In This Week’s Star

- New Life Sciences Glovebox, Managed at Marshall, to Fly to Space Station Sept. 10

- ‘Big Voice Test’ Prepares New Support Center for First SLS Launch

- New NASA Competition Aims to Convert Carbon Dioxide into Exploration Sweet Success

- Marshall Tackles Hunger with Feds Feeds Families Campaign

- This Week in NASA History: OSIRIS-Rex Launches – Sept. 8, 2016

- NASA’s New Horizons Spacecraft Highlighted on ‘This Week @NASA’

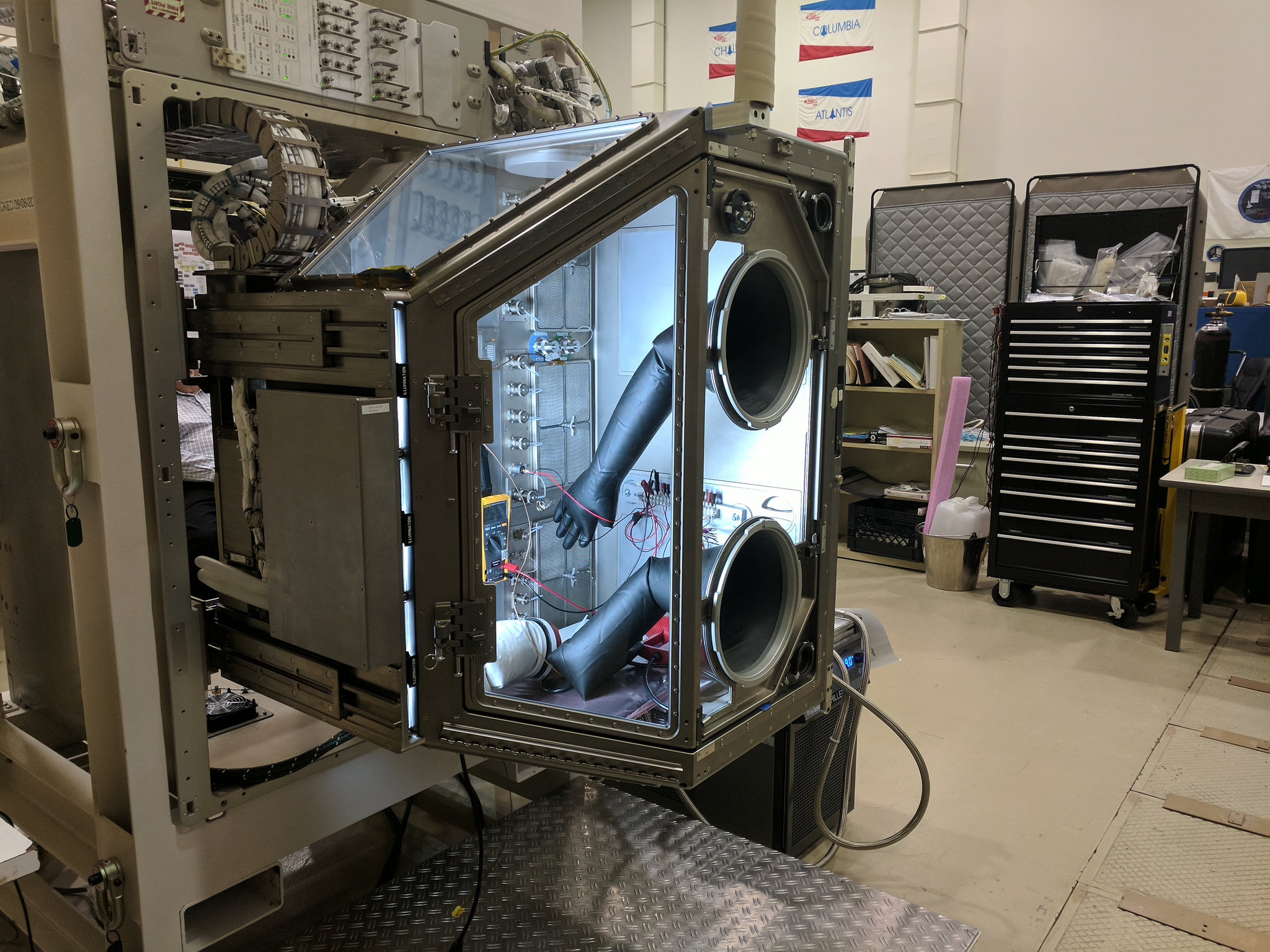

New Life Sciences Glovebox, Managed at Marshall, to Fly to Space Station Sept. 10

By Rick Smith

NASA and its Japan Aerospace Exploration Agency partners will launch the state-of-the-art microgravity research facility, the Life Sciences Glovebox, Sept. 10 — commencing its journey to expedite new research on the International Space Station.

Liftoff is scheduled for 5:32 p.m. CDT from Tanegashima Space Center off the coast of Japan. The glovebox will be lofted to space via a Japanese H-IIB rocket hauling the HTV-7, or Kounotori 7, transfer vehicle — an uncrewed cargo carrier delivering equipment and supplies to the station.

The Life Sciences Glovebox primarily will be used to study the long-term impact of microgravity on human physiology, revealing new ways to protect human explorers on space missions — while also aiding in advances to improve life on Earth.

“The teamwork and global partnership that delivered this innovative, mission-critical hardware have been simply amazing,” said Chris Butler, payload integration manager for the Life Sciences Glovebox at NASA’s Marshall Space Flight Center. “We can’t wait to see it launched and installed on station to enable more high-value biological and physical science experiments, with untold benefits on and off-world.”

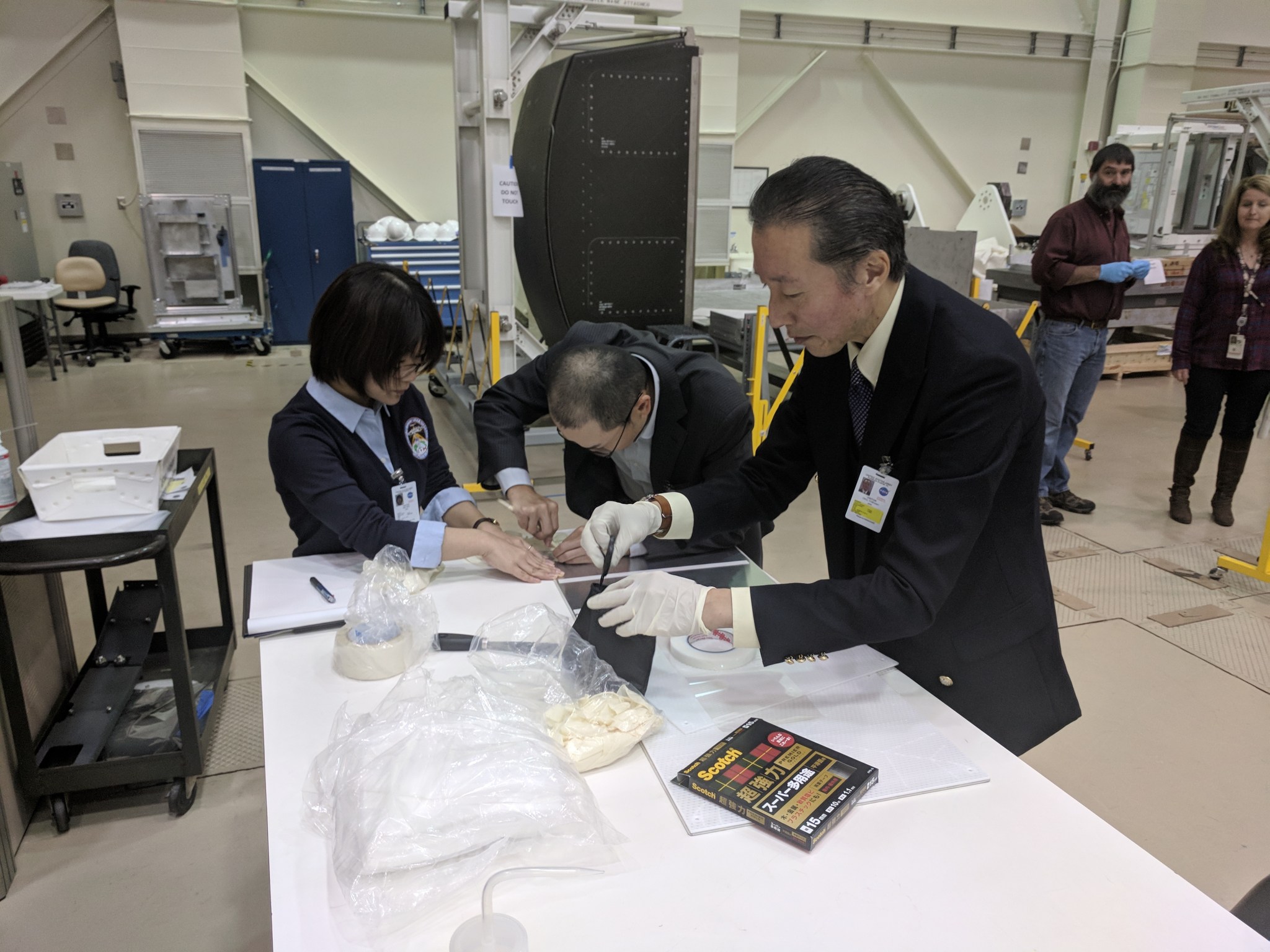

Its launch will mark an unusual first. The glovebox will be packed in a refrigerator-freezer rack modified by Boeing engineers to accommodate the core facility and a cushioning foam clamshell. This “soft-stowed” approach — packing hardware in protective foam and securely containing it for launch — isn’t new; it’s an efficient, low-cost alternative to the conventional approach of hard-mounting flight hardware inside the launch vehicle. But the Life Sciences Glovebox, bulkier than most standard space station science gear, is officially the largest piece of flight hardware ever to be soft-stowed for launch.

“Participating engineers and researchers from our partner organizations around the world came to Huntsville to conduct fit-check tests of the hardware, ensuring a successful soft-stowage,” Butler said. “Successfully flying such a large piece of equipment may open up new possibilities for other oversized flight hardware.”

The new experiment facility itself will be a welcome addition on the space station, reducing the workload on its veteran cousin, NASA’s Microgravity Science Glovebox. Installed on the station in 2002, that workhorse facility remains in high demand by researchers around the world, said Susan Spencer, deputy project manager at Marshall.

“For 15 years, the Microgravity Glovebox has been constantly in use and constantly in demand,” Spencer said. “It was clear we needed to relieve the congestion, providing a second facility to better serve the research community competing for experiment time.”

Built several years ago by JAXA and the Dutch firm Bradford Engineering, the glovebox effort was revived in 2017. The partners updated heritage hardware and prepared the new glovebox for flight. Engineers at Marshall contributed the facility’s secondary support structure and its thermal control and power control systems, and designed its power supply, air filtration, lighting, video and data recording and real-time downlink capability.

Roughly the size of a large fish tank, the glovebox has 15 cubic feet of workspace and multiple access points, permitting up to two station crew members to simultaneously conduct one or more experiments. Biologists and other researchers back on Earth can continuously oversee and participate in their experiments. The new glovebox will be housed in a zero-gravity stowage rack in the space station’s Kibo module.

The glovebox’s avionics package and ancillary hardware flew in June as part of a SpaceX commercial resupply mission to the space station.

NASA expects to begin using the glovebox for experiments before the end of 2018.

Marshall manages the Life Sciences Glovebox and Microgravity Science Glovebox for NASA. Marshall also monitors station science and communications from its Payload Operations Integration Center, supporting the ISS Research Integration Office at NASA’s Johnson Space Center. Learn more here.

Smith, an ASRC Federal/Analytical Services employee, supports Marshall’s Office of Strategic Analysis & Communications.

‘Big Voice Test’ Prepares New Support Center for First SLS Launch

Engineers Fred Whisnant and Jennifer Vollmer check out communication systems during a big voice test Aug. 21 at the Space Launch System Engineering Support Center in the Huntsville Operations Support Center at NASA’s Marshall Space Flight Center. The test verified that all systems are “go” when it comes to voice communications for the first integrated flight of the SLS deep space rocket and the Orion spacecraft: Exploration Mission-1. During the test, participants used headsets and voice loops to communicate with 13 locations across America, including NASA’s Johnson Space Center, NASA’s Kennedy Space Center and the U.S. Air Force’s Patrick Air Force and Cape Canaveral Air Force Station, as well as many NASA contractor sites around the country. The support center allows experts who designed and built SLS to work together, saving agency resources by minimizing the need for travel to the Kennedy launch site. Leading up to launch, the Marshall team, along with teams from Johnson and Kennedy, will conduct numerous tests to verify video, data and other systems in the new mission support room. In addition to the voice tests, Orion recently completed a series of tests to ensure the spacecraft and mission controllers at Johnson can flawlessly communicate through NASA’s satellite networks in space and on the ground when Orion and its crew are far from Earth on missions to the Moon and beyond. These tests will culminate in full-up mission simulations to ensure engineers and technicians from across the country are virtually connected during the countdown, launch and flight of the world’s most powerful rocket and the Orion spacecraft.

Image credit: NASA/Tyler Martin

New NASA Competition Aims to Convert Carbon Dioxide into Exploration Sweet Success

By Janet Sudnik

When future astronauts begin exploring Mars, they’ll need to make use of local resources, freeing up cargo space for other mission-critical supplies. Carbon dioxide is one such resource that is readily abundant within the Martian atmosphere.

NASA’s new CO2 Conversion Challenge, conducted under the Centennial Challenges program, which is managed at Marshall Space Flight Center, is a public competition seeking novel ways to convert carbon dioxide into useful compounds. Such technologies will allow us to manufacture products using local, indigenous resources on Mars, and can also be implemented on Earth by using both waste and atmospheric carbon dioxide as a resource.

“Enabling sustained human life on another planet will require a great deal of resources and we cannot possibly bring everything we will need. We have to get creative.” said Monsi Roman, Centennial Challenges program manager. “If we can transform an existing and plentiful resource like carbon dioxide into a variety of useful products, the space — and terrestrial — applications are endless.”

Carbon and oxygen are the molecular building blocks of sugars. Developing efficient systems that can produce glucose from carbon dioxide will help advance the emerging field of biomanufacturing technology on Earth.

While sugar-based biomaterials are inexpensively made on Earth by plants, this approach cannot be easily adapted for space missions because of limited resources such as energy, water and crew time. The CO2 Conversion Challenge aims to help find a solution. Energy rich sugars are preferred microbial energy sources composed of carbon, hydrogen and oxygen atoms. They could be used as the feedstock for systems that can efficiently produce a variety of items. Glucose is the target sugar product in this challenge because it is the easiest to metabolize, which will optimize conversion efficiency.

The competition is divided into two phases. During Phase 1, teams must submit a design and description of a conversion system that includes details of the physical-chemical approaches to convert carbon dioxide into glucose. NASA will award up to five teams $50,000 each, to be announced in April 2019. Phase 2, the system construction and demonstration stage, is contingent on promising submissions in Phase 1 that offer a viable approach to achieving challenge goals. Phase 2 will carry a prize purse of up to $750,000, for a total challenge prize purse of $1 million.

The Centennial Challenges program, part of NASA’s Space Technology Mission Directorate, bridges the innovation gap between NASA and the nation by stimulating research and technology solutions inside and outside of the traditional aerospace community. The program offers incentive prizes to generate revolutionary solutions to problems of interest to NASA and the nation. Centennial Challenges is managed at NASA’s Marshall Space Flight Center.

Sudnik, an ASRC Federal/Analytical Services employee, supports the Office of Strategic Analysis & Communications.

Marshall Tackles Hunger with Feds Feeds Families Campaign

By Morgan MacMillan

NASA Marshall Space Flight Center team members are encouraged to participate in the annual Feds Feed Families campaign — a nationwide effort by federal agencies to collect millions of pounds of non-perishable food items for those in need. The food drive, which began Aug. 20, is intended to serve local communities.

All Marshall donations will be delivered to the Food Bank of North Alabama for distribution. Marshall’s Office of Human Capital is challenging the workforce to donate a combined 30,000 pounds of canned goods and other non-perishable food items. No money will be collected for the campaign.

Organization representatives will collect and drop donations off at a centralized location through Oct. 16.

For more information, including a list of organization representatives and food donation updates, please visit ExplorNet or contact the Feds Feed Families lead, Mat Park.

MacMillan, an ASRC Federal/Analytical Services employee, supports the Office of Strategic Analysis & Communications.

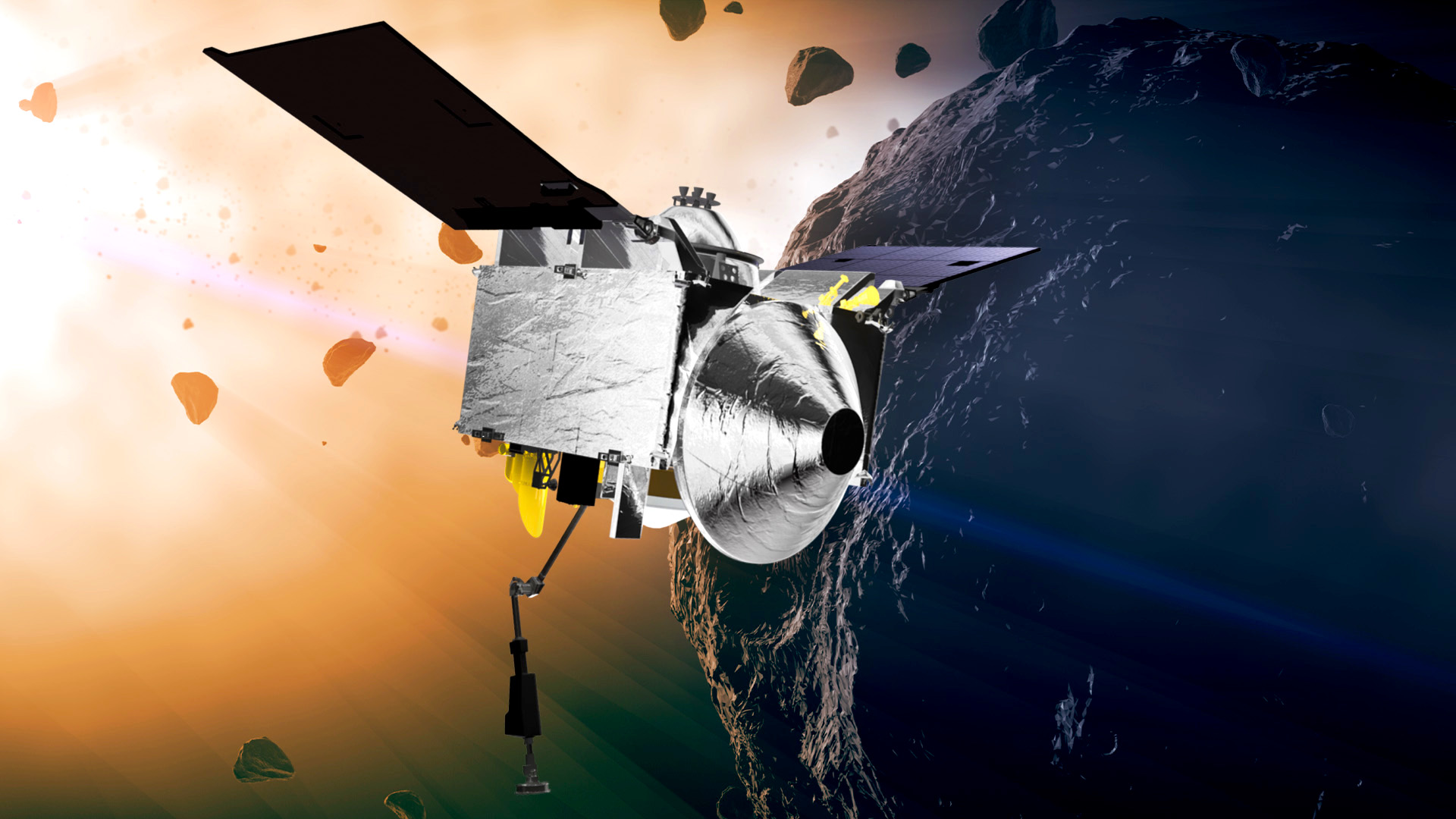

This Week in NASA History: OSIRIS-Rex Launches – Sept. 8, 2016

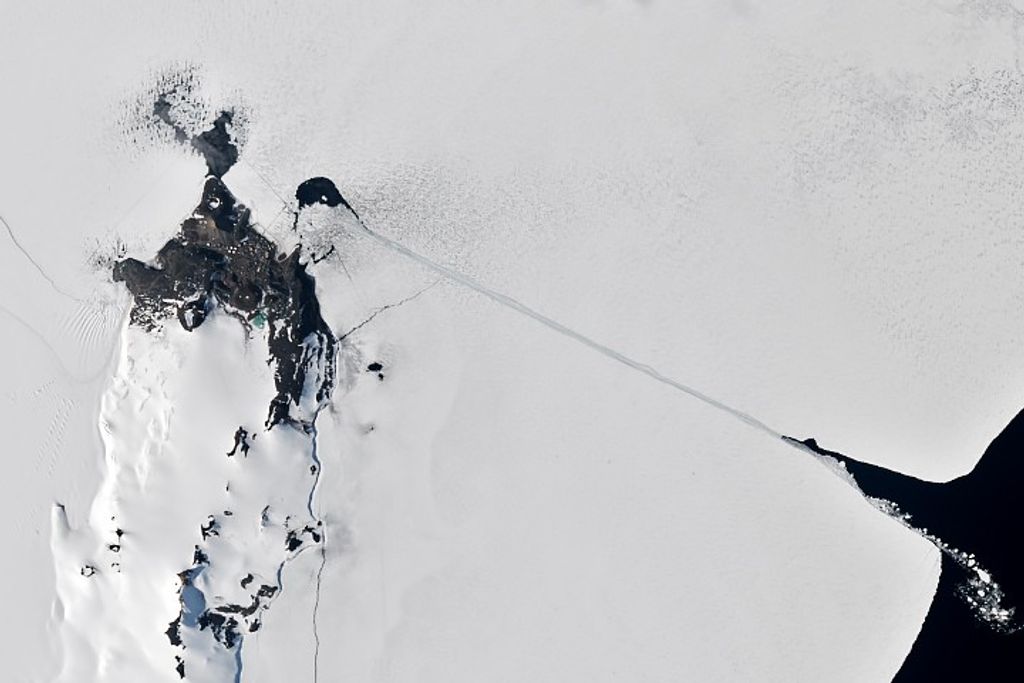

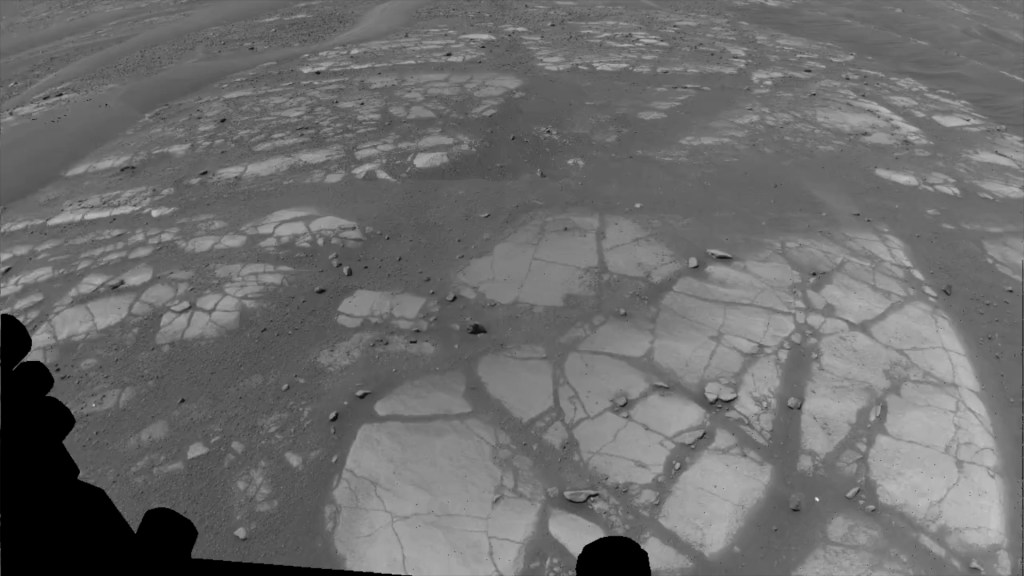

This week in 2016, OSIRIS-Rex — the Origins, Spectral Interpretation, Resource Identification, and Security-Regolith Explorer — spacecraft was launched aboard an Atlas V rocket from Cape Canaveral Air Force Station. OSIRIS-Rex will be the first U.S. mission to sample an asteroid, retrieve at least two ounces of surface material and return it to Earth for study. In this illustration, OSIRIS-Rex approaches the asteroid Bennu. OSIRIS-REx is the third mission in the agency’s New Frontiers Program, which is managed by NASA’s Marshall Space Flight Center. The NASA History Program is responsible for generating, disseminating, and preserving NASA’s remarkable history and providing a comprehensive understanding of the institutional, cultural, social, political, economic, technological and scientific aspects of NASA’s activities in aeronautics and space. For more pictures like this one and to connect to NASA’s history, visit the Marshall History Program’s webpage. (NASA)

NASA’s New Horizons Spacecraft Highlighted on ‘This Week @NASA’

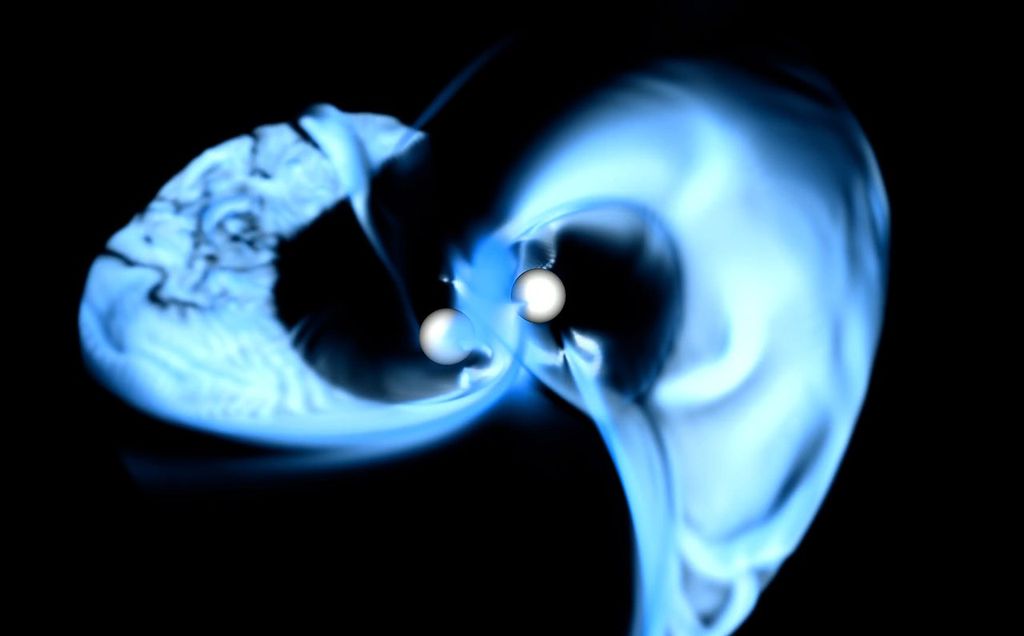

NASA’s New Horizons spacecraft captured its first image of its Kuiper Belt target, and that story is featured in the latest edition of “This Week @NASA,” a weekly video program broadcast nationwide on NASA-TV and posted online.

NASA’s New Horizons spacecraft has made its first detection of the Kuiper Belt object it is scheduled to flyby on New Year’s Day, 2019. The small, dim object — nicknamed Ultima Thule — was detected by the spacecraft’s telescopic Long Range Reconnaissance Imager from a distance of more than 100 million miles. The flyby will be the first-ever close-up exploration of a small Kuiper Belt object and the farthest exploration of any planetary body in history, shattering the record New Horizons itself set at Pluto in July 2015 by about 1 billion miles. The Kuiper Belt is a ring of icy objects around the Sun that extends just beyond the orbit of Neptune and includes Pluto.

NASA’s Marshall Space Flight Center manages New Horizons as part of the New Frontiers Program.

View this and previous episodes at “This Week @NASA” on NASA’s YouTube page.