NASA’s X-57 “Maxwell,” the agency’s experimental all-electric aircraft, is working to provide industry and regulators with knowledge that will revolutionize sustainable aviation. Developing that knowledge involved more than a decade of close alignment between NASA and its private sector partners – and that started with support for a small business.

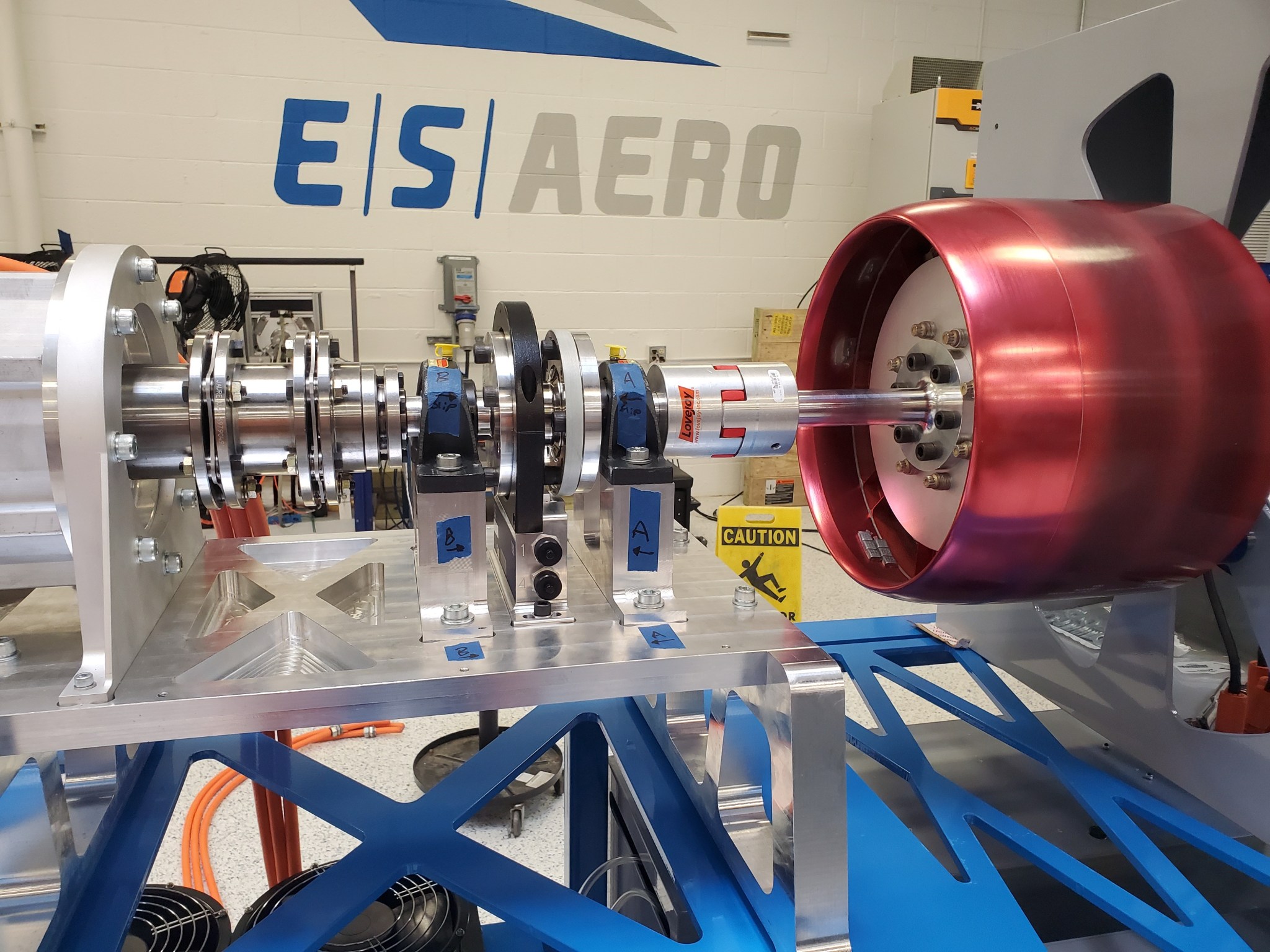

Creating this novel aircraft required intense research and development, and to produce that, NASA has worked with Empirical Systems Aerospace (ESAero), a small business based in San Luis Obispo, California. ESAero, the prime contractor for the X-57 project, provided support for air vehicle and all-electric propulsion design, analysis, manufacturing, integration, ground testing, diagnostic tools, and software modeling for the aircraft.

ESAero’s early efforts in electric aircraft research were supported by NASA through its Small Business Innovation Research and Small Business Technology Transfer (SBIR/STTR) program. In 2009, the company received its first NASA SBIR award to design and analyze the efficiency of novel all- and hybrid-electric aircraft concepts. Stemming from this and later SBIR awards came the experimental Scalable Convergent Electric Propulsion Technology Operations Research (SCEPTOR) aircraft, later designated as the X-57 Maxwell.

Starr Ginn was an early supporter of NASA’s electric aircraft research. During ESAero’s early days developing SCEPTOR, Ginn served as deputy aeronautics research director at Armstrong Flight Research Center in Edwards, California. In this role, she issued the NASA SBIR/STTR program’s call for proposals related to flight testing, including hybrid electric aircraft. She also assisted ESAero as the company’s SBIR work evolved to larger scales. A Phase III NASA SBIR award allowed ESAero to transition into the X-57 project’s prime contractor.

During her time on the project, Ginn said she saw the X-57 aircraft serve as an important partnership between the private and public sectors.

“This industry of building electric airplanes is very competitive,” said Ginn, who now serves as NASA’s Advanced Air Mobility lead strategist; “Having a NASA-sponsored project, where we get to share all our lessons learned with the public, allows the industry to grow. The X-57 project has been a wealth of knowledge so people don’t have to reinvent the wheel.”

The X-57 project is a team effort. It has involved collaboration among NASA’s Armstrong Flight Research Center, its Langley Research Center in Hampton, Virginia, and its Glenn Research Center in Cleveland, and ESAero has added multiple small business subcontractors to the team of industry innovators supporting research and development of the electric aircraft:

- Urban Air Mobility industry innovator Joby Aviation of Santa Cruz, California supplied the JMX57 air cooled electric cruise motors and controllers

- Battery innovator Electric Power Systems EPS of Logan, Utah, is responsible for development of the aircraft’s battery system

- Sierra Technical Services of Tehachapi, California, supported design, packaging, and cooling improvements on the cruise nacelle and the manufacturing of composite parts

- TMC Technologies of Fairmont, West Virginia, supported the validation and verification of all the software systems

The X-57 aircraft plans to make its inaugural test flight in 2023 and continues to be a pathfinder for a new generation of electric aircraft. Its success thus far serves as a testament to the importance of NASA’s investments in American small businesses and the sharing of knowledge.

“NASA’s work with the private sector on this project has brought a lot of transparency to the industry, and the companies have been able to grow themselves,” says Ginn. “That’s a big part of SBIRs. The government takes on the high-risk ideas and helps mature them to where they become a viable product for industry.”

The NASA SBIR/STTR program is part of NASA’s Space Technology Mission Directorate (STMD) and is managed by NASA’s Ames Research Center in Silicon Valley. The X-57 project was also bolstered by STMD’s Center Innovation Fund, which supported research into electric systems that was used to develop technology for the advanced aircraft.

To learn more about NASA’s SBIR/STTR program and apply to future opportunities, visit: https://sbir.nasa.gov/