In 2013, a startup company had an idea for using extremophile organisms from volcanic springs to create edible proteins that would serve as an environmentally conscious alternative to meat-based proteins. Following a handful of small investments from government agencies, including a $124,000 Small Business Technology Transfer (STTR) contract from NASA, Sustainable Bioproducts announced in early 2019 it received $33 million in venture capital financing, including backing from two of the world’s biggest food and agriculture companies.

The Small Business Innovation Research (SBIR) and STTR programs call themselves America’s seed fund, targeting promising technologies from small U.S. businesses for development and commercialization.

Each year, NASA invests in hundreds of companies through the programs. Many small SBIR and STTR investments, each between around $125,000 and $750,000, have led to successful commercial products over the years, boosting the economy and advancing the general state of American technology.

NASA benefits from the program by selecting technologies that could support future missions — such as the ability to essentially “brew” foods, fuels and building materials from waste products in space, which Sustainable Bioproducts explored with the NASA funding.

Spinoff 2019, the latest edition of a NASA publication that highlights how space technologies have turned into commercial products, features 15 commercial technologies benefiting the public that were developed in part using NASA SBIR or STTR funding. Here are some highlights:

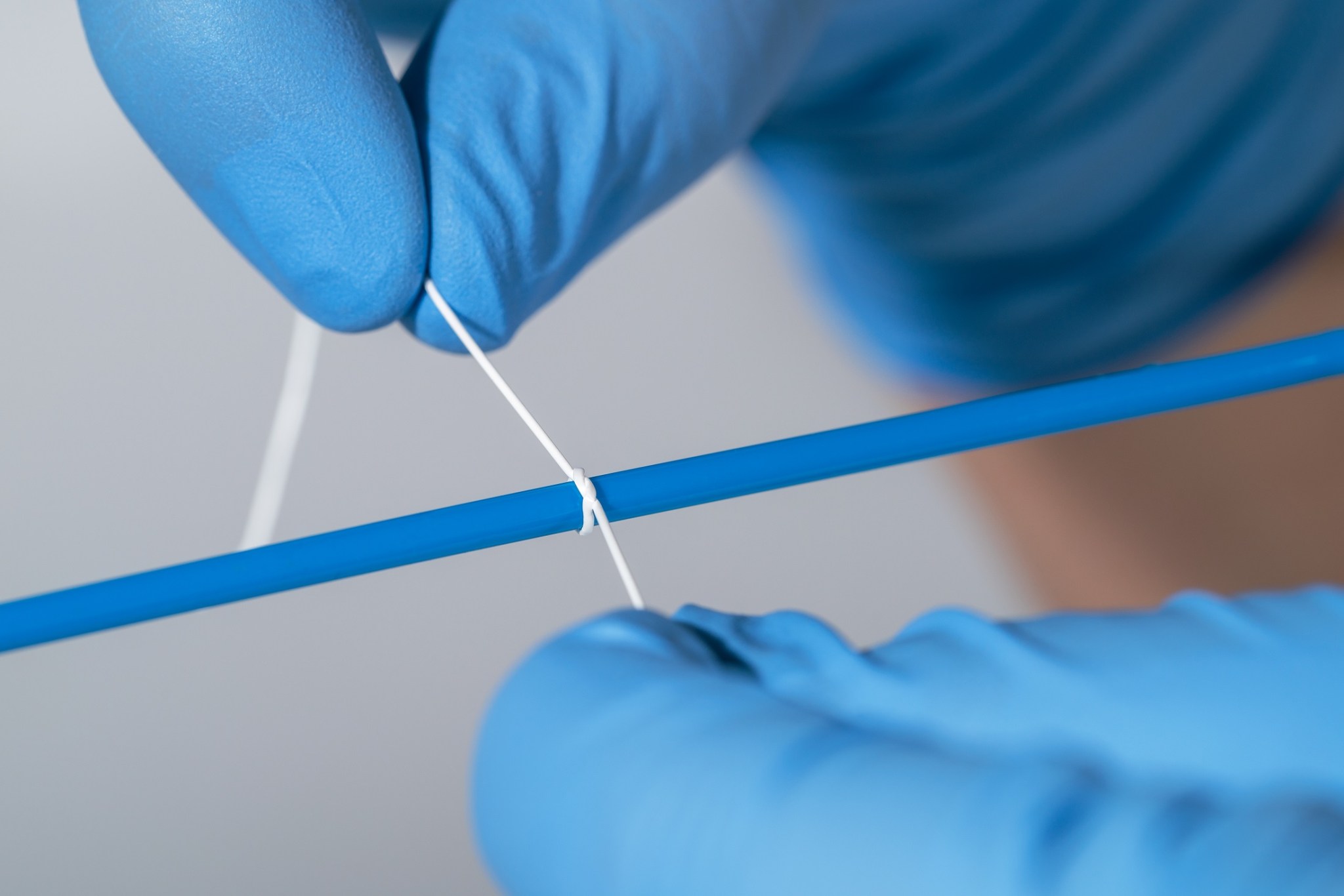

New Type of Teflon Makes Life-Saving Sutures and More

What began as a seal for a Mars sample-return canister prototype is now used in surgeries, fiber optics, shipping, and oil and gas drilling.

The company designing the canister for NASA’s Jet Propulsion Laboratory in Pasadena, California, came up with a complex plan for forming an airtight seal despite all the Martian dust that would likely be on the lip of the container. It would require some type of Teflon, also known as polytetrafluoroethylene, or PTFE. The company subcontracted South Carolina-based Zeus Inc. to provide expanded PTFE (ePTFE), which is thinner and stronger than untreated Teflon, but it didn’t work as planned. So Zeus came up with a new way to manufacture the material that would be stiffer while keeping the material’s other desirable characteristics.

The result is a new type of ePTFE that’s soft, strong, flexible and biocompatible — meaning it doesn’t interact with anything in the body — making it useful for sutures and stents used in heart surgery and other medical applications. It’s also now used in fiber optics.

The material also happens to have tiny, sub-micron-sized pores, which allow gas to pass through but not liquid. This makes it useful for keeping valuable package contents dry during shipping. And because it absorbs hydrocarbon vapor, oil and gas companies use pouches of it to figure out where to drill.

Zeus’ significant innovation to meet NASA’s needs on a small order ended up paying off for the company and its customers.

All-Electric Passenger Aircraft Becomes a Reality

NASA is working to eliminate barriers to all-electric passenger planes by building one — the X-57 Maxwell. One of those hurdles is battery power that’s light enough to be feasible for flight but also safe. Lithium-ion batteries, among the lightest on the market, run the risk of combustion. A pack of lithium-ion cells must minimize this risk and prevent a chain reaction in the event that a cell ignites.

In 2017, NASA’s Armstrong Flight Research Center in Edwards, California, awarded two SBIR contracts to Electric Power Systems (EP Systems) to build such a battery pack. The company incorporated its own innovations but also worked with a team of NASA engineering, safety and battery experts to successfully build an 850-pound battery pack that could prevent a chain reaction. EP Systems now offers a commercial version based on its X-57 battery.

Bye Aerospace became the battery’s first customer, using it to power the eFlyer — a small airplane for training pilots, which Bye hopes will be the first all-electric plane certified by the Federal Aviation Administration.

Electric motors are far more efficient than internal combustion engines and require much less maintenance. Bye Aerospace calculates that the eFlyer operates at a cost of $3 per hour while also generating less noise than a traditional small aircraft — and with no emissions.

Air Filters for Space Eliminate Household Pet Odors

Are you a cat person or a dog person? Or perhaps more of a hamster fan? Either way, NASA-backed research can improve the air quality in your home — and the same technology keeps cars smelling fresh and filters contaminants out of the air in microchip manufacturing facilities.

NASA’s Johnson Space Center in Houston awarded Serionix Inc., located in Champaign, Illinois, three SBIR contracts beginning in 2016 to develop air filters for possible use in spacesuits and the Orion crew spacecraft. The work focused especially on eliminating ammonia and formaldehyde, the two contaminants most likely to exceed allowable concentration levels in a spacesuit.

As Serionix began considering commercial markets for its filters, the company found that ammonia happened to be an issue in the consumer market, particularly for pet owners. Unpleasant odors from cat boxes, hamster cages and other pet spaces is due to ammonia and related chemicals in urine that Serionix filters excel at removing.

The filters’ technology changes color when a filter is spent, which prevents unnecessary changes and saves on costs. The company now sells a Colorfil-branded air purifier, an HVAC filter and a cabin air filter for automobiles. The products’ filtering capability is based on polymer substances with a permanent electrical charge that remove toxic chemicals and kill viruses, bacteria and mold.

Electricity-“Breathing” Bacteria Support Wineries, Breweries

We breathe oxygen because the sequence of chemical reactions in our metabolism ends with inhaled oxygen atoms accepting electrons and sharing them with hydrogen atoms to produce water. But in 1988, scientists discovered a bacteria that, in the absence of oxygen, can pass that electron to a metal outside the cell, transferring a charge. Since then, scientists have identified a host of similar, so-called exoelectrogens that can “exhale” or “inhale” electricity. Some can do both.

Cambrian Innovation Inc. was founded on a NASA grant to study concepts for “bioelectric space exploration,” including a microbial fuel cell based on exoelectrogenic microbes and powered by wastewater. Grants from several federal agencies followed, including an SBIR contract from Johnson and another from NASA’s Ames Research Center in California’s Silicon Valley.

A couple of years later, the company announced it had successfully field-tested and commercialized a bioelectrically enhanced wastewater treatment system called the EcoVolt Reactor. In the shipping container-sized units, electroactive bacteria break down waste and generate methane-rich natural gas to be burned for power.

Wineries and breweries, which produce large amounts of contaminated water, were the first customers. The EcoVolt removes enough contaminants for the output to be discharged into a municipal treatment system. It can be paired with the EcoVolt Membrane Bioreactor to make water pure enough for reuse.

By late 2018, Cambrian had industrial-scale projects at more than 10 wineries and breweries. By May 2019, the company had treated over 115 million gallons of wastewater, recycled over 35 million gallons, and created and saved over a gigawatt hour of energy.

Across the country, companies are using funding from SBIR and STTR contracts to carry out basic research and development that leads to new products and tackles big problems on Earth, like food and water supply and pollution. And one day NASA could take some of those solutions to the Moon, to Mars and beyond.

To read more about these and other SBIR/STTR-related spinoffs, and to request a free copy of Spinoff 2019, visit:

For more information on NASA’s SBIR and STTR programs, visit:

Mike DiCicco

Goddard Space Flight Center, Greenbelt, Maryland