The first four Artemis missions will use NASA’s 16 upgraded RS-25 engines that previously powered space shuttle flights. For future flights on the Space Launch System (SLS), NASA and prime contractor Aerojet Rocketdyne are changing the way they build major parts for the RS-25. Engineers and technicians are fabricating some of these parts using advanced manufacturing techniques that increase reliability while reducing both the cost and time to build the engine.

The first RS-25 powerhead produced by Aerojet Rocketdyne in over a decade arrived at NASA’s Stennis Space Center near Bay St. Louis, Mississippi on Oct. 25. Here, it will be installed to a flight certification engine built specifically for testing newly designed parts for the latest production RS-25 engine that will power SLS flights beyond Artemis IV.

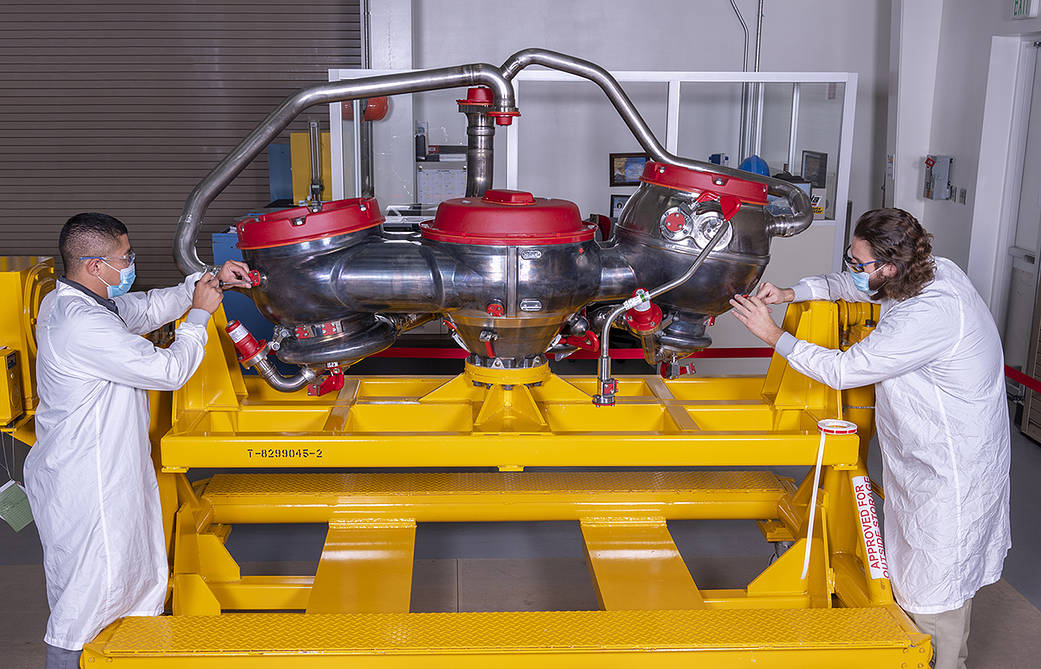

The powerhead serves as the structural backbone to the RS-25. It houses three highly complex injectors that produce the combustion to power the engine and acts as a junction for several critical parts, including both high pressure pumps and the main combustion chamber.

Key powerhead components, such as the main injector, heat exchanger, and structural forgings, come with cost and schedule benefits due to the incorporation of advanced machining and forging processes as well as a reduction in welds and part counts, making the powerhead more reliable.

Powerhead unit 7001 recently completed proof pressure testing at Aerojet Rocketdyne’s site in Los Angeles, California. This test required the part to be pressurized beyond normal operating levels, confirming its capability to safely operate the engine.

The new powerhead, along with other engine parts made from advanced manufacturing technologies such as the engine nozzle and main combustion chamber, will undergo hot fire testing on the same certification engine early next year. The manufacturing changes incorporated into this new powerhead configuration are an integral part of NASA’s and Aerojet Rocketdyne’s strategy to reduce RS-25 manufacturing costs by more than 30% compared to its shuttle predecessor.

Sixteen new powerhead units are currently in production as part of Aerojet Rocketdyne’s commitment to deliver NASA 24 new RS-25 engines.

SLS and NASA’s Orion spacecraft, along with the commercial human landing system and the Gateway in lunar orbit, are NASA’s backbone for deep space exploration. SLS is the only rocket that can send Orion, astronauts, and supplies to the Moon in a single mission. With Artemis, NASA will land the first woman and the first person of color on the Moon and establish sustainable exploration in preparation for missions to Mars.