Emily Hacopian

William Marsh Rice University

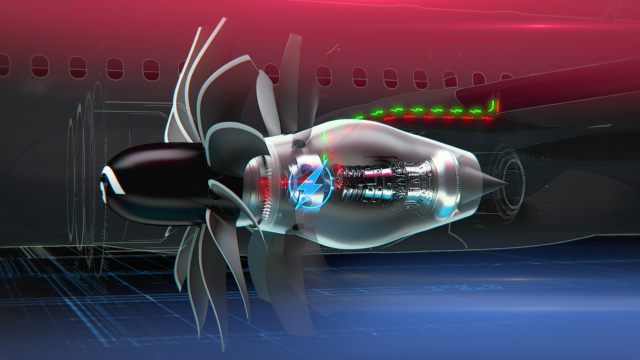

Understanding the impact of integrating nanomaterials into current technology is of great importance to design composite structures to meet our application needs. The reliable addition of nanomaterials to materials currently being used will improve electronics. Reinforcing current materials with nanotechnology will boost their performance and allow for the use of lighter structures. The better the understanding of how nano and bulk materials work together, the more we can tailor their properties to optimize their performance. There is a constant search for lightweight, chemically stable, and mechanically/thermally/electrically robust materials that can withstand the harsh environments encountered by aerospace technology. In this proposal, a research initiative is presented that focuses on the development and investigation of coaxial graphene on copper wires for aerospace applications. A characterization of the mechanical properties of these graphene-coated wires will be performed. Thermal properties, electronic properties, and corrosion resistance will also be explored. Many theoretical predictions have been made regarding the use of graphene on bulk materials, however minimal experimental research in this field has been done. Currently, there is a dearth of experimental validation of these predictions. This study provides experiments that will predict the material’s behavior under harsh environments that aerospace technology encounters. This project will test a range of wire diameters to determine how thin the wire can be for graphene growth, yet still be strong enough to withstand the physical demands of aerospace applications. It is hypothesized that the addition of nanomaterials to copper wires will improve mission performance and increase payload mass fraction. These wires will allow for the use of a thinner gauge of wire than is currently used, decreasing the mass of wire needed, but with an improvement in performance. Graphene coated copper wires will exhibit higher conductivity, more corrosion resistance and lighter weight than traditional copper wires. A decrease in total mass of wires required allows aircraft and spacecraft to travel further and opens up new mission opportunities. One of the most beneficial uses for this novel material is in aerospace applications. For instance, the Boeing 747 and 787 currently use 4,000 lbs and 8,000 lbs, respectively, of metallic data and power cables. Reinforcing conventional copper wires with graphene will allow for the use of a thinner gauge of wire, reducing the weight of wires required, yet still creating a material that performs better than the current technology. The copper wires that are commonly used today are in the range of about 1.6 mm in diameter, however this project will study wires around the 50 micron diameter scale with properties surpassing the thicker, heavier wires. By adding nanotechnology to copper wires, this material meets many of the goals in both the “Materials, Structures, Mechanical Systems, and Manufacturing” technology area, section 12.1.1 “Materials-Lightweight Structures”, and the “Nanotechnology” technology area, section 10.1.1 “Engineered Materials and Structures-Lightweight Structures”. The lightweight structures category ranked highest of all the Nanotechnology high priority level 3 technologies.