In This Week’s Star

- Marshall Strives to Inspire New Rover Challenge Teams With Educator Workshop

- Three Expedition 55 Crewmates Welcomed Aboard International Space Station

- Look Inside NASA’s Exploration Mission-1 Rocket

- Essential to the Mission: Adesh Singhal

- Marshall Showcases Safety at Shared Experiences with Bobby Watkins

- This Week in NASA History: Saturn I SA-4 Launches – March 28, 1963

- 3-D Printed Rocket Engine Nozzle Technology Highlighted on ‘This Week @NASA’

- Obituaries

Marshall Strives to Inspire New Rover Challenge Teams With Educator Workshop

By Rick Smith

NASA’s Marshall Space Flight Center is preparing for the NASA Human Exploration Rover Challenge, in which student teams — as many as 100 of them from around the world — will converge on the U.S. Space & Rocket Center April 13-14 to pit lightweight vehicles of their own design against a series of tasks echoing science and engineering challenges facing future planetary explorers.

On April 13, organizers also will welcome some 30 American educators with no previous “rovernaut” experience. They’re participants in NASA’s Rover Challenge Workshop, seeking to excite their pupils at schools around the country about the competition — and potentially inspire students to pursue career opportunities in engineering, science and space exploration.

“Our goal is to show off the competition firsthand to educators who’ve demonstrated an interest in participating,” said Mona Miller, Rover Challenge project manager at Marshall. “Bringing them out to experience all that energy and exhilaration is a great way to show them the payoff for the long hours of development, construction and testing that their students and faculty advisors will undertake.”

It’s an exhilarating proposition indeed. High schools compete in one division, colleges and universities in another, taking on the 24-year-old competition’s carefully designed, grueling half-mile course, which includes new obstacles and challenges for 2018.

Teams start in the fall, designing and building human-powered rovers to be piloted by one male and one female driver. Each team will have six minutes to tackle 14 obstacles, such as sand traps and rocky “extraterrestrial” terrain, and five tasks new in 2018 — from flag-planting to sample retrieval and deployment of a science instrument. Then drivers have one final minute to reach home base before their simulated on-board oxygen supply runs out. If they exceed the seven-minute time limit, all points are lost.

As teams compete, educators taking part in the Rover Challenge workshop will mingle with veteran competitors and event planners, discussing rover construction techniques, competition rules and other aspects of the challenge. But Miller is most excited for them to witness the event itself. Marshall organized similar introductory workshops in 2016 and 2017, she said, but both were held independently of the actual competition.

“Bringing workshop participants here to ‘Rocket City’ to watch the Rover Challenge firsthand is going to be crucial,” she said. “We believe it will inspire them to participate next year, and that it will help ensure that new ranks of dreamers and doers become passionate about aerospace careers.”

The competition, she noted, is designed to do just that — addressing practical engineering problems much like those faced by NASA workers preparing for space exploration missions.

“The competition teaches students to troubleshoot and solve problems the way NASA teams do,” she said. “It’s no longer just a timed race. Students must analyze the course and decide which challenges to tackle to accrue points, leaving enough time to complete their journey, beat the countdown and achieve mission success.”

The one-day Rover Challenge workshop is sponsored by NASA Headquarters, which will cover expenses for a designated faculty advisor and an administrator from each institution. The competition itself is organized by Marshall’s Academic Affairs Office and sponsored by NASA’s Human Exploration and Operations Mission Directorate. The U.S. Space & Rocket Center hosts the competition each year.

Smith, an ASRC Federal/Analytical Services employee, supports the Office of Strategic Analysis & Communications.

Three Expedition 55 Crewmates Welcomed Aboard International Space Station

The Soyuz MS-08 spacecraft docked to the Poisk module of the International Space Station March 23 at 2:40 p.m. CDT while both spacecraft were flying over Serbia.

Following their two-day trip, NASA astronauts Drew Feustel and Ricky Arnold and cosmonaut Oleg Artemyev of Roscosmos docked to the space station. The three new crew members were welcomed aboard later in the day when the hatches between the two spacecraft opened at 4:48 p.m. CDT. The trio launched aboard the Soyuz MS-08 rocket from the Baikonur Cosmodrome in Kazakhstan on March 21.

They join Scott Tingle of NASA, Commander Anton Shkaplerov of Roscosmos and Norishige Kanai of the Japan Aerospace Exploration Agency aboard the orbiting laboratory. The crew members will spend more than five months conducting about 250 science investigations in fields such as biology, Earth science, human research, physical sciences and technology development.

Shkaplerov, Tingle and Kanai are scheduled to remain aboard the station until June 2018, while Feustel, Arnold and Artemyev are slated to return to Earth in August.

This crew continues the long-term increase in crew size on the U.S. segment from three to four, allowing NASA to maximize time dedicated to research on the space station. Highlights of upcoming investigations include: a new facility to test materials, coatings and components of other large experiments in the harsh environment of space; a study on the effects of microgravity on bone marrow and blood cells produced in bone marrow; and a newly developed passive nutrient delivery system for the Vegetable Production System plant growth facility.

Learn more about station activities by following @space_station and @ISS_Research on Twitter as well as the ISS Facebook and ISS Instagram accounts.

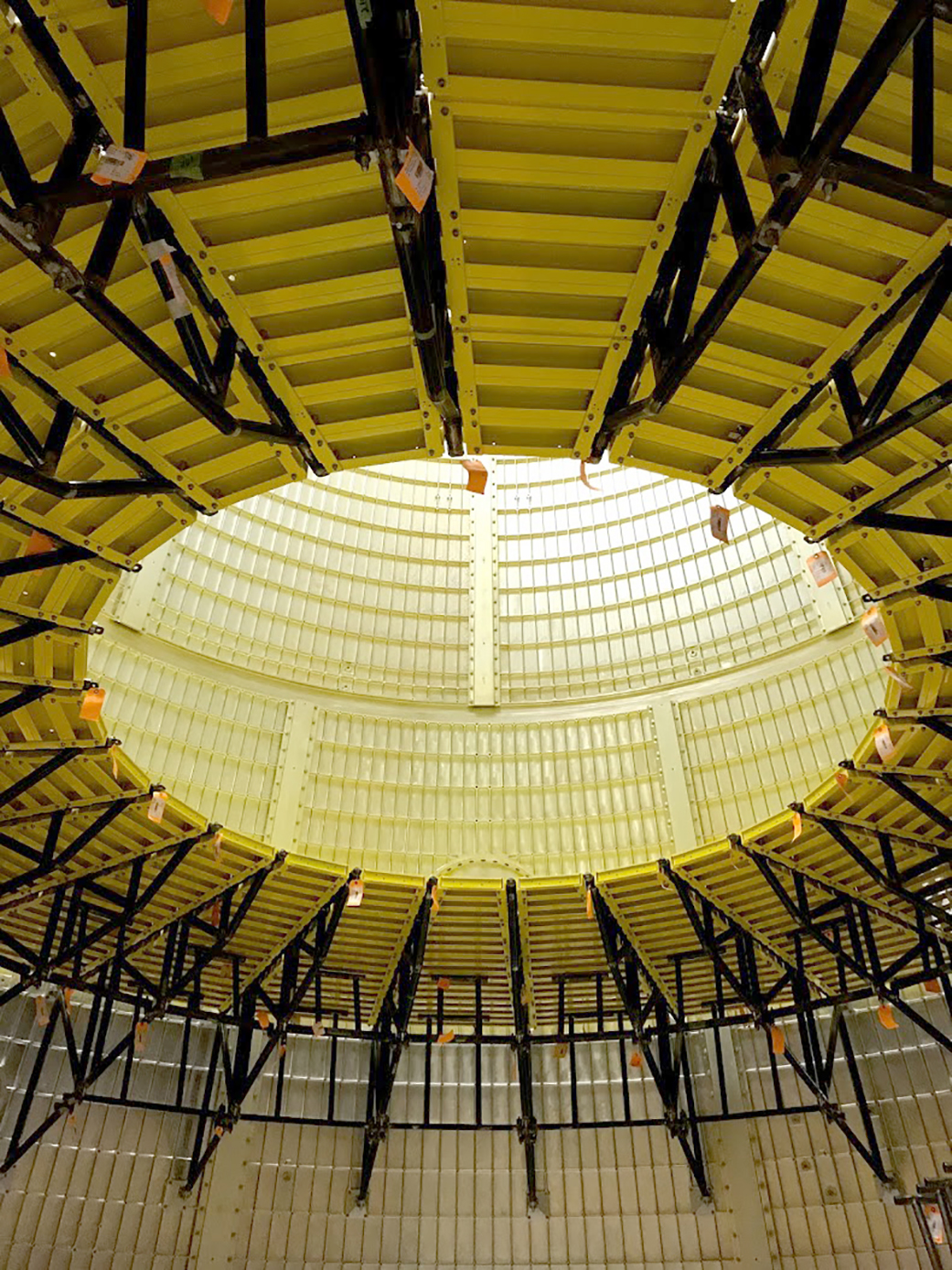

Look Inside NASA’s Exploration Mission-1 Rocket

While the outside of NASA’s new deep-space rocket, the Space Launch System, often gets all the glory, the inside works hard too. NASA is busy outfitting the rocket with what it needs for Exploration Mission-1, the first integrated mission of SLS and the Orion spacecraft. Engineers installed two sets of work platforms inside the rocket’s launch vehicle stage adapter. The adapter connects the rocket’s core stage with the interim cryogenic propulsion stage, which will fire its engine to send Orion into lunar orbit. SLS is the only rocket that can send Orion with its crew to the Moon. Future upgrades to SLS will enable the rocket to launch both Orion with its crew and a large amount of cargo to lunar orbits on a single mission. This picture shows platforms inside the launch vehicle stage adaptor that will allow technicians at NASA’s Kennedy Space Center access to the stage while the rocket is on the launch pad. The cone-shaped adapter, which measures 28 feet tall and tapers from about 27.5 feet at the bottom to 16.5 feet at the top, was built by SLS prime contractor Teledyne Brown Engineering in an advanced manufacturing facility at NASA’s Marshall Space Flight Center. NASA’s Pegasus barge will take the adapter to Kennedy for launch where it will join the interim cryogenic propulsion stage, which was delivered in 2017. (NASA/MSFC: Amy Buck)

Essential to the Mission: Adesh Singhal

By Jonathan Deal

Some of the world’s most cutting-edge research is performed daily by NASA astronauts aboard the International Space Station. Before those complex scientific experiments can be carried out in space, researchers at NASA’s Marshall Space Flight Center test those experiments here on Earth.

It’s the responsibility of Adesh Singhal, an engineer in the International Space Station Projects Office of Marshall’s Human Exploration Development and Operations Office to coordinate, facilitate and schedule these experiments at Marshall.

As project manager for research, planning and integration in the payload office, Singhal coordinates testing of these science payloads to ensure they will work properly before they launch to the space station. She works closely with payload developers as well as Marshall’s Huntsville Operations Support Center, Payload Operations Integration Center and Space Station Integration Test Facility to conduct successful testing of these payloads.

“At the Space Station Integration Test Facility, we simulate the International Space Station interfaces and databases for Microgravity Science Glovebox and EXPRESS Rack payloads. That allows us to simulate the power and command and data handling of what the individual payloads will experience on the space station,” she said. “We want to make sure — before these experiments are launched — that they will not cause any harm to our existing station systems. We also want to make sure they will operate successfully to achieve their science objectives and complete the research.”

Singhal began her career at NASA’s Glenn Research Center in 1995, supporting microgravity science experiments before joining Glenn’s Space Communication Office. In 2003, she had a chance to move to Marshall, where she joined the Flights Projects Office, working with the integration of space station elements and the completion of the space station.

Since 2005, Singhal has been a part of the International Space Station Projects Office, coordinating and scheduling the payload testing that is performed at Marshall.

“It’s a really a very fulfilling experience to be able to work with such a diverse team of engineers, system leads and payload developers from different industries, universities and other NASA centers. We have a common goal to make these research payloads successful, so it’s a really fun and fulfilling experience. I’m happy to be here every day,” she said.

During her career at NASA, Singhal has traveled to NASA’s Kennedy Space Center to witness space shuttle launches, and even played a role in the completion of the space station — traveling to NASA’s Johnson Space Center to work in mission control for integration of space station hardware during the station’s completion.

“I had a chance to see astronauts build the space station piece by piece,” she said. “I worked the third shift and you could look up at the screens and see Earth going by every 90 minutes. It makes you realize just how fragile our planet is and how the space station is the only platform that provides this opportunity for research. It’s amazing to be part of that.”

Deal, an ASRC Federal/Analytical Services employee and Marshall Star Editor, supports the Office of Strategic Analysis & Communications.

Marshall Showcases Safety at Shared Experiences with Bobby Watkins

Bobby Watkins, director of the Human Exploration Development and Operations Office at NASA’s Marshall Space Flight Center, highlights the importance of benefitting from both successes and failures by sharing personal career experiences and lessons learned from previous missions at the March 22 Shared Experience forum. Shared Experiences is part of Marshall’s Mission Success is in Our Hands initiative, sponsored by the Safety & Mission Assurance Directorate. The initiative seeks to help team members make meaningful connections between their jobs and the safety and success of NASA missions and is made possible through a partnership between Marshall and Jacobs Engineering. (NASA/MSFC/Emmett Given)

This Week in NASA History: Saturn I SA-4 Launches – March 28, 1963

This week in 1963, the Saturn I SA-4 flight launched from NASA’s Kennedy Space Center. SA-4 was an uncrewed test flight of the Saturn I booster. One-hundred seconds into flight, a pre-set timer disabled engine number 5 to test the “engine-out” capability of the booster. Fuel was successfully rerouted to the other seven engines and the flight continued, completing the Block 1 Saturn tests. Managed by NASA’s Marshall Space Flight Center, the Saturn I vehicle and its follow-on, the Saturn IB, served as test-bed rockets for the larger and more powerful Saturn V that would eventually carry the first humans to the Moon. Today, Marshall is developing NASA’s Space Launch System, the most powerful rocket ever built, capable of sending astronauts to the Moon, Mars and deeper into space than ever before. The NASA History Program is responsible for generating, disseminating and preserving NASA’s remarkable history and providing a comprehensive understanding of the institutional, cultural, social, political, economic, technological and scientific aspects of NASA’s activities in aeronautics and space. For more pictures like this one and to connect to NASA’s history, visit the Marshall History Program’s webpage. (NASA)

3-D Printed Rocket Engine Nozzle Technology Highlighted on ‘This Week @NASA’

A 3-D printed rocket engine nozzle, developed using a new additive manufacturing technique at NASA’s Marshall Space Flight Center, is featured in “This Week @NASA,” a weekly video program broadcast nationwide on NASA-TV and posted online.

A team of engineers at Marshall has developed and tested a new 3-D printing technique that can greatly reduce the cost and time needed to make rocket engine nozzles. This new technology, which could reduce manufacturing time from several months to several weeks, is now being licensed and considered in commercial applications across the industry.

View this and previous episodes at “This Week @NASA” on NASA’s YouTube page.

Obituaries

Charles L. Chisam, 86, of Huntsville, died March 16. He retired from the Marshall Center in 1987 an electronic technician.