Director’s Corner: Marshall Demonstrates Resilience During Year of COVID-19, Telework

March 13 marks one year of mandatory telework at NASA’s Marshall Space Flight Center due to COVID-19. If you’d told me one year ago that all this would happen, I wouldn’t have believed you. I would not have thought most of us would be working from home, testing our IT capabilities, time management, and above all, patience. I wouldn’t have imagined that for those on-site, courage, vigilance, and perseverance would be required to come to work. I want to encourage you today, to see it how I see it now, as time has passed.

Together, we have delivered through tremendous adversity. We faced our challenges. We have endured loss in our families, including in our Marshall family. We learned more about this virus, and we continue to learn more each day. And we witnessed what we can do when we do it together. Thank you for pushing forward. I know it hasn’t been easy.

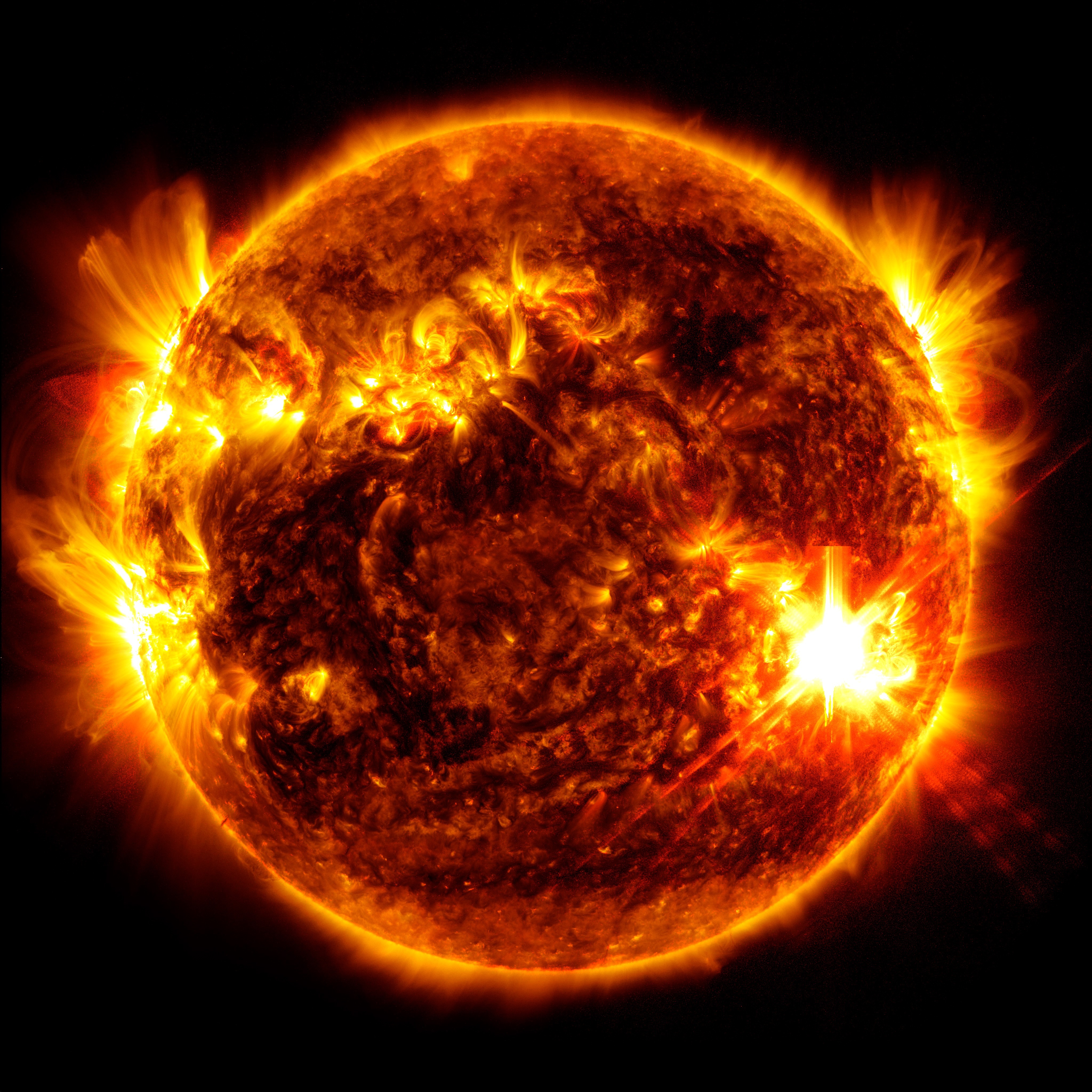

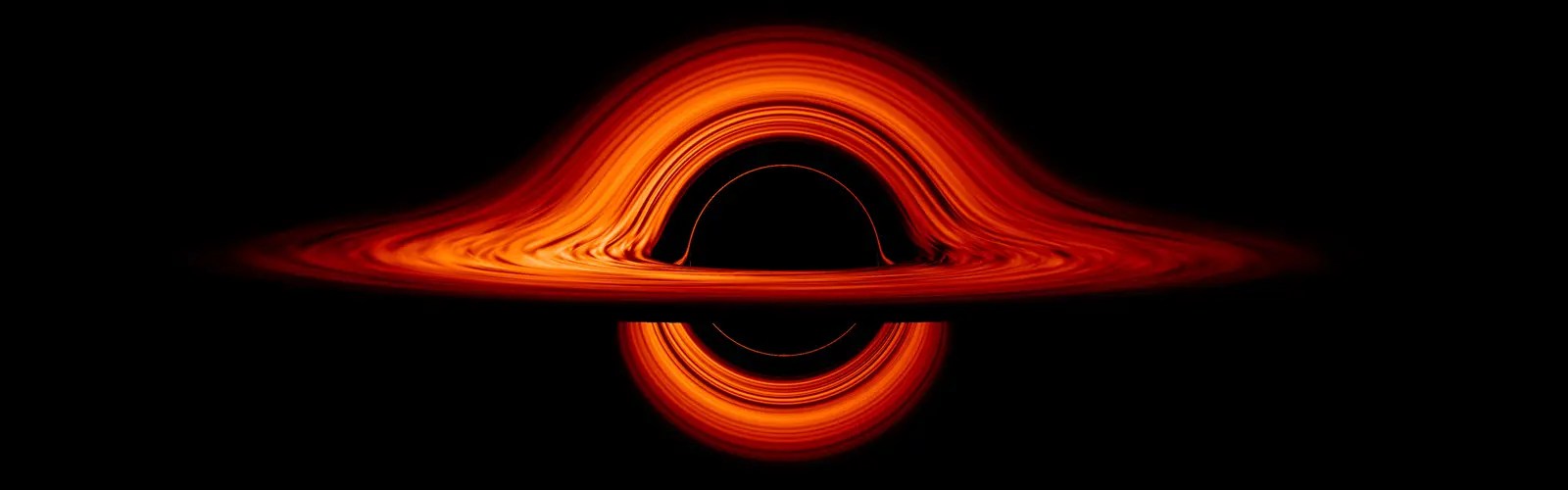

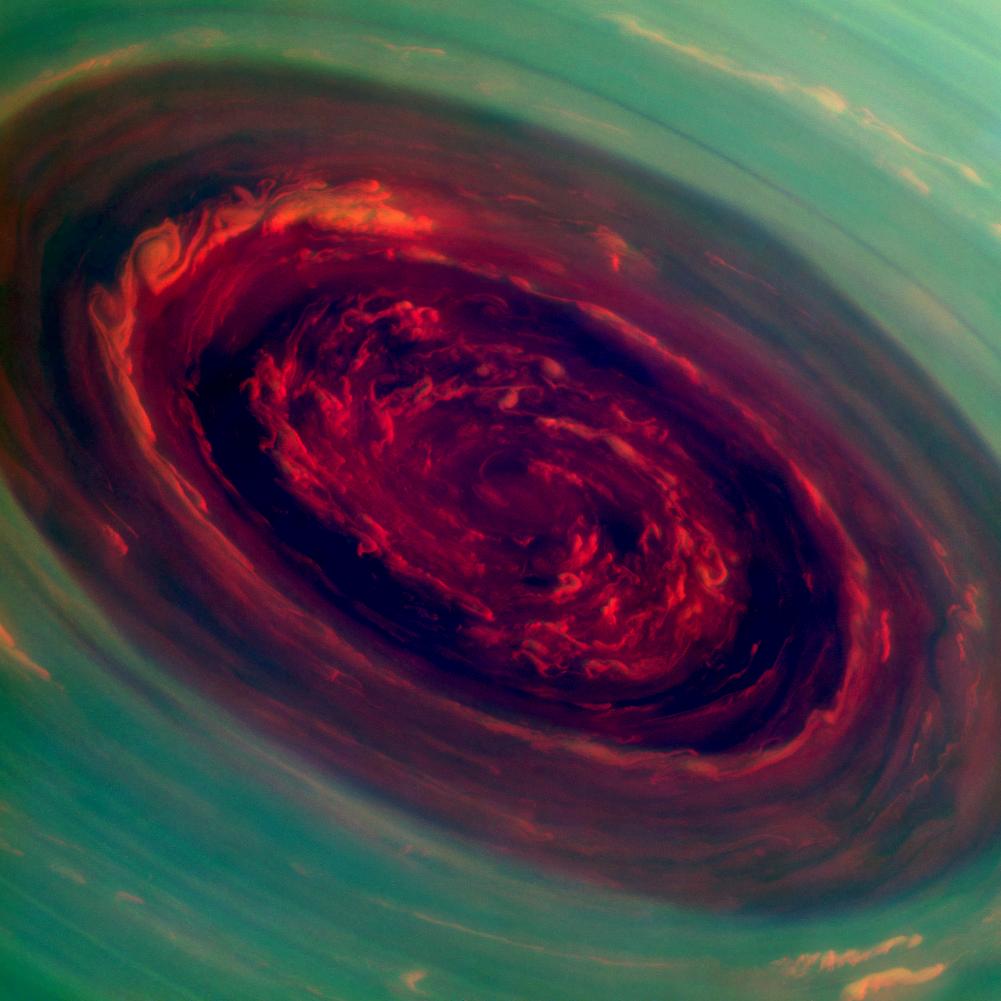

But Marshall is still making the impossible possible every day. And that’s because of you. I look at all we have done and I feel pride in what we will do next. These lessons will pay forward. This team is leading the way for the first woman and next man to land on the Moon and go to Mars. We continue to learn and work toward the next great scientific discoveries about asteroids, black holes, our Sun, and our own planet.

And we continue to develop technologies that will solve our greatest spaceflight challenges. Our renewed commitment to safety will make sure we do it all right.

We persevere, we grow, we achieve, and we move forward – together.

Thank you.

NASA Test Teams Repair Valve for Mid-March Hot Fire Test

Engineers at NASA’s Stennis Space Center have successfully repaired a liquid oxygen valve on the core stage for NASA’s Space Launch System rocket. Subsequent checks have confirmed the valve is operating properly. Following completion of functional testing, teams will move forward with final preparations for a second Green Run hot fire test targeted for March. 18. The valve is part of the core stage’s main propulsion system and is opened at the beginning of the test and closed, if necessary, to stop the flow of liquid oxygen from the core stage propellant tank to the respective RS-25 engine during a hot fire. The hot fire is the last test before the Artemis I core stage is shipped to NASA’s Kennedy Space Center for assembly and integration with the rest of the rocket’s major elements and NASA’s Orion spacecraft. For the latest on the Green Run preparations, visit the Artemis blog here. (NASA)

NASA Completes Stacking of SLS Rocket Boosters for Artemis I

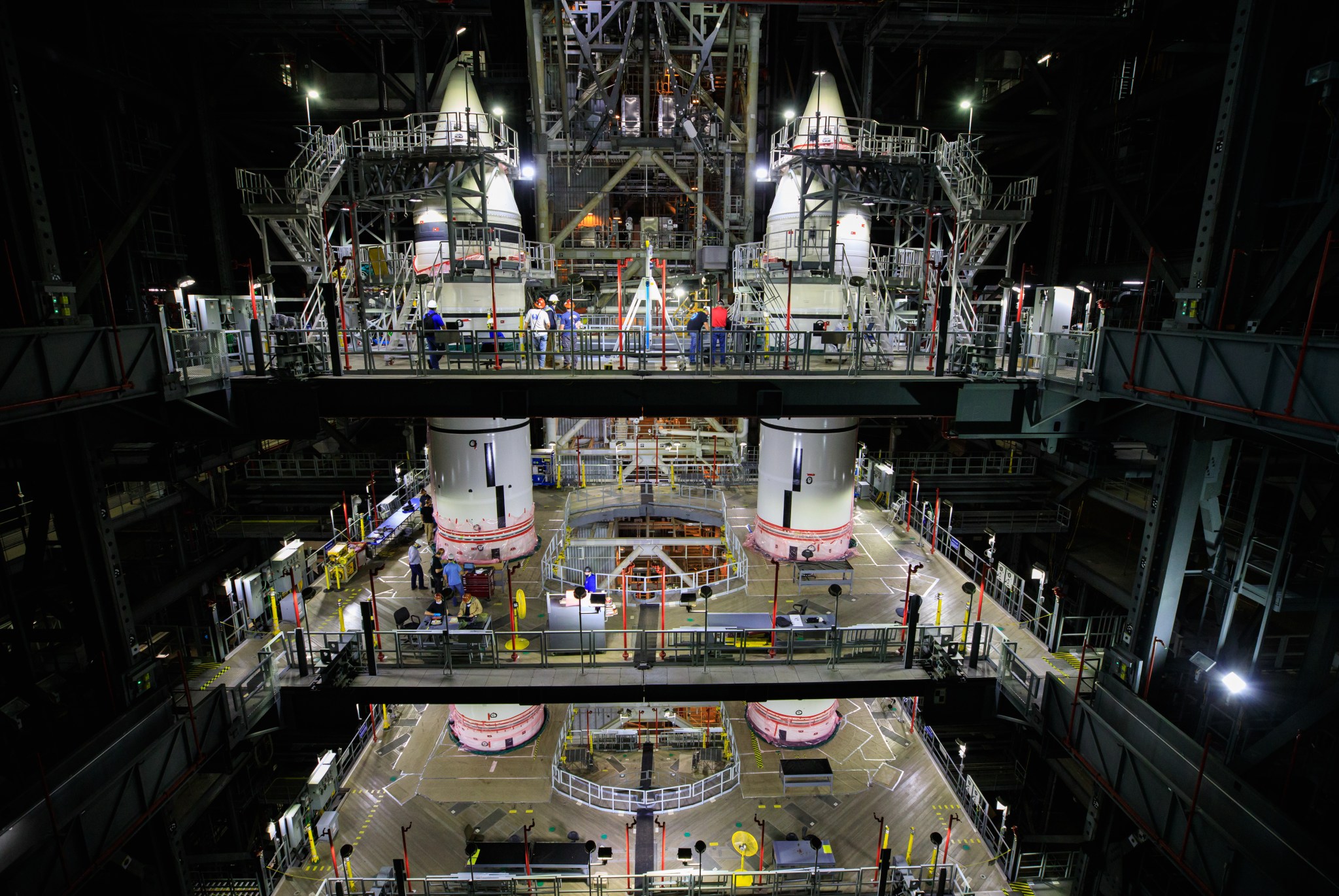

The Artemis I twin solid rocket boosters for NASA’s Space Launch System rocket have been fully stacked on the mobile launcher inside the Vehicle Assembly Building at NASA’s Kennedy Space Center.

Engineers and technicians with NASA’s Exploration Ground Systems placed the first segment on Nov. 21, 2020, and completed the stacking process when the final nose assembly was lowered on top of the fifth motor segment March 2. Now fully stacked, the SLS solid rocket boosters are the largest solid rocket boosters ever built for spaceflight. Each booster is more than 17 stories tall.

Prior to the arrival of the core stage, the team will finish installing electrical instrumentation and pyrotechnics, then test the systems on the boosters. When the SLS core stage arrives at Kennedy following the completion of the core stage Green Run test series at NASA’s Stennis Space Center, technicians will transport it to the Vehicle Assembly Building and then stack it on the mobile launcher in between the two boosters.

“Seeing the Space Launch System solid rocket boosters stacked completely on the mobile launcher for the first time makes me proud of the entire team, especially the Exploration Ground Systems crew at Kennedy, who are assembling them and also the teams at Marshall and Northrop Grumman who designed, tested, and built them,” said Bruce Tiller, SLS boosters manager at NASA’s Marshall Space Flight Center. “This team has created the tallest, most powerful boosters ever built for flight, boosters that will help launch the Artemis I mission to the Moon.”

Artemis I is an uncrewed flight to test the SLS rocket and NASA’s Orion spacecraft as an integrated system. The boosters provide more than 75% of the thrust at liftoff. Along with the four RS-25 engines at the bottom of the core stage, the SLS rocket will produce more than 8.8 million pounds of thrust to power missions to deep space.

Marshall, Michoud Workers, Teams Receive Agency-level NASA Honor Awards

On March 4, individuals and team members at NASA’s Marshall Space Flight Center and NASA’s Michoud Assembly Facility were honored during the annual, agency-level NASA Honor Awards. The virtual event included introductory remarks from Marshall Director Jody Singer, left, and her administrative team, and keynote remarks by Kathy Lueders, associate administrator of NASA’s Human Exploration and Operations Mission Directorate. “Looking across the breadth of human spaceflight activity, I see connections between our work on every level,” Lueders said, “pushing the boundaries of technology, learning more about our planet, and solving some really big problems along the way.” Singer also praised her team’s contributions to the nation’s mission in space. “When all of our people work together to achieve a common goal, we transform all that is possible – and we lead the way from liftoff to landing to make deep space exploration possible,” she said. Among the honors presented were 19 NASA Outstanding Leadership Medals, 17 NASA Exceptional Service Medals, 14 NASA Exceptional Achievement Medals, 15 NASA Early Career Achievement Medals, 25 individual NASA Silver Achievement Medals, and 24 NASA Group Achievement Awards. Find the complete list of awards and recipients here. (NASA)

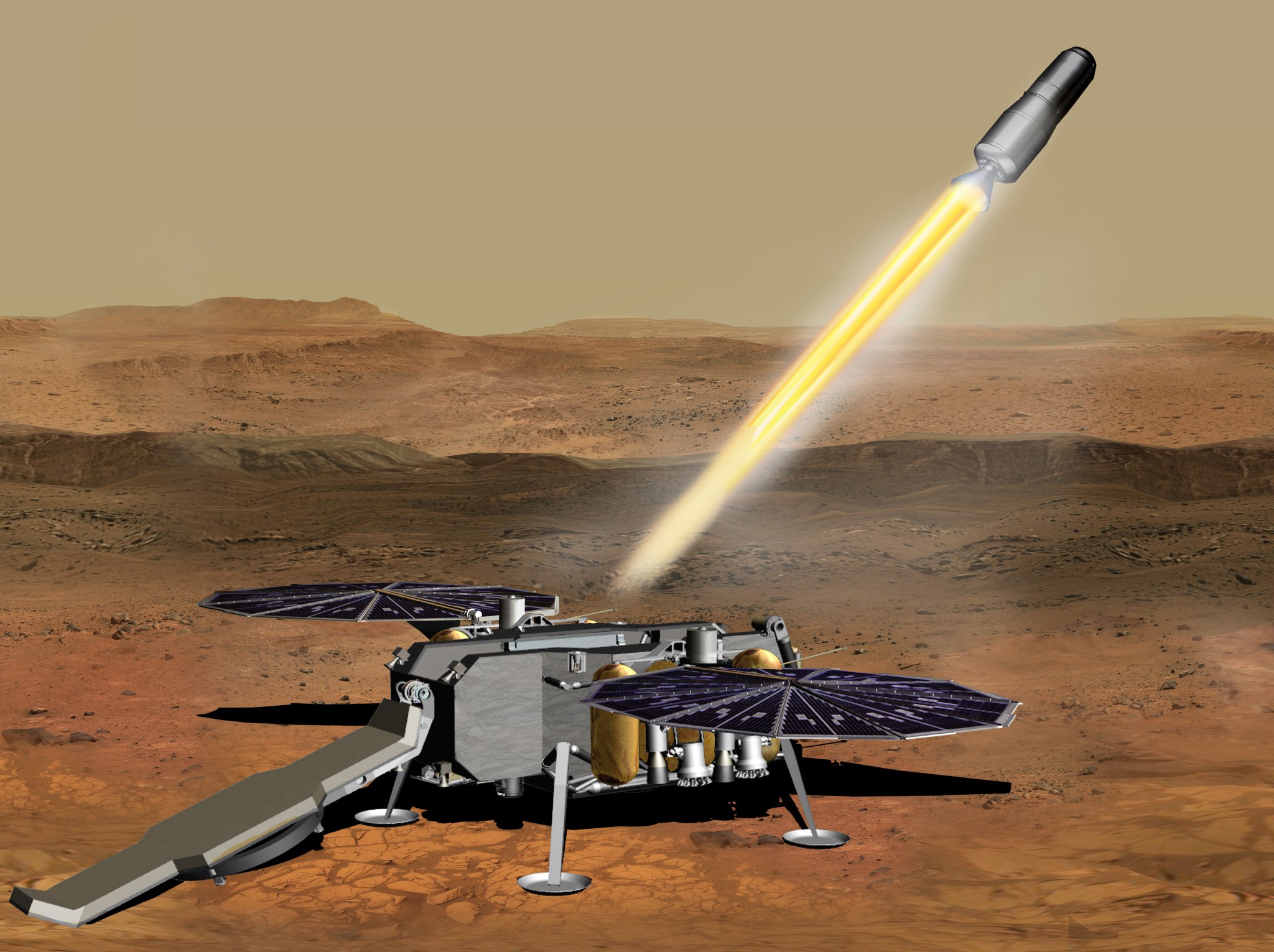

NASA Awards Mars Ascent Propulsion System Contract for Sample Return

NASA has awarded the Mars Ascent Propulsion System contract to Northrop Grumman Systems Corporation of Elkton, Maryland, to provide propulsion support and products for spaceflight missions at the agency’s Marshall Space Flight Center.

Coupled with the successful touchdown of the Mars Perseverance rover, this award moves NASA and the European Space Agency one step closer to realizing Mars Sample Return, a highly ambitious planetary exploration program that will build upon decades of science, knowledge, and experience of Mars exploration.

The cost-plus, fixed-fee contract has a potential mission services value of $60.2 million and a maximum potential value of $84.5 million. Work on the Mars Ascent Propulsion System begins immediately with a 14-month base period, followed by two option periods that may be exercised at NASA’s discretion.

In the next steps of the Mars Sample Return campaign, NASA and the European Space Agency will provide components for a Sample Retrieval Lander mission and an Earth Return Orbiter mission. The lander will deliver a Sample Fetch Rover and Mars Ascent Vehicle to the surface of the Red Planet. Marshall is responsible for the ascent element, a two-stage vehicle that will be critical in retrieving and returning samples that Perseverance collects.

The Martian environment will be a significant factor in the design, development, manufacturing, testing, and qualification of two different solid rocket motors with multiple deliveries of each. Through the contract, Northrop Grumman will provide the propulsion systems for the Mars Ascent Vehicle, as well as other supporting equipment and logistics services.

Bringing Mars samples back to Earth will allow scientists across the world to examine the specimens using sophisticated instruments too large and too complex to send to Mars, and will allow future generations to study them using technology not yet available. Curating the samples on Earth will allow the science community to test new theories and models as they are developed, much as the Apollo samples returned from the Moon have done for decades.

Marshall Spinoffs Increase 3D Printing Capabilities, Tackle Foot Odor

Newly reported spinoffs from NASA’s Marshall Space Flight Center offer an unlikely pair of benefits for space and commercial applications. An insert made from space-age material helps reduce pungent shoe odors, and an advanced 3D printer enables printing of electronics on demand. The technologies are featured in the latest edition of NASA’s Spinoff publication, released December 2020.

“Technologies derived from Marshall demonstrate our capability to create solutions that are effective from the workspace to outer space,” said Terry Taylor, manager of the Technology Transfer Office at Marshall.

Air quality in a contained environment is important, especially for spacefaring astronauts. Space purification systems must clear the air of carbon dioxide introduced by astronauts’ exhalations as well as chemical compounds produced by experiments and equipment.

One such compound is siloxane, which is off-gassed from plastics like printed circuit boards. Researchers like Jay Perry, a filtration technologies expert at Marshall, tested a variety of materials to filter the gas.

“There is a rich and long history of using activated carbons for these applications going back to Project Mercury,” Perry said, referencing NASA’s first human spaceflight program from 1958-1963.

While Perry and researchers ultimately landed on a solution using granular activated charcoal, they found that an alternative – activated charcoal cloth – performed strongly as well.

Taylor Wiegele became familiar with Perry and his research through his time working at SpaceX of Hawthorne, California. While attending Harvard Business School, Wiegele and four classmates decided to use the cloth as a shoe insert as part of an assignment. It worked.

Wiegele and business partner Sierra Smith launched the company Zorpads in New York; this move led to an appearance on the popular TV show “Shark Tank.” They even secured an investment from personalities on the show.

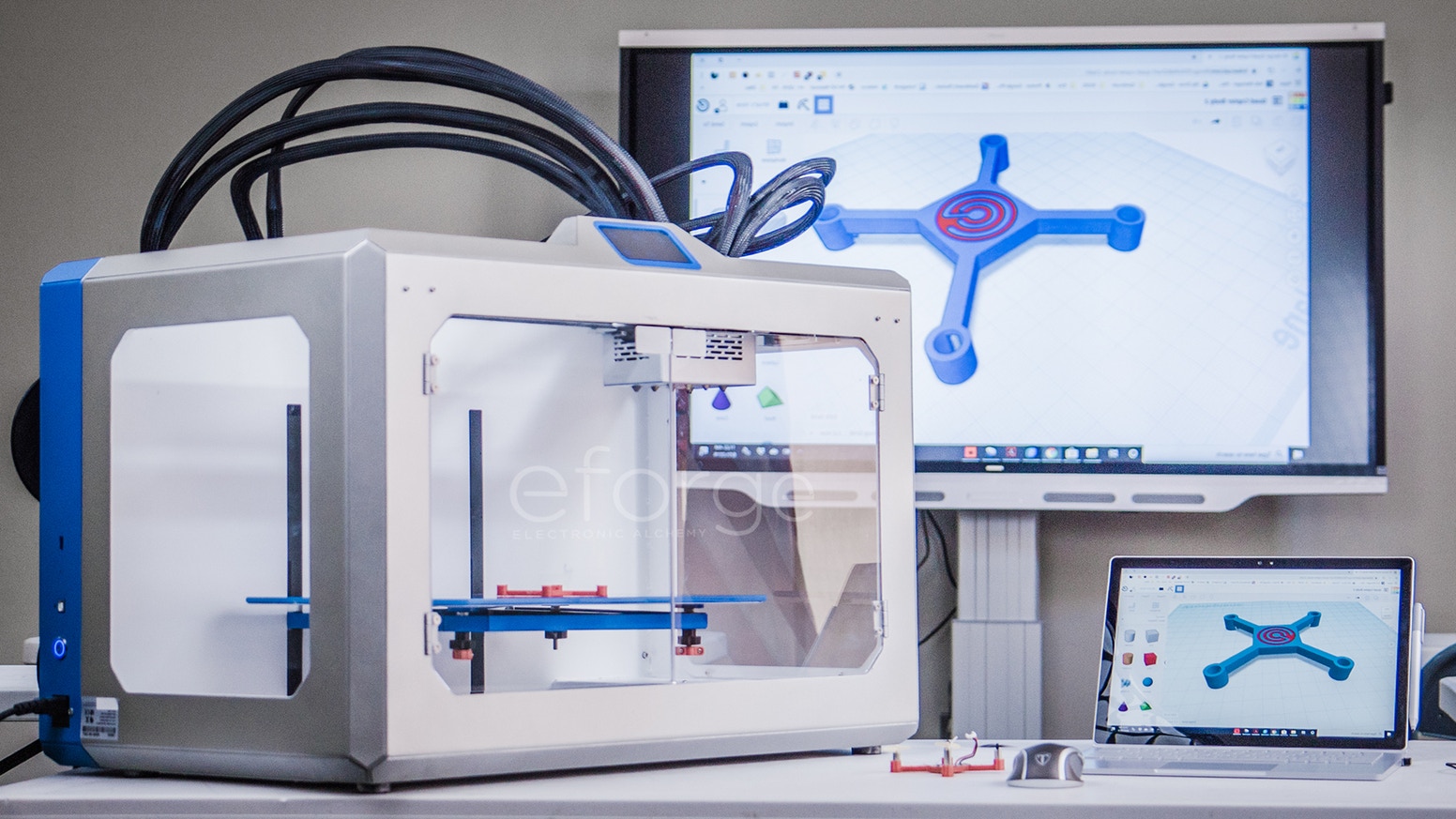

Chance Glenn also relied on Marshall expertise to advance the Huntsville-based Electronic Alchemy’s eForge – a 3D printer for electronics that enables anyone to print their own sensors, lights, and other electronic components on demand.

Glenn received approximately $1 million in Phase I and Phase II NASA Small Business Technology Transfer contracts. The transfer program funds research and development projects in technology areas that contribute to the agency’s missions. He also received a Phase III Small Business Innovation Research contract.

Tracie Prater, a materials engineer at Marshall working on the agency’s In-Space Manufacturing Project, provided technical oversight of the novel printer’s development.

“Currently the paradigm is that everything that’s used in space gets launched from Earth,” Prater said. “When you’re looking at analyses for long-duration missions – going to Mars or having a sustained deep space habitat – the logistics requirements become, in some ways, prohibitive.”

On-demand printing of parts, tools, and components could help reduce launch mass, making crewed missions to deep space more feasible and self-sufficient.

Glenn and the Electronic Alchemy team not only had to develop a machine that could print electronics, but they also had to develop the filaments to do it. The eForge printer uses fused disposition modeling, which is similar to how a hot glue gun works: the filament is heated into a liquid, extruded, deposited, and allowed to re-solidify.

Initially, six materials were developed with verification from engineers at Marshall. The materials can be used in switches, communications equipment, and solar cells, and they can be combined to create more complex machines, such as circuits and computers.

More filaments are being developed, as are improvements to the printer. The first eForge has a single arm that picked up a filament cartridge, printed with it, and put it back down before retrieving the next filament. The materials are laid down in layers, and the machine can print up to eight materials per layer. Future iterations will allow for more materials per layer.

Glenn hopes eForge will be also useful for universities and schools, as well as research and development applications, citing the capability to design, print, test, and iterate all in a matter of minutes.

Zorpads and eForge are just two examples of how NASA investments in the advancement of aeronautics and exploration of space are used in everyday life.

To learn more about spinoffs, visit here.

If you think you have a technology that could have applications outside of NASA, submit a New Technology Report here.

Lessons in Leadership: Marshall Deputy Director Rick Burt

By Rick Smith

As deputy director of NASA’s Marshall Space Flight Center, Rick Burt helps guide the next era in exploration and discovery for one of NASA’s largest field installations, with a broad portfolio of human spaceflight, science, and technology development efforts that touch nearly every mission NASA pursues.

Turns out growing up on his family’s farm in Columbia, Tennessee, was just the career training he needed. He and his older brother Danny spent weekends and summers as de facto farmhands – honing skills Burt would leverage throughout his NASA years.

“We quickly learned to be jacks-of-all-trades: carpenters, mechanics, veterinarians,” he said. “I grew up baling hay, tending livestock, running and repairing tractors, and tinkering with machinery – and the latter got me interested in engineering.”

Danny – whom Burt credits, along with their father, for teaching him the value of hard work and applying ingenuity to solve problems – went into the family cattle trade not far from the old homestead. Burt, however, has spent more than 30 years supporting and leading design, construction, testing, and quality assurance certification of machines – some of them quite a bit larger than his dad’s tractor.

It was a leap of faith, he said, but his family gave him the skills and confidence to take it. He also credits his upbringing for teaching him to embrace Marshall’s 21st century business strategy: risk leadership. More than just practiced managerial oversight, risk leadership identifies and addresses the enterprisewide costs and impact of risk, seeking open communications and top-down cooperation among an entire workforce and all those contributing or standing to benefit from the task.

“NASA has a long history of success, but not without risk, and not without mishaps,” Burt said. “True risk leadership examines risks associated with any challenging endeavor, and weighs those risk against manageable development cycle factors including time and cost, near-term and long-term mission goals, and the potential rewards of success.”

The nation’s space program can’t be overly risk averse and still meet its objectives, he added. “The safest ships may be those in the harbor,” he said, “but that’s not what ships are built for.”

At the same time, Burt’s years supporting the Space Shuttle Program – often working side by side with astronauts waiting their turn to ride the rockets – guide him every day.

“It drove home the impact and importance of the work,” he said. “We only borrow astronauts from their families to fly a mission, and it’s our job to get them safely up there and safely back home again, making each mission as safe and successful as possible.”

He’s proud of how Marshall continues to champion safety in the midst of a pandemic, with so many team members working virtually. “We’ve done a great job staying productive,” he said, “continuing to build and fly hardware, conduct major milestone reviews, and meet our other obligations to the American people. We haven’t missed a beat.”

After earning a bachelor’s degree in mechanical engineering in 1978 from Tennessee Technological University in Cookeville, Burt worked for 12 years for the Tennessee Valley Authority’s nuclear power program. He joined NASA in 1990 as a manager in Marshall’s Reusable Solid Rocket Motor Project. From 1998-1999, he led development, testing, and evaluation of shuttle propulsion elements as deputy manager of the Space Shuttle Projects Office. As chief engineer for the Reusable Solid Rocket Motor Project from 2000-2005, he guided technical reviews to return NASA to flight after the loss of space shuttle Columbia in 2003.

Following his appointment in 2006 to the Senior Executive Service – the personnel system covering top managerial positions in federal agencies – Burt was named manager of the Ares I First Stage, the rocket program which preceded development of NASA’s Space Launch System. He managed the Engineering Directorate’s Test Laboratory from 2007-2011, and served as Marshall’s chief safety officer in the Safety and Mission Assurance Directorate from 2011-2016, when he was named director of that organization, overseeing all safety, reliability, and quality assurance operations for the center.

He received the NASA Outstanding Leadership Medal in 2005 for his support of the space shuttle’s return to flight. In 1997, he received the Silver Snoopy Award, presented by NASA’s astronaut corps for outstanding contributions to the space program. He also was a Spaceflight Awareness honoree, the highest honor bestowed on NASA workers by the agency’s Spaceflight Awareness Program, in 1996.

More than three decades in, and Burt’s still eager and ready to do the job til the cows come home.

“There’s a real sense of pride,” he said. “I never tired of working at a place as special as Marshall, which inspires and motivates so many people.”

Smith, a Manufacturing Technical Solutions employee, supports Marshall’s Office of Strategic Analysis & Communications.

20th Anniversary of Payload Operations at Marshall

The Payload Operations Integration Center, or POIC, at NASA’s Marshall Space Flight Center has provided 24/7 support for science operations on the International Space Station since March 8, 2001. The POIC’s unique capabilities allow science experts and researchers to perform cutting-edge science in the unique microgravity environment of space. The POIC team coordinates the use of valuable in-orbit resources, orchestrates delivery and retrieval of payloads, ensures safety for station crews while working with payloads, and configures complex systems aboard the station to support payloads. Other members of the team train astronauts, cosmonauts, and ground personnel on payloads, and coordinate the plans for payload activities with scientists and control centers around the world. (NASA/Fred Deaton)

Registration Open for 31st Marshall Small Business Alliance Meeting March 18

The Office of Procurement and Small Business Office at NASA’s Marshall Space Flight Center will host the 31st Marshall Small Business Alliance Meeting on March 18, virtually via Webex. The event will include presentations from the Human Exploration Development & Operations and Science and Technology offices, updates on acquisition and agency product service lines from representatives from Marshall and other NASA centers. Three breakout sessions will also be offered: “Doing Business with NASA”; “Doing Business with NASA Prime Contractors”; and “Challenges Facing Small Businesses Today.”

The Marshall Small Business Alliance was created to provide industry with maximum exposure to the NASA marketplace. The semiannual meeting helps small businesses in pursuit of NASA procurement and subcontracting opportunities, and provides program updates, training sessions, and a chance to network. The event is open to all Marshall team members. All attendees must register here. Prospective participants should register individually, and are asked not to share their meeting link as the total number of online attendees is limited.

This Week in NASA History: Hubble Redeployed after Fourth Servicing Mission – March 9, 2002

This week in 2002, the Hubble Space Telescope was redeployed following five days of service and upgrades. The STS-109 mission performed the fourth servicing of Hubble, replacing solar panels and installing the Advanced Camera for Surveys, which took the place of the Faint Object Camera – the telescope’s last original instrument. Here, the crew took a snapshot of Hubble while still berthed in the cargo bay of space shuttle Columbia. NASA’s Marshall Space Flight Center had overall responsibility for design, development, and construction of Hubble. Today, Marshall calibrates telescopes such as the James Webb Space Telescope and the Chandra X-ray Observatory at the X-ray and Cryogenic Facility, as well as managing the project offices for the Chandra and the upcoming Imaging X-Ray Polarimetry Explorer missions. The NASA History Program is responsible for generating, disseminating, and preserving NASA’s remarkable history and providing a comprehensive understanding of the institutional, cultural, social, political, economic, technological, and scientific aspects of NASA’s activities in aeronautics and space. For more pictures like this one and to connect to NASA’s history, visit the Marshall History Program’s webpage. (NASA)