NASA Moon Rocket Flight Software Readied for Artemis I Launch

By Corinne Edmiston

As crews at NASA’s Kennedy Space Center assemble the Moon rocket for the Artemis I mission, teams have installed the flight software that will help steer, fly, track, and guide the the spacecraft during launch and ascent to space. Engineers loaded the flight software onto the Space Launch System rocket Aug. 6 after powering up the core stage that contains the flight computers for the first time since stacking began.

With the software installed, the engineers who developed the flight software at NASA’s Marshall Space Flight Center are supporting final checkouts and completing tests to certify the software for the mission.

“NASA’s Space Launch System is on the path to the pad, and the SLS flight computer application software is complete and ready to perform the mission,” said David Beaman, SLS systems engineering and integration manager. “The mission certification and performance certification tests are the next step for the rocket’s software on the path to launch and flight ahead of Artemis I.”

The software is loaded on three flight computers, along with the avionics systems inside the SLS rocket’s core stage. On the day of launch, the SLS’s twin solid rocket boosters and four RS-25 engines fire together to produce more than 8.8 million pounds of thrust to send NASA’s Orion spacecraft to the Moon. The software and avionics operate with the rocket’s three flight computers to harness the power of the rocket through ascent and communicate with avionics systems inside the engines and the boosters. That same software is monitored in real time by NASA’s Exploration Ground Systems team at the agency’s launch complex at Kennedy and SLS Program engineers at the SLS Engineering Support Center at Marshall.

Once the rocket and Orion are fully stacked and assembled on the mobile launcher, they will undergo several additional tests and checkouts leading up to launch. The software is designed to be tested and certified for each launch window so that ascent performance parameters can be updated right up until launch to enhance mission success.

“It is important to test and certify the SLS flight software for each launch opportunity to account for day of launch weather and other factors,” said Dan Mitchell, lead SLS integrated avionics and software engineer. “Those tests also ensure that all the software elements and systems on the rocket, Orion, and the ground work together seamlessly for prelaunch checks and preparations, liftoff, and ascent.”

NASA conducts integrated end-to-end testing for the software, hardware, avionics, and integrated systems needed to fly Artemis missions. Each hardware element is tested before delivery to Kennedy. In addition, testing in the agency’s sophisticated software development laboratories uses actual SLS, Orion, and Exploration Ground Systems flight hardware and software, as well as emulators – versions of the software that each team employs to test how their code works with the integrated system – to support both system-level interface testing and integrated mission testing to ensure software and avionics systems work together.

Earlier this year, the flight software and avionics systems completed a series of checkouts and tests as part of the comprehensive, eight-part SLS core stage Green Run test series at NASA’s Stennis Space Center. Key tests and checkouts included powering on the stage, simulating the launch countdown, and operating the flight computers and avionics systems during the eight-minute hot fire test March 18.

During Green Run, the core stage flight computers, software, and avionics systems performed as expected as test teams monitored and operated the flight software just like they would in a launch environment for the first time. Those data findings were then used to inform the mission certification testing for the Artemis I flight software.

Extensive testing was also completed on the flight computer application software for Artemis I in Marshall’s System Integration Lab. Inside, software engineers create real-time launch simulations to further test the flight software under normal and unplanned mission scenarios.

“The flight software test campaign for the Artemis I mission involves more than 300,000 different mission scenarios to satisfy all flight software requirements,” said Shaun Phillips, SLS flight software project team lead based at Marshall. “Each of these scenarios are focused on evaluating different interfaces and situations the vehicle may face during launch and flight.”

NASA thoroughly tests and evaluates all software and hardware for every phase of the Artemis I mission to ensure that it meets safety requirements and is fully qualified for human spaceflight. With Artemis, NASA will land the first woman and the first person of color on the Moon and establish a long-term presence while preparing for human missions to Mars. SLS and NASA’s Orion spacecraft, along with the commercial human landing system and the Gateway in orbit around the Moon, are NASA’s backbone for deep space exploration. SLS is the only rocket that can send Orion, astronauts, and supplies to the Moon in a single mission.

Edmiston, a Media Fusion employee, supports Marshall’s Office of Strategic Analysis & Communications.

NASA Continues RS-25 Testing with Sixth Installment at Stennis

NASA conducted its sixth RS-25 single-engine hot fire Aug. 5 on the A-1 Test Stand at Stennis Space Center, a continuation of its seven-part test series to support development and production of engines for the agency’s Space Launch System rocket on future missions to the Moon.

Operators fired the engine for more than eight minutes (500 seconds), the same amount of time RS-25 engines need to fire for launch of the SLS rocket. Four RS-25 engines, along with a pair of solid rocket boosters, will help power SLS at launch. NASA already has tested engines for the rocket’s first four Artemis missions to the Moon, allowing operators to turn their focus toward collecting data to demonstrate and verify various engine capabilities for future engines.

Along with providing performance data to Aerojet Rocketdyne, lead contractor for the SLS engines, the Aug. 5 test enabled the team to evaluate new engine components manufactured with cutting-edge and cost-saving technologies, eliminate operating risks, and enhance engine production. In addition to operating the engine at 109% of its original power level for extended periods during the hot fire, NASA verified new manufacturing processes while evaluating the performance of the engine’s low-pressure fuel turbopump. The pump significantly boosts the pressure of liquid hydrogen delivered to the high-pressure fuel turbopump to help prevent cavitating, the forming of “bubbles” or “voids,” which can collapse or cause shock waves that may damage machinery.

An integrated team conducts RS-25 tests at Stennis, including NASA, Aerojet Rocketdyne, and Syncom Space Services, the prime contractor of Stennis facilities and operations.

Liftoff of Northrop Grumman’s 16th Commercial Resupply Mission

A Northrop Grumman Antares rocket carrying a Cygnus resupply spacecraft launches at 5:01 p.m. CDT on Aug. 10 at NASA’s Wallops Flight Facility. The Cygnus spacecraft, dubbed the SS Ellison Onizuka in honor of the first Asian American astronaut, is loaded with more than 8,200 pounds of research – the largest resupply to date. It will arrive and dock with the International Space Station at about 6:30 a.m. Aug. 12. Expedition 65 NASA astronaut Megan McArthur will capture Cygnus with the station’s robotic arm, and European Space Agency astronaut Thomas Pesquet will support her. After the Cygnus capture, the Mission Control Center at NASA’s Johnson Space Center will send ground commands for the station’s arm to rotate and install the cargo spacecraft on the Earth-facing port of the station’s Unity module. Cargo resupply from U.S. companies ensures a national capability to deliver critical science research to the space station, significantly increasing NASA’s ability to conduct new investigations at the orbiting laboratory. Each resupply mission to the station delivers scientific investigations in the areas of biology and biotechnology, Earth and space science, physical sciences, and technology development and demonstrations. This Cygnus carries three experiments with a tie to NASA’s Marshall Space Flight Center. (NASA/Joel Kowsky)

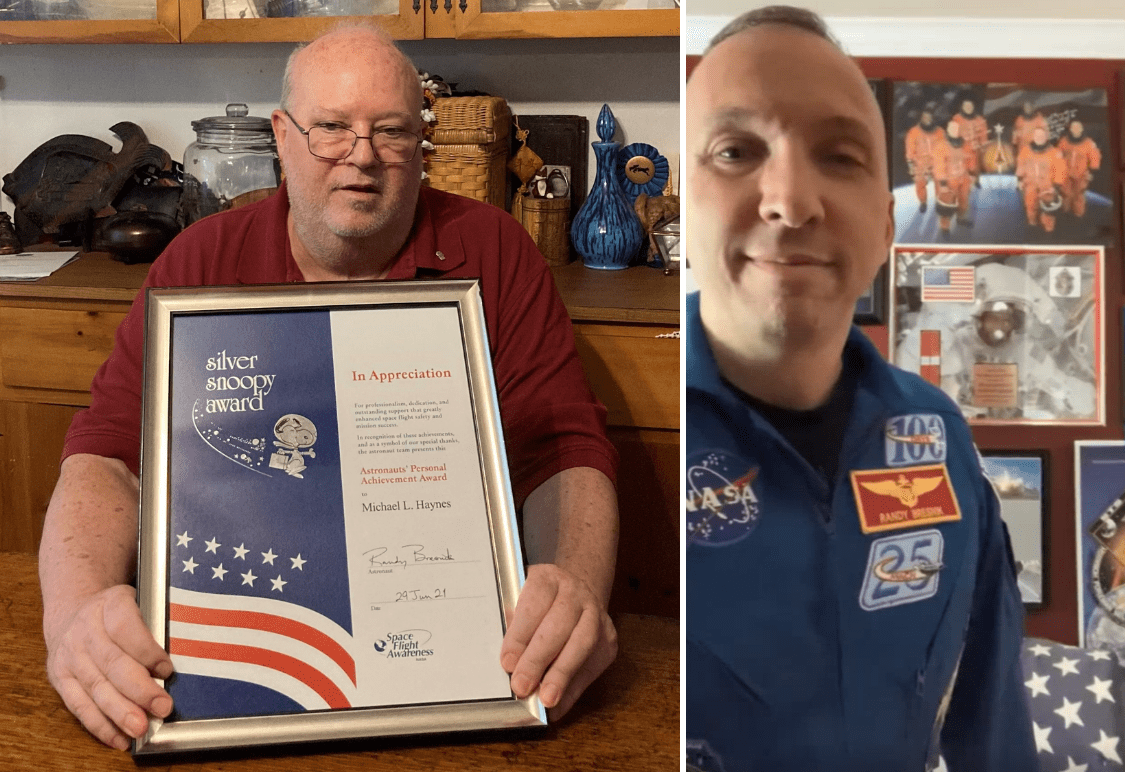

Retired Marshall Engineer Michael Haynes Receives Silver Snoopy Award

Michael Haynes, left, who retired from NASA’s Marshall Space Flight Center in 2020 as a reliability and quality assurance engineer for the Orion Launch Abort System, displays the Silver Snoopy award he received during a ceremony July 27. The presentation included a video from astronaut Randy Bresnik, right, who nominated Haynes for his outstanding technical leadership in achieving Orion Program safety goals throughout the Launch Abort System development and qualification phases. The Launch Abort System will allow astronauts to safely escape in the event of an emergency during launch pad operations and through the Orion’s ascent phase. “When we get to the Moon and get back safely, we’ll have you in part to thank for allowing that to happen,” Bresnik said. The Silver Snoopy award is presented by the NASA astronaut corps to civil service and contractor employees who have made direct, significant contributions to America’s human spaceflight program. Haynes started at Marshall in 2003. Bresnik, who became an astronaut in 2004, was commander of the International Space Station during Expedition 53 and a flight engineer for Expedition 52, both during 2017, and a member of STS-129 in 2009. (NASA)

Pair of Marshall Proposals Selected to Help Advance Deep Space Human Exploration

NASA’s Advanced Exploration Systems division has announced that 10 proposals led by early-career employees at eight NASA centers have been selected for two-year projects that will enable new capabilities for deep space human exploration.

Teams submitted proposals to Project Polaris, a new initiative to help NASA’s workforce meet the challenges of sending humans to the Moon and Mars. Project Polaris seeks to fill high-priority capability gaps on deep space missions like Artemis, and introduce new technologies into human exploration flight programs. The program also aims to create opportunities for early-career employees across NASA centers to gain experience building and testing flight hardware while developing technologies and reducing risk for future human exploration missions.

Two of the selections came from NASA’s Marshall Space Flight Center.

The Bioremediation of Microgravity Biofilms and Water Processor Health proposal is led by J.P. Wilson and includes three early-career employees. Robust life support systems, especially those that operate without the need for component replacement during a mission, are necessary for continued human space exploration. However, one of the main issues is the risk of biofouling and clogging.

Similar to the gene drive approaches to stop the spread of the Zika virus, this team proposes developing methods that cause the splitting of essential genes for biofilm formation. Results from ground testing will be compared to results in microgravity, and then compared to other technologies.

The Data Planning and Control Tool proposal is led by Mason Hall and includes six early-career employees. As NASA missions and technologies evolve, ground operations will move away from 24/7 manual support, emphasizing the importance of autonomy in ground operations.

The tool will automate planning by merging telemetry, flight control, and procedures into a seamless interface for mission operators. It will also reduce workload, lower the risk for human errors, and provide modularity across programs, such as Gateway and Lunar Surface Ops.

Read about selections from other centers here. For more information about Project Polaris, visit here.

NASA Retirees, Volunteers Refurbish Groundbreaking Astro Spacelab Flight Hardware for Display in US Space & Rocket Center, Smithsonian

By Rick Smith

NASA and space enthusiasts who fondly remember the era of Spacelab are getting ready to welcome back an old friend.

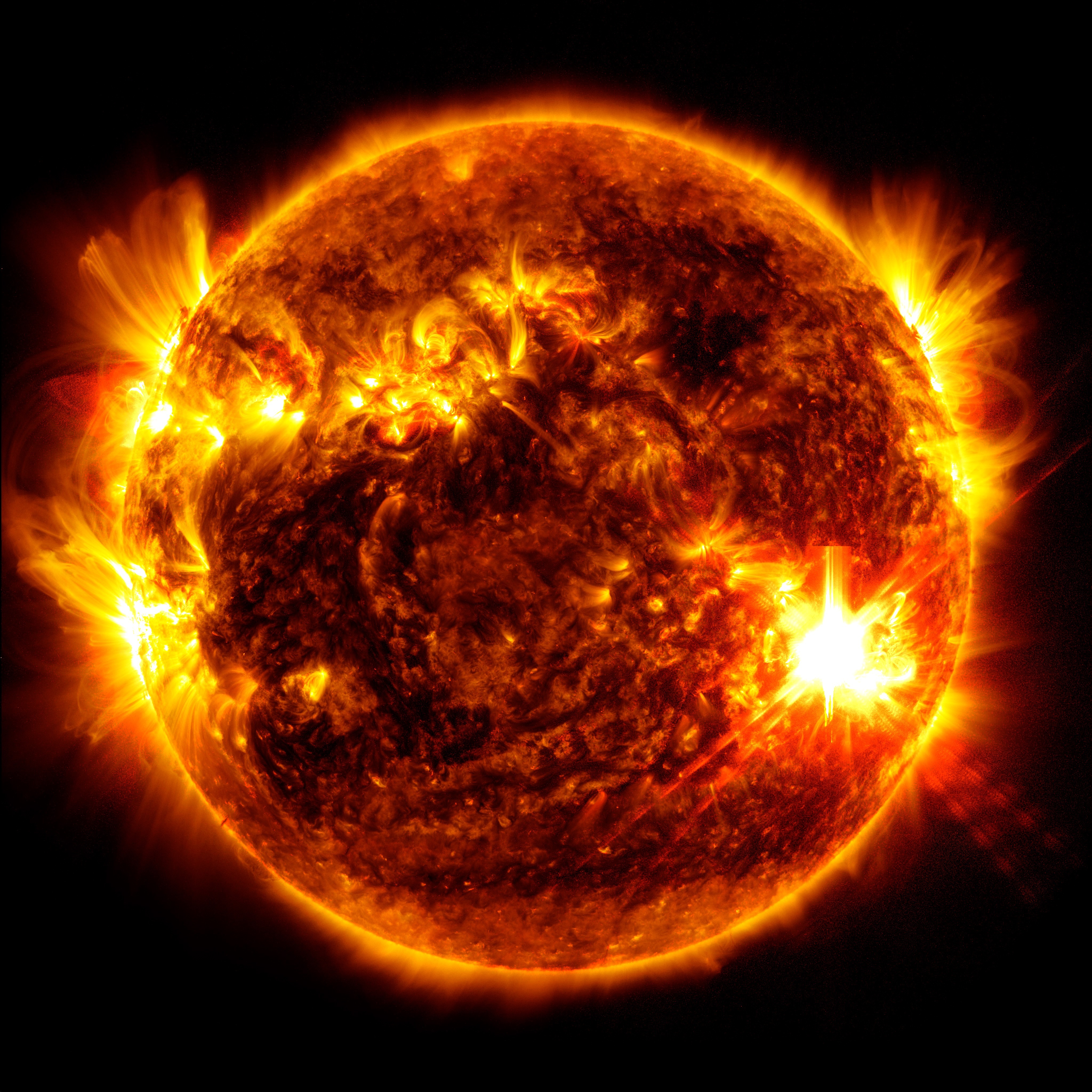

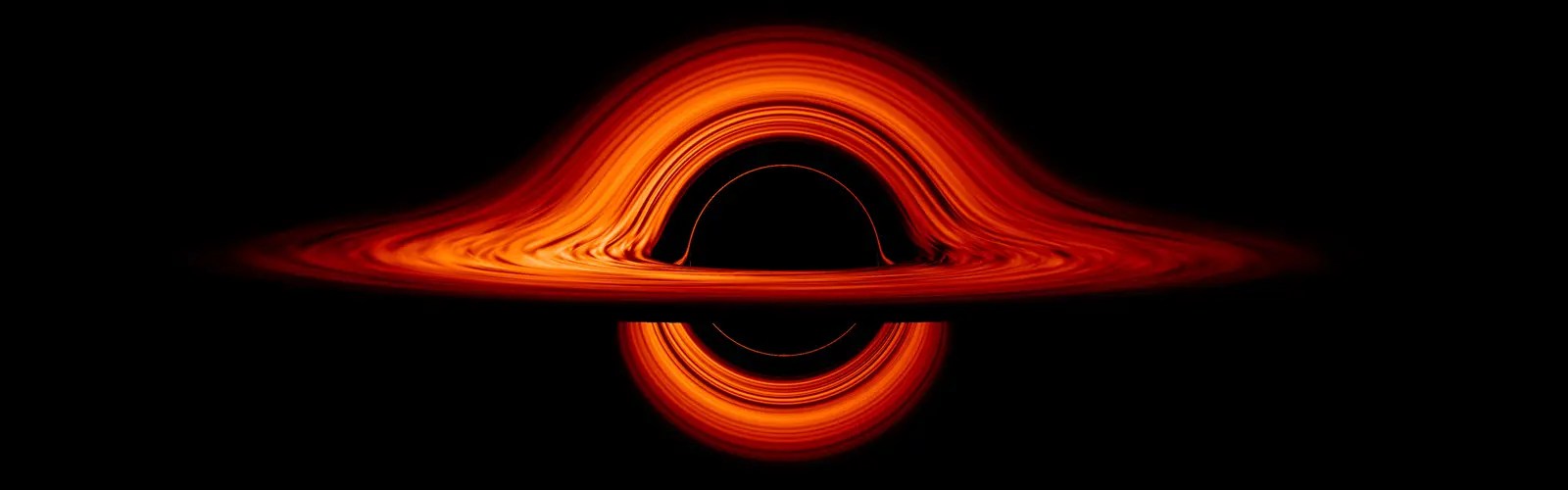

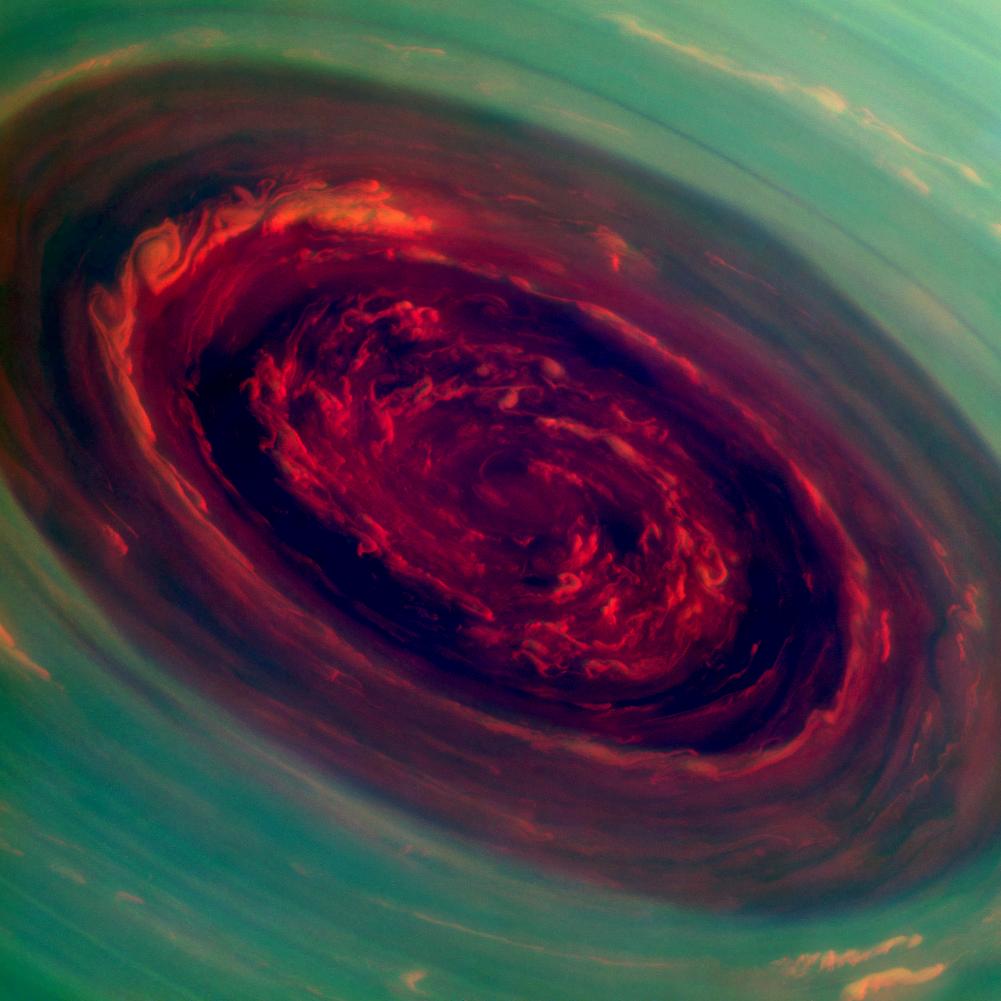

When NASA launched its Astro-1 and Astro-2 Spacelab missions in 1990 and 1995, the complex array of synchronized telescopic imagers observed quasars, supernovas, and other astronomical objects. More than a quarter-century later, NASA volunteers and their industry partners are refurbishing the landmark hardware for public display.

The Astro Restoration Project is funded by retirees and commercial supporters, working in donated space at the U.S. Space & Rocket Center, where it will be on display for the next two years. Thereafter, it will move to the Smithsonian’s National Air & Space Museum annex at Dulles International Airport in Washington, where it may be seen – alongside space shuttle Discovery – by some 60,000 daily flyers from all over the world.

“It is so exciting to see this restoration project come together, ensuring this important hardware will inspire our children and generations still to come,” said Tia Ferguson, director of the Space Systems Department in the Engineering Directorate at NASA’s Marshall Space Flight Center, and a key facilitator in the restoration effort. Astro was among her first hands-on engineering tasks when she joined the agency in 1990. “This has been a truly heroic labor of love by passionate engineers and team members.”

Astro’s journey back to life hasn’t been an easy one, said project lead Scott Vangen, a 37-year NASA veteran who retired from the agency’s Kennedy Space Center in 2019. The restoration team knew the three flight telescopes had gone back to the principal investigators, he said. The Instrument Pointing System had been claimed by the Smithsonian for display at the Udvar-Hazy Space Science Center in Chantilly, Virginia.

“We knew some of Astro’s hardware went to government surplus auctions in Huntsville and at the Cape, and other pieces were still in storage at Kennedy, but numerous other vital pieces of hardware were unaccounted for,” Vangen said.

It happens, added his project partner, former NASA mechanical engineer Mike Haddad, who worked for 32 years at Kennedy and installed cabling and electronics for Astro and other Spacelab and shuttle missions. He retired from NASA in 2011.

“Typically, when flight hardware is returned to Earth, NASA refits or refurbishes it for other missions, or strips and cannibalizes components for other uses,” Haddad said. In cases of unique, one-off pieces – affectionately dubbed “mission peculiar” – a lot of old hardware is auctioned off to collectors and museums, or simply sold for scrap.

But luck was on their side. Byron Bonds, who had worked on Astro as Teledyne Brown Engineering’s resident office chief engineer, was browsing in a North Alabama auction yard when he discovered Astro’s massive, 3,000-pound aluminum cruciform, designed and built by Teledyne Brown. Not long after, in a scrapyard in Titusville, Florida, Vangen himself stumbled upon Astro’s 500-pound optical sensor package, built by a German contractor to help train the telescopes on a single observation point in space.

With time and persistence, the team recovered 90% of the missing hardware – but that was just the first hurdle. Time and exposure to the elements had caused some of the hardware to deteriorate. Some pieces had become nesting sites for wasps and field mice. Still others, particularly individual brackets and fasteners, were missing altogether.

Aiding their efforts was a mission procedures log, meticulously maintained by former Astro engineer Sharolee Huet, who passed away in 2018. Her notes identified detailed drawings and schematics that broke down every component of the Astro payload.

“Preserving the hardware is somewhat academic if you don’t have the documentation,” Vangen said. “We needed the original drawings to put the pieces back together again.”

Marjorie Moore, manager of Marshall’s documentation repository, had archived the drawings when the Spacelab program ended. Using Huet’s log notes, Moore and fellow Marshall documents specialist Courtney Lovell were able to retrieve, scan, digitize, and email to the restoration team a total of 334 drawings and associated documents. The puzzle pieces were all falling into place.

The Space & Rocket Center’s restoration staff offered crucial insight for properly cleaning and restoring the time-worn pieces. Dozens of civil service and contractor volunteers stripped the rotted insulating blankets, cleaned some parts with toothbrushes, and pressure-washed others. The team even got help manufacturing replacement brackets and parts from NASA’s HUNCH – High school students United with NASA to Create Hardware – program, which includes more than 200 high schools nationwide and teaches students practical hardware design and fabrication techniques.

The restored optical sensor package and the first of the telescopes, the Wisconsin Ultraviolet Photo Polarimeter Experiment, are slated to be reinstalled on the Astro cruciform this fall. The remaining two ultraviolet telescopes will follow by spring 2022. Astro will remain on exhibit at the Space & Rocket Center until the Smithsonian is ready to debut its own exhibition site at Dulles.

That physical presence may be the most important aspect of the work, Vangen said. “Free-flying payloads and deployables such as Hubble rewrote the science books, but they’ll never come back to Earth, never stand on display as examples of what we can achieve,” he said. “With Astro, our grandchildren and great-grandchildren will be able to touch hardware that flew to space and into the history books. Generations to come will see firsthand what human beings are capable of doing.”

A more in-depth feature version of this story, including a look back at Astro’s career, is available here. Smith, a Manufacturing Technical Solutions employee, supports Marshall’s Office of Strategic Analysis & Communications.

Juno Celebrates 10 Years With New View of Jovian Moon Ganymede

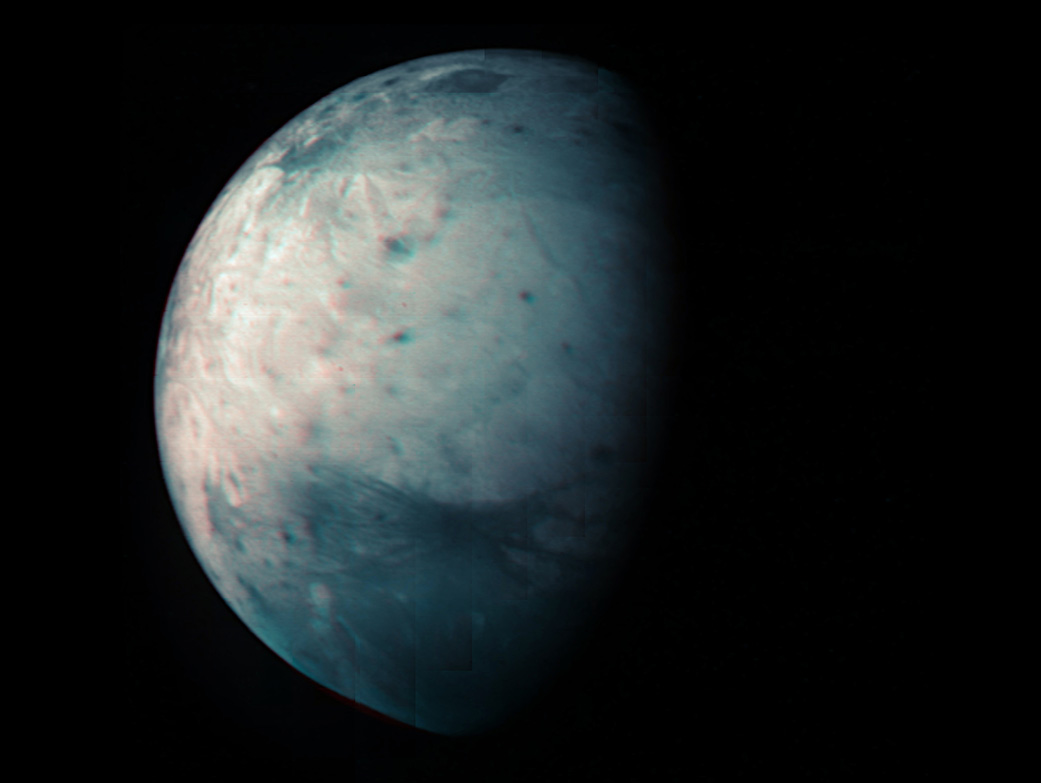

This infrared view of Jupiter’s icy moon Ganymede was obtained by the Jovian Infrared Auroral Mapper instrument aboard NASA’s Juno spacecraft. The instrument developed the image during three recent flybys of Jupiter’s mammoth moon, including its latest approach July 20, to create this latest map, which comes out a decade after Juno’s Aug. 5, 2011, launch. These observations by the instrument, which “sees” in infrared light not visible to the human eye, provide new information on Ganymede’s icy shell and the composition of the ocean of liquid water beneath. The instrument was designed to capture the infrared light emerging from deep inside Jupiter, probing the weather layer down to 30 to 45 miles below Jupiter’s cloud tops. But the instrument can also be used to study the moons Io, Europa, Ganymede, and Callisto. Juno is part of the Science Mission Directorate’s New Frontiers Program, managed by the Planetary Missions Program Office at NASA’s Marshall Space Flight Center. (NASA/JPL-Caltech/SwRI/ASI/INAF/JIRAM)

Lucy Progress Highlighted on ‘This Week @NASA’

The start of launch preparations for the Lucy spacecraft is featured in “This Week @NASA,” a weekly video program broadcast on NASA-TV and posted online.

Lucy arrived at NASA’s Kennedy Space Center on July 30 and was transported to nearby Astrotech for final prelaunch preparations. The spacecraft’s 23-day launch window opens Oct. 16. It will be the first space mission to the Trojan asteroids, a diverse population of small bodies believed to be remnants of our early solar system that are trapped in stable orbits associated with the planet Jupiter. Lucy is a project of the Science Mission Directorate’s Discovery Program, managed by the Planetary Missions Program Office at NASA’s Marshall Space Flight Center.

View this and previous episodes at “This Week @NASA” on NASA’s YouTube page.

This Week in NASA History: STS-43 Lands – Aug. 11, 1991

This week in 1991, space shuttle Atlantis, mission STS-43, landed at NASA’s Kennedy Space Center following a successful eight-day mission. The primary payload, the Tracking and Data Relay Satellite-5, above, was attached to an Inertial Upper Stage and deployed about six hours into flight. The Inertial Upper Stage propelled the satellite into a geosynchronous orbit. The satellite became the fourth member of the orbiting Tracking and Data Relay Satellite series, which provides and maintains improved tracking and data acquisition services to spacecraft in low-Earth orbit. The NASA History Program is responsible for generating, disseminating, and preserving NASA’s remarkable history and providing a comprehensive understanding of the institutional, cultural, social, political, economic, technological, and scientific aspects of NASA’s activities in aeronautics and space. For more pictures like this one and to connect to NASA’s history, visit the Marshall History Program’s webpage. (NASA)