Joel Sercel

TransAstra Corporation

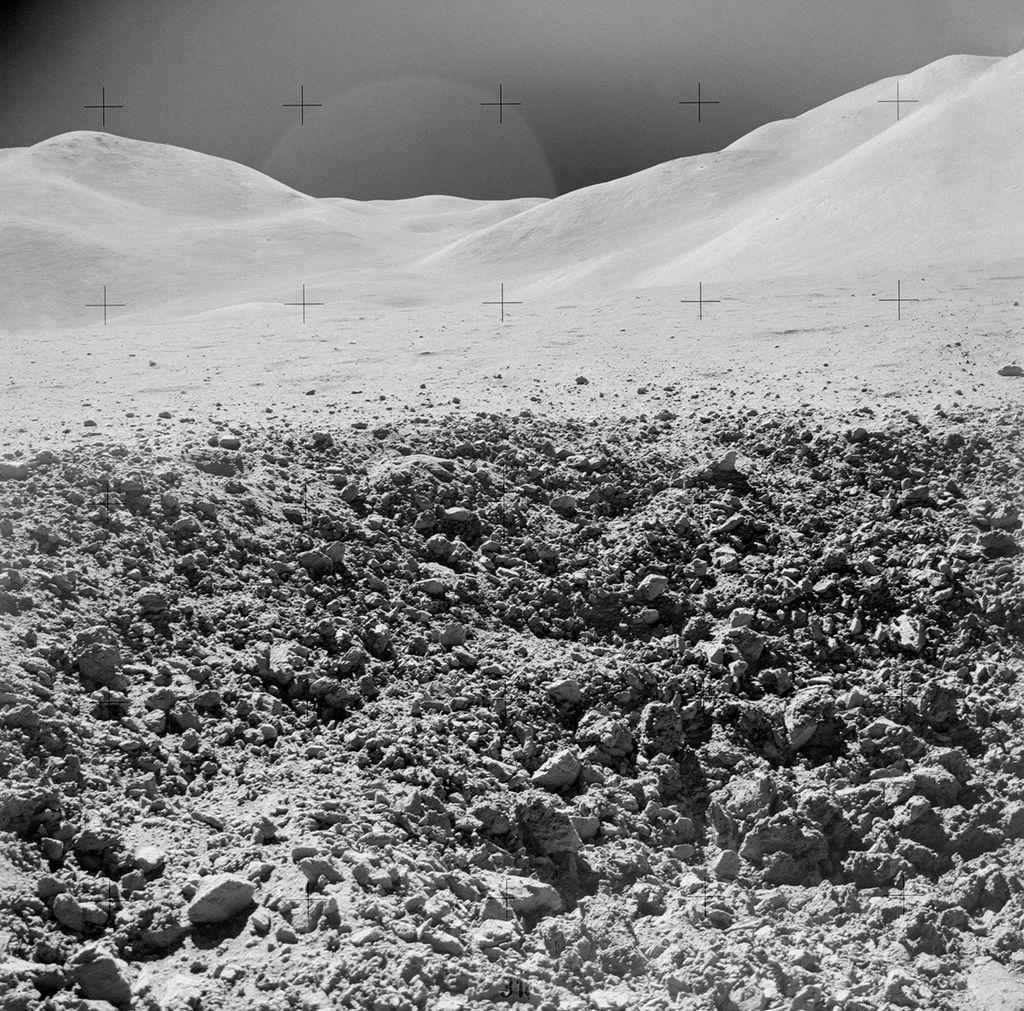

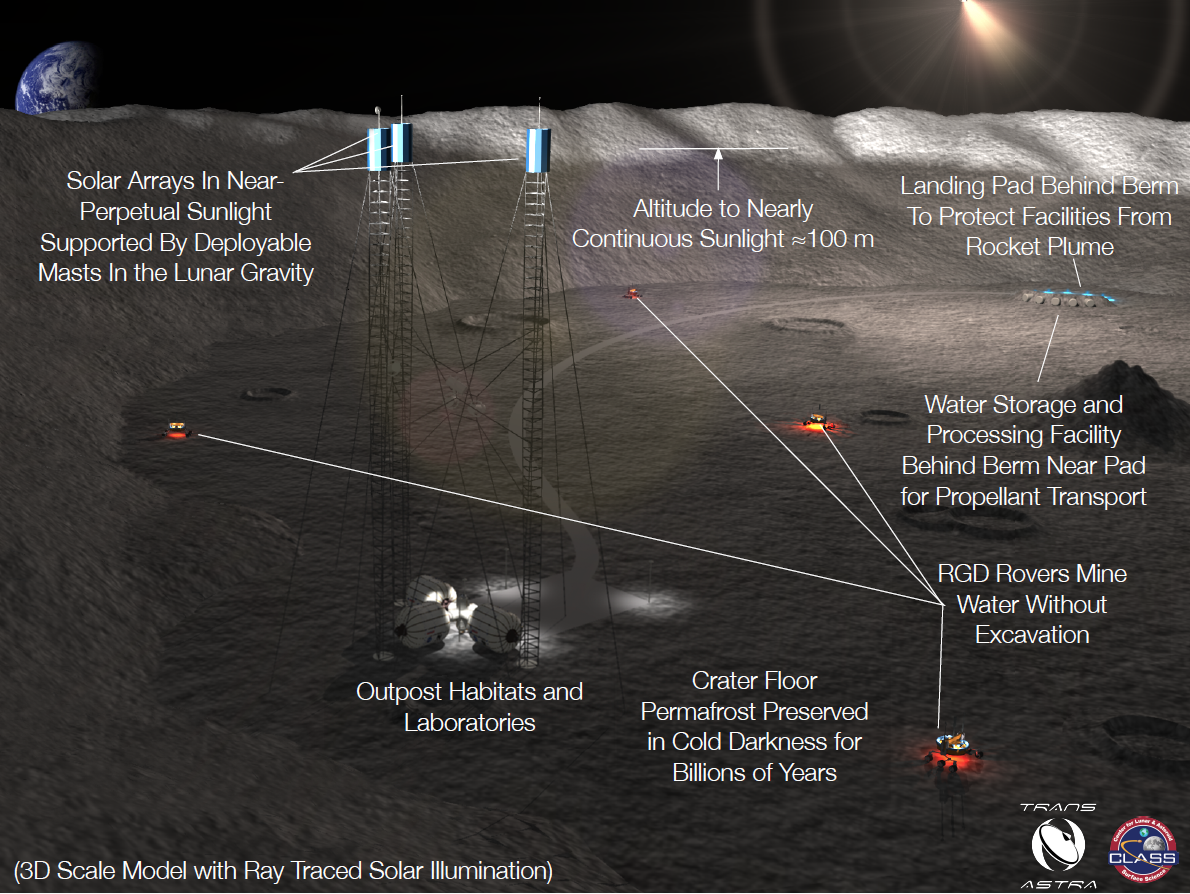

The Lunar Polar Gas-Dynamic Mining Outpost (LGMO) (see quad chart graphic) is a breakthrough mission architecture that promises to greatly reduce the cost of human exploration and industrialization of the Moon. LGMO is based on two new innovations that together solve the problem of affordable lunar polar ice mining for propellant production. The first innovation is based on a new insight into lunar topography: our analysis suggests that there are large (hundreds of meters) landing areas in small (0.5-1.5 km) nearpolar craters on which the surface is permafrost in perpetual darkness but with perpetual sunlight available at altitudes of only 10s to 100s of meters. In these prospective landing sites, deployable solar arrays held vertically on masts 100 m or so in length (lightweight and feasible in lunar gravity) can provide nearly continuous power. This means that a large lander, such as the Blue Moon vehicle proposed by Blue Origin, a BFR; or a modestly sized lunar ice mining outpost could sit on mineable permafrost with solar arrays in perpetual sunlight on masts providing affordable electric power without the need to separate power supply from the load.

The second enabling innovation for LGMO is Radiant Gas Dynamic (RGD) mining. RGD mining is a new Patent Pending technology invented by TransAstra to solve the problem of economically and reliably prospecting and extracting large quantities (1,000s of tons per year) of volatile materials from lunar regolith using landed packages of just a few tons each. To obviate the problems of mechanical digging and excavation, RGD mining uses a combination of radio frequency, microwave, and infrared radiation to heat permafrost and other types of ice deposits with a depth-controlled heating profile. This sublimates the ice and encourages a significant fraction of the volatiles to migrate upward out of the regolith into cryotraps where it can be stored in liquid form. RGD mining technology is integrated into long duration electric powered rovers. In use, the vehicles stop at mining locations and lower their collection domes to gather available water from an area before moving on. When on-board storage tanks are full, the vehicles return to base to empty tanks before moving back out into the field to continue harvesting. The rover can be battery operated and recharge at base or carry a laser receiver powered by a remote laser. Based on these innovations, LGMO promises to vastly reduce the cost of establishing and maintaining a sizable lunar polar outpost that can serve first as a field station for NASA astronauts exploring the Moon, and then as the beachhead for American lunar industrialization, starting with fulfilling commercial plans for a lunar hotel for tourists.

RGD mining will allow the development of a practical system that can be constructed on a mobile platform to enable the use of a mixture of different types of radiant energy with different penetration depths to control the release of water vapor from hard lunar permafrost in such a way that it can be trapped and captured by a water collection system. Although microwave extraction methods have been proposed in the past they have typically required prior excavation of substrate material or did not include methods to prevent re-trapping of water by cold regolith. By using a multi frequency radiant system, RGD provides a variable heating profile that sublimates water vapor in layers from the top down and encourages evolved water to migrate into cryotraps in the vehicle while minimizing refreezing of the water vapor in the surrounding substrate. This design combines subsurface ice prospecting via low voltage DC subsurface sensing integrated with TRL-6 drills for detection and volatile gas collection in a single vehicle. We estimate that rovers sized for a New Glenn or SLS payload faring would mass between 2 and 5 tons and would each be capable of harvesting between 20 and 100 times its mass per year in water.