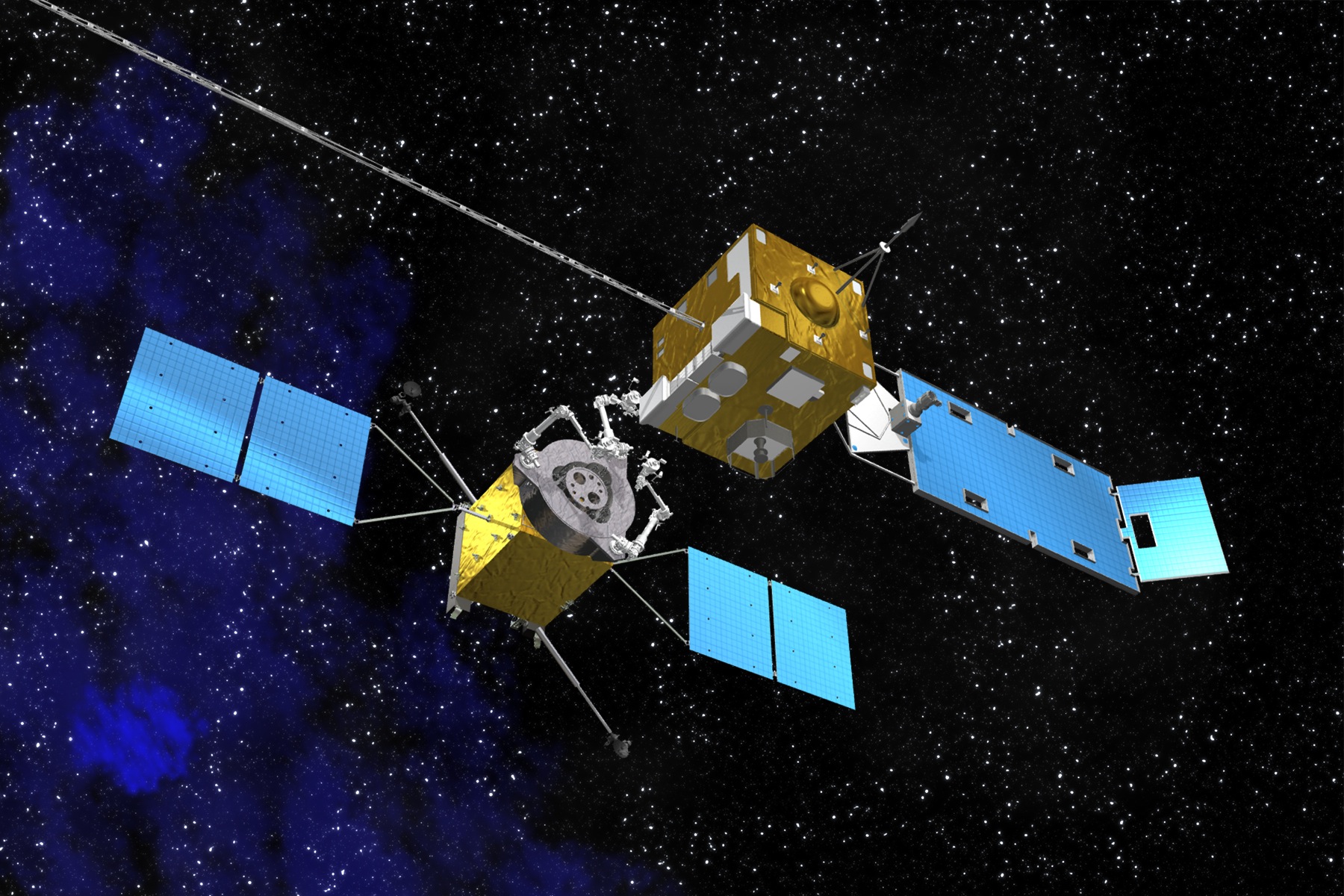

With satellites playing increasingly important roles in everyday life, NASA is developing the technology to build Earth-orbiting, roving “service stations” capable of extending the life of these spacecraft. Engineers at the Kennedy Space Center in Florida are assisting the space agency’s Goddard Space Flight Center in Greenbelt, Md., in developing the concept for bringing a high-technology gas pump, robotic mechanic and tow truck to satellites in space.

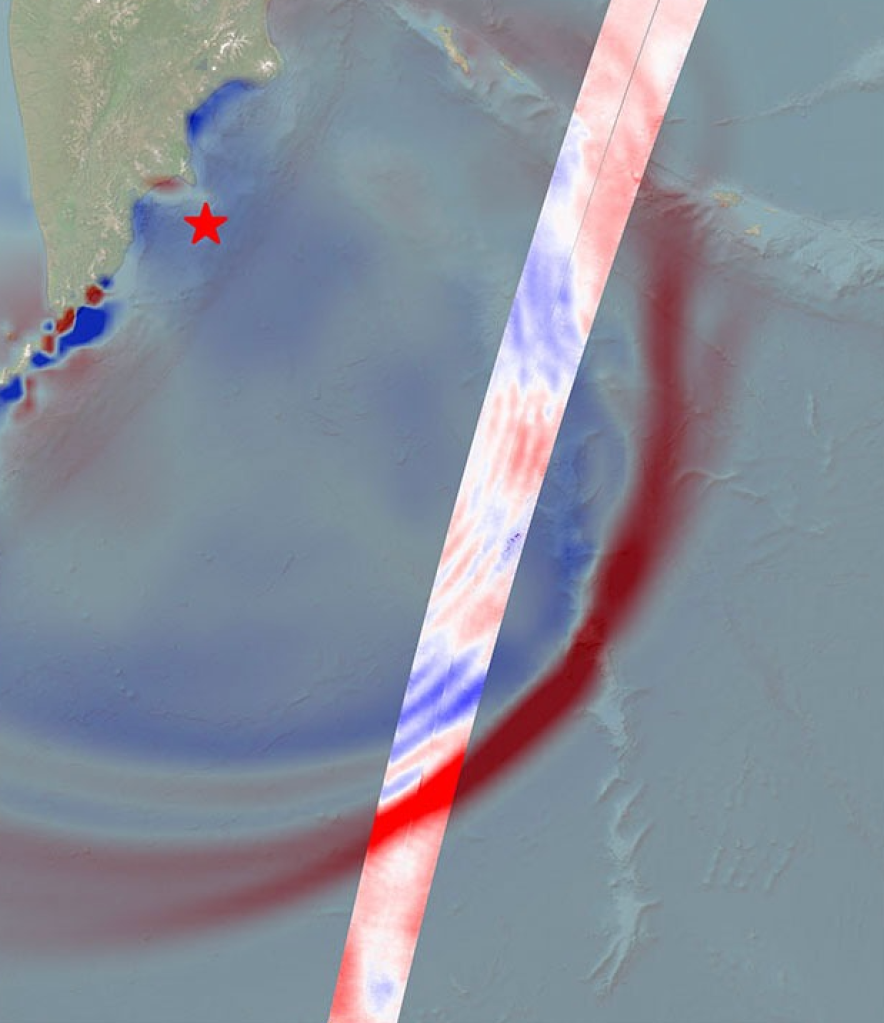

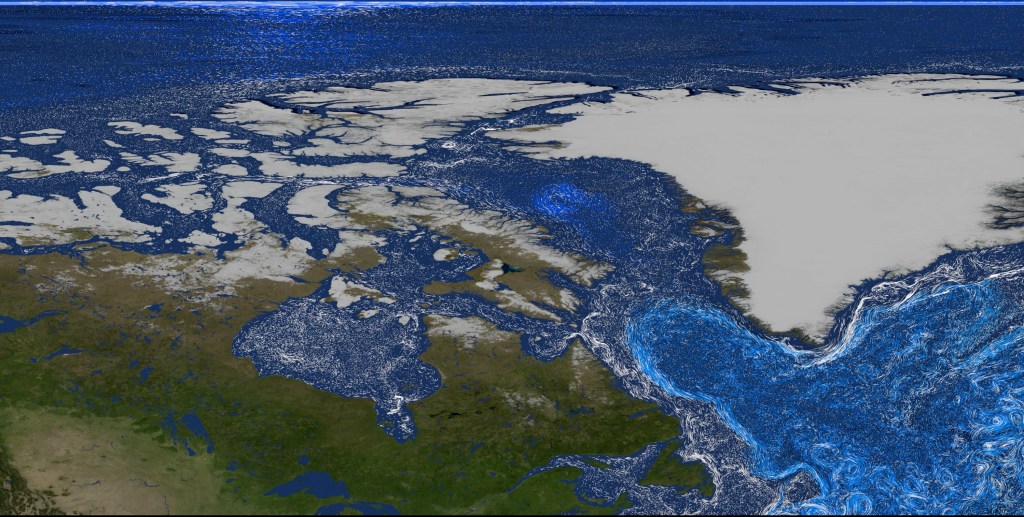

There are 149 government-owned spacecraft and 275 commercial satellites currently in geosynchronous Earth orbit, or GEO, around the Earth. Placed 22,300 miles above the Earth, these satellites play key roles in communications, science, defense and weather monitoring. GEO permits these spacecraft essentially to stay over the same point, allowing for constant coverage of a designated position. This is crucial for satellites relaying meteorology and television signals covering specific portions of the globe.

According to Tom Aranyos, technical integration manager in NASA’s Fluids and Propulsion Division at Kennedy, engineers at the Florida spaceport are supporting the hypergolic propellant refueling portion of the Goddard-led study examining how free-flying servicing spacecraft could expand options in orbit for government and commercial satellite owners.

“America depends on satellites in geosynchronous orbit,” said Aranyos. “These expensive spacecraft eventually develop systems failures or run out of propellant. Servicing and refueling these satellites can keep them operating longer and in the correct orbit, giving the nation and their owners more value for their investment.”

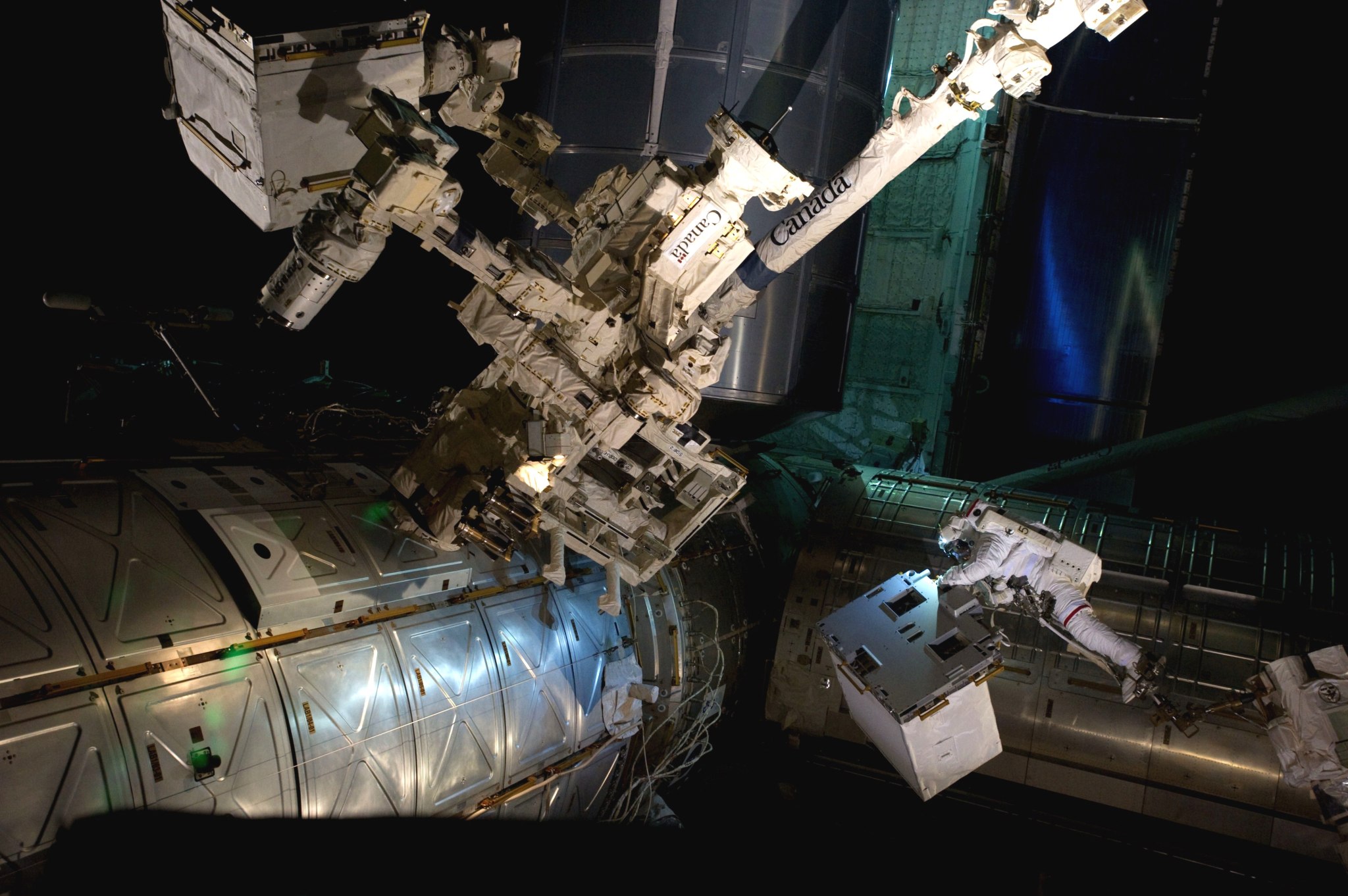

Preliminary work with a technology demonstrator is underway on the International Space Station. The crew of space shuttle Atlantis’ STS-135 flight delivered the Robotic Refueling Mission, or RRM, hardware to the station in July 2011.

During a spacewalk, astronauts Mike Fossum and Ron Garan transferred the RRM onto a temporary platform on the Special Purpose Dexterous Manipulator, also known as Dextre, a two-armed robot developed by the Canadian Space Agency that serves as part of the station’s Mobile Servicing System. RRM now resides on the Express Logistics Carrier 4 platform outside the station.

Designed by the same team that developed the instruments and astronaut tools for the Hubble Space Telescope servicing missions, the four RRM tools cut and manipulate wires, unscrew caps, open and close valves and transfer fluid demonstrating that a remote-controlled robot can service and refuel a satellite in orbit. In March 2012, the 12-food Dextre perfumed the most intricate operation ever attempted by a space robot: cutting two twisted “lock wires,” each 20 thousandths of an inch (0.5 millimeters) in diameter using the RRM Wire Cutter Tool. The RRM refueling demonstration is scheduled to take place on the space station in the fall of 2012. Meanwhile, back on the ground, preparations are ramping up for a second set of activities and task boards to continue RRM operations through 2014.

Goddard’s study and associated development campaign to advance Technology Readiness Levels, or TRLs, of satellite-servicing technologies are the next steps in building capabilities for a fully robotic maintenance vehicle that could service satellites, including those that were not originally intended to be serviced.

Goddard envisions a future in which servicer spacecraft equipped with a state-of-the-art navigation system, enhanced robotic arms and tools and a supply of propellant would be able to autonomously rendezvous and dock with a satellite needing aid. Depending on the type of assistance needed, the servicing spacecraft could perform one of five “R” capabilities: refueling, repositioning, remote survey, component replacement or repairing an ailing satellite. The Goddard development campaign is designed to ensure that the capabilities and technologies are matured, vetted and ready for potential future servicing missions.

“Kennedy, as part of the Goddard team, is studying and performing preliminary tests for the design, development and qualification testing of the critical subsystem for an in-orbit hypergolic propellant transfer system,” said Aranyos, who is leading Kennedy’s technical team for the project. “That will include a pumping system with high metering accuracy and hose management system to transfer propellant to multiple client locations on existing orbiting satellites.”

Since May 2011, Aranyos’ technical team has been developing a highly reliable, leak-free hypergolic propellant transfer module capable of high accuracy metering at high pressure, low flow rates. Hypergolic propellants such as nitrogen tetroxide, hydrazine and monomethyl hydrazine are the propellants most frequently used in satellites.

A key milestone in the Kennedy effort was completed in August with testing of the low-TRL “proof of concept” pump led by Brian Nufer who leads the propulsion subsystem team. NASA engineers working with technicians from Sierra Lobo of Fremont, Ohio, under an institutional support contract to conduct the first simulation of proof-of-concept hardware to see how to pump highly corrosive, toxic, low viscosity (low thickness) and high density nitrogen tetroxide propellant at required transfer pressures.

“The operation was highly successful in that it showed that the experimental system worked as designed,” Aranyos said. “It provided the engineering team with an enormous amount of performance data to better understand how the pump operates and provide lessons learned to be incorporated to the flight pump fabrication and operating procedures.”

In the near future, Kennedy’s engineering team will design and perform functional risk reduction tests on a propellant transfer module similar to a flight-like unit.

“It will be a full-scale engineering development unit,” Aranyos said. “The propellant hose management system which completed initial proof-of-concept testing in May 2012 led by Erik Tormoen, of NASA’s Launch Vehicle Electrical Systems Branch, is planning engineering development unit testing for the second quarter of fiscal year 2013.”

Aranyos is pleased with the progress so far.

“This is a great partnership with Goddard,” he said. “Through most of Kennedy’s history, we have received, processed and launched vehicles developed at other centers. Over our 50-year history, we’ve developed an extensive knowledge base and diverse capabilities. Projects such as this give us an opportunity to put that expertise to work.”