On Saturn’s giant moon Titan, liquid methane and other hydrocarbons rain down, carving rivers, lakes and seas in a landscape of frozen water. The complex chemistry on this icy world could be analogous to the period when life first emerged on Earth, or it might yield an entirely new type of life. And even farther – light-years away in deep space, a black hole shreds the ultra-dense core of a dead star, warping the fabric of space itself and sending waves of space-time flying across the universe.

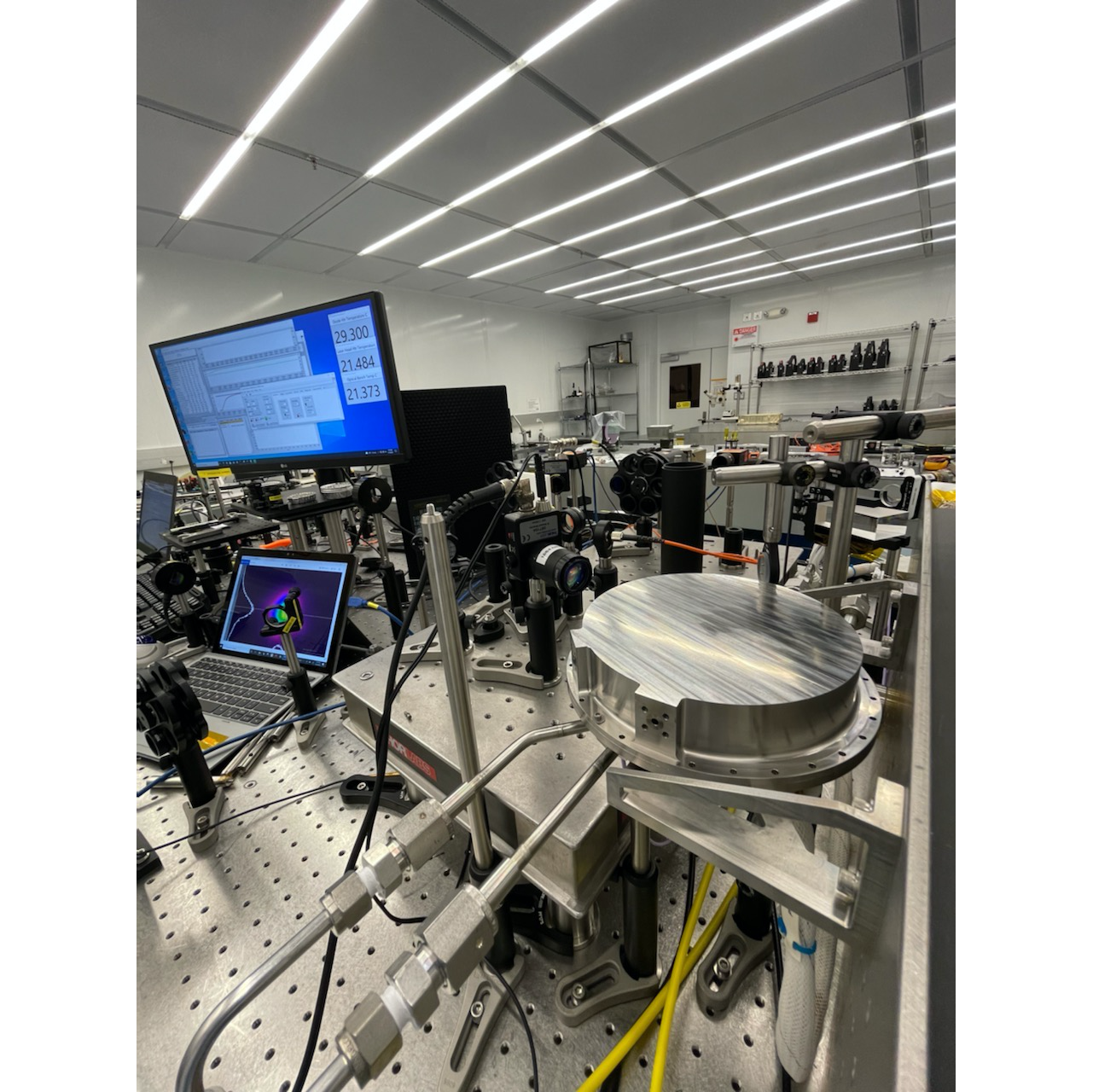

At the Space Laser Assembly Cleanroom (SLAC) at NASA’s Goddard Space Flight Center in Greenbelt, Maryland, the Laser and Electro-Optics Branch is building lasers for NASA’s Dragonfly mission to Titan and the European Space Agency’s (ESA) Laser Interferometer Space Antenna (LISA), which will measure waves in space-time caused by massive collisions.

Goddard’s SLAC is a center of expertise for the art and science of building lasers for advanced instruments to explore exotic and extreme environments such as those investigated by Dragonfly and LISA.

Lasers are difficult — they don’t “want” to work, says Barry Coyle, physicist at NASA Goddard.

“Everything has to perfect,” Coyle said.

That’s why assembling them in one place is so critical to efficiency — both in production and cost. This is the idea behind the SLAC, and it was conceived shortly after the launch of ICESat-1. ICESat-1 housed the Geoscience Laser Altimeter System, which was produced at a joint University of Maryland and Goddard facility. Although the laser worked well, Coyle said, producing space-flight laser systems outside of NASA could be expensive and inefficient.

Coyle said he and others realized these expenses could be reduced if lasers were produced at an in-house laboratory. Additionally, time and energy could be saved.

Pamela Millar, head of the Earth Science Technology Office, was the Remote Sensing branch head at the time and lead the effort to secure the funding for the SLAC, Coyle said. Ever since, the lab has been churning out lasers.

Currently, the Goddard team is developing an ultraviolet (UV) laser in the SLAC — the Dragonfly Mass Spectrometer (DraMS) laser — for the Dragonfly mission. The mission involves a rotorcraft lander designed for multiple stops across the surface of Titan. The lander, being designed and built at the Johns Hopkins Applied Physics Laboratory in Laurel, Maryland, will carry a full suite of instruments to sample materials and develop further knowledge of the moon’s surface composition and other properties.

Goddard laser engineer Matt Mullin is currently working on the DraMS laser, where his day-to-day work involves building or aligning hardware, building the laser, or running testing on subcomponents.

“Basically, the UV laser beam will be focused down into a sample cup, which holds some of Titan’s surface materials. The beam will desorb molecular compounds from the sample and excite ions (atoms and molecules with a net electric charge) to be ingested into the mass spectrometer which the scientists can use to detect what that sample is comprised of,” he said.

The laser is exciting because it is flying on a New Frontiers mission, Mullin said. The New Frontiers program is a NASA initiative that aims to fund missions that will explore parts of the solar system that are considered high priorities in planetary science.

“We’ve sent a probe to Titan in the past, but this instrument and this mission is destined to solve a lot of the mysteries involved with this really interesting moon following on previous exploration,” Mullin said. “And to see if this moon could potentially harbor any form of life would be very interesting.”

However, extremely cold temperatures and methane in Titan’s atmosphere and on its surface pose obstacles.

“How do you get a laser there and how do you get it to work there?” Coyle said. “Those are the two challenges.”

It is critical that the instrument is as small as possible and that the weight and energy consumption is minimized. On top of that, lasers need the perfect conditions to work properly.

“You’re like balancing an egg on its end, it always wants to not work. You’re harnessing photons (particles of light) to do what you want — that’s very hard,” Coyle said.

This is why the SLAC helps. Without SLAC, producing the laser would involve a lot of moving between buildings with separate teams working on it.

“It helps having a central location where we can do the optics bonding, the cleaning assembly, all the infrastructure here — it’s great,” Coyle said.

In addition to its work on Dragonfly, NASA-designed lasers, contributions to the ESA-led LISA mission, will be built in the lab. LISA will be the first space-based observatory of space-time waves, called gravitational waves. ESA looks to test Einstein’s theory of gravity by measuring gravitational waves in space generated by extremely violent events like black hole collisions.

“The SLAC is a perfect place for us to build the LISA lasers,” Anthony Yu, the product development lead for the LISA laser, said. “The LISA lasers have many stringent requirements and we need to set up in-situ test stations to verify the laser performance during the build process. The SLAC allows us to set up specialized test stations for testing the laser real-time and also when it undergoes thermal vacuum cycling tests after it is assembled.”

Paul Stysley, Goddard’s associate branch head of laser and electro-optics, and product development lead for the DraMS laser, said the heart and soul of SLAC is in the way it streamlines the technology development and production of lasers.

“What makes the SLAC unique is having a centralized location to develop, build and test space-flight laser systems,” Stysley said. “A product flow and infrastructure are in place to develop, environmentally test and monitor a laser design from cradle to grave for a space-flight mission leading to significant reduction of technical risk and cost.”

Mullin said working on Dragonfly and with the team has been amazing.

“The real pleasure and the exciting part has been working with some of the best engineers and scientists in the world on this project,” Mullin said. “I remember watching the Discovery Channel about future exploration to outer moons like Europa or Titan, but I never really imagined that I’d be on one of the teams helping explore it.”

By: Julie Freijat

Media Contact: William Steigerwald