware, suits, habitats, and systems that will make the Moon habitable during surface missions, astronauts must be able to thrive in an environment covered with lunar dust.

What makes lunar dust difficult to study on Earth is that the terrestrial environment causes the dust to behave in different ways than it would on the Moon. Replicating the conditions found on the Moon including partial gravity and the even dust coating of large surfaces to effectively measure the effects of dust is particularly difficult. For teams to understand how dust may affect a piece of hardware, they will now be able to utilize the Lunar Dust Distributor to evenly coat hardware with dust of varying types and consistencies, to mimic how it would be coated on the Moon.

“This device will allow engineers to evaluate materials, design sensors capable of detecting dust contamination, and define methods, technologies, and processes that will allow humanity to thrive safely on the Moon,” says Erica Worthy, deputy of the Thermal Design Branch within the Structural Engineering Division at Johnson. “The fact that this project is being led by early-career engineers is even more exciting and shows how our workforce is motivated to actively meet the challenges of modern spaceflight.”

Following this project, the team will study changes in how heat transfers when lunar dust is present and the optical properties of materials with simulated lunar dust accumulation. Engineers from Johnson’s structural engineering division, including the early-career team, will seek to apply this knowledge for future Artemis missions.

Learn more about how NASA innovates for the benefit of humanity at: