In This Week’s Star

- Marshall Leaders Provide Updates at Live Virtual Town Hall

- ‘Good Bones,’ Strong Core: 20 Years On, Space Station Structures Managed by Marshall Still Soar

- Even in Midst of Pandemic, Work Goes On for Marshall Small Business Office

- Nick Johnston Recognized as HEO HErO

- Marshall Kicks Off Virtual Combined Federal Campaign

- No Flu Shots at Marshall This Winter – But Med Center Leaders Encourage Vaccinations, Offer Health Tips

- OSIRIS-REx Stows Sample of Asteroid Bennu, Highlighted on ‘This Week @NASA’

- This Week in NASA History: First Flight of FOXSI – Nov. 2, 2012

Marshall Leaders Provide Updates at Live Virtual Town Hall

By Taylor Goodwin

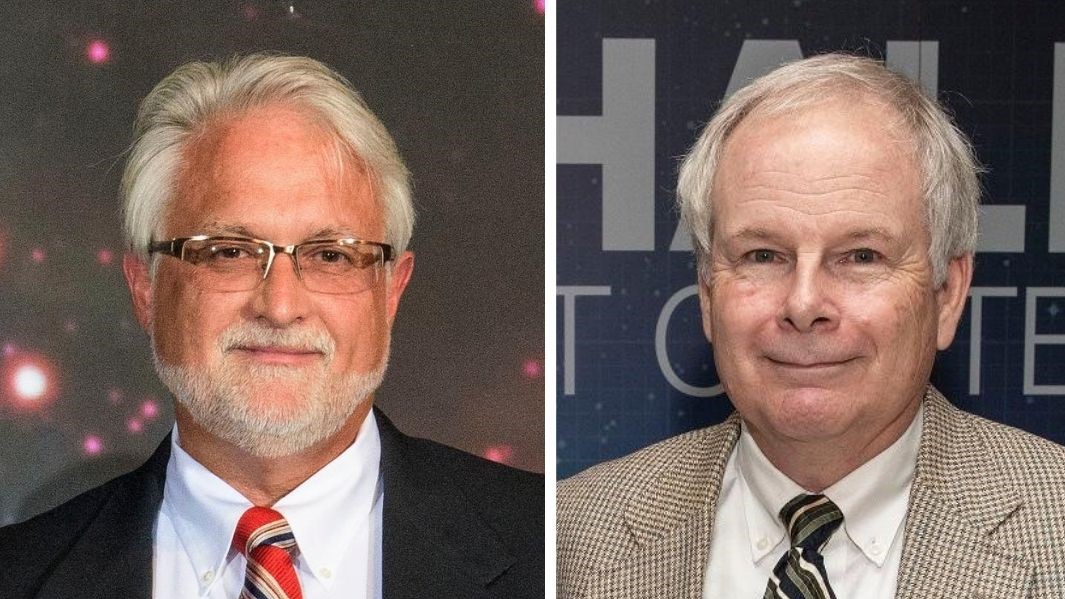

Leaders at NASA’s Marshall Space Flight Center held their second live virtual town hall meeting Oct. 29. Marshall Director Jody Singer, Deputy Director Paul McConnaughey, and Associate Director Steve Miley provided administrative and program updates followed by a question-and-answer session with team members.

The discussion primarily focused on mission milestones and updates, the center’s COVID-19 response, NASA Framework for Return to On-Site Work, and Building 4200.

Singer noted the success of the 13th annual Wernher von Braun Memorial Symposium, which was entirely virtual due to the coronavirus pandemic. The event featured panel discussions and guest speakers reflecting government, industry, academia, business, and international perspectives on space exploration.

Singer also praised the Space Launch System team on their progress with Green Run testing of the SLS core stage. Six out of the eight test cases have been completed, and the team is currently preparing for the final tests – known as wet dress rehearsal and hot fire.

“Keep in mind that this is the Artemis I hardware,” Singer said. “We have to make sure we do this right and protect this equipment. I am amazed at the SLS team and all that they have accomplished.”

Singer highlighted the Human Landing System program’s work in preparing to release Option A in the spring. This announcement will be a downselect of the companies selected to design and build the human landing systems that will deliver the first woman and next man to the lunar surface.

Singer acknowledged NASA Administrator Jim Bridenstine’s efforts in fostering bipartisan support for the agency. She recalled several accomplishments by the agency this year, including the Commercial Crew Program launch of Americans from American soil, the International Space Station celebrating 20 years in low-Earth orbit, and the OSIRIS-REx mission successfully retrieving an asteroid sample.

“I am so proud that we’re delivering on our mission and staying safe,” Singer said. “Please continue following safety protocols to maintain safety and continue missions successfully. Remember the three Ws: Wear your mask, watch your distance, and wash your hands,” Singer cautioned the workforce.

Miley provided an update on the center’s response to the COVID-19 pandemic, reporting that 1,400 to 1,500 team members are working on-site each day – approximately 23% of Marshall’s overall workforce, with the remainder of the workforce teleworking.

Miley emphasized that when the time is right, the center has a Stage 2 transition plan ready reflecting the NASA Framework for Return to On-Site Work. Once the center makes the transition to Stage 2, about 500 additional team members will return on-site and all will need to be even more vigilant in following the safety protocols. Leadership is closely monitoring virus transmission is our area and the framework to ensure the center is prepared to transition when it is safe to do so.

“We want to avoid having to stop our work, and we are very thankful for those following the guidelines to prevent that from happening,” Miley said. “In the meantime, we are going to try to leverage teleworking capabilities and use it to our advantage. We will be deliberate about how to implement this blended workforce to maximize productivity in the future.”

An exterior-facing panel fell off Building 4200 in May, which Singer explained led to building inspections, analysis of the center’s master plan, and, ultimately, the decision to deactivate the building in 2021. Building 4200 occupants will remain in mandatory telework until they can be transitioned to alternate work spaces. Safety netting will be installed around the building. Team members can currently enter the building only through the loading dock entrance at the southwest corner, provided they have received permission from their supervisor. There will be a staggered schedule for team members to pack their personal belongings. Team members can expect more communication to come as the planning and execution of the project progresses.

McConnaughey spoke to the current telework situation – explaining that leadership is analyzing how Marshall is successfully working, what areas could improve, and other teleworking techniques used in industry and other NASA centers.

“There is no one-size-fits-all solution for everybody,” McConnaughey said. “We recognize that there is stress on the workforce. We should be building our culture, building our teams, and working together to build our future. We’re looking at how these elements can be added to the current environment and put forward in the future blended workforce. This is a priority in our future planning.”

Singer closed by expressing her appreciation for the communication and diligence of team members.

“Please take care of yourselves and continue to watch out for each other,” she said. “Keep submitting your questions and we will provide as much information as we possibly can.”

Goodwin, a Media Fusion employee, supports Marshall’s Office of Strategic Analysis & Communications.

‘Good Bones,’ Strong Core: 20 Years On, Space Station Structures Managed by Marshall Still Soar

By Rick Smith

High above the turn of the world, a mammoth construct largely made of aluminum, titanium, and human ingenuity – big as a football field, easily seen from the ground with the naked eye – skates forever along the edge of the sky, while its pioneering crew works to prepare the way for new human journeys to the Moon, Mars, and beyond.

NASA is marking 20 years of continuous crew operations aboard the International Space Station, comprised of a 360-foot integrated “backbone” truss structure, four sets of 112-foot-long solar arrays, and 16 pressurized modules containing crew living quarters and state-of-the-art laboratories. Designed, built, and tested by NASA and its 15 partner nations, the station’s elements launched to orbit one by one over a 13-year period. The station is one of a kind – it weighs more than 925,000 pounds, has roughly the interior volume of a six-bedroom house, and is often the third-brightest object in the night sky.

The structure provided the backbone to transform the station into the orbiting laboratory it is today. And many of its largest structures were built, tested, and readied for flight by teams at NASA’s Marshall Space Flight Center, working in partnership with American contractors and international firms.

“We helped give the station good bones,” said retired Marshall engineer Ann McNair, a deputy division chief in Marshall’s Systems Analysis & Integration Laboratory in the late 1990s. “And on that foundation, we built a 20-year legacy of engineering and scientific discovery.”

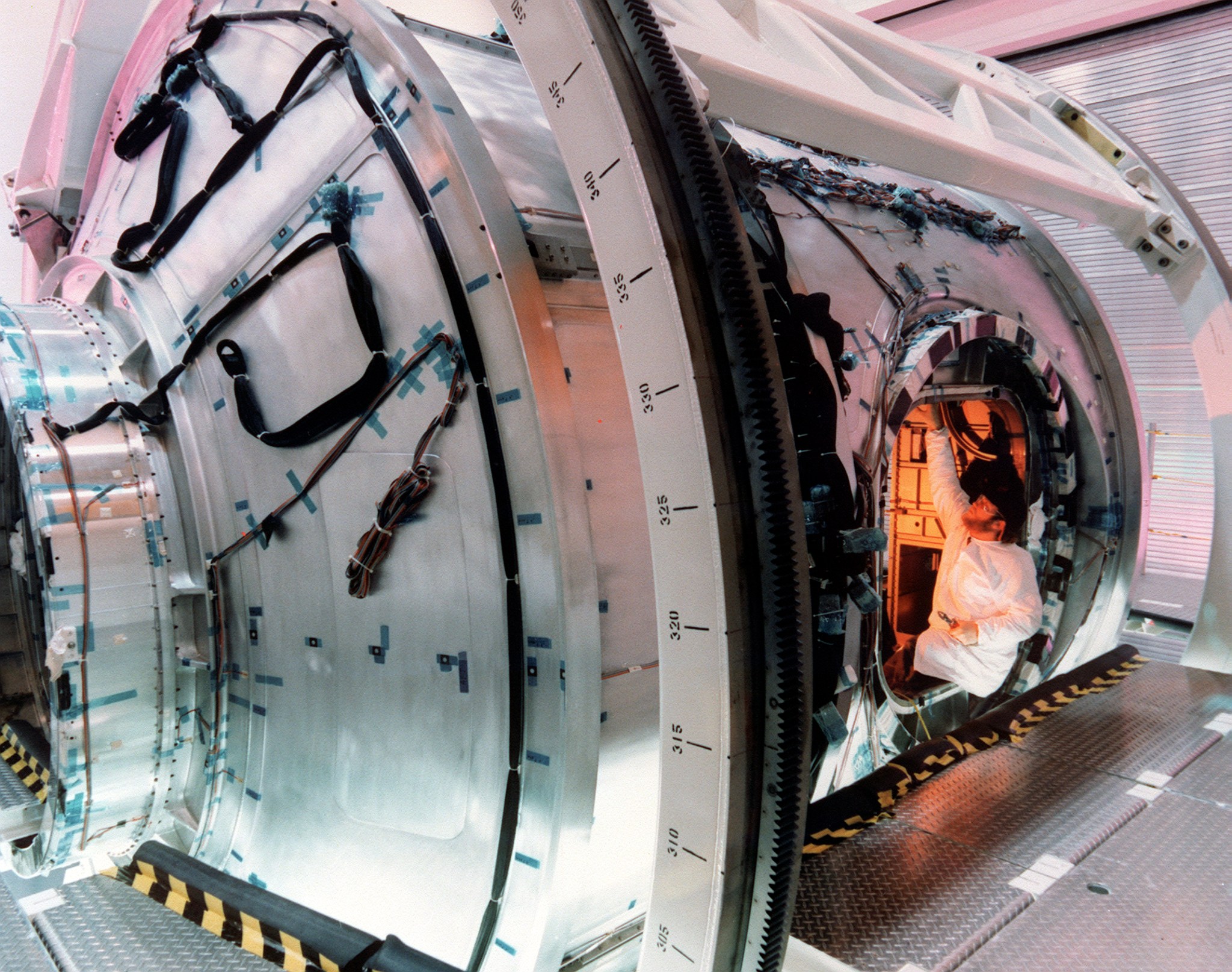

The Boeing Co. of Huntsville built Node 1 – later named Unity – as well as the Destiny lab module and the 6-ton Joint Quest Airlock at Marshall, in the same manufacturing bays and clean rooms where the first Apollo-era Saturn V rockets were built.

“As the first U.S. element to fly, Node 1 served as the fleet leader for many components and subsystems,” said Brian Mitchell, who was Node 1 element manager and subsystem manager for hatches and common berthing mechanisms. “There was tremendous enthusiasm within the Boeing and NASA teams – knowing it was our opportunity and responsibility to deliver this hardware,” he said.

Unity was mated with the Russian Zarya module in 1998, paving the way for the Zvezda module in 2000 – and continuous human occupation ever since.

Marshall also partnered with European Space Agency contractor Thales Alenia Space – formerly Alenia Spazio – in Turin, Italy, to test, integrate, and deliver Node 2 and Node 3, later named Harmony and Tranquility, respectively.

Steve Pavelitz was a systems engineer who managed module-to-module interfaces for Node 2, working with Boeing, Alenia, and engineers at Marshall and NASA’s Glenn Research Center, guided by the NASA Vehicle Office at Johnson Space Center.

“We had oversight of everything inside the modules, from ventilation valves and electrical equipment to power connections for the science racks, lab hardware, and life support equipment,” Pavelitz said. “The station’s configuration evolved on the fly, instantly changing specifications for structures and connective elements – most of which were being individually built and tested at facilities separated by thousands of miles.”

Jimmy Grisham, a 20-year NASA engineer who retired in 2011, was a Marshall technical advisor, part of a nodes project team tasked with overseeing timely delivery to Italy of electrical and communications hardware and instrumentation. They even traveled periodically to Torino to assist with integration of node hardware and support technology.

“We were always glad to work with our Italian and European counterparts, who were as proud as we were to be part of this historic endeavor,” Grisham recalled. “The work sealed friendships among many of us around the world. We still keep in touch.”

Node 2, flown to orbit in 2007, expanded crew accommodations from three astronauts to six and now connects the Destiny lab, Columbus laboratory and Kibo laboratory. Node 3, flown and installed in 2010, added regenerative life support systems and the Cupola observation module, which offers the crew stunning views of their homeworld below.

Boeing was NASA’s prime contractor on the station’s integrated truss structure, the framework that supports the entire orbiting platform. It was fabricated segment by segment in 2001-2002 in the company’s Huntington Beach, California, facilities, then shipped to Marshall and other NASA sites for flight readiness testing.

On-site at Marshall, NASA and Boeing engineers tackled integration and testing of the S1 truss, the primary central backbone. They installed critical flight hardware, verified electrical connections, and used Marshall’s cutting-edge test hardware to simulate the dynamic stresses endured by the truss during launch and in space.

Launched to orbit in 2002, the backbone truss links the mighty solar arrays and the modules, routes power to crew compartments and labs, and siphons away heat from the modules to the port and starboard thermal radiator truss sections.

“We still have the S1 truss structural test article in our building, and it reminds us what makes the International Space Station different from any other station: its iconic truss structure and central power-generation capability, enabling more and more research,” said Tim Tripp, Boeing’s space station senior manager in Huntsville. “The science underway up there keeps improving the future – and the truss network helps get it done.”

NASA and its global partners assembled the station in orbit, delivering all hardware and elements via 37 space shuttle flights and four uncrewed Russian launches. To date, more than 240 individuals from 19 countries have spent time on the station. More than 3,000 research investigations have been conducted, involving scientists from more than 100 countries.

At Marshall, the work goes on. Mitchell is the space station chief engineer, continuing to refine hardware and technology for future use in Moon and Mars missions. Pavelitz is a payload manager for NASA’s Imaging X-ray Polarimetry Explorer space observatory, set to launch in 2021. McNair and Grisham are enjoying their retirement.

But each one still walks outside when they know the station is passing overhead – each flyover a reminder of what can be achieved by people of passion, vision, and will.

“It still takes my breath away,” McNair said. “Every single time.”

Read the complete anniversary feature here.

Smith, a Manufacturing Technical Solutions employee, supports Marshall’s Office of Strategic Analysis & Communications.

Even in Midst of Pandemic, Work Goes On for Marshall Small Business Office

By Rick Smith

October ended in a flurry of successes – new partnerships and new opportunities for more to come – for the Small Business Office at NASA’s Marshall Space Flight Center.

On Oct. 27, Marshall small business leaders oversaw the official signing of a NASA Mentor-Protégé Agreement between NASA prime contractor Jacobs Engineering of Tullahoma, Tennessee, and Huntsville-based JBS Solutions Inc. The agreement combines Jacobs’ proven business acumen with its protégé’s cutting-edge technical capabilities to deliver NASA mission solutions and grow the spaceflight industry.

“The NASA Mentor-Protégé Program is a vital tool for advancing NASA’s mission in space, honing the skills of our commercial partners, and providing a pipeline to train and replenish the industry’s science and engineering workforce for generations to come,” said David Brock, program manager of NASA’s Mentor-Protégé Program, who has served as Marshall’s small business specialist for more than three decades.

NASA approved the agreement between Jacobs and JBS in April, but delayed the signing event until COVID-19 safety protocols could be enacted. Under the two-year agreement, JBS Solutions, an 8(a) certified, woman-owned, small disadvantaged business, will aid Jacobs in delivering engineering and science support services at Marshall.

JBS’s corporate offices are located in a Historically Underutilized Business Zone, qualifying it as a HUBZone-certified business as well. The U.S. government established HUBZone certification in 1997 to empower economically challenged communities.

Created in 2008, the Mentor-Protégé Program facilitates mutually rewarding agreements between NASA’s large contractors and eligible small businesses and academic institutions. Marshall, a six-time recipient of the NASA Small Business Administrator’s Cup for the agency’s most effective center-led small business program, has guided 18 of the 41 agreements signed across NASA since 2008, and has managed the program for NASA’s Office of Small Business Programs since 2019.

The Small Business Office virtually hosted a contingent of area and regional business representatives Oct. 29 for the 30th Marshall Small Business Alliance meeting.

Hundreds of small business leaders and executives logged in to hear Marshall updates about ongoing work to deliver NASA’s flagship rocket, the Space Launch System, and to develop, test, and fly the new Human Landing System, which will ferry Artemis Generation crews to and from the surface of the Moon.

Brock welcomed NASA Deputy Administrator James Morhard, Marshall Associate Director Steve Miley, and other speakers. Participants also took part in breakout panel sessions about doing business with NASA and NASA prime contractors, and the challenges facing small businesses in the modern corporate climate.

For more than a decade, the Marshall Small Business Alliance meeting has aided small businesses in their pursuit of NASA procurement and subcontracting opportunities. The meeting, which was held virtually for the first time due to COVID-19 safety protocols, is cosponsored by Marshall’s Office of Procurement.

The Small Business Office also virtually held its sixth annual Historically Black Colleges and Universities/Minority Serving Institutions Partnerships Meeting on Nov. 3. Nearly 100 participants, representing some 25 minority-serving schools around the country, took part.

The event highlights the critical role historically Black colleges and universities and other minority-serving institutions play in the success of NASA’s missions, and the long-term national value and impact of those partnerships.

Smith, a Manufacturing Technical Solutions employee, supports Marshall’s Office of Strategic Analysis & Communications.

Nick Johnston Recognized as HEO HErO

Nick Johnston is the latest team member from NASA’s Marshall Space Flight Center to be named a HEO HErO. Johnston is lead of the Thrust Vector Control Team and test conductor for Space Launch System core stage system level testing. His team has proven proficient at collaborating, planning, preparing, reviewing data, reporting results, and communicating with decision makers regarding their findings. Each week, NASA’s Human Exploration and Operations Mission Directorate recognizes HEO HErOes, team members from across the agency who have made vital contributions in their support of NASA’s mission to land the first woman and next man on the Moon by 2024. (NASA)

Marshall Kicks Off Virtual Combined Federal Campaign

By Stephanie Kelley

On Nov. 4, NASA’s Marshall Space Flight Center officially kicked off its support of the Combined Federal Campaign of Greater Tennessee Valley, the annual federal government giving campaign to benefit local, state, and national charitable organizations.

In light of the COVID-19 pandemic, this year’s campaign is a virtual event. Marshall will not offer charity van tours or in-person volunteer activities for the health and safety of its workforce and in keeping with the center’s Stage 3 status in the NASA Framework for Return to On-site Work. Marshall team members are encouraged to “Show Some Love” as well as “Be the Face of Change,” this year’s returning theme and new sub-theme for the 2020 campaign.

Although an in-person rally will not be held, the Marshall workforce is invited to watch Marshall Deputy Director Paul McConnaughey in an official kickoff video. Charitable organizations have also posted videos and success stories online. For more local organizations’ videos, visit the CFC page on Inside Marshall. Marshall team members can make a one-time contribution or set up a recurring one to support local organizations such as the Land Trust of North Alabama, the Food Bank of North Alabama, the Downtown Rescue Mission in Huntsville, and many more charities that rely on support from the CFC campaign each year.

“While this year has brought us all many challenges and doesn’t allow for us to gather together as in years past, the many charitable organizations that CFC supports still need our support, possibly more now than ever before,” said Kristin Morgan, contractor’s officer representative for the SLS Liquid Engines Office and Marshall CFC chair for 2020. “I hope that our Marshall community will continue to ‘show some love’ and generosity as it has in the past and be the light these groups need during this unprecedented time.”

Last year’s campaign donations from Marshall’s workforce totaled more than $312,000, exceeding the prior year’s, and volunteer hours more than doubled from the 2018 CFC campaign.

Team members who have signed up to serve as CFC organization leads and keyworkers are encouraged to join one of the first virtual training sessions on Microsoft Teams Thursday, Nov. 5, at 10 a.m. or 3 p.m. Contact Morgan or Lindsey Ingram, Marshall’s CFC vice chair, for more details.

Civil servants engaging in CFC volunteer activities should do so on their own time. The agency has considerable flexibility for employees seeking to volunteer for CFC activities during the workweek, which may include approving alternative work schedules, granting employees annual leave, leave without pay, and compensatory time off. Contractors should consult their company program manager for guidance regarding leave to volunteer.

The campaign, which will run until Jan. 15, 2021, will include “Causes of the Week,” weekly spotlights which highlight various charitable organizations and need-based causes supported by CFC.

“There’s no shortage of worthy causes our workforce can support and help to make a positive impact,” Morgan said. “CFC has made it easy, even in the midst of a pandemic, to help make a difference to others in need.”

Since CFC was founded in 1961, the national effort has raised more than $8.4 billion for charitable organizations. Team members can learn more about the campaign and download Marshall-specific contribution instructions and materials on Inside Marshall, or sign up for updates about the national effort. Follow the Tennessee Valley CFC effort on Facebook and Twitter.

Kelley, a Media Fusion employee, supports Marshall’s Office of Strategic Analysis & Communications.

No Flu Shots at Marshall This Winter – But Med Center Leaders Encourage Vaccinations, Offer Health Tips

By Rick Smith

In light of NASA’s COVID-19 safety protocols, the medical center at NASA’s Marshall Space Flight Center is not offering on-site flu shots for the 2020-21 winter season.

All team members and their families, however, are strongly encouraged to get vaccinated as soon as possible, stressed Marshall Medical Director Dr. Joseph Musick and Occupational Health Officer David Thaxton.

“Call your personal or family physician and schedule your shots,” Musick suggested. “Alternately, you can get flu vaccinations at many neighborhood pharmacies, including CVS, Kroger, Publix, Walgreens and Walmart. Some even offer incentives to get them on-site in their facility.”

Musick and Thaxton – who discussed the COVID-19 pandemic in an article in the Aug. 12 issue of The Marshall Star and provided safety tips for team members and their families – said it’s important to be proactive, but also not to panic at the first signs of illness.

“Many COVID-19 symptoms can mimic common flu symptoms,” Musick said. “Team members and their families who show signs of viral infection or have been exposed to any positive or potentially positive case should get tested right away.” Once flu symptoms develop, it’s too late for a shot – the time to get vaccinated is now, before the winter season takes hold.

Flu shots don’t always prevent the recipient from getting a flu virus, Musick noted, but they can, in most cases, minimize the effects and length of a bout of flu.

The U.S. Centers for Disease Control and Prevention estimates that flu has accounted for 12,000 to 79,000 deaths annually in the United States since 2010. Those at highest risk include small children and the elderly, people with underlying lung problems such as asthma, and those who are immunologically compromised due to a previous illness or condition.

“But reducing the spread of flu among healthier persons is critical,” Thaxton noted, “to help protect these at-risk groups – and to reduce the burden of care already taxing the medical industry due to the COVID-19 pandemic.”

Most modern flu vaccinations are quadrivalent doses, designed to help curb the spread of the two influenza A strains and two influenza B strains that are most prevalent worldwide each year. Because the flu virus is constantly mutating, it requires precision medical tracking and evaluation to get the formula right for as many shot recipients as possible.

“The makeup of these vaccines changes each year as the CDC and its global epidemiology partners track new cases around the world to determine which flu strains are on the move and which present the greatest risk,” Thaxton said.

That means scientists typically are working a year in advance to deliver their analysis and enable industry to begin manufacturing vaccines. Medical professionals and pharmacists typically order winter flu shot doses in early summer each year. The uncertainties and safety precautions associated with COVID-19 quarantine hindered that process for 2020, Musick said.

One small positive this season, he noted, is that it’s highly unlikely for a person who isn’t severely immunologically compromised to develop both viruses at once.

“Viruses are hard taskmasters. They take over cells in the body and force them to reproduce the virus,” Musick said. “They’re bad sports, even within their own taxonomic families, so they also produce a chemical called interferon, which inhibits the growth of competing viruses.”

Both experts caution against self-diagnosis or “riding it out” if one becomes ill. “There is no sure way to determine at home which virus you have,” Thaxton stressed. “The only truly distinctive COVID-19 symptom that does not correlate with flu is the loss of smell or taste – but you can still have coronavirus and never exhibit that particular symptom.”

“Get your flu shots,” Musick said. “Practice social distancing and other safety measures. And if you develop symptoms, call your doctor. This isn’t the season for monkeying around with illness.”

For more health and safety information, visit the Marshall Medical Center’s page on Inside Marshall here.

Smith, a Manufacturing Technical Solutions employee, supports Marshall’s Office of Strategic Analysis & Communications.

OSIRIS-REx Stows Sample of Asteroid Bennu, Highlighted on ‘This Week @NASA’

NASA’s OSIRIS-REx mission has safely stowed the sample collected of asteroid Bennu and is featured in “This Week @NASA,” a weekly video program broadcast on NASA-TV and posted online.

The OSIRIS-REx spacecraft collected so much sample material from Bennu on Oct. 20 that the collection unit could not hold it all. Mission managers made the call to stow the sample days earlier than planned to minimize losing any more material. The stowage process safely sealed the material in a capsule that will transport it back to Earth in 2023 for study.

OSIRIS-REx is a project of the Science Mission Directorate’s New Frontiers Program, managed by NASA’s Marshall Space Flight Center.

View this and previous episodes at “This Week @NASA” on NASA’s YouTube page.

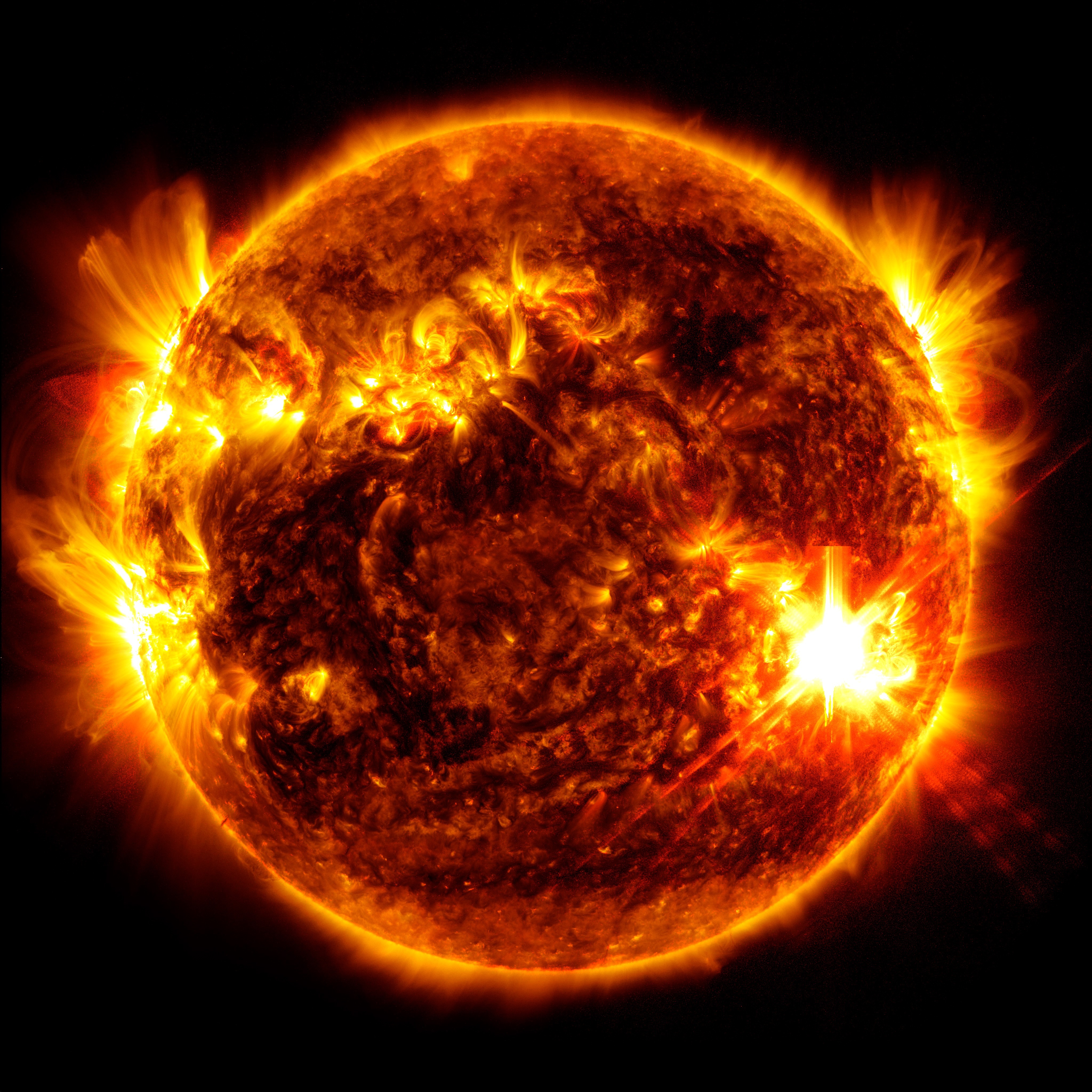

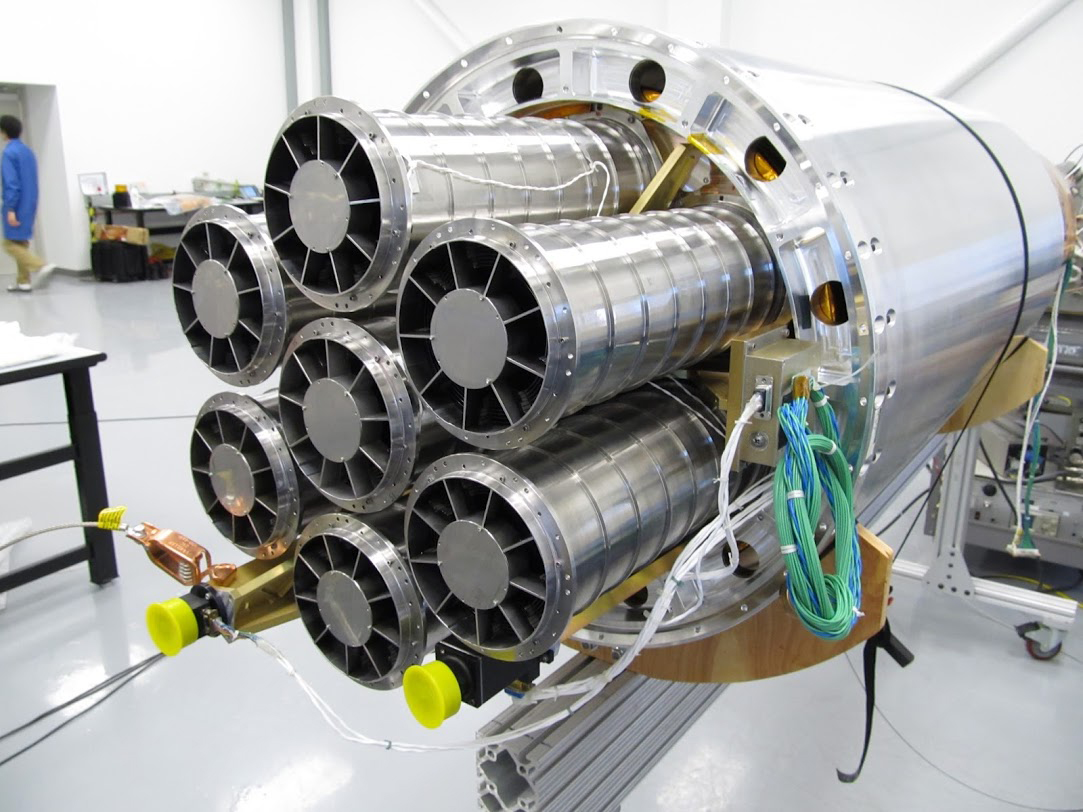

This Week in NASA History: First Flight of FOXSI – Nov. 2, 2012

This week in 2012, the Focusing Optics X-ray Solar Imager was launched from White Sands Missile Range in New Mexico. Composed of seven grazing-incidence telescope modules, FOXSI examined barely visible solar nanoflares. NASA’s Marshall Space Flight Center built the FOXSI mirrors in a collaboration between the Astrophysics Office and the Sensors, Imaging and Optics Branch with support from Jacobs Technology in Huntsville. The NASA History Program is responsible for generating, disseminating, and preserving NASA’s remarkable history and providing a comprehensive understanding of the institutional, cultural, social, political, economic, technological, and scientific aspects of NASA’s activities in aeronautics and space. For more pictures like this one and to connect to NASA’s history, visit the Marshall History Program’s webpage. (NASA)