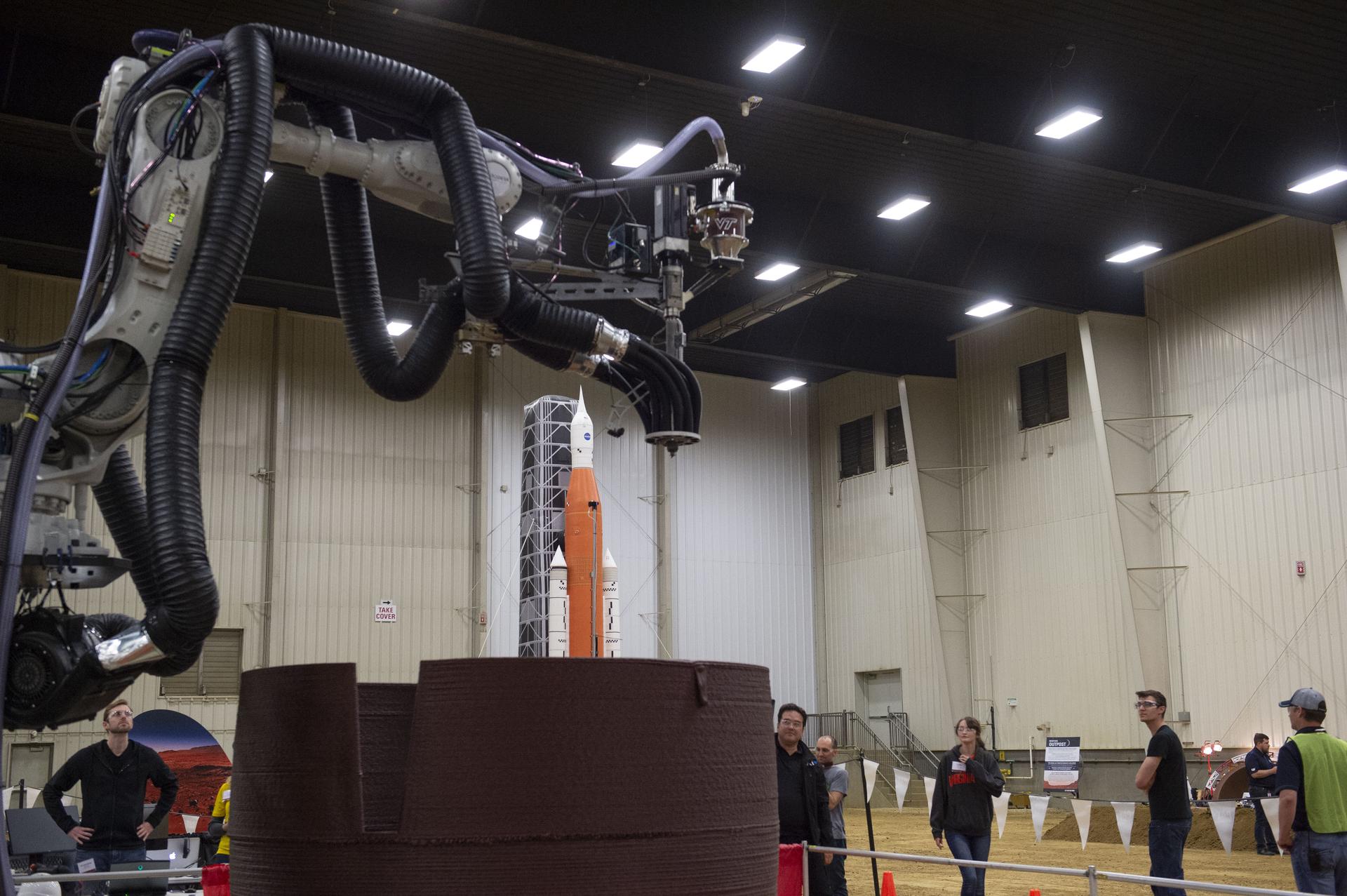

Building structures on other planets is challenging for many reasons, including that it is difficult to send supplies from Earth. Typical construction materials such as concrete and steel are too heavy and bulky to launch on a rocket to the Moon and especially Mars. A solution to that problem is using local materials already at the destination.

AI SpaceFactory – an architectural and construction technology company and winner of NASA’s 3D Printed Habitat Challenge – will collaborate with NASA’s Kennedy Space Center in Florida to mature new planetary construction technologies. NASA announced the partnership, and 19 others across the agency, under the 2020 Announcement of Collaboration Opportunity (ACO).

AI SpaceFactory and Kennedy will develop a new 3D print material that uses simulated lunar regolith, which mimics the crushed rock and dust covering the Moon’s surface. AI SpaceFactory and NASA will then use the material to 3D print a test structure in a vacuum chamber simulating environmental conditions on the Moon. The research will help inform how to build structures on other worlds and benefit construction projects here on Earth.

The technology relies on in-situ resource utilization, or ISRU, to make space exploration more affordable. Nathan Gelino, a principal investigator with the Exploration Research and Technology programs at Kennedy, referred to ISRU as “living off the land” and explained it as something pioneers have done throughout history. At Kennedy’s Swamp Works innovation environment in the Granular Mechanics and Regolith Operations Laboratory, he has studied numerous in-situ construction technologies, including 3D printing with lunar regolith, and thinks this approach has many benefits.

“3D printing has already revolutionized how we design, build, and test products because it has greatly increased design flexibility and prototyping speed in our lab and across the world,” said Gelino. “The collaboration between AI SpaceFactory and NASA is an opportunity to use those new capabilities to redefine how we construct buildings and other structures, not just on the surface of the Moon, but here on Earth, too.”

David Malott, the founder of CEO of AI SpaceFactory, agreed. “From off-world to on-world, 3D printing with local resources is a far more sustainable alternative to building with concrete and steel,” said Malott. “The technology AI SpaceFactory is developing with NASA for space could be a game-changer for how things are built on Earth.”

NASA’s plan for sustained lunar exploration and development calls for building up infrastructure over time that allows explorers to stay on the Moon for long durations where they can test systems and gain experience living off-world before venturing to Mars. To sustainably live and work on the Moon, Gelino said large structures would eventually be needed to support launch and landing sites for human outposts. This collaboration is an early step in developing the technology to make that happen.

Working with lunar resources won’t be easy. According to Alex McCarthy, the principal investigator with AI SpaceFactory, while lunar regolith looks very similar to terrestrial sand, examining it more closely shows that individual grains have sharp jagged edges, unlike sand, which is smoother and has a more rounded shape. The grain shape and size dramatically affects mechanical properties and 3D printability. AI SpaceFactory’s strategy to print with simulated lunar regolith is to create a printable polymer/regolith composite, but the challenge is incorporating as much lunar regolith simulant as possible while maintaining reliable 3D printability and mechanical properties of the composite.

McCarthy said the vacuum of space also poses an interesting challenge since it completely changes the thermodynamics compared to Earth. Their current 3D printing process relies on melting the regolith/polymer composite and then depositing it. He described it as working in a similar way to a giant glue gun, and there will have to be adjustments to account for the environmental conditions.

The new collaborative project aims to solve these challenges and develop the technology that could help construct buildings on the Moon in the future.

“Working with the brilliant minds at NASA has been a childhood dream for many of us at AI SpaceFactory,” said Malott. “It’s exciting to see that our experience with construction and materials is now contributing to space exploration. Scientists and builders working together – it’s going to be an incredible collaboration.”

The selection will result in an unfunded Space Act Agreement between the company and NASA. NASA’s Space Technology Mission Directorate (STMD) made the ACO selections and will manage the partnerships. For more information about NASA’s 2020 ACO selections, visit: