2013 CIF Winner details

For the full list of winners, please visit:

https://www.nasa.gov/ames-cct/cif/cif-archive

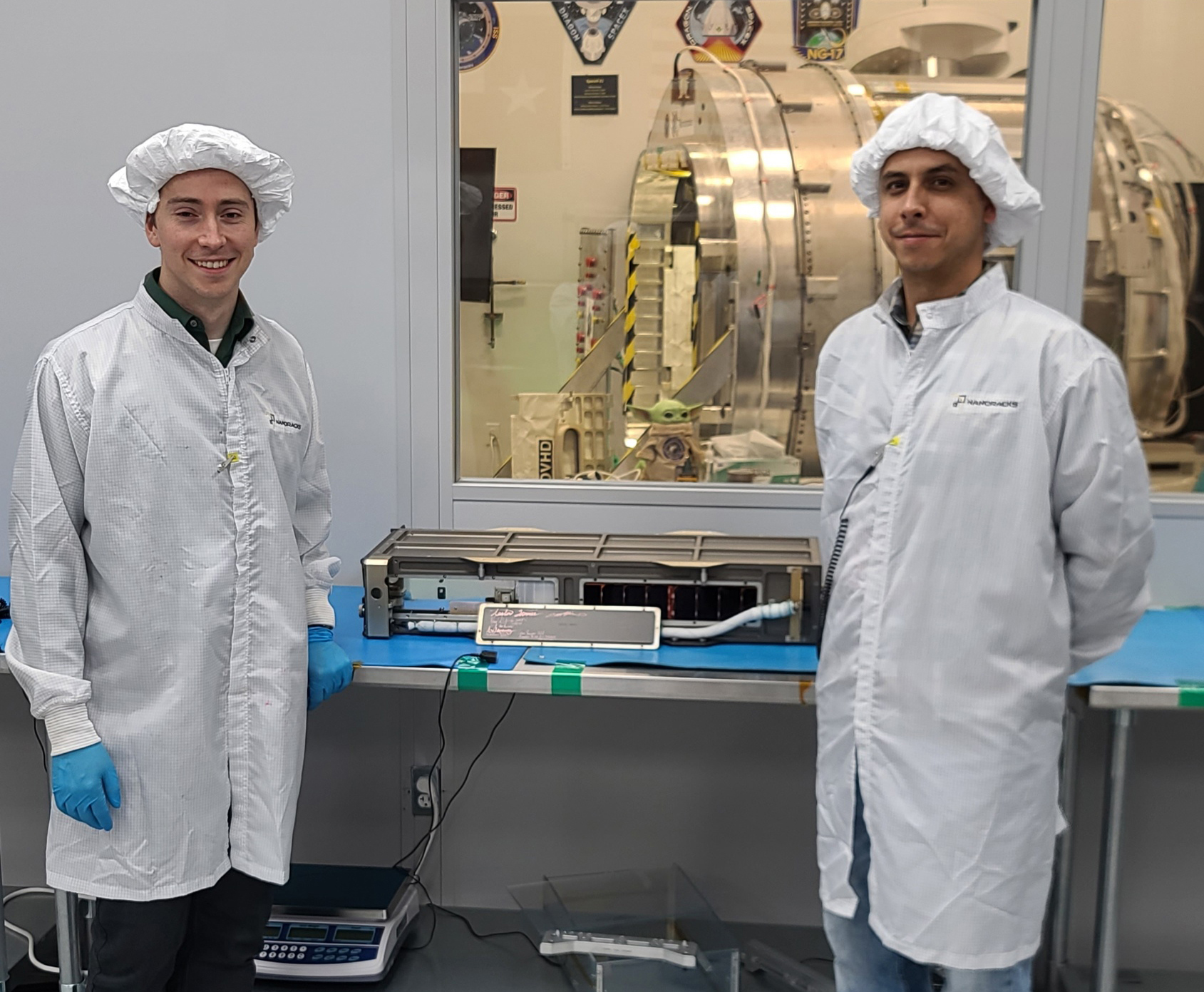

Micro-cathode Arc Thruster PhoneSat Experiment

Principle Investigator: Elwood Agasid

Increased launch opportunities and the rapid pace of technology development have paved the way for small satellites to become an accepted platform for conducting research by the scientific space community as well as supporting space mission operations. A safe, easy to integrate micro-propulsion system is highly desired and would further enable the small satellite platform to support an even more diverse array of missions, including inter-planetary, earth observation, proximity operations, communications as well as technology validation.

The goal of this project is to integrate multiple micro-cathode arc thrusters, under development at George Washington University, with the Phonesat bus avionics to demonstrate commanding of the thrusters for Attitude control and orbit maneuvers. The micro-cathode arc thruster is a low mass, low volume, chemically inert propellant thruster that mitigates the hazards normally associated with chemical reactivity or pressurized gas based systems. The micro-cathode arc thruster has a predicted isp of 2000-3000 sec with a Delta V=300m/s for 3 Kg satellite and 30 gr of propellant. The Phonesat team will develop an Adroid App to control four thrusters and test the integrated system in a vacuum chamber.

Deployable Telescope for Compact Spectropolarimeter

Principal Investigator: Kimberly Ennico Smith

Co-Investigators: Abraham Rademacher, Dana Lynch, Amanda Cook

With this Center Innovation Fund we are evaluating the optical and mechanical performance of a collapsible Cassegrain telescope for use as a fore-optic to a compact spectropolarimeter. This effort builds upon previous design work by the NASA Ames Research Center’s Small Spacecraft Division on their mechanical-deployment mechanism for a collapsible 152.4mm diameter f/8 Ritchey-Chretien telescope for a 6U (a “U” is a 10-cm cube) spacecraft with an imager as the payload [1]. The 6U spacecraft measures approximately 30 cm x 20 cm x 10 cm. Deployable larger aperture high-throughput telescopes enable scientific investigations on a small spacecraft platform that would otherwise have required larger packaging environments.

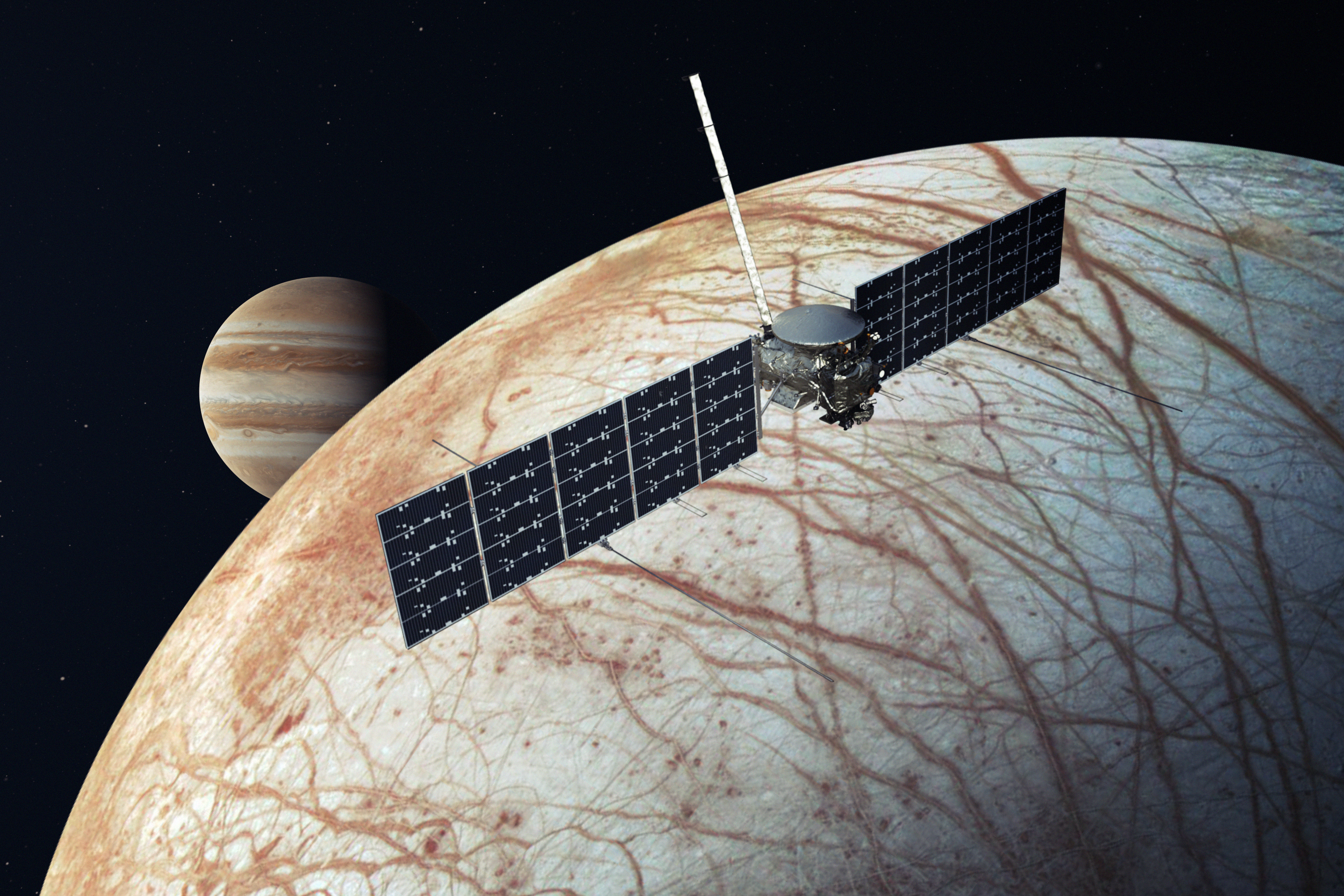

Our spectropolarimeter design requires a high-throughput entrance aperture. Obtaining a smallsat-compatible packaging for a telescope and spectropolarimeter provides a unique instrument for future astrobiology remote sensing applications of Earth, Mars, outer planet icy moons, and biosignature studies of exoplanets. Prior to this effort, our baseline aperture diameter for our instrument compatible with a small-sat architecture was 76.2 mm (3-inch). This new collapsible telescope design potentially increases our collecting area by a factor of four, doubling the aperture diameter.

Our efforts to date have focused on evaluating designs that meet the following requirements for our science instrument application:

- The telescope shall have at least a 91.6 cm2 unobscured collecting area.

- The telescope’s effective f/# shall be faster or equal to f/6.

- The distance between the back of primary mirror and system focus shall be at least 6 cm.

- At best focus, the telescope system shall deliver spot size and shape repeatability of 10 % at center of the field of view (FOV) and 25 % at the edges of the FOV.

- The telescope system shall deliver a bore-sight repeatability of at least 100 microradians.

- The telescope system shall deliver a fully-illuminated field over the 50um x 5 mm slit area.

We will select the best design, procure the optics, fabricate the truss and mounting structure, and conduct end-to-end imaging tests with a laboratory test camera and a benchtop version of our spectropolarimeter. We are specifically addressing optical performance, mechanical repeatability, mechanisms and packaging compatibility with small spacecraft payload requirements.

LPX First flight of Lunar plant growth experiment

Principal Investigator: Chris McKay

Can humans live and work on the moon? Not just visit for a few days but stay for decades? A first step in long term presence is to send plants. As seedlings, they can be as sensitive as humans to environmental conditions, sometimes even more so. They carry genetic material that can be damaged by radiation as can that of humans. They can test the lunar environment for us acting as a “canary in a coal mine”.

If we send plants and they thrive, then we probably can. Thriving plants are needed for life support (food, air, water) for colonists. And plants provide psychological comfort, as the popularity of the greenhouses in Antarctica and on the Space Station show.

Good idea, but how can we send plants to the Moon soon? Hitchhiking. Thanks to Google, there are many potential rides to the moon in the near future, with commercial spacecraft companies competing to collect the Google Lunar X-Prize in 2015.

We are constructing a small technology demonstration unit to study germination of plants in lunar gravity and radiation on the Moon. The self-contained habitat will have a mass of about 1 kg and could be a payload on any NASA or commercial lunar lander; for example the Astrobotics and Moon Express landers, both potential entries in the Google Lunar X-prize competition. After landing in late 2015, water will be added to the seeds in the module and their growth will be monitored for 5-10 days and compared to Earth based controls. Seeds will include Arabidopsis, basil, and turnips. This will be the first life sciences experiment on another world and an important first step in the utilization of plants for human life support. Follow up experiments will improve the technology in the growth module and allow for more extensive plant experiments.

Points of Contact: Chris McKay, Arwen Davé, Bob Bowman

Science Goal: Study germination of plants in lunar gravity and radiation.

ISRU Goal: (In Situ Resource Utilization) Use the natural sunlight on the Moon for plant germination.

Education Goal: Create a simple version of the lunar plant growth chamber that can be reproduced in large numbers for use in K-12 education.

Opportunity: The first Moon Express lander late 2015.

Our Concept: To develop a very simple sealed growth chamber that can support germination over a 5-10 day period in a spacecraft on the Moon. Filter paper with dissolved nutrients inside the container can support ~100 seeds of Arabidopsis and 10 seeds each of basil and turnips. Upon landing on the Moon a trigger would release a small reservoir of water wetting the filter paper and initiating germination of the seeds. The air in the sealed container would be adequate to for more than 5 days of growth. No additional air supply or air processing would be necessary. The seedlings would be photographed at intervals with sufficient resolution to compare with growth in Earth controls. We would use the natural sunlight on the moon as the source of illumination for plant germination as a first ISRU (in situ resource utilization) demonstration.

Science Background: Plant growth at Earth gravity has been well studied and there has been a lot of research on plant growth in microgravity on Shuttle and Space Station. Recently, ISS payloads have been able to simulate partial gravity (eg. Kiss et al. 2012, Planta 236, 635-645.). The surface of the Moon however is the only location in which the effects of both lunar gravity and lunar radiation on plant growth can be studied. Eventually human exploration of the Moon will require plant growth systems for life support. Germination is the first step in plant growth and thus forms the focus of this first experiment. We will also look for phototropism and circumnutation. The basic data from the experiment would be the growth rate, expressed as leaf area, over time. This would be extracted from images of the plant growth area. In addition image data would be collected to investigate both phototropism (plant motion in response to changes in position of the light source) and circumnutation (plant circular motion). The growth and movement of the plants on the Moon would be compared to similar data from Earth controls in identical growth units.

Germination: Shows that minimum environmental factors for Earth-normal growth are available; sensitive to hazards, temperature, moisture and light.

Phototropism: Shows that plants on the Moon responds normally to external environmental cues

Circumnutation: Shows that Earth-normal endogenous growth patterns and growth rates are expressed in lunar conditions

Follow-on Science: After LPX-0 demonstrates germination and initial growth in lunar gravity and radiation, we anticipate follow on experiments that expand the biological science. These include: 1) long term, over-lunar-night experiments, 2) multi-generation experiments, 3) Diverse plants.

Survival to 14 days demonstrates plants can sprout in the Moon’s radiation environment at 1/6 g. Survival to 60 days demonstrates that sexual reproduction (meiosis) can occur in a lunar environment. Survival to 180 days shows effects of radiation on dominant & recessive genetic traits. Afterwards, the experiment may run for months through multiple generations, increasing science return.

This classroom activity is written for the prototype, stay tuned to this website for updates about the flight version.

http://microbes.arc.nasa.gov/educators/resource.html

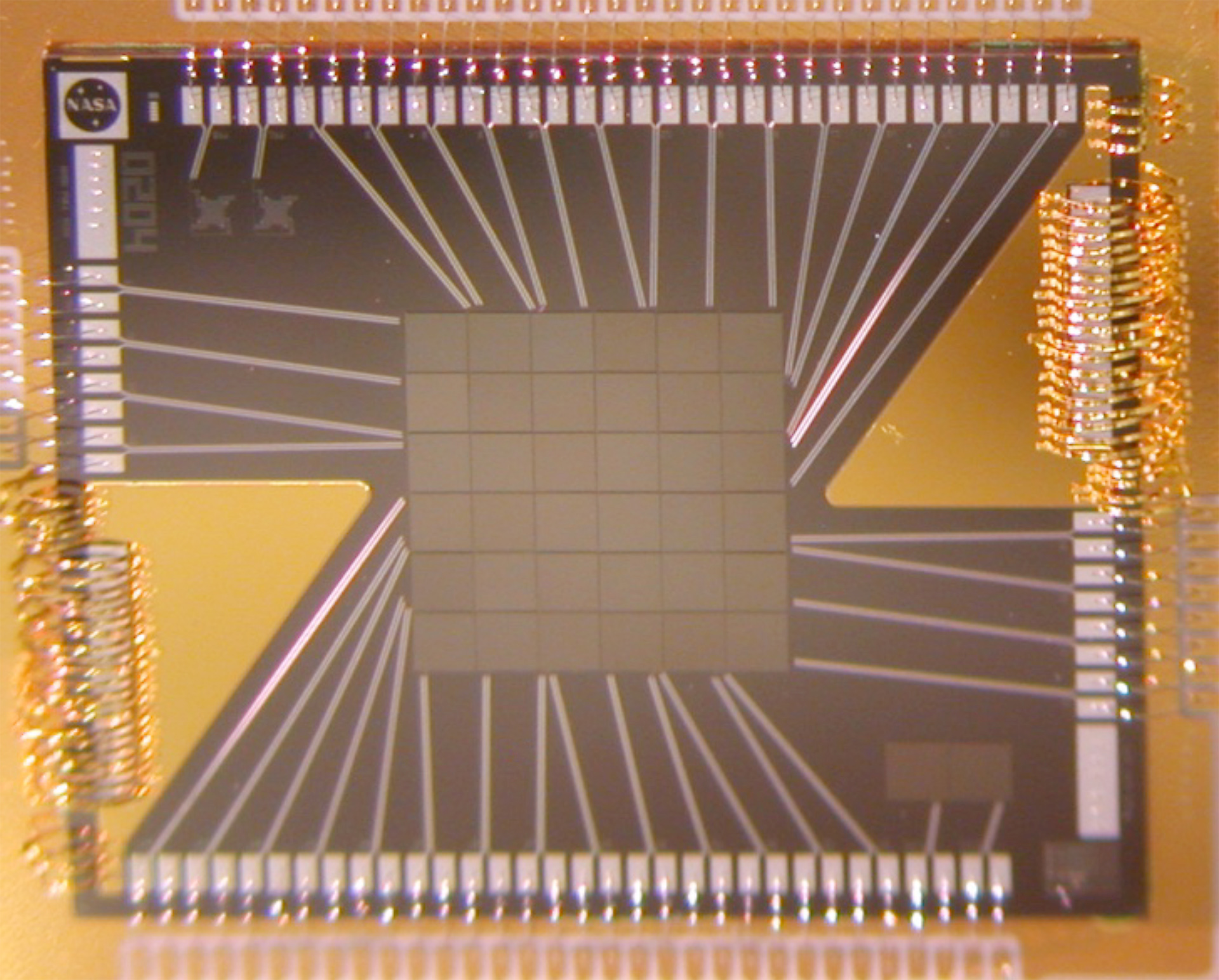

Nanoscale Vacuum Electronics: Back to the Future?

Principal Investigator: Meyya Meyyapan

Vacuum tubes went away because their replacement – the integrated circuit – could be miniaturized and operated at significantly lower power levels. However, vacuum is superior to all semiconductors because electrons do not suffer any collisions and thus electron transport is the fastest possible.

The novel idea in our work is to combine the best of vacuum tubes and conventional silicon semiconductor processing to create nanoscale vacuum tubes or transistors. Why? It is possible to get high speed operation at low power levels. More importantly, for NASA and the military, the device will be inherently immune to space radiation. Thus, high performance devices can be used very quickly in missions without the usual extensive steps involving radiation-proofing steps and packaging requirements.

As a preliminary demonstration, we have fabricated a nanoscale vacuum transistor with a source-drain gap of 150 nm. Note that currently commercial production of silicon chips features a 32 nm gap in silicon based transistors, about 5 times smaller than our first effort. Our device shows an operating frequency of 0.4 THz or 400 GHz, already exceeding the performance of commercial devices. We are currently working on wafer-scale fabrication as opposed to individual devices. The processing steps in our work are identical to those in conventional integrated circuit manufacturing and thus fabrication costs are expected to be low as in semiconductor industry. In this regard, a competitive advantage exists compared to novel materials such as graphene or carbon nanotubes which are struggling to reach wafer scale production.

Materials Manufactured from 3D-Printed Synthetic Biology Arrays

Principal Investigators: Diana Gentry, NASA Ames Research Center, SGE, Ashley Micks, Stanford University, Lynn J. Rothschild (POC), NASA Ames Research Center, SGE

The Problem

Many complex, biologically-derived materials have extremely useful properties (think wood or silk), but are unsuitable for space-related applications due to production, manufacturing, or processing limitations. Large-scale ecosystem-based production, such as raising and harvesting trees for wood, is impractical in a self-contained habitat such as a space station or potential Mars colony. Manufacturing requirements, such as the specialized equipment needed to harvest and process cotton, add too much upmass to be practical.The Vision

Cells in nature are already highly specialized for making complex biological materials on a micro scale. We envision combining these strengths with the recently emergent technologies of synthetic biology and additive manufacturing to create 3D-structured arrays of cells that are bioengineered to secrete different materials in a specified three-dimensional pattern.

Applications

- Manufacturing of biological materials, ranging from construction materials to foodstuffs, from small stocks of cells and a basic palette of local resources.

- Creation of microstructured materials, such as honeycomb-grained wood, out of materials previously unworkable at that scale.

- Synthesis of new and novel biocomposites, such as reinforced silk, that were previously impossible.

Potential Impact

If successful, this application would dramatically expand manufacturing capabilities both on Earth and in space in several ways:

- In situ resource utilization. The ability to make a far greater range of materials and products out of the limited basic resource palette offered by existing in situ resource extraction techniques makes the dream of an off-world habitat closer to reality.

- Reduced equipment and material upmass. Production of a wide variety of ready-to-use highly specialized materials with low labor cost and starting mass gives greater range and flexibility to all space missions.

- Structured biomaterial production. New ready-to-use macro-, micro-, and molecular manufacturing techniques for traditional materials such as wood, reduce cost and enable new, innovative products.

- New and novel biocomposite creation. The ability to create completely novel material composites from any base material that cells can be engineered to produce opens up a new frontier in materials design and manufacturing.

The Study

We are using a custom microdispensing setup to deposit two types of cells. Each cell type is engineered to secrete a different protein. The cells will be deposited on a protein-binding substrate in a simple grid pattern. After the cells and substrate have been removed, the resulting two-material protein grid will remain as a proof of concept of this technique.