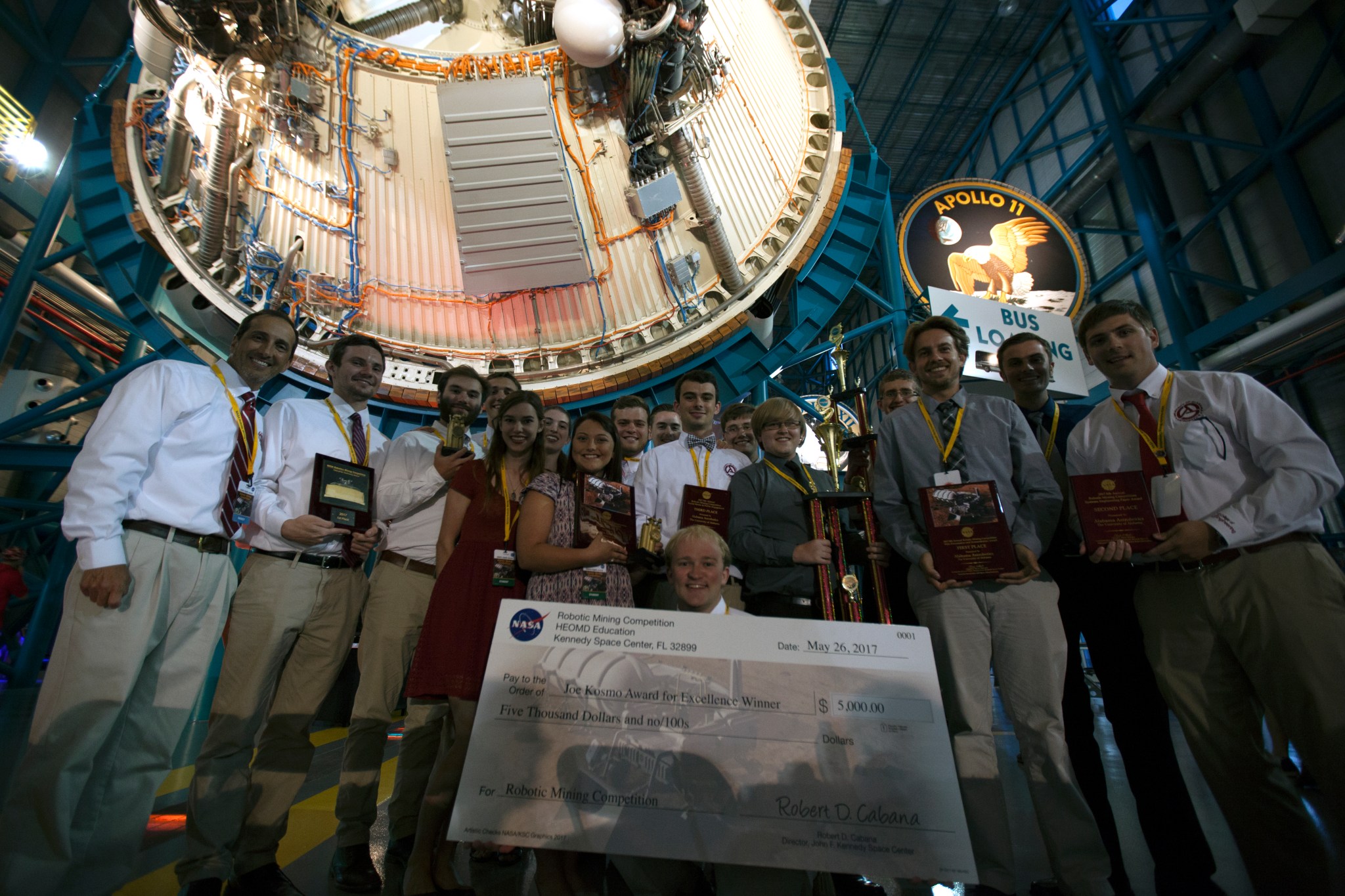

Team Astrobotics from the University of Alabama received the top award, the Joe Kosmo Award for Excellence, at NASA’s Eighth Annual Robotic Mining Competition (RMC) awards ceremony May 26. The mining competition was held May 22-26 at the Kennedy Space Center Visitor Complex in Florida.

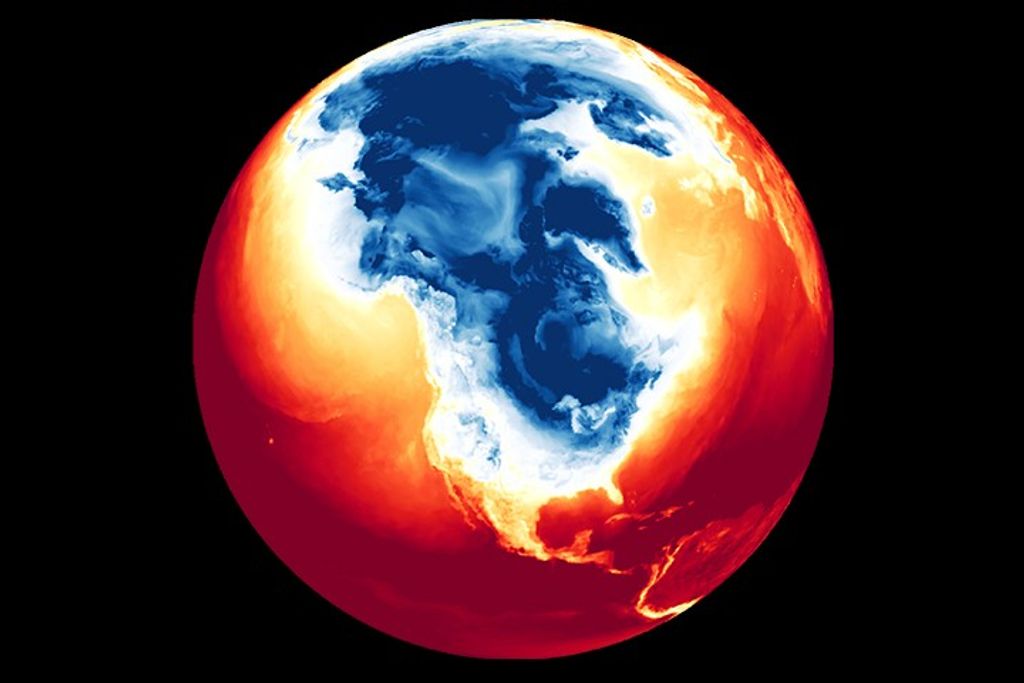

The RMC is a NASA Human Exploration and Operations Mission Directorate project designed to encourage students in science, technology, engineering and math, known as STEM fields. The project provides a competitive environment to foster innovative ideas and solutions that could be used on NASA’s Journey to Mars.

Joe Kosmo, for whom the top award is named, is a retired NASA engineer with a keen interest and background in robot mining. He served several years as an advisor and judge during the competition.

“It’s been a wonderful experience. It’s humbling,” said Joseph Kabalin, graduating senior and Team Astrobotics lead. “We know how hard it is to get here for the competition. Our hats are off to all of the other teams.”

Team Astrobotics took first place in the Robotic On-Site Mining category, collecting a total of 336 kilograms of regolith during two mining runs. Their robot accomplished all of the mining autonomously, without communication from the team or use of a remote-controlled device in the control room.

“Before we go to Mars, we need to learn about it. We need to pre-stage supplies and equipment,” said Kennedy Center Director Bob Cabana. “There’s a lot we can accomplish using robots.”

The weeklong competition featured teams of undergraduate and graduate students from 45 colleges and universities across the United States. They traveled with their robot miners to Kennedy from schools in Alaska, Hawaii, Utah, Vermont, the Commonwealth of Puerto Rico, and the Florida cities of Melbourne and Orlando.

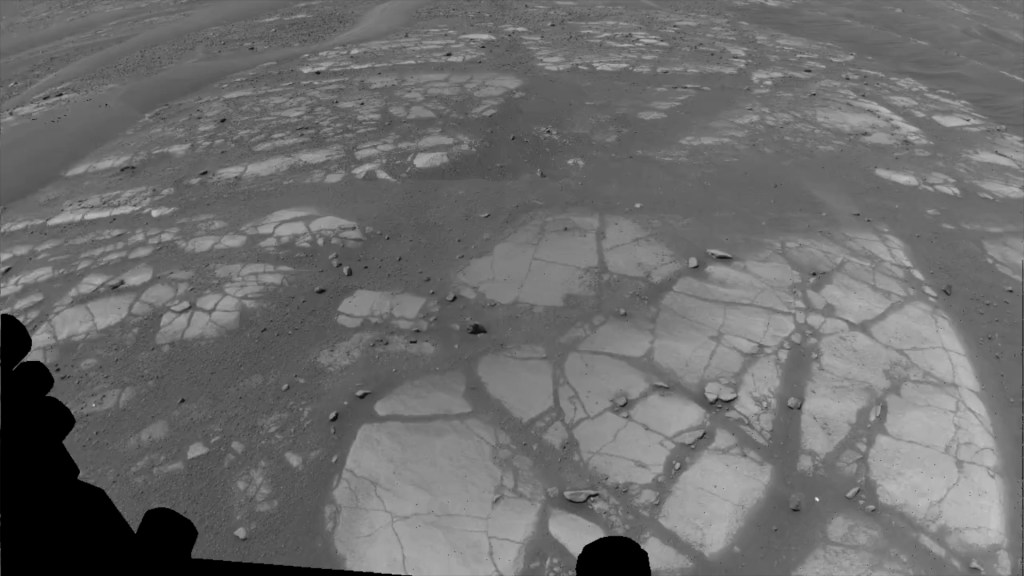

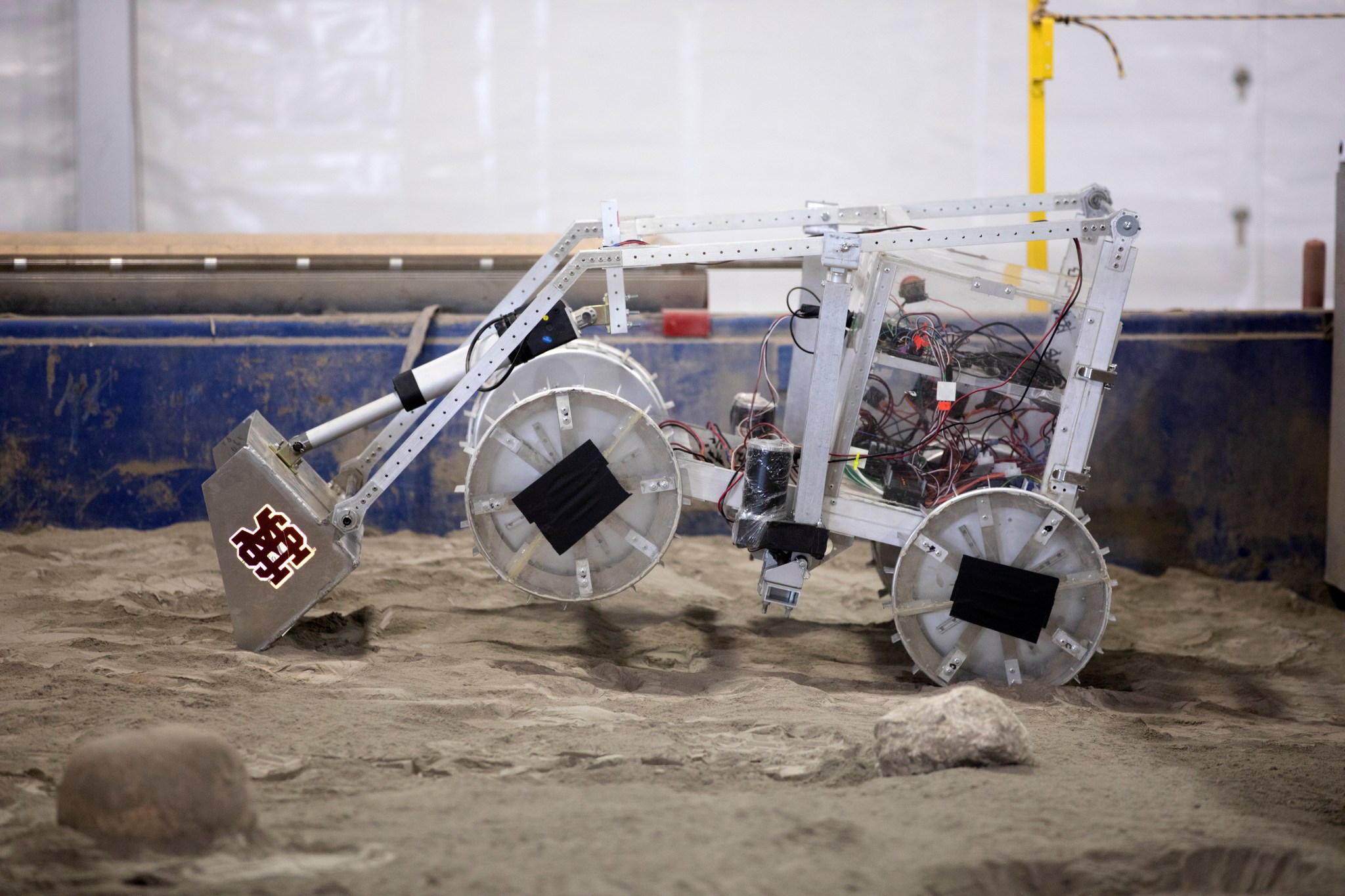

Before traveling to the space coast, each team spent up to a year planning, designing, building and testing robots that can traverse in a mining arena filled with simulated Martian terrain or regolith, called BP-1, excavate the regolith and deposit it into a collector bin within 10 minutes.

Each team’s robot had two opportunities to traverse and excavate simulated Martian dirt, seeking to move and collect the most regolith, within a specified amount of time. Teams had to mine a combined total of at least 10 kilograms to qualify for the mining portion of the competition.

From control rooms near the mining area, teams monitored their autonomous robots or commanded their robots to perform the intricate movements required to collect the regolith and maneuver through the rocky terrain to the collector bin and complete the task. Hidden below the surface of the regolith was a layer of small rocks, representing ice water below the simulated regolith surface. This change brought the competition more in line with the requirements of future off-world mining missions.

Other RMC competition categories included submission of a systems engineering paper, and a slide presentation and robot demonstration. Also factored in was how well each team reached out to its community through social media and engagement with area schools and the general public.

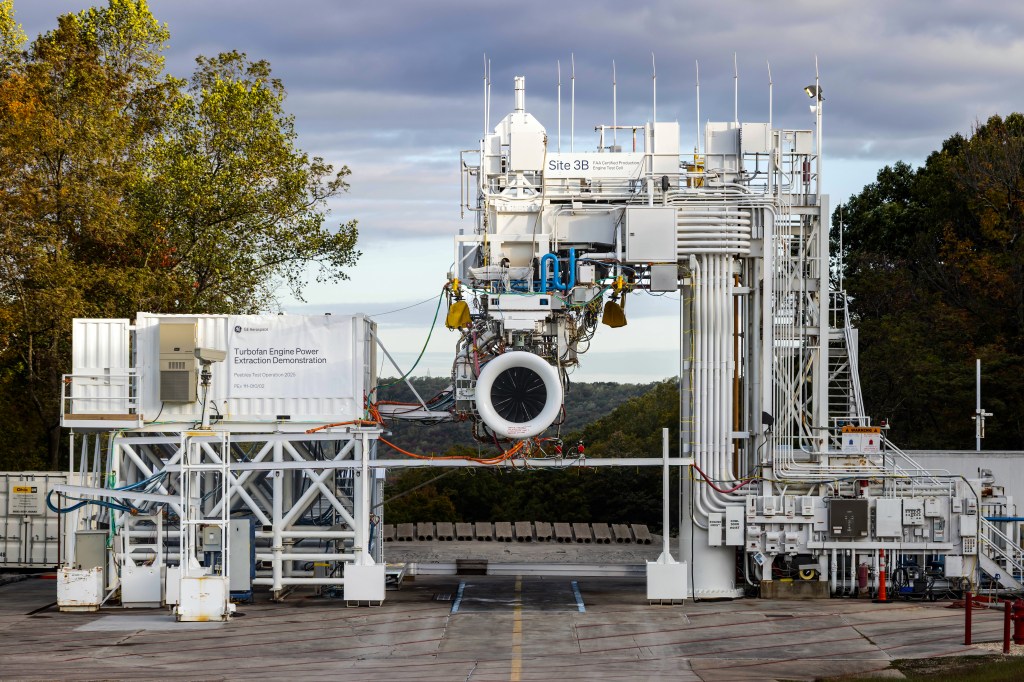

Rob Mueller, lead judge for the mining competition, is a NASA senior technologist for Advanced Projects Development in the Exploration Research and Technology Directorate at Kennedy.

“Once again, the university teams showed a remarkable variety of designs for Mars mining robot prototypes,” Mueller said. “This year, many machines showed increasing sophistication of robotic perception sensors and autonomy software, reflecting the general advancement of available technologies with reduced costs.”

Several teams tried out new innovations this year, ranging from 3-D printed parts and twin robotic miners, to making adjustments or adding parts in real time to solve problems.

First-time participant was the Scarlet Space Hawks team from the Illinois Institute of Technology, Armour College of Engineering. They designed and built their robot, named “Lofty,” in just three months. Their efforts paid off with 72 kilograms of mined regolith and a third-place award in the Robotic On-Site Mining category.

“It is mind-blowing, seeing all of the cool robots here,” said Shawn Zachariah, a junior studying electrical engineering. “We wanted to go with a simple design. We plan to return for the 2018 competition.”

Also a first-timer was Trickfire Robotics, from the University of Washington Bothell. They had some issues with their robot “Daybreak” tipping in the mining arena during practice runs.

“We added a third wheel in between the front and back wheels on both sides of our robot to help with stability, and it worked,” said team member Brian Gonzalez-Montoya.

In their eighth year of competition, the team from University of Nebraska-Lincoln improved on previous designs and used 3-D printed wheels, eight inches in diameter and five inches thick. The auger, or digger, also printed from composite material, was used to mine deep below the surface and bring a section of the regolith to the surface to scoop it up. Making more parts from 3-D printed composites helped reduce the robot’s weight.

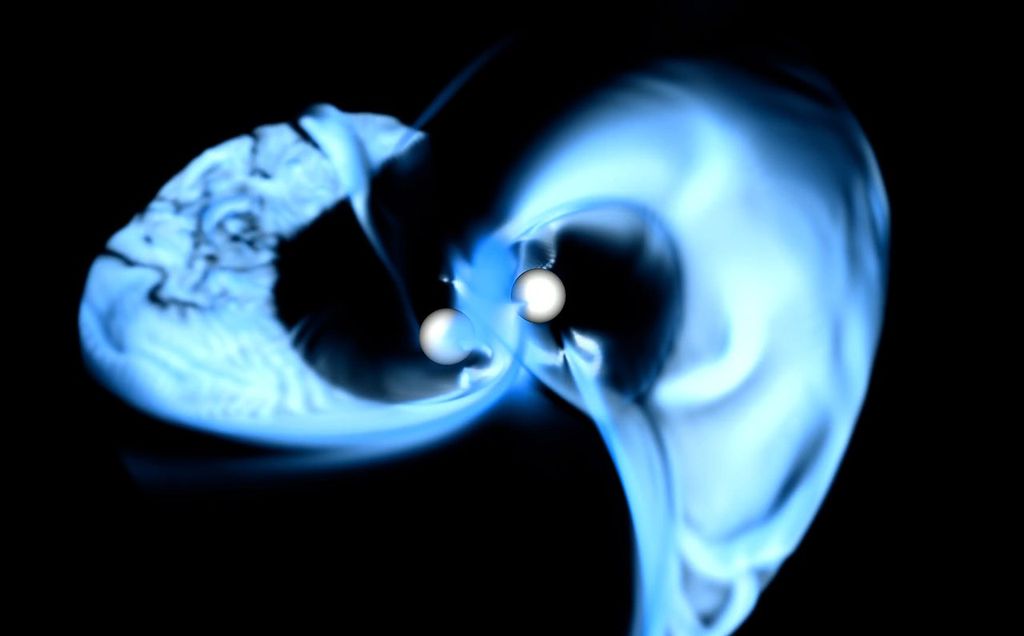

Also in its eighth year at RMC, the Cyclone Space Mining Club from Iowa State University spent a full year building two robots, “Space Ketchup” and “Space Mustard.” According to Jakob Hartl, a graduating senior in aerospace engineering, the team focused on high efficiency and doubling the production capability of previous years. In the mining arena, one robot failed, but the second one continued to mine the regolith and deposit it in the collection bin.

Montana State University’s team took their design in a new direction. Their SCARAB robot’s tracks were designed to dig, much like an animal digs with its front paws, and send the regolith behind to its collector bin.

Mueller said the Robotic Mining Competition is important to NASA. Most of the resources available in space are contained in the regolith. In order to take advantage of these resources for in-situ resource utilization — living off the land — the regolith must first be excavated and then delivered to a processing plant to extract water, silicates and minerals.

“We are looking for ideas. We need small robots that can do big things,” said Pat Simpkins, director of Kennedy’s Engineering Directorate. “Robotics is hard, but robotics in space is doubly hard, whether it’s on the moon, Mars or another destination in space.”

For more information on the RMC, associated activities and social media, visit https://www.nasa.gov/nasarmc.

Winners List

Grand Prize: The Joe Kosmo Award for Excellence

Awarded to the team that scores the most points in all competition events.

Winner: The University of Alabama

On-Site Mining Award

Awarded to the team that passes robot and communication inspections, mines more than 10 kilograms of regolith, most efficient use in bandwidth, minimizes robot mass, reports energy consumed, has a dust tolerant design and performs dust-free operations, performs tele-robotic and or autonomously, and mines the most resources.

First Place: The University of Alabama

Second Place: University of Colorado at Boulder

Third Place: Illinois Institute of Technology

Systems Engineering Paper

Awarded to the teams that best discuss the systems engineering methods used to design and build their mining robot. The paper is peer reviewed by support and operations personnel from across NASA.

First Place: Case Western Reserve University

Second Place: The University of Alabama

Third Place: The University of Utah

Outreach Project Report

Awarded to the teams with the best educational outreach projects in their local community to engage students in STEM (Science, Technology, Engineering and Math). Outreach activities should capitalize on the excitement of NASA’s discoveries to spark student (K-12) interest and involvement in STEM.

First Place: The University of Alabama

Second Place: Iowa State University

Third Place: Embry-Riddle Aeronautical University

Slide Presentation and Demonstration

Awarded to the teams that best present their project at the competition in front of an audience, including NASA and private industry judges.

First Place: The University of Alabama

Second Place: Case Western Reserve University

Third Place: Virginia Tech

Social Media and Public Engagement

Awarded to the teams that use various social media platforms to engage the public in their participation with MC and engages with NASA and other robotic teams.

First Place: University of Central Florida

Second Place: Iowa State University

Third Place: The University of Alabama

Judges Innovation Award

Award to the team that demonstrates the most innovative design.

Winner: Embry-Riddle Aeronautical University

Efficient Use of Communications Power Award

Awarded to the team for using the lowest average data utilization bandwidth per regolith points earned in both the timed and NASA monitored portion of the competition. Teams must collect the minimum amount of regolith to qualify for this award.

Winner: The University of Alabama

The Regolith Mechanics Award

Awarded to the team with the best example of a real granular innovation that identified a specific regolith mechanics problem (like the way the soil flows around the grousers, or angle of repose too high in their dump bucket, etc.) and intentionally improved their design to deal with it. Courtesy of the Center for Lunar and Asteroid Surface Science (CLASS), part of NASA’s Solar System Exploration Research Virtual Institute (SSERVI) Network.

Winner: Worcester Polytechnic Institute

Honorable Mention: University of North Dakota

Caterpillar Award for Autonomy

Awarded to the teams with the most autonomous points averaged from both mining attempts, even if no regolith is deposited. In the event of a tie, the team that deposits the most regolith will win.

First Place: The University of Alabama

Second Place: University of Illinois at Chicago

Third Place: University of North Carolina at Charlotte