NASA has awarded a total of $201,023 to teams of citizen inventors that have reached the latest milestone of NASA’s 3D-Printed Habitat Challenge, completing the Phase 2: Level 2 Beam Member competition. The teams are working to find ways to 3-D print habitation structures using recyclables and simulated Martian soil, a technology goal that could support deep space exploration and advance construction capabilities on Earth.

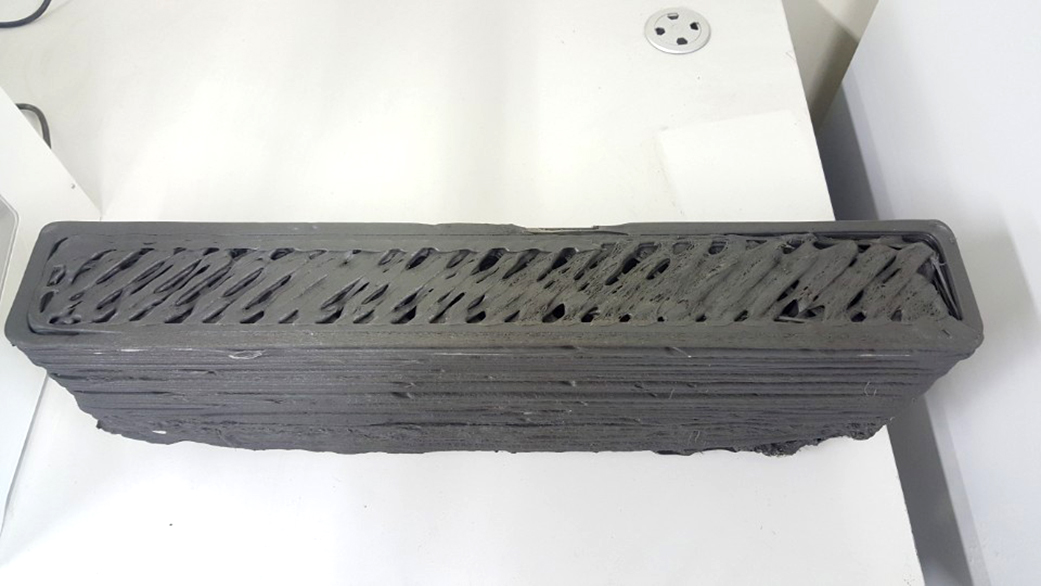

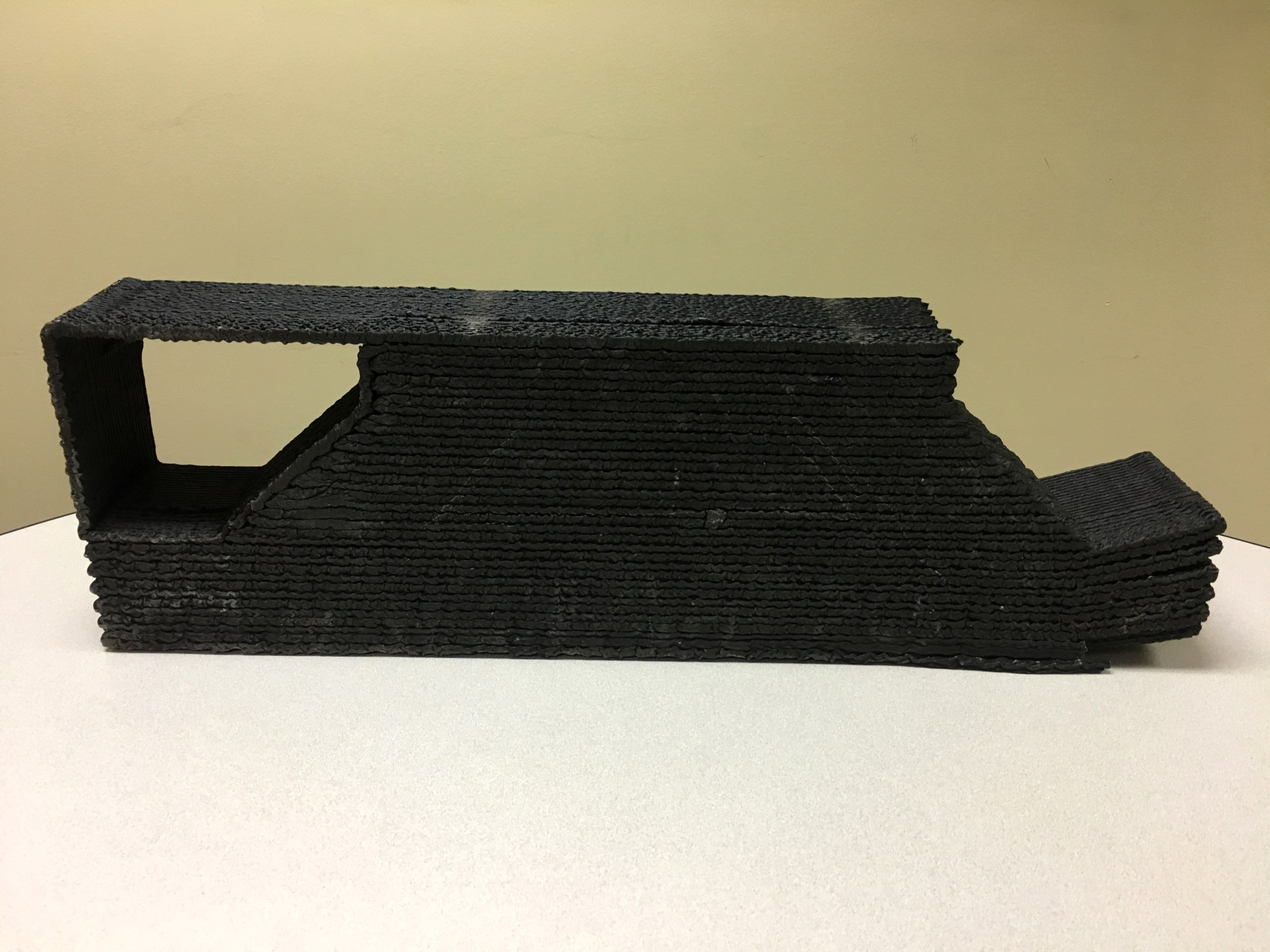

For this level, which is the second of three sub-competitions within Phase 2, teams had to 3-D print a beam for bend testing. Scores were calculated based on the material composition and the maximum load of the beam at failure.

The winning teams are:

1st place: Moon X Construction of Seoul, South Korea (International team, not eligible for prize money)

2nd place: Form Forge of Oregon State University, Corvallis – $67,465

3rd place: Foster +Partners | Branch Technology of Chattanooga, Tennessee – $63,783 (earned first place and $85,930 in Phase 2: Level 1)

4th place: University of Alaska of Fairbanks – $35,573 (earned second place and $14,070 in Phase 2: Level 1)

5th place: CTL Group Mars of Skokie, Illinois – $34,202

6th place: ROBOCON of Singapore (International team, not eligible for prize money)

A seventh team, from Pennsylvania State University of University Park, competed but did not meet the structural strength requirement for a cash award.

“Recyclable plastics were used in the top three scoring teams, indicating that a thermoplastic concrete material may be viable for 3-D printing habitats on Mars,” said Rob Meuller, senior technologist for advanced projects development at the Swamp Works laboratory at NASA’s Kennedy Space Center in Cape Canaveral, Florida, and a subject matter expert for the competition. “Thermoplastics, which are plastic polymers that become moldable when heated, could be obtained from discarded packaging material or even created on Mars using the carbon dioxide atmosphere and hydrogen from water found in the soil. Such concrete materials could also have applications on Earth while using discarded plastic trash.”

The goal of the challenge is to foster the development of technologies to manufacture a habitat using local indigenous materials with, or without, recyclable materials. The vision is that autonomous machines will someday be deployed in deep space destinations, including Mars, to construct shelters for human habitation. On Earth, these same capabilities could be used to produce affordable housing wherever it is needed or where access to conventional building materials and skills are limited.

The 3D-Printed Habitat Challenge is run through a partnership with NASA’s Centennial Challenges Program and Bradley University in Peoria, Illinois. Bradley University has partnered with sponsors Caterpillar, Bechtel and Brick & Mortar Ventures to run the competition.

“These competitors are working to advance critical systems needed for human space exploration,” said Lex Akers, dean of the Caterpillar College of Engineering and Technology at Bradley University. “We are on the edge of developing new, innovative and disruptive ideas that could change our future. This type of work will allow us to explore new ideas as we partner in creating solutions for our world and beyond.”

The challenge comprises three phases: Phase 1, the Design Competition, was completed in 2015. Phase 2, the Structural Member Competition, has three sub-competitions, carries a $1.1 million prize purse and focuses on the material technologies needed to create structural components. The Phase 3 On-Site Habitat Competition has a $1.5 million prize purse, and will focus on automated 3-D print systems to autonomously construct a complete habitat.

Teams will now work toward Phase 2: Level 3, where they will be required to 3-D print a dome structure and provide samples for crush testing. Teams must qualify for this level based on their performance in the previous levels. The event will be open to the public in Peoria on Aug. 25 and 26 through registration.

NASA’s Centennial Challenges program is part of the agency’s Space Technology Mission Directorate, and is managed at NASA’s Marshall Space Flight Center in Huntsville, Alabama. NASA invites the public to participate in prize competitions and challenges to drive innovation and enable solutions in aeronautics and space technology focus areas.

For more information about the competition, visit:

To register for competition and for official rules and documents, visit: