In This Week’s Star

- Sharon Cobb Named Associate Program Manager for Space Launch System

- Michoud Transitions to Stage 2 of NASA’s Response Framework

- Marshall, Other NASA Centers Partner With Industry Selectees for 2020 ‘Tipping Point’ Technology Development Efforts

- COVID-19 Safety: Marshall Workers Urged to Remain Vigilant When Returning On-site

- Teamwork, Communication, Understanding Risk are Keys to Mission Success, Says Lisa Watson-Morgan

- Rodney Grubbs, Bryan Walls, Andrew Bush Recognized as a HEO HErO

- Scientists, Researchers Gather Virtually to Plan Space Station Science

- Celebrate 20 Years of Human Presence by Sweatin’ with the Station

- Marshall’s Twice-Annual ‘Go Green, Buy Local’ Event Goes Virtual in November

- This Week in NASA History: STS-120 Launches to the Space Station – Oct. 23, 2007

Sharon Cobb Named Associate Program Manager for Space Launch System

Sharon Cobb has been appointed to the Senior Executive Service position of associate program manager for the Space Launch System Program Office at NASA’s Marshall Space Flight Center. As the third-ranking manager within the office, she assists SLS Manager John Honeycutt and Deputy Manager Chris Cianciola in overall programmatic and technical planning, coordination, management, and integration of activities.

The Senior Executive Service is the personnel system that covers most of the top managerial, supervisory, and policy positions in the executive branch of the federal government

Cobb has 34 years of management and technical expertise. She began her NASA career in 1986 as a senior research scientist conducting pioneering studies on the effects of reduced gravity processing on a variety of complex semiconductor materials. She went on to be Materials Science team lead and element scientist; and program executive for the In-Situ Resource Utilization and Fabrication and Repair programs at NASA Headquarters.

As a congressional fellow from 2006 to 2007, Cobb served as advisor to former Rep. Bud Cramer of Alabama on issues such as science and technology, education, trade, and telecommunications. She joined Marshall’s Office of Strategic Analysis & Communications in 2007 as assistant to the office’s director of the organization, and was named manager of the External Relations Office in 2008. Since joining the SLS Program Office in 2012, Cobb has been SLS assistant program manager; manager of the SLS Program Operations and Strategy Communications Office; acting SLS deputy program manager; and deputy element manager for the Block 1B Development Office.

Cobb has been honored with a NASA Exceptional Service Award, NASA Space Flight Awareness Management Award, Federal Women’s Program Outstanding Achievement Award, and numerous special service and group awards.

A native of Birmingham, Cobb received bachelor’s and master’s degrees in materials engineering from the University of Alabama in Birmingham, and a doctorate in materials science and engineering from the University of Florida.

Michoud Transitions to Stage 2 of NASA’s Response Framework

NASA’s Michoud Assembly Facility moved to Stage 2 of the agency’s Framework for Return to On-site Work on Oct.19. This move follows careful evaluation of agency guidance, updated federal, state, and local guidelines, and conditions in the community. Specific factors included the ease of restrictive orders by the state of Louisiana and city of New Orleans, the increase of COVID-19 testing capabilities in the region, and the decrease in COVID-19 cases in the greater New Orleans area over a 14-day period.

Due to the size of Michoud, many tenants and employees have already been on-site for work by using staggered work schedules – 832 acres provides plenty of space to spread out and keep 6 feet apart. However, this change means increased access to facility amenities like the cafeteria in Building 102 and to the gym on a limited basis. Employees should contact their supervisors for specifics on these newly opened areas.

Michoud Director Robert Champion emphasized that “while prioritizing the health and safety of our MAF family, we are keeping the mission moving forward.” Since Michoud transitioned to Stage 3 in May, the production on Artemis II and III has not faltered. Mission-critical work and preparations have continued on hardware such as the engine section, liquid oxygen tank, liquid hydrogen tank, intertank, forward skirt, and exploration upper stage.

“NASA guidance and facility plans will be steadfast, safety-driven, and adjusted accordingly should conditions diminish,” Champion said. “Meaning, if conditions worsen in the community, MAF is prepared to return to an elevated stage of the response framework. I urge you to remain in constant contact with your supervisors for specific instructions. Please continue to read all communications from your supervisors, the agency, our facility, and regularly visiting NASA People and MAFSpace for the latest information.”

Marshall, Other NASA Centers Partner With Industry Selectees for 2020 ‘Tipping Point’ Technology Development Efforts

NASA has selected 14 American businesses to pursue a range of technology development efforts – aided by subject matter experts at NASA’s Marshall Space Flight Center and other NASA field centers – that will help forge a path to sustainable Artemis operations on the Moon by the end of the decade.

The chosen proposals in NASA’s fifth competitive Tipping Point solicitation have an anticipated, combined award value of more than $370 million – development money that will help ambitious spaceflight companies thrive and suffuse industry and local communities around the nation with new technology dollars. NASA’s Space Technology Mission Directorate will negotiate with the companies to issue milestone-based, firm-fixed-price contracts lasting for up to five years.

NASA Administrator Jim Bridenstine announced the selections Oct. 14 at the virtual fall Lunar Surface Innovation Consortium meeting.

“NASA’s significant investment in innovative technology demonstrations, led by small and large U.S. businesses across nine states, will expand what is possible in space and on the lunar surface,” Bridenstine said. “Together, NASA and industry are building up an array of mission-ready capabilities to support a sustainable presence on the Moon and future human missions to Mars.”

Tipping Point projects help NASA determine whether technologies have been sufficiently matured to pursue full-scale flight demonstrations or to be infused into future exploration missions.

Under the guidelines of the agreement, each company must contribute a minimum percentage, based on its size, of the total project cost. Combining NASA resources and legacy expertise with contributions by industry innovators shepherds the development of critical space technologies while saving the agency, and American taxpayers, money.

“This is the most Tipping Point proposals NASA has selected at once and by far the largest collective award value,” said Jim Reuter, NASA’s associate administrator for Space Technology. “We are excited to see our investments and collaborative partnerships bring about new technologies for the Moon and beyond while also benefiting the commercial sector.”

The majority of the funding will help mature cryogenic fluid management technologies via in-space demonstrations. Long a vital area of research and development at Marshall and NASA’s Glenn Research Center, NASA seeks a variety of solutions for safe, cost-effective launch, in-space storage, and tank-to-tank transfer of these super-cold propellants, which will power vehicles and systems in space and on the Moon – and help enable future human missions to Mars.

Cryogenic Fluid Management Technology Demonstration awards include:

- Eta Space of Merritt Island, Florida ($27 million): Small-scale flight demonstration of a complete cryogenic oxygen fluid management system, collecting critical cryogenic fluid management data in orbit for nine months. Eta Space will collaborate with Marshall, Glenn, and NASA’s Kennedy Space Center.

- Lockheed Martin of Littleton, Colorado ($89.7 million): In-space demonstration mission using liquid hydrogen to test more than a dozen cryogenic fluid management technologies for potential infusion into future space systems. Lockheed Martin will collaborate with Marshall and Glenn.

- SpaceX of Hawthorne, California ($53.2 million): Large-scale flight demonstration to transfer 10 metric tons of liquid oxygen cryogenic propellant between tanks on a Starship vehicle. SpaceX will collaborate with Glenn and Marshall.

- United Launch Alliance of Centennial, Colorado ($86.2 million): Demonstration of a liquid oxygen/hydrogen propulsion cryogenic system in orbit, testing precise tank pressure control, tank-to-tank transfer, and extended propellant storage. United Launch Alliance will collaborate with Marshall, Kennedy, and Glenn.

Additionally, Masten Space Systems of Mojave, California, was selected for a projected $10 million Tipping Point award to demonstrate a closed-loop descent and landing capability. This vital area of study tests integrated precision landing and hazard avoidance technologies, using lunar trajectories during descent and landing – another area NASA has made strides in since the era of the Apollo Moon missions.

Another 10 Tipping Point project selections will support development and demonstration of technologies for the lunar surface in the areas of in-situ resource utilization, using resources available at the Moon, Mars, and other destinations. These capabilities will help humans and robots efficiently explore more of the Moon, generating surface power, storing energy, communicating with Earth, and more.

See the complete roster of Tipping Point awardees and their projects here. Read NASA’s announcement about the selections here.

Marshall manages NASA’s Technology Demonstration Missions program, which includes advanced cryogenic technologies development projects led by researchers at Glenn and their partners at Marshall, and across government, industry, and academia.

COVID-19 Safety: Marshall Workers Urged to Remain Vigilant When Returning On-site

By Adam Farragut

As the workforce at NASA’s Marshall Space Flight Center continues navigating the impacts of the COVID-19 pandemic, team members are urged to remain vigilant and continue following all center safety protocols when working onsite. By doing simple things like wearing masks, maintaining physical distance from co-workers as much as possible and frequent hand-washing, team members can help ensure the center keeps moving missions forward in a healthy and safe manner.

“We can continue to do great things for NASA because we take our COVID-19 precautions seriously,” said David Thaxton, Marshall’s occupational health officer. “Wearing face covering or masks when you can’t maintain a 6-foot distance, and routinely washing your hands are preventative measures that can help reduce the spread of the virus.”

Marshall leadership strives to create a workplace culture in which each employee contributes to the NASA mission and then returns safely to his or her family and loved ones. Marshall’s incident- and injury-free safety culture approach empowers team members to act on what is most important – safety and well-being. It involves taking personal responsibility for what happens and having the courage to have conversations that focus on positive outcomes.

“It’s a good time to renew our commitment to caring about our co-workers and the impact of an unsafe practice on not just an individual, but their families and each other too – that’s what our incident- and injury-free safety culture is all about,” said Rick Burt, director of Marshall’s Safety and Mission Assurance Directorate. “We all have a personal responsibility for safe and healthful work practices – and we need to care for our team members too. If you see a co-worker not complying with precautions, it’s OK to speak up to either your peer or your supervisor. Simple, everyday actions could save a life.”

Team members working on-site are required to follow job-specific COVID-19 precautions and wear a cloth face covering or surgical mask while navigating buildings and in situations where maintaining social distancing is difficult. Employees should also keep a distance of 6 feet between themselves and colleagues whenever possible.

Additionally, general safety procedures such as frequent cleaning and disinfecting work surfaces, and limiting in-person meetings continue to be required for those working on-site.

Because Marshall is committed to keeping team members as safe as possible, the center has created a number of helpful resources and protocols for working safely during this unique time. Marshall team members can learn more through the frequently updated Safe at Work Protocols, FAQs and other COVID-19 resources on Inside Marshall.

Farragut, a Manufacturing Technical Solutions employee, supports Marshall’s Office of Strategic Analysis & Communications.

Teamwork, Communication, Understanding Risk are Keys to Mission Success, Says Lisa Watson-Morgan

By Will Bryan

Creating new technology. Exploring the unforgiving environment of space. Meeting tight deadlines. Making history. For more than 60 years, it is what NASA and the agency’s Marshall Space Flight Center have done.

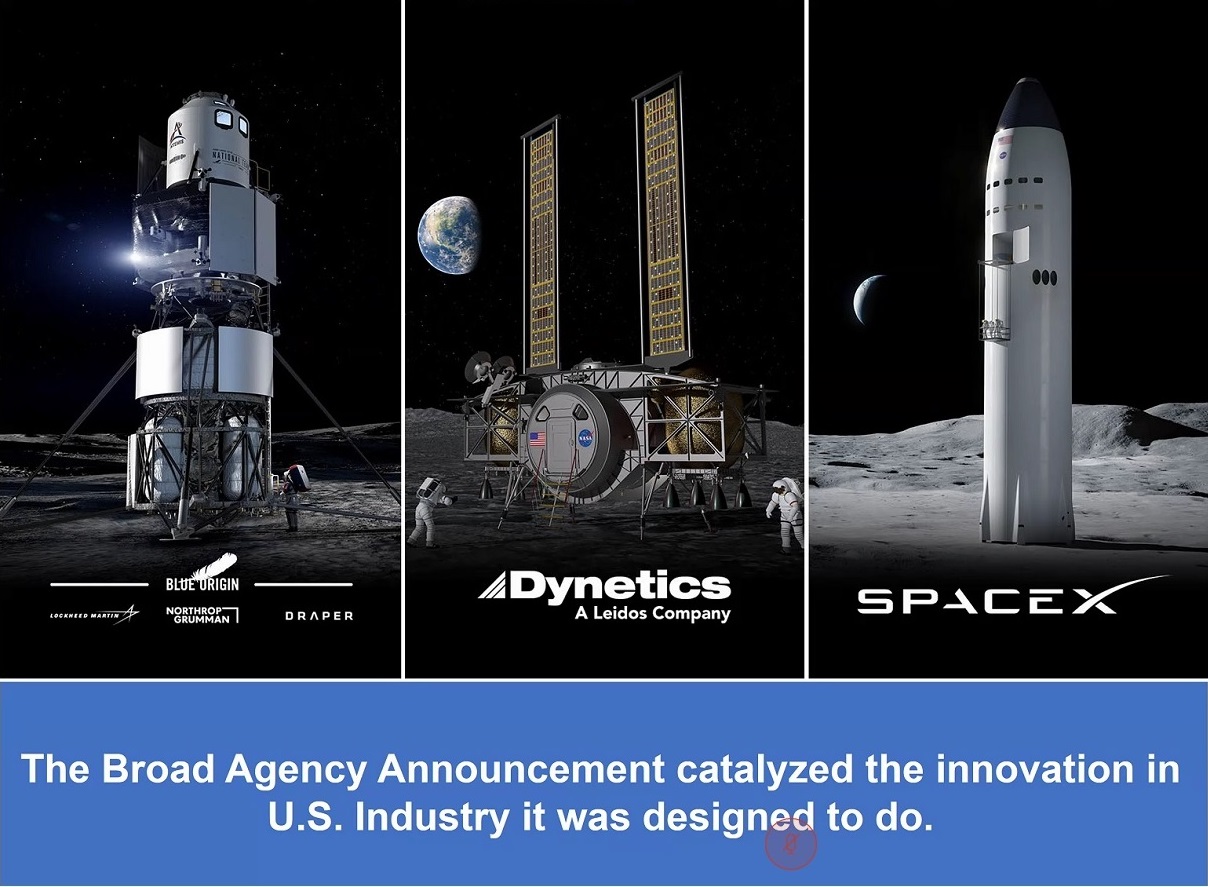

Lisa Watson-Morgan, manager of NASA’s Human Landing System program at Marshall, is one of the leaders tasked with ensuring the center continues those traditions. She delivered the final Mission Success is in our Hands talk of 2020, virtually, Oct. 15.

Watson-Morgan presented an overview of the Human Landing System program and introduced the concepts of the three companies – Blue Origin, Dynetics, and SpaceX – competing to be chosen for the historic Artemis III mission that will land the first woman and next man on the Moon’s South Pole in 2024. She discussed the capabilities that will be enabled by a human landing system and crewed exploration of the Moon – including scientific investigations, technology testing and development, and in-situ resource utilization.

It is not without risk, though.

According to Watson-Morgan, effective communication, strong teamwork, and studying past successes and failures, as well as the risk culture of other government agencies, help the collective NASA-industry-stakeholder team understand the risks, develop solutions to minimize them, and accept what risks cannot be eliminated.

NASA and the spaceflight industry will use the Moon as a testbed to further evaluate and demonstrate technologies, processes, and procedures needed to send humans to Mars.

“On the Moon, we can take reasonable risks while astronauts are just three days from home,” Watson-Morgan said. “There we will prove technologies and mature systems necessary to live and work on another world before embarking on what could be a two- to three-year mission to Mars.”

During the Mission Success is in Our Hands program, four Marshall team members were honored with the Golden Eagle Award for their roles in a successful and safe test in 2019 of components for a future NASA robotic lander mission to Europa, one of Jupiter’s moons. The test involved cryogenic liquid nitrogen, and the team of Rebecca Crownover, Jacob Johnson, Chelsea Pickett, and Amanda Anthony ensured that the test was conducted safely with the proper protocols. They all work for Huntsville-based Jacobs Engineering. The award is presented to those who make significant, identifiable contributions to flight safety and mission success.

Marshall’s Safety & Mission Assurance Directorate, with partner Jacobs Engineering, promote awareness and appreciation for the connections between employees’ everyday activities, the overall success of NASA and Marshall missions, and the safety of astronauts through the Mission Success is in Our Hands program.

To learn more about the program, visit here.

Bryan, a Manufacturing Technical Solutions employee, supports Marshall’s Office of Strategic Analysis & Communications.

Rodney Grubbs, Bryan Walls, Andrew Bush Recognized as a HEO HErO

From left, Rodney Grubbs, Bryan Walls, and Andrew Bush are the latest team member from NASA’s Marshall Space Flight Center to be named a HEO HErO. The trio were part of the team that assisted with prep and monitoring of television coverage for NASA’s SpaceX Demo-2 mission. The team helped NASA engage a more diverse audience. Each week, NASA’s Human Exploration and Operations Mission Directorate recognizes HEO HErOes, team members from across the agency who have made vital contributions in their support of NASA’s mission to land the first woman and next man on the Moon by 2024. (NASA)

Scientists, Researchers Gather Virtually to Plan Space Station Science

Dwight Mosby, manager of the Payload and Mission Operations Division for the International Space Station, welcomes a virtual audience of scientists and engineers from around the world as they participate in the annual Payload Operations Integration Working Group meeting, held virtually Oct. 20-21. The event offers payload developers, investigators, and project managers the opportunity to coordinate processes and schedules and to review the status of scientific payloads currently on or soon launching to the space station. The event was hosted by the Payload Operations Integration Center at NASA’s Marshall Space Flight Center. The POIC is mission control for science on the space station. (NASA/Fred Deaton)

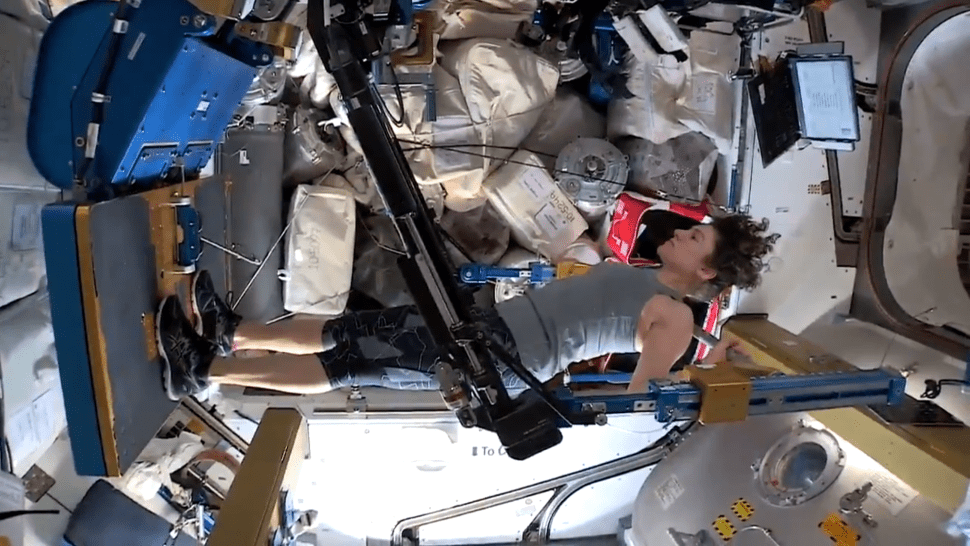

Celebrate 20 Years of Human Presence by Sweatin’ with the Station

By Janet Anderson

Join NASA for Sweatin’ with the Station, the most out-of-this-world workout as the agency celebrates 20 years of continuous human presence on the International Space Station.

Lace up your running shoes and get outside, hop on the treadmill, or choose any workout that you envision lasting up to 91minutes and 12 seconds – the amount of time it takes the space station to orbit Earth.

Think your workout can “beat” the station? Just for fun and to participate in the virtual race – simply track your start time and workout and attempt to complete the workout before the station makes one orbit.

“Considering our ties to the orbiting laboratory, we want to celebrate nearly two decades of human presence on the space station,” said Dwight Mosby, Payload Mission Operations Division manager at NASA’s Marshall Space Flight Center. “We want to encourage folks to pause and consider all the research that has gone on for 20 years and the benefits to each of us on Earth.”

Humans have lived and worked continuously aboard the space station since the Expedition 1 crew arrived Nov. 2, 2000. This orbiting laboratory has advanced capabilities in long-duration human space operations and in conducting scientific research and technology development in space. The station remains the sole, space-based proving ground, greatly enabling NASA to go forward to the Moon and Mars.

Although living and working in free fall around Earth has the advantage of providing a one-of-a-kind research platform, microgravity is also known to have health impacts to the body, including the deconditioning of bone and muscle compared to what a person experiences on Earth. To preserve muscle and bone strength and prevent microgravity adaptation, astronauts spend more than two hours a day exercising in space. They can use the space station’s bicycle, the Cycle Ergometer with Vibration Isolation and Stabilization, simulate weight lifting with the Advanced Resistive Exercise Device, or run on the treadmill.

Sweatin’ with the Station began Oct.16, with opportunities to complete the workout through the Expedition 1 anniversary Nov. 2. Participants are encouraged to take a photo as they are completing their workout and share it on social media using the hashtag #SweatinWithTheStation. These will be shared on Marshall’s social media accounts. To demonstrate success, participants can then download a completion certificate.

It is important that participants are aware that any physical activity can potentially be very challenging and thus lead to injury, illness, discomfort and, in some cases, even death. Consult with a primary physician before starting any exercise program or exercise activities.

Sweatin’ with the Station is being held in place of Racin’ the Station, a duathlon that traditionally takes place each fall at Marshall. This year’s Racin’ the Station was canceled due to the coronavirus pandemic.

Marshall oversees space station hardware development and implementation for NASA, and agency personnel at Marshall’s Payload Operations Integration Center monitor experiments continuously. As NASA’s primary space station science command post, the operations center coordinates scientific and commercial experiments on the station, synchronizes payload activities of international partners, and directs communications between researchers around the world and their onboard experiments. To help the crew in orbit conduct scientific study, the operations center is staffed 24 hours a day, seven days a week, 365 days a year.

For more information on the space station, visit here. For more about the Payload Operations Integration Center, visit here.

Anderson is a public affairs officer in Marshall’s Office of Strategic Analysis & Communications.

Marshall’s Twice-Annual ‘Go Green, Buy Local’ Event Goes Virtual in November

To mark America Recycles Day at NASA’s Marshall Space Flight Center, event organizers will expand Marshall’s “Go Green, Buy Local” sustainability event throughout November – and team members are invited to take part in the all-virtual celebration.

Twice a year for the past seven years, Marshall’s Environmental Engineering and Occupational Health Office has sponsored the center’s Go Green, Buy Local activity to promote promoting a culture of sustainability to protect the environment and sustain natural resources for current and future generations.

This year, more than 25 local vendors – all of which do business within a 50-mile radius of Marshall – will take part, providing virtual links and online information about recycled and environmentally friendly products and services they offer. Vendors confirmed at this time include A Few Old Bags, Mr. Barry’s Canned Creations, Groovy Creations, The Little Green Store and Gallery, Lulu’s Lights, Mama Kat’s Country Store, Simply Crafted, Wild About Herbs, and Huntsville Virtual Farmer’s Market contributors.

Team members are invited to visit Inside Marshall to view the Go Green, Buy Local vendor fair plus recycling and sustainability webinars and informational videos.

Environmental specialist Alura Garrison, an Amentum contractor who supports the Environmental Engineering and Occupational Health Office, said organizers continue to add new vendors daily ahead of the event.

“It’s our hope that this 30-day virtual campaign will help Marshall maintain an effective, sustainable recycling program all year long,” said Donna Leach, lead engineer for sustainability and coordinator for Marshall’s Environmental Management System.

Garrison, who has led planning for the event for the past two years, hopes Marshall’s green efforts will encourage team members to extend sustainability practices from the workplace to their homes and family activities.

“With so many of us working from home right now, it’s more important than ever to adopt green habits wherever possible,” she said. “Recycling and reducing is crucial. Even shopping locally is a sustainable effort. Every little bit helps.”

NASA’s recycling goal is to divert at least 50% of nonhazardous solid waste from landfills. In 2020, Marshall diverted 93% of landfill solid waste. Most is diverted through Marshall’s extensive Single Stream Recycling program, which allows recycling of most waste products. Other programs, like used tire recycling, battery recycling, and the Free Office Supply Exchange, also contribute to NASA’s ongoing goals to reduce, reuse, and recycle.

America Recycles Day is celebrated nationally Nov. 15 to promote recycling and environmental stewardship.

This Week in NASA History: STS-120 Launches to the Space Station – Oct. 23, 2007

This week in 2007, space shuttle Discovery, mission STS-120, launched from NASA’s Kennedy Space Center on a 15-day mission to the International Space Station. This was the 23rd shuttle mission to the orbiting lab. Discovery carried the Italian-built multiport module, named Harmony, which connected the U.S. segment of the station to the European and Japanese laboratory modules. Today, the Payload Operations Integration Center at NASA’s Marshall Space Flight Center serves as “science central” for the space station, working 24/7, 365 days a year in support of the orbiting laboratory’s science experiments. After 20 years of continuous human presence, the space station remains the sole space-based proving ground and stepping stone toward achieving the goals of the Artemis program. The NASA History Program is responsible for generating, disseminating, and preserving NASA’s remarkable history and providing a comprehensive understanding of the institutional, cultural, social, political, economic, technological, and scientific aspects of NASA’s activities in aeronautics and space. For more pictures like this one and to connect to NASA’s history, visit the Marshall History Program’s webpage. (NASA)