In This Week’s Star

- Mask Up, Marshall: Medical Center Leaders Cite Studies Showing Basic Safety Measures Limit COVID-19 Risk

- Four Down, Four to Go: Artemis I Rocket Moves Closer to Hot Fire Test

- Motor Test Helps Evaluate New SLS Materials

- Five Team Members Honored as a HEO HErO

- New Educational Website Celebrates 20 Years of Space Station Science

- Exchange Leadership Connects Team Members During Pandemic

- NASA’s Lucy Mission Passes Critical Mission Milestone, Highlighted on ‘This Week @NASA’

- This Week in NASA History: HEAO-1 Launches – Aug. 12, 1977

Mask Up, Marshall: Medical Center Leaders Cite Studies Showing Basic Safety Measures Limit COVID-19 Risk

By Rick Smith

As NASA’s Marshall Space Flight Center transitions to Stage 3 safety protocols to continue the nation’s mission in space, representatives of the Marshall Medical Center point to a growing body of research that documents the effectiveness of basic preventative measures – particularly face masks.

“It’s human nature to wish for a silver bullet, a cure-all that will relieve us of worry and let us get on with our work,” said Dr. Joseph Musick, Marshall’s medical director. “But the simplest precautionary measures actually make the biggest difference.”

David Thaxton, Marshall’s occupational health officer, agreed. “I call them the three W’s of health consciousness in the workplace,” he said. “Wash hands often and thoroughly. Watch proximity to people while onsite. Wear a face covering or mask when a 6-foot distance can’t be maintained. These simple practices, elements of NASA’s Safe at Work Protocol Guidelines, can help safeguard each of us – and everyone with whom we come in contact.”

They offered tips for thorough precaution, such as avoiding touching or rubbing one’s face and eyes, refraining from shifting or resettling surgical masks or face coverings – which can reduce their effectiveness at catching droplets of moisture expelled from the mouth – and using hand sanitizer after any direct, in-person encounter or interaction. Both agree that covering the mouth and nose effectively in public are key for reducing the spread of COVID-19.

Musick and Thaxton cited a report published July 22 by the Centers for Disease Control and Prevention, assessing the relative effectiveness of properly fitted and fastened cloth masks at reducing the risk of contagion.

The mask’s main job, Thaxton noted, is to protect others. “You can be asymptomatic and unaware that you have contracted the virus,” he said. “Breathing into a mask or face covering can reduce the risk of larger, potentially infectious expelled droplets of moisture from going airborne and spreading to others.”

“It’s about care and consideration for everyone around us,” Musick agreed.

Such tactics already have proved successful onsite at Marshall, Thaxton added. “To date, we’ve had no documented onsite transmission of COVID-19 between workers wearing face coverings,” he said. “Is wearing a mask or other face protection an absolute guarantee of prevention? Certainly not. But it definitely lessens the risk.”

In addition to the CDC article, Musick pointed to a report published by the University of California at San Francisco which noted that high-speed photography showed a significant decrease in airborne, microscopic droplets expelled in a room occupied by people wearing face coverings. One simulation cited in the article suggested that if 80% of the population wore masks, it could do more to reduce the spread of COVID-19 than a strictly enforced nationwide lockdown.

The Mayo Clinic, a leading healthcare and medical research hospital network, also has published extensive guidance on the efficacy and proper use of masks, and the relative merits of various types of face coverings. Additional mask-positive studies have been reported recently in the International Journal of Nursing Studies, the Proceedings of the National Academy of Sciences, and the medical journal Anesthesiology.

Musick and Thaxton also cited documented cases where effective masking has worked to slow the spread of the virus. An epidemiology study published in the June issue of the journal Health Affairs, analyzing data gathered in 15 states and the District of Columbia, identified a significant decrease in new cases after masking mandates were put in place by state and local governments.

All these studies inform their contributions to Marshall’s path forward. Musick and Thaxton meet at least weekly with Marshall Director Jody Singer and her leadership team, and consult regularly with NASA’s Office of the Chief Health and Medical Officer, led by Dr. JD Polk. They work closely with Marshall organizations to develop strategies for making work areas as safe as possible wherever job requirements preclude telework.

“The Engineering Directorate, the Payload Operations Center, and other organizations are developing innovative workflows and procedures to limit potential transmission of the virus among workers,” Thaxton said. “From reorganizing workstations for optimal social distancing to ensuring personnel have a supply of masks and all other necessary personal protective gear, they’re committed to making Marshall the safest workplace possible.”

Musick said some changes in personal work habits may be necessary. “I’m part of a generation that has always worn a tie to work, but I doubt I’ll ever do it again. I’m fastidious about keeping work surfaces clean – but I realized recently how often my tie drags on tabletops when I’m working. You can wash most clothes at day’s end to remove germs and bacteria, but you can’t just throw a tie in the washing machine.”

Behind his mask, Thaxton chuckled. “No silver bullet for this pandemic – but maybe a silver lining.”

Thaxton and Musick encourage team members to visit Inside Marshall and NASA People to stay abreast of COVID-19 news and the latest health and safety guidance pertinent to NASA and Marshall teams.

Smith, an ASRC Federal/Analytical Services employee, supports the Office of Strategic Analysis & Communications.

Four Down, Four to Go: Artemis I Rocket Moves Closer to Hot Fire Test

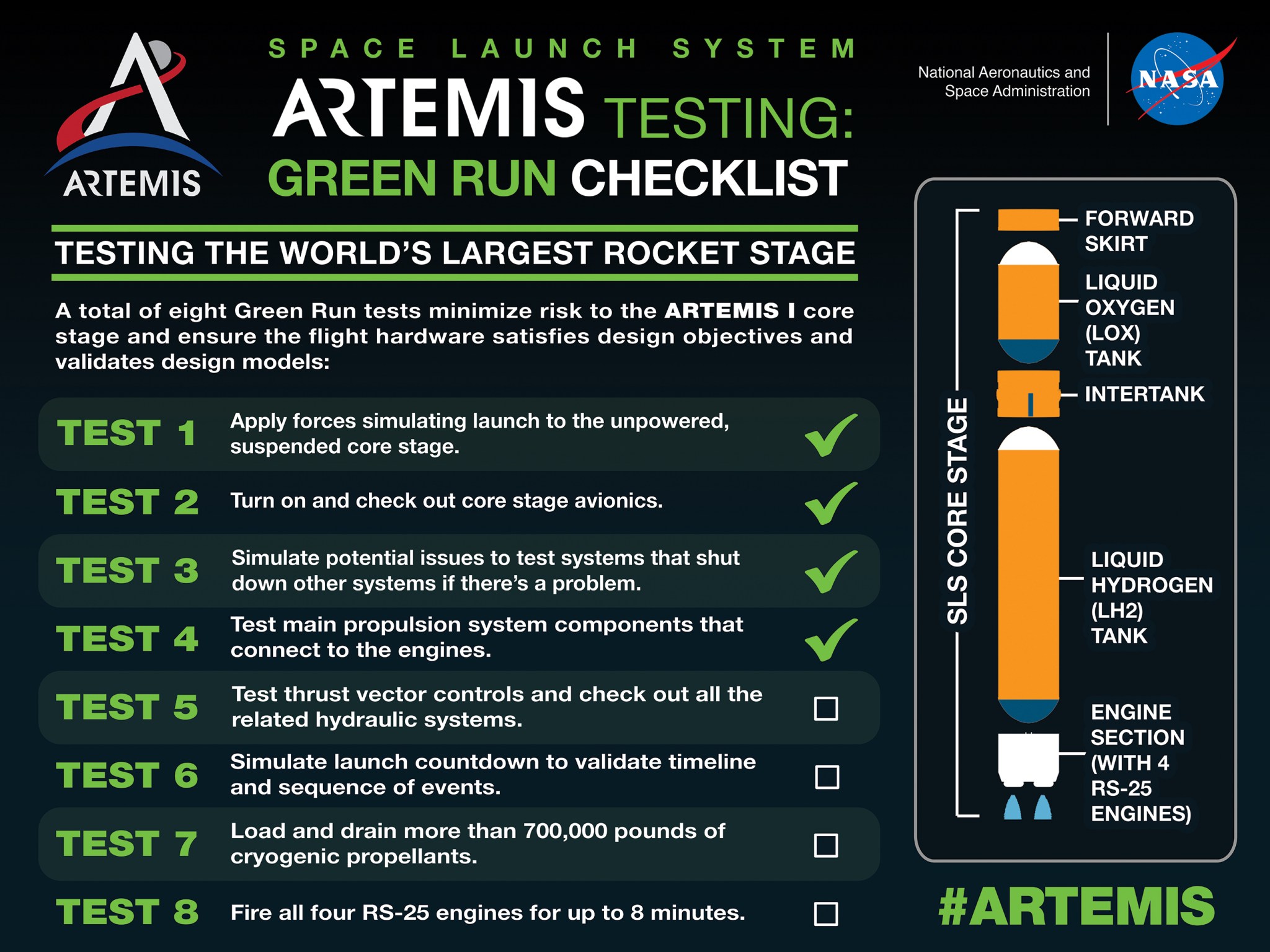

The Space Launch System rocket core stage for the Artemis I lunar mission has successfully completed its first four Green Run tests and is building on those tests for the next phase of checkout as engineers require more capability of the hardware before hot firing the stage and its four powerful engines.

The Green Run series includes eight demanding tests, among them nearly 30 firsts for the rocket stage, including the first loading of the propellant tanks, first flow through the propellant feed systems, first firing of all four engines, and first exposure of the stage to the vibrations and temperatures of launch.

“We are methodically bringing several complex systems to life and checking them out during the first seven tests,” explained Julie Bassler, SLS stages manager at NASA’s Marshall Space Flight Center. “Then it is showtime for the eighth test, when we put it all together and fire up the rocket’s core stage – just like we’ll fire it up for the Artemis I launch to the Moon.”

On Aug. 5, engineers at NASA’s Stennis Space Center, where the stage is loaded into the B-2 Test Stand, completed the fourth test of the 212-foot-tall core stage. During the test, engineers performed the initial functional checkout of the main propulsion system components to verify command and control operability and performed leak checks on the core stage-to-facility umbilical fluid and gas connections.

“With test gases flowing through this many parts of a complex rocket stage, we expected the test team to encounter some issues,” said Jonathan Looser, who manages the SLS core stage main propulsion system at Marshall. “Historically, there’s never been a NASA human-rated launch vehicle flown without one or more full-up tests before flight, and they all encountered first-time issues. As expected, we found a few with valve and seal issues and addressed them, and now we’re ready to complete the next four Green Run tests.”

The Green Run test series began in January with testing to verify computer models and support guidance and navigation control systems. In May, the team completed Test 2, which included activation of computers, data collection health monitoring, and other avionics systems that comprise the core stage’s brains and nervous system. Test 3 was a check of the fail-safe systems designed to shut down the stage in a contingency situation. Each test builds on the prior test and is longer than the previous one, adding new hardware activations to those already completed.

For Test 4, functional and leak checks of the stage main propulsion systems and engines lasted three weeks. Engineers conducted the test with gaseous nitrogen and helium, efficient alternatives to liquid hydrogen and oxygen propellants, which are only needed for actual hot fire tests. As the gases flowed through systems, special instrumentation monitored for any leaks or poor connections.

Next up is Test 5, ensuring the stage thrust vector control system properly steers the four RS-25 engines and provides hydraulics to the engine valves. Test 6 will simulate the launch countdown, including step-by-step fueling procedures, to validate the launch sequence timeline. During Test 7, called the “wet dress rehearsal,” the team once again will power up the avionics, hydraulic systems, and other related systems checked out in the previous six tests, and then will load, control, and drain more than 700,000 gallons of cryogenic, or super cold, propellants.

Only after passing all seven tests will it be time for Test 8, a full countdown and hot fire test for up to eight minutes. During the test, all four RS-25 engines will be firing a combined 1.6 million pounds of thrust – just as they will on the launch pad. Once Test 8 is complete, engineers will prepare the stage for its trip to NASA’s Kennedy Space Center.

By the time all eight Green Run tests are complete, Boeing, the prime contractor for the core stage, estimates it will collect 75-100 terabytes of data, not including collected voice and video recordings. That’s a lot of homework – all the data in the Library of Congress amounts to just 15 terabytes.

NASA is working to land the first woman and next man on the Moon by 2024. SLS and Orion, along with the human landing system and the Gateway in orbit around the Moon, are NASA’s backbone for deep space exploration. SLS is the only rocket that can send Orion, astronauts and supplies to the Moon in a single mission.

Motor Test Helps Evaluate New SLS Materials

By Will Bryan

Every detail that goes into space exploration matters. While habitat design or making sure a rocket is powerful enough to launch supplies are obviously important, what may be less apparent are the smaller things, including the solvents used in manufacturing materials for spaceflight.

On Aug. 6, a 22-second hot fire test in the East Test Area at NASA’s Marshall Space Flight Center helped NASA and Northrop Grumman Corp. in Promontory, Utah – the solid rocket booster prime contractor – evaluate a new nozzle material for the Space Launch System solid rocket boosters. These boosters produce more than 75% of the power to launch the rocket.

The nozzle construction enables the boosters to provide consistent performance while withstanding the 5,000-degree Fahrenheit flame produced as the solid fuel is burned to launch the rocket. Such material changes are checked out in phases from subscale to full-scale tests and this motor was a significant step in that process. Using a 24-inch-diameter, 20-foot-long subscale test motor that burned nearly 1,800 pounds of propellant and produced 23,000 pounds of thrust, the team collected data to help verify use of the solvent on future SLS flights beyond Artemis III.

“This 24-inch motor test is to evaluate the material in a solid rocket motor environment and make sure that we don’t get any unexpected changes in how it performs,” said Tim Lawrence, manager for motor and booster separation motor systems at Marshall.

While the solid rocket boosters that will be used on the SLS are 177 feet tall and 12 feet in diameter, the motor used in the test is still large enough to produce valuable data.

“This booster is only 24 inches but the ability to fire it in a test stand helps us get the data we need to confirm that we want to test it in a larger, full-scale test,” test conductor Dennis Strickland said.

In addition to data about the solvent’s effects on the material during motor operation, engineers also collected information about its behavior during booster assembly.

“The 24-inch motor is large enough that we were able to use the same processes to manufacture the nozzle as are used on the full-scale motor and that gives us confidence it will provide a good indication of full-scale performance,” Lawrence explained.

The test data may also be used by other government agencies to help advance their solid rocket propulsion technology. NASA routinely shares data with other government agencies and industry, which enhances capabilities and maximizes the return on investment for the taxpayer.

NASA’s SLS booster is based on three decades of knowledge and experience gained with the space shuttle boosters and has been updated with the latest technology. The agency is working to design, develop, and test next-generation boosters that will power SLS flights after all available shuttle-era hardware is expended. NASA has cast segments for the Artemis I and Artemis II lunar missions, the first two SLS flights, and has begun casting the Artemis III mission. Northrop Grumman delivered the segments for Artemis I to NASA’s Kennedy Space Center on June 15.

SLS and the Orion spacecraft, along with the Gateway in orbit around the Moon, are NASA’s backbone for deep space exploration and the Artemis program, which will send the first woman and next man to the lunar surface by 2024. SLS is the only rocket that can send Orion, astronauts, and supplies to the Moon on a single mission.

Bryan, an ASRC Federal/Analytical Services employee, supports the Office of Strategic Analysis & Communications.

Five Team Members Honored as a HEO HErO

From left, Lisa Grady, Amanda Stein, Jamie Crews, Nathan Marchman, and Ryan Hardy are the latest team members from NASA’s Marshall Space Flight Center to be named a HEO HErO. Grady provides support to NASA’s Space Launch System booster procurement team as the lead for the SLS Booster Contract for SLS flight sets 1-3. Stein develops flight rationale for multiple Merlin engine issues, such as clearing the issues for NASA’s SpaceX Demo-2 mission flight acceptance. Crews led the successful installation of the SLS core stage into the B-2 Test Stand at NASA’s Stennis Space Center. Marchman is the subject matter expert for the Multi-Purpose Transportation System and self-propelled modular transporters. Hardy is the contracting officer supporting Marshall’s Facilities Operations and Construction Office. Each week, NASA’s Human Exploration and Operations Mission Directorate recognizes HEO HErOes, team members from across the agency who have made vital contributions in their support of NASA’s mission to land the first woman and next man on the Moon by 2024. (NASA)

New Educational Website Celebrates 20 Years of Space Station Science

Orbiting some 250 miles overhead is the International Space Station, the brightest object in the night sky, except for the Moon. For almost 20 years, astronauts have continuously lived and worked on the space station, testing technologies, performing science, and developing the skills needed to explore farther from Earth.

NASA’s Office of STEM Engagement is kicking off a Celebrating Station Science series, which will provide an opportunity to connect students and educators to 20 years of space station experiments and research through monthly themes with K-12 science, technology, engineering, and mathematics resources. NASA astronauts, scientists, engineers, and operations personnel will share their stories and highlight their career paths.

Each month during the 2020-2021 school year, educators will have readily available lesson plans, activities, information on space station science experiments, and other resources to excite the Artemis Generation of explorers. All of this information is accessible via a recently launched website, which will regularly feature new content: https://www.nasa.gov/stem/iss20/

“Our goal is to inspire students with the ISS story to engage in STEM learning and to connect students and educators to resources and opportunities,” said Carrie Olsen, manager for OSTEM’s Next Gen STEM project, which sponsors the Celebrating Station Science initiative. “By celebrating the people and the accomplishments of the last 20 years, we hope to engage the Artemis Generation in the authentic STEM learning that will catalyze their future success in STEM careers.”

The International Space Station Payload Operations Integration Center at NASA’s Marshall Space Flight Center is the heartbeat of space station science research operations. As NASA’s primary space station science command post, the payload operations team coordinates scientific and commercial experiments on the station, synchronizes payload activities of international partners, and directs communications between researchers around the world and their onboard experiments. To help the crew in orbit conduct scientific study, the operations center is staffed 24 hours a day, seven days a week, 365 days a year.

“The payload operations team at Marshall is at the heart of what we’re celebrating this school year,” Olsen said. “Their dedication, hard work, and ingenuity have enabled the success of research on the ISS. We look forward to featuring their educational and profession journeys to help students today see themselves in the NASA workforce of the future.”

Through NASA’s Artemis program, the agency will send first woman and next man to the Moon by 2024. The International Space Station Program has advanced capabilities in long-duration human space operations and in conducting scientific research and technology development in space. The space station remains the sole, space-based proving ground, greatly enabling NASA to go forward to the Moon and Mars.

Stay connected to the latest information via Marshall’s Facebook and Twitter accounts.

Exchange Leadership Connects Team Members During Pandemic

By Daniel Boyette

Jose Matienzo’s inbox stays pretty full these days. As operations manager of the Marshall Exchange, he has seen his daily centerwide email skyrocket in popularity since the majority of the workforce began mandatory telework March 16 to reduce the spread of coronavirus.

Pre-pandemic, Matienzo’s messages were known for food truck listings, Exchange services and updates on center activities. Now, they’ve taken on a new feel, featuring reader-submitted photos of kids, pets, home offices, and vacations, plus trivia and games, all with commentary from the fun-loving Matienzo.

“I can show you my inbox – it’s got hundreds of emails from people just saying, ‘Thank you for bringing a little of my colleagues into my life,’ ” he said. “They like the sense of humor. They say they look forward to seeing that morning picture of a sunrise or sunset, or a colleague’s backyard with the blooming flowers or the hummingbird.”

The pandemic has presented new challenges for the Exchange, which contributes to the overall welfare and morale of employees by overseeing Marshall’s fitness center, the Space Shop, food trucks, nearly 30 clubs, large events with food and music, and a number of other services.

With social distancing rules prohibiting the Exchange from one of its primary functions – bringing team members together – Matienzo and Exchange business manager Bill Mayo have found other avenues to maintain the Exchange’s spirt, such as offering virtual exercise classes and launching an online store.

“Hopefully the online store is going to help out,” Matienzo said. “There’s always been a demand. But with telework, we’ve had to do something.”

Navigating COVID-19 is the latest chapter in the Exchange story for Matienzo and Mayo, who took different avenues to their current roles.

Matienzo joined Marshall in 1983 as a co-op while attending the University of Alabama in Tuscaloosa. He went on to spend three decades at Marshall as a systems engineer and project manager before taking over leadership of the Exchange in 2013 – a role he seemed destined for.

“Honestly, I’ve had one real bad day at work in the 37, 38 years that I’ve been here. Other than that, it’s always been fun,” Matienzo said. “When I was an engineer, my bosses always came to me for the non-engineering things, like when it came time to do fundraising for the Combined Federal Campaign or Feds Feed Families. Your typical engineer personality is a little more reserved. They knew that I didn’t mind.”

Mayo, who was a Walmart store manager before joining Marshall 20 years ago, said he has watched the Exchange grow from a tiny, fledgling store into an organization that, in normal circumstances, contributes to the daily lives of thousands of team members.

“I’m very proud of the growth that we have at the Exchange and the number of activities that we now do,” he said. “We’ve added clubs and we do at least three big events every year, along with three or four smaller events. The big events will have 1,500-2,000 people and the smaller events will have a couple hundred. In previous years, we did one big event, and that was at Christmas. It’s been a lot of hard work, but it’s paying off.”

What’s next for the Exchange? Matienzo shook his head and gave a little laugh when fielding the question.

“I don’t know, with this COVID thing,” he said. “We’re going to adjust for this year. We want to do the events. We’ll figure out how to do them safely. We may have to do a virtual barbecue. We want to make sure that the families and retirees are included.”

Boyette, an ASRC Federal/Analytical Services employee and Marshall Star editor, supports the Office of Strategic Analysis & Communications.

NASA’s Lucy Mission Passes Critical Mission Milestone, Highlighted on ‘This Week @NASA’

NASA’s Lucy mission is featured in “This Week @NASA,” a weekly video program broadcast on NASA-TV and posted online.

The mission has been cleared to proceed with assembly and testing in preparation for its targeted launch in 2021. Lucy will be the first mission to study Jupiter’s Trojan asteroids.

The Trojans are time capsules from the birth of the solar system more than 4 billion years ago. The swarms of Trojan asteroids associated with Jupiter are thought to be remnants of the primordial material that formed the outer planets. These primitive bodies hold vital clues to deciphering the history of the solar system and, perhaps, even the origins of organic material on Earth.

The mission takes its name from the fossilized human ancestor – called “Lucy” by her discoverers – whose skeleton provided unique insight into humanity’s evolution.

Lucy is a project of the Science Mission Directorate’s Discovery Program, managed by NASA’s Marshall Space Flight Center.

View this and previous episodes at “This Week @NASA” on NASA’s YouTube page.

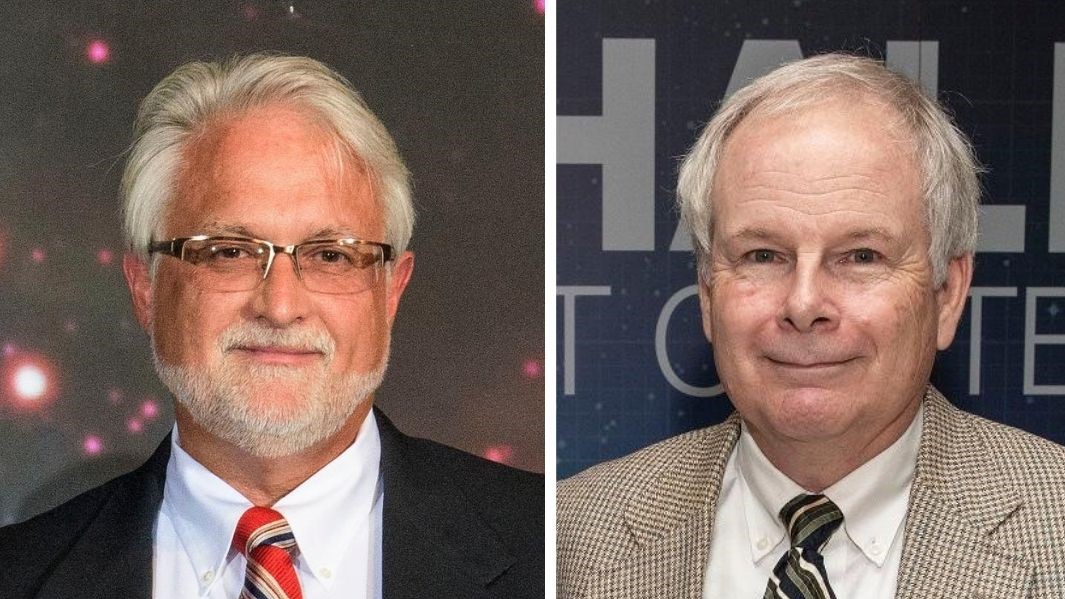

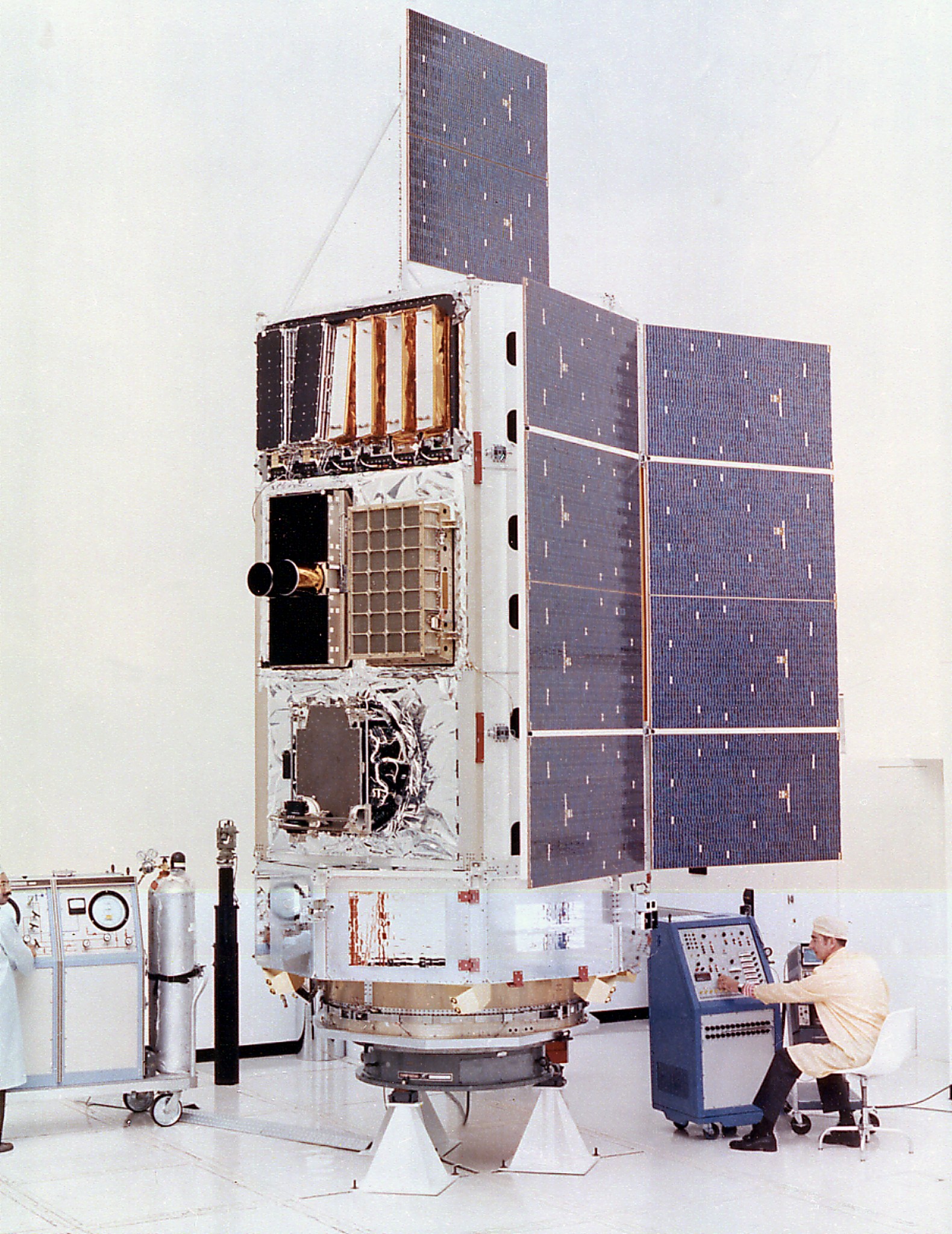

This Week in NASA History: HEAO-1 Launches – Aug. 12, 1977

This week in 1977, the High Energy Astronomy Observatory-1 launched aboard an Atlas-Centaur rocket from NASA’s Kennedy Space Center. Managed by NASA’s Marshall Space Flight Center and developed by TRW, HEAO-1 was the first in a series of three spacecraft in the HEAO Program and was designed to survey the sky for additional X-ray and gamma-ray sources and to pinpoint their positions. The mission lasted 17 months. The NASA History Program is responsible for generating, disseminating, and preserving NASA’s remarkable history and providing a comprehensive understanding of the institutional, cultural, social, political, economic, technological, and scientific aspects of NASA’s activities in aeronautics and space. For more pictures like this one and to connect to NASA’s history, visit the Marshall History Program’s webpage. (NASA)