Michael Sangid

Purdue University

ESI19 Michael Sangid Quadchart

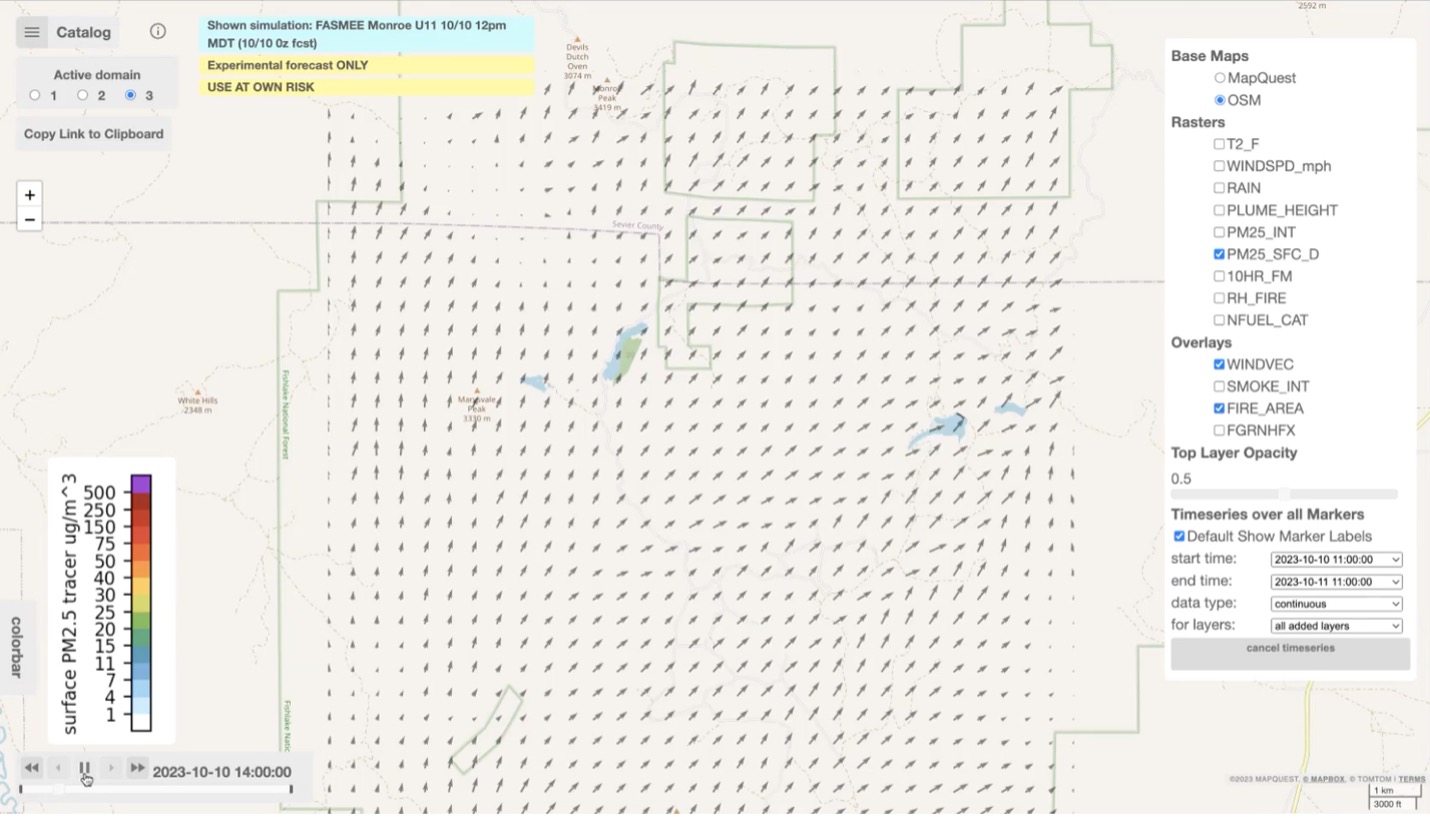

Polycrystalline materials form the backbone of the structural components within spacecraft vehicles, in which fatigue crack initiation and propagation are the predominate failure mechanisms. Accurate assessments of the probability of fatigue failure is critical to manage uncertainty and mission risk over a vehicle’s lifecycle. In this work, a generalized, holistic framework to predict microstructural sensitive fatigue crack initiation and small fatigue crack propagation behaviors for a range of polycrystalline materials, loading configurations, and environments is developed. The outcomes of this work will produce next generation prognosis methodologies for material durability and damage tolerance of structural polycrystalline materials, including uncertainty quantification and experimental validation through in situ high energy x-ray diffraction microscopy to develop trust in the model predictions. Two use cases of the predictive model capabilities will be demonstrated, including a (i) Ni-based superalloy subjected to extreme environments based on elevated temperatures and oxidation and (ii) Ti-6Al-4V within a structural components with dimensions of thin web features similar to that of the microstructure.