Adam P. Arkin

University of California, Berkeley

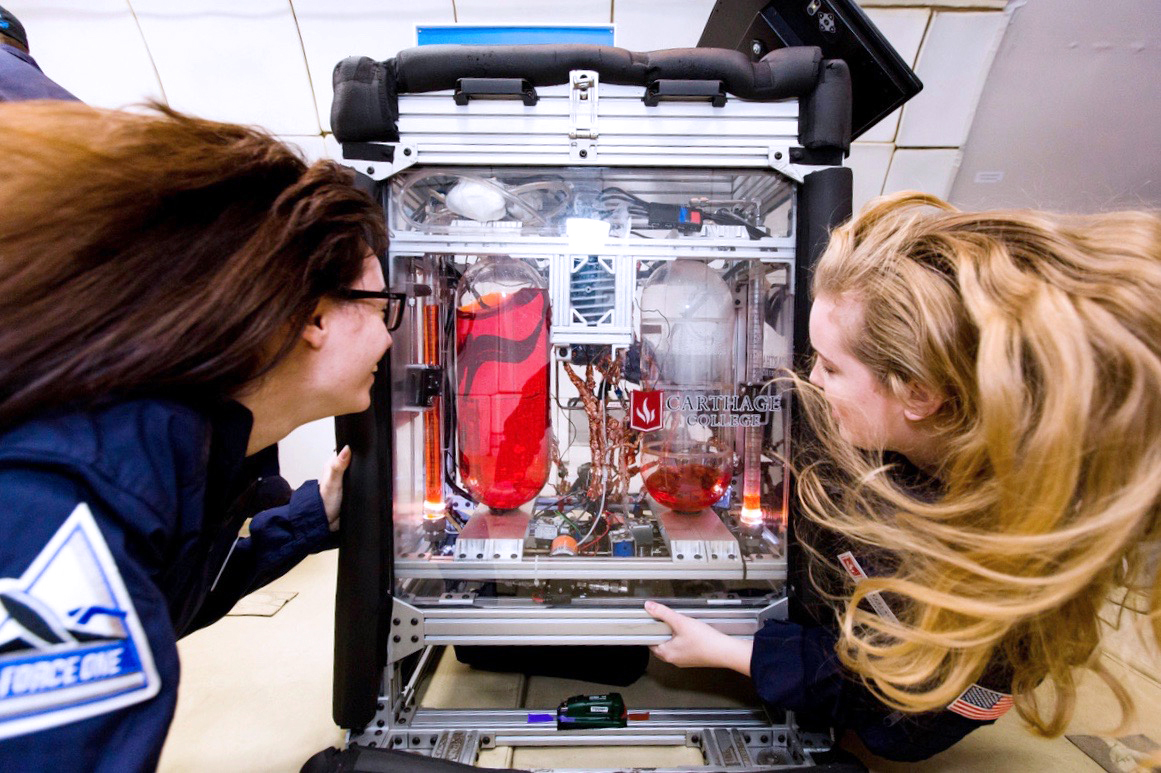

STRI 2017 The Center for the Utilization of Biological Engineering in Space (CUBES) Quad Chart

Center for the Utilization of Biological Engineering in Space

Vision

The Center for the Utilization of Biological Engineering in Space (CUBES) will leverage partnerships between NASA, other federal agencies, industry, and academia to:

- Support biomanufacturing for deep space exploration;

- Advance the practicality of an integrated, multi-function, multi-organism biomanufacturing system on a Mars mission; and

- Showcase a continuous and semiautonomous biomanufacturing of fuel, materials, pharmaceuticals, and food in Mars-like conditions.

Background and NASA Relevance

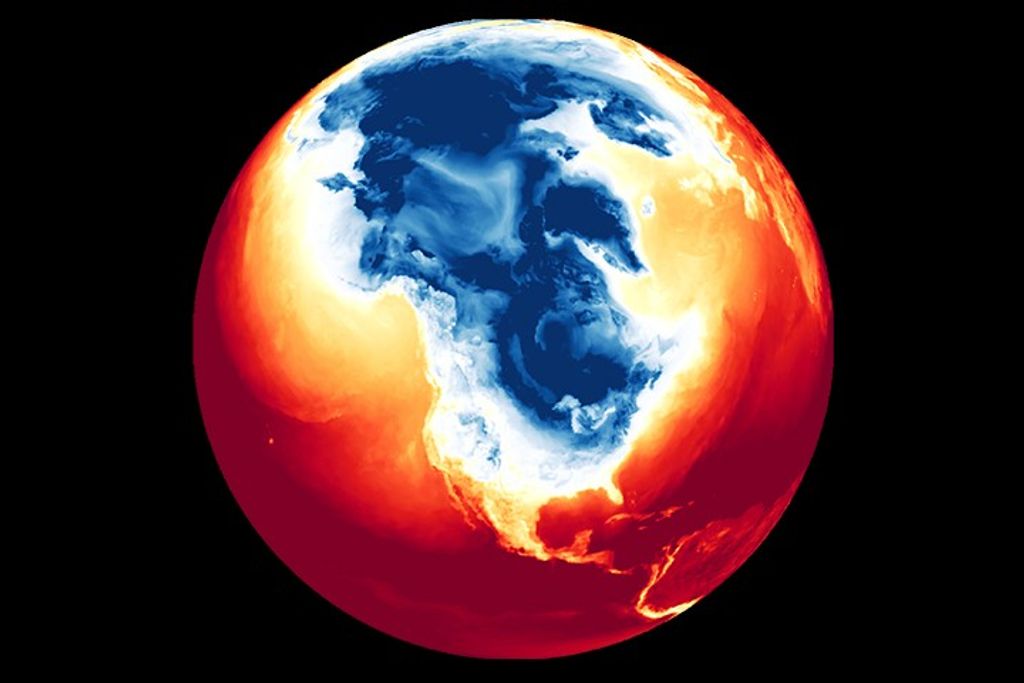

NASA’s 2015 Journey to Mars document describes the next pioneering steps in space exploration through three tiers of missions: Earth Reliant, Proving Ground, and Earth Independent. CUBES will be strategically aligned with all three tiers. A CUBES demonstration biosystem will baseline future Earth Reliant testing in 3D-printing, in situ resource utilization, and food and pharmaceutical production. CUBES research could help minimize resupply needs on a Proving Ground mission. Finally, use of the CUBES-produced biosystem to harvest Martian resources for fuel, water, oxygen, and building materials will satisfy requirements for Earth Independence.

There are inherent mass, power, and volume advantages of space biotechnology over traditional abiotic approaches. CUBES will harness these advantages in a biosystem that will have tightly coupled subsystem inputs and outputs, and that will use Mars-like resources and conditions to expand from an initial seed set to meet the space biomanufacturing goals.

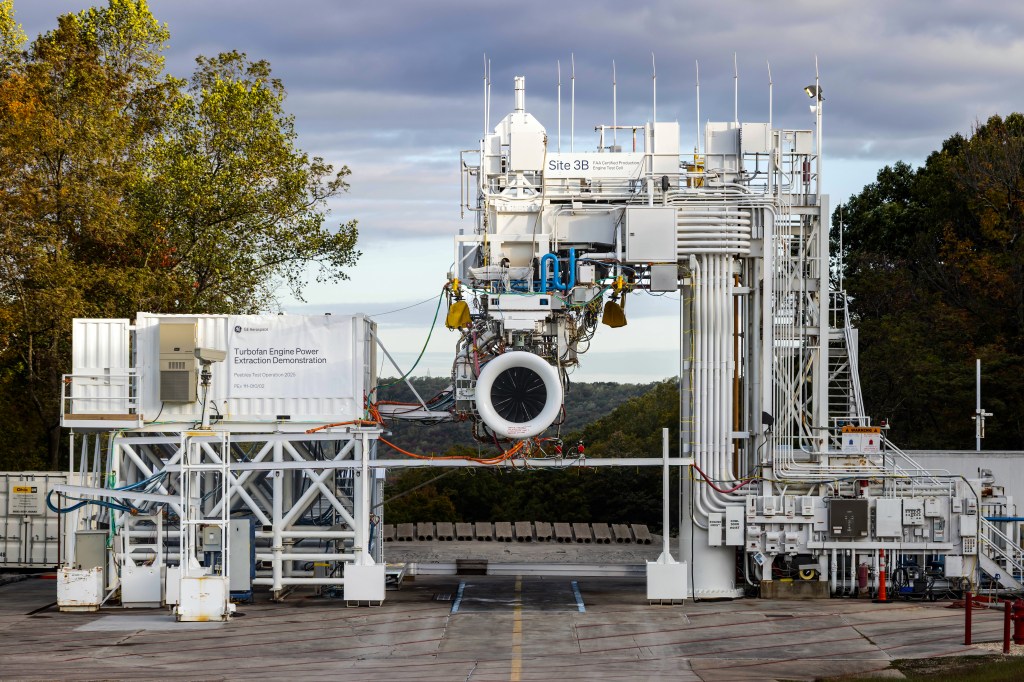

CUBES will be organized into four divisions to achieve this planned showcase. The requisite systems design and engineering efforts to optimally allocate and utilize Mars resources, tightly integrate and automate internal processes, and satisfactorily achieve biological and mechanical performance according to mission specifications will be the domain of the Systems Design and Integration Division (SDID). Activities to harness in situ resources, decontaminate and enrich regolith, and transform human and mission wastes to media and feedstocks for utilization by downstream processes will be the responsibility of the Microbial Media and Feedstocks Division (MMFD). The manufacture of propellants, biopolymers and useful chemicals from MMFD media and feedstocks along with the recycling of manufactured products at the end of their serviceable life will be tasked to the Biofuel and Biomaterial Manufacturing Division (BBMD). A key component of the BBMD-SDID interface will be the use of generated biopolymers in additive manufacturing (3D-printing). Plant and microbial engineering to realize food and pharmaceuticals for astronauts along with the recycling of plant wastes will be the focus of the Food and Pharmaceutical Synthesis Division (FPSD).

These CUBES divisions will be aligned with the 2015 NASA Technology Roadmaps, especially TA07 Human Exploration Destination Systems. TA07 includes TA7.1 In Situ Resource Utilization (the MMFD, BBMD, and FPSD will all use such inputs), TA7.2 Sustainability and Supportability (the MMFD, BBMD, and FPSD will all use sustainable resource recycling), TA7.4 Habitat Systems (CUBES will develop a semi-autonomous proof-of-concept biomanufacturing demonstration), and TA7.6 Cross-Cutting Systems (the BBMD additive manufacturing technology will be designed for scaling assembly). Additionally, CUBES will facilitate the development of technologies in TA06 Human Health, Life Support, and Habitation Systems by enabling long-duration, deep-space human exploration through the minimization of resupply consumables and increased Earth independence via Martian in situ resource utilization, synthetic biology, and biomanufacturing. The FPSD will address TA6.3 Human Health and Performance, and the MMFD will address TA6.1 Environmental Control, Life Support Systems and Habitation Systems, and TA6.4 Environmental Monitoring, Safety, and Emergency Response through remediation of toxic perchlorate in the Martian regolith.

Research Objectives

The primary CUBES research objectives are:

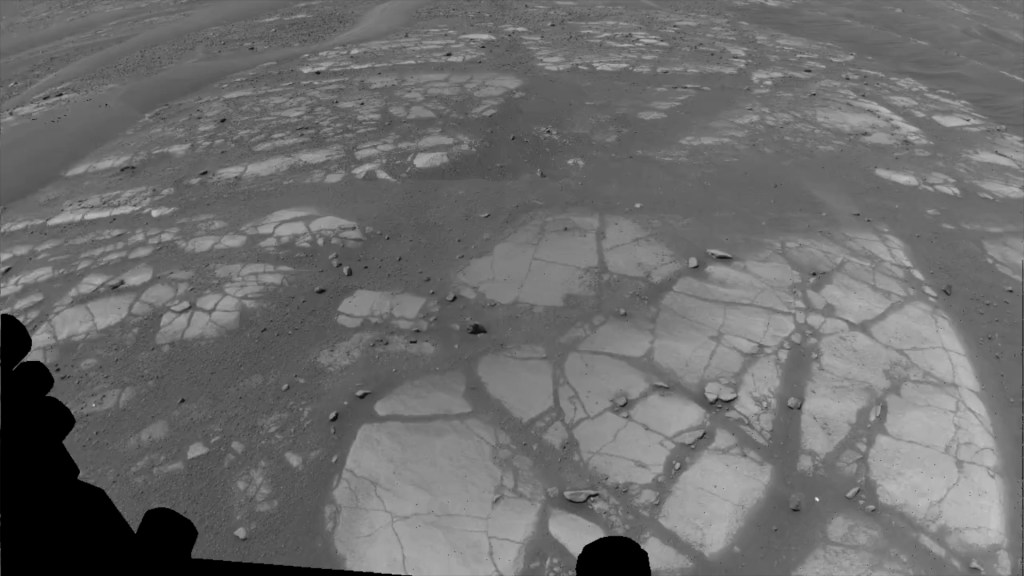

- In situ microbial media production, which harnesses Mars atmospheric and regolith resources for downstream biological use;

- In situ manufacture of mission products, which creates outputs like propellants and building materials that are fundamental enablers of any long-duration space mission;

- In situ food and pharmaceutical synthesis, which allows these long-duration space missions to be manned, and uses plants and microbes that provide food, nutrients and medicine; and

- Space and complex systems engineering, which analyzes, guides, tests, improves, and integrates the internal processes of objectives 1-3 above.

Impact

The CUBES goal of efficiently using in situ resources and effectively recycling them to drive the manufacture of useful products will meet a long-standing need for space missions, which is to substantially reduce manufacturing-infrastructure mass and related costs in harsh conditions. The planned CUBES output of a semi-closed loop that integrates resource-recovery in a resource-poor environment with waste streams to biologically drive the manufacture of fuel, materials, pharmaceuticals, and food will establish the capacity to biologically support manned space exploration on par with abiotic techniques.

CUBES benefits will include:

- Engineered microbes to convert limited or marginally accessible Martian feedstocks, such as atmospheric gases at low partial pressure and nutrients from contaminated/toxic land, into valuable commodities.

- Novel biologically-coupled nanotechnologies to fix available carbon and nitrogen and to transfer energy into biosynthetic processes;

- Refined plants and plant microbiomes that grow in restricted space, light, water, and nutrients, and that can still provide substantial yields of nutritive foods;

- Biologically-produced pharmaceuticals, cell-based treatments/therapeutics, and materials for on-demand diverse additive manufacturing applications; and

- Optimized, integrated operation of the above processes.

CUBES’ individual approaches to media production, mission product manufacture, and food and pharmaceutical synthesis, amplified by a focus on integration and optimization, will lead to a strong data-driven, technologically-backed platform for space biomanufacturing.

Participants

CUBES will involve five universities: The University of California, Berkeley; the University of California, Davis; the University of Florida; Utah State University; and Stanford University. The team of investigators includes authorities on nanobiotechnology, extremophile microbiology, synthetic biology, laboratory simulation of extreme environments, microbial waste recycling, and bioprocess control, who will develop innovative approaches for ISRU for the MMFD Division; experts in bioplastics and pharmaceutical biomanufacturing, polymer chemistry and material science, biofuel production, additive manufacturing, and bioprocess optimization for the BBMD; experts in space-optimized plant biology, plant engineering, plant/microbiome interaction, and microbial genetics for the FPSD; and experts in systems engineering and optimization and biosystems modeling for the SDID.