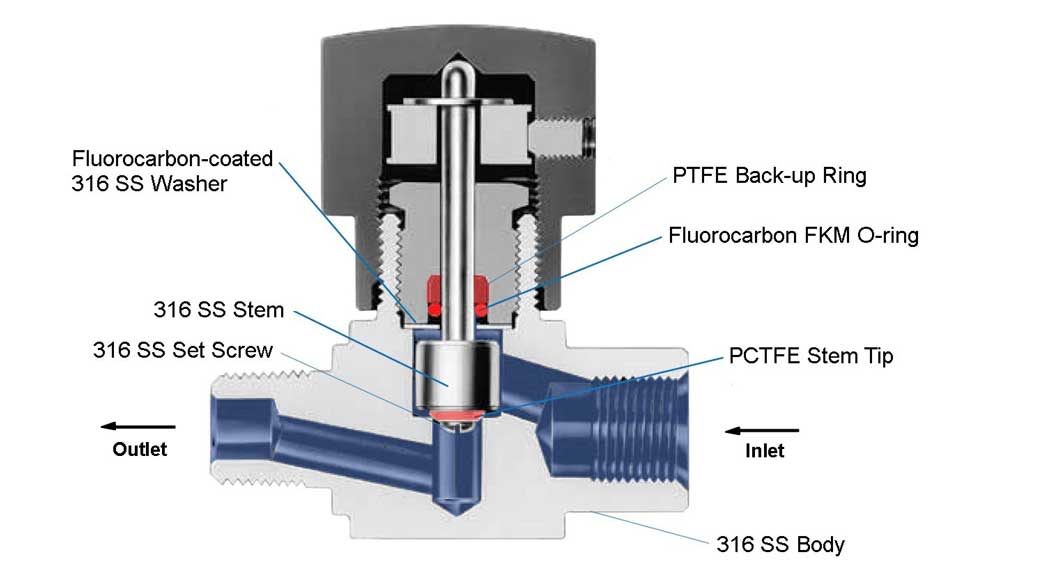

When designing, maintaining, and operating oxygen systems, understanding and preventing the fire hazards decreases the risk of fire and its potential effects on personnel and systems. The oxygen compatibility assessment process provides a systematic approach for identifying fire hazards and may recommend changes to design, materials, and procedures in order to mitigate any fire hazards identified via “Guide for Oxygen Compatibility Assessments on Oxygen Components and Systems“, NASA/TM-2007-213740. There are several component involved in an assessment.

Determine the Worst-Case Operating Conditions

The worst-case operating environment is determined in order to evaluate the ignition and flammability risks for a component or system. Increased oxygen concentration, temperatures, pressures, flow rates, and contamination can intensify ignition and flammability risks. Therefore, quantifying each of these conditions is a prerequisite of analyzing a system or component.

Assess the Flammability of System Materials

The configuration of a system or component can significantly influence the ignitability and flammability of the materials of construction. For example, metals, including those that normally exhibit high resistance to ignition, are more flammable in oxygen when they have thin cross-sections (e.g., thin-walled tubing) or when they are finely divided (e.g., wire mesh or sintered filters).

Evaluate the Presence and Probability of Ignition Mechanisms

An ignition mechanism is a source of heat that under the right conditions can lead to ignition of the materials of construction or contaminants in a system. The most effective way to analyze the ignition risks in a system is to methodically analyze the system for known ignition mechanisms.

Determine the Kindling Chain

The kindling chain, the ability of a fire to propagate and burn through a component, begins when a material is ignited, and the material’s heat of combustion is sufficient to heat and ignite the surrounding materials leading to a burn-through of the component.

Analyze the Reaction Effect

The effects of a fire on personnel, mission, and system objectives are assessed by determining the reaction effect which is the potential loss of life, mission, and system functionality as the result of a fire. The potential consequences of a fire are based on the extent of fire propagation in the materials that surround the component.

Identify the History of Use

The history of use is determined by whether a component has experienced routine operation/cycling in similar or more severe conditions over an extended period of time. History of use is assigned a rating of either successful, negative, or unknown. For example, if a valve has been used in similar or more severe conditions over a period of time then the component may be given a positive rating to indicate a successful history of use.

Report the Results of the Analysis

The results of the compatibility assessment may recommend changes to design, materials, and procedures in order to mitigate the fire hazards identified and includes a listing of the most severe hazards and suggested mitigation. Ignition risks can be minimized by controlling heat sources and using materials that will not ignite or will not support burning in the end-use environment.

3 min read