In This Week’s Star

- › NASA, Louisiana Renew National Center for Advanced Manufacturing Partnership

- › NASA Engineer Elizabeth Robertson Takes Engine Development to the Next Level

- › Marshall’s ‘Take Our Children to Work Day’ Draws Crowds

- › 2015 NASA on the Square

- › Volunteer to Be a Mentor: NASA GIRLS and NASA BOYS

- › Ten Years After Katrina: Marshall and Michoud Prepare for Hurricane Season

- › Winning Team of NASA Robot Challenge Featured On ‘This Week @NASA’

NASA, Louisiana Renew National Center for Advanced Manufacturing Partnership

NASA, Louisiana Economic Development and university leaders celebrated the renewal of their partnership in the National Center for Advanced Manufacturing during a signing ceremony June 16 in New Orleans.

Through NCAM, located at NASA’s Michoud Assembly Facility, NASA is expanding its efforts to engage industry and academia on advanced manufacturing topics central to the nation’s space mission, with a particular focus on manufacturing technologies that reduce the weight of materials during spaceflight.

“The rockets and technology required to take human explorers on missions into deep space and to Mars are possible only with the development of advanced manufacturing techniques,” said Patrick Scheuermann, director of NASA’s Marshall Space Flight Center, which manages Michoud for the agency. “National Center for Advanced Manufacturing tools are among those being used today at Michoud to build the core stage of NASA’s Space Launch System — the most powerful rocket in history — and the Orion spacecraft that will carry astronauts on missions farther from Earth than ever before.”

NCAM, originally formed in 1999, is a partnership among NASA, the State of Louisiana, Louisiana State University and the University of New Orleans. LSU leads NCAM on behalf of the partnership. The new five-year agreement will allow for greater flexibility as NCAM explores fresh opportunities to work with government, industry and other universities.

Edward James, Louisiana Economic Development director of business development; Dr. Richard Koubek, dean of the LSU College of Engineering; and Dr. Emir Macari, dean of the University of New Orleans College of Engineering, joined Scheuermann for a signing ceremony at the Hyatt Regency New Orleans.

To date, NASA and the State of Louisiana have infused more than $62 million into NCAM, which has more than 100,000 square feet of high-bay manufacturing space with large-scale, multi-axis robotic equipment. Other assets include a uniquely skilled workforce, educational outreach programs and a suite of specialized welding, composite fiber placement and non-destructive evaluation and inspection equipment.

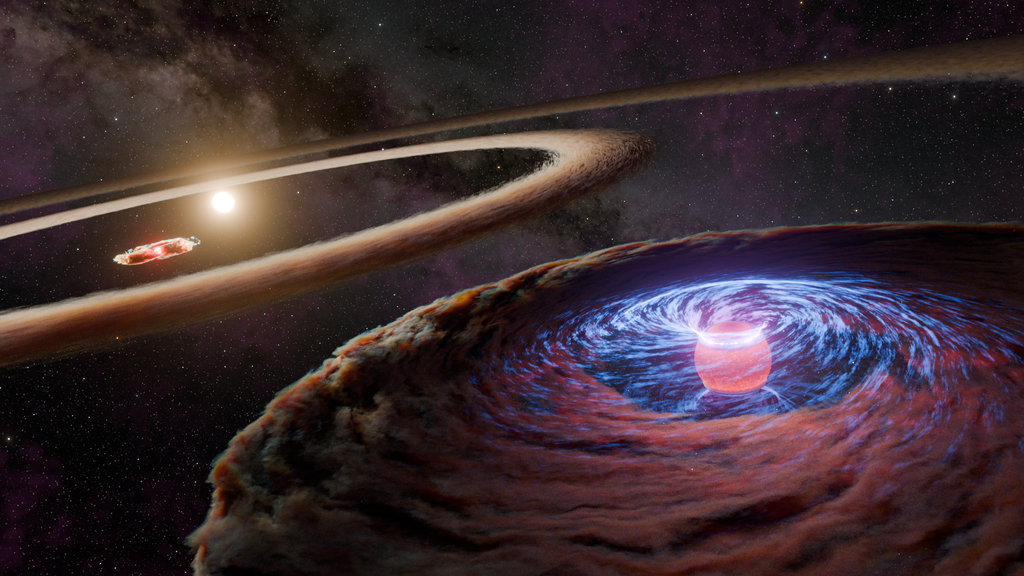

NASA Engineer Elizabeth Robertson Takes Engine Development to the Next Level

By Logan Moore

The Advanced Manufacturing Demonstration Engine team is using innovative technology to build more affordable rocket engine parts. One of the most essential components of a team is its leader, and there is no doubt Elizabeth Robertson, a liquid propulsion systems engineer at NASA’s Marshall Space Flight Center, is on fire about the work she and her team are doing to use additive manufacturing to revolutionize the design and development of rocket engines.

Robertson has been working at Marshall for 11 years. The Natchez, Mississippi, native received a bachelor’s degree in business from Washington and Lee University in Lexington, Virginia. Soon after, she realized her dreams were pulling her in a different direction. Robertson changed gears and went to Louisiana State University in Baton Rouge, Louisiana, to pursue a degree in mechanical engineering.

“I really knew when I went back to school for engineering that I wanted to work for the space program,” said Robertson.

During the summer of 2003, she interned at Marshall through the Undergraduate Student Research Program. As an intern, she helped design the deep space test bed, a gondola launched from high altitude balloons in Earth’s Polar Regions that carries multiple instruments for measuring radiation in interplanetary space.

The next year, she joined NASA, and her first job as an employee was supporting the space shuttle’s main propulsion system problem resolution team in the Valves, Actuators and Ducts Design and Development branch of the Propulsion Systems Department.

In 2008, a piece of a flow control valve of the space shuttle main engine did not perform as expected in flight. Robertson and a team of engineers across NASA centers worked to ensure that engine problem was resolved and the shuttle was safe and could fly with confidence.

Robertson was then detailed to the position of deputy chief engineer for propulsion systems engineering and integration for the Space Shuttle Program for the final five shuttle launches. She was honored with a Silver Snoopy Award in 2010 for her service to the shuttle program.

“That was a lot of fun,” said Robertson. “It was the end of the program, but I was able to go see the last several launches, sit on console during the launch and really be a part of the end of an era.”

She continued her propulsion work on an upper stage main propulsion system and with liquid oxygen component designs.

Robertson now works in the Liquid Engines Design and Development branch, leading the Advanced Manufacturing Demonstration Engine project. The team is using 3-D printing to build parts of rocket engines, which is revitalizing the way NASA propulsion engineers think about engine design and development. All the printing done by the AMDE team is with metals.

The team has been taking representative designs for rocket engines and putting them into relevant environments that simulate launch conditions — such as extreme heat, freezing temperatures or vibration — to test the technology’s viability for propulsion.

Robertson and her team have already completed several valve and injector hot-fire tests to measure the quality of the parts. One component, the Fuel Turbopump, will be tested soon. All components will be put together for a systems test planned for later this summer.

“We feel like the work we’ve done in putting this hardware together and testing it is going to be beneficial not only to applications in the engine world, but also across almost any discipline you can imagine,” said Robertson.

Others would agree. At the Joint Army-Navy-NASA-Air Force propulsion meeting held in Nashville in early June, the AMDE team received the Outstanding Achievement Award in Liquid Propulsion Systems for its work in technology development.

“We are proud of all our hard work,” Robertson said, “so it was nice to be recognized, but most of us just can’t wait to put the hardware to the test and see how it performs.”

Robertson and her team are working toward testing all of the hardware components it takes to make a rocket engine, which will bring them closer to building an entire engine mostly made from 3-D printed parts.

The engineer makes other contributions to NASA as a board member at the Marshall Child Development Center. She is a wife and a mother of two young boys.

“My sons will be able to see the technology we’re advancing eventually take us to Mars,” said Robertson. “As a mom and NASA engineer, that truly excites me.”

Moore, a NASA intern, is supporting the Office of Strategic Analysis & Communications this summer.

Marshall’s ‘Take Our Children to Work Day’ Draws Crowds

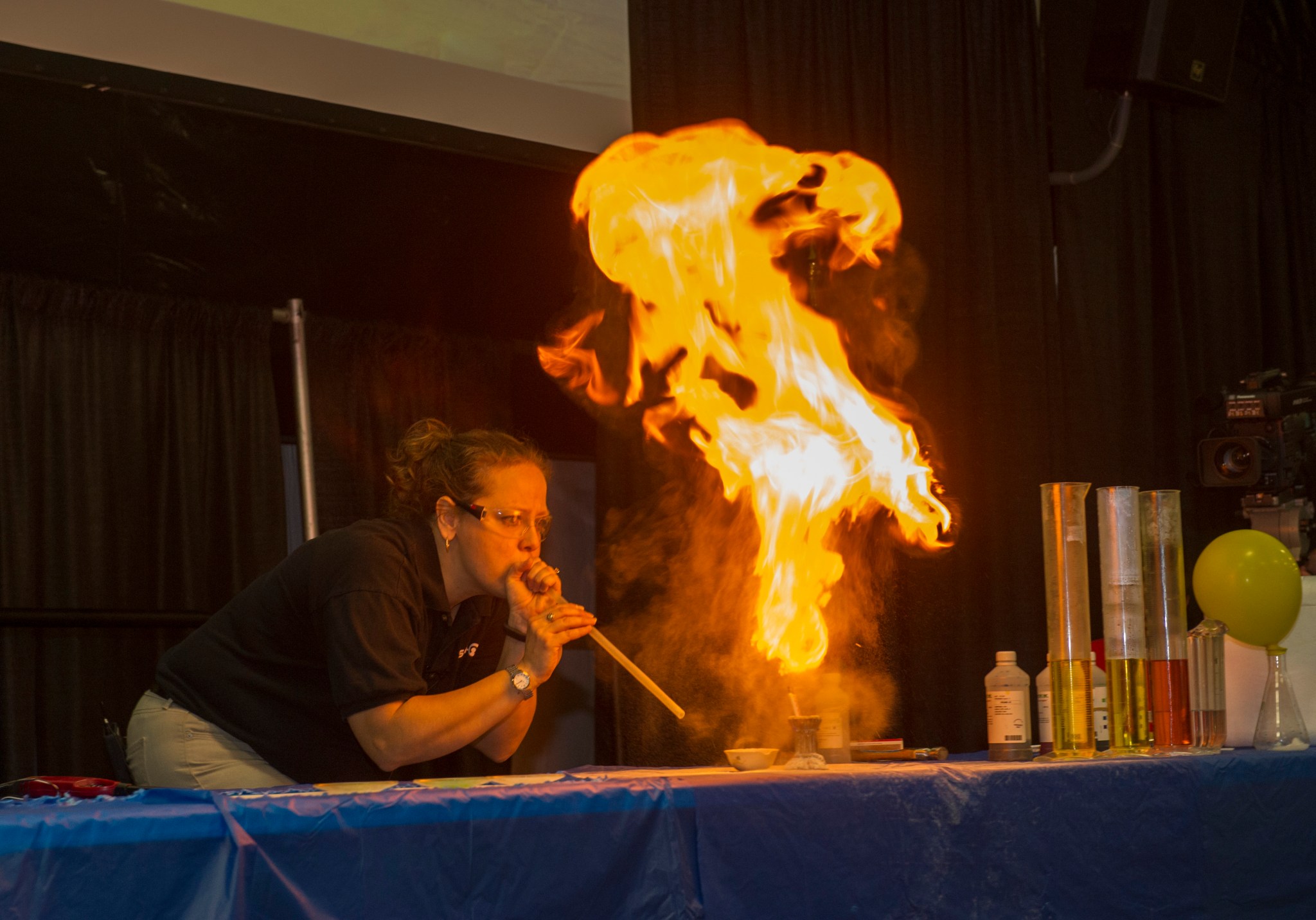

Loucious Hires, director of the Office of Diversity and Equal Opportunity at NASA’s Marshall Space Flight Center, welcomes children in grades 3-12 to “Take Our Children to Work Day” June 18. Approximately 500 young people, mostly sons and daughters of Marshall civil service and contractor employees, traversed the campus with parents in tow to explore a variety of hands-on activities, demonstrations and participatory events. (NASA/MSFC/Fred Deaton)

Heather Rodin, an employee of Sci-Quest of Huntsville, shows her young audience how oxygen is necessary to produce combustion. Rodin’s “Fire & Ice” presentation was among several devoted to space science, Earth science and solar physics. Others showcased Marshall’s lead role on the Space Launch System, and the Payload Operations Integration Center, which supports the International Space Station. Huntsville-area businesses including Boeing, Jacobs Technology, Sci-Quest and Redstone Federal Credit Union joined numerous Marshall teams in contributing to “Take Our Children to Work Day.” (NASA/MSFC/Emmett Given)

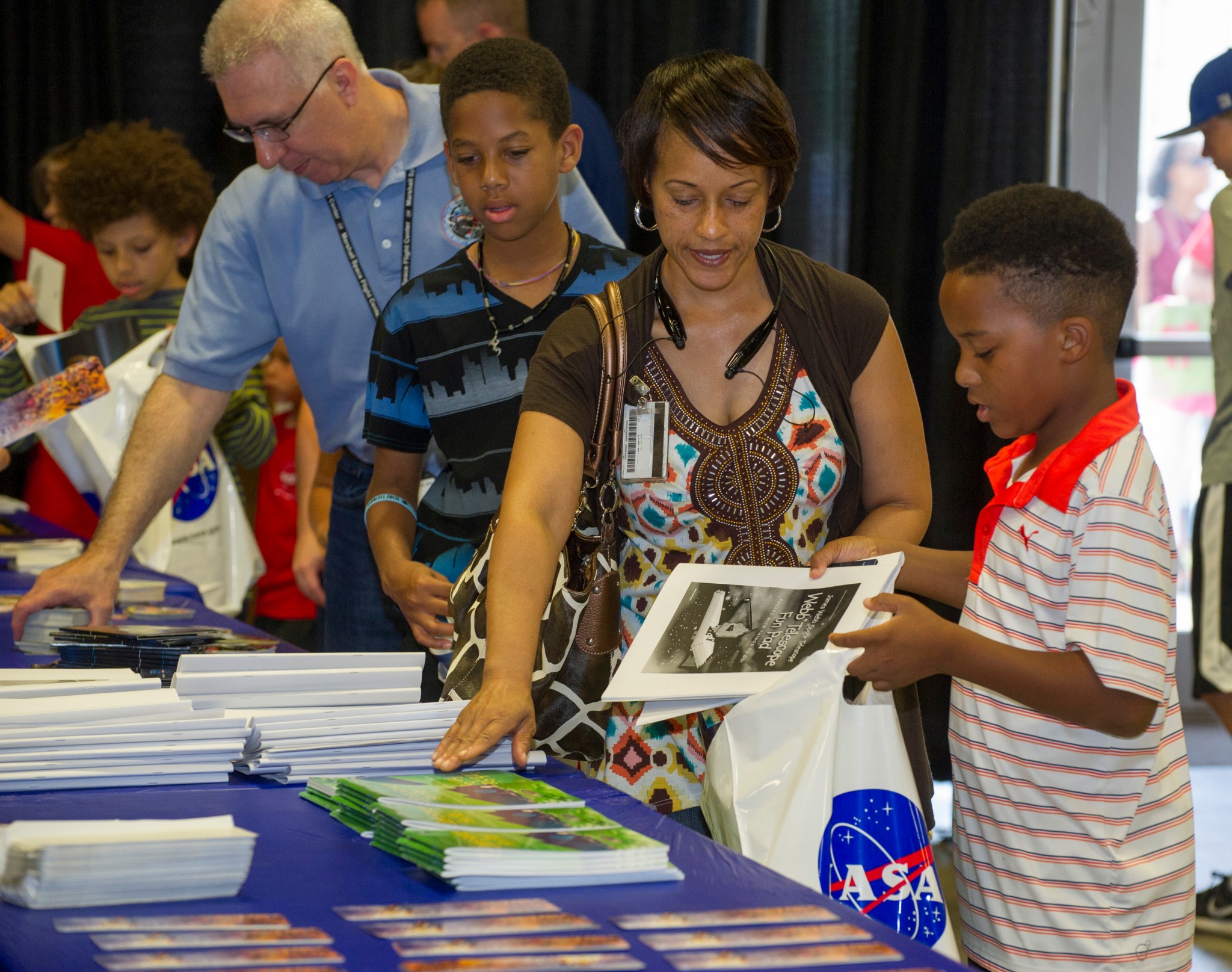

Browsing NASA handouts in Marshall’s Activities Building are Nicola Duncombe, an administrative officer in the Office of the Chief Information Officer; her son Prince, right; and her nephew Garth Shields, center left. Engaging young people and inspiring them to pursue classes and eventually careers in the STEM fields — science, technology, engineering and mathematics — is a critical element of the Marshall event, which is organized each year by the Office of Diversity and Equal Opportunity. (NASA/MSFC/Emmett Given)

2015 NASA on the Square

The full-size inflatable Orion was one of 55 exhibits that filled the streets and sidewalks at the second NASA on the Square event in downtown Huntsville June 20 and helped Marshall Space Flight Center celebrate its 55th year. Visitors could see and touch an RS-25 rocket engine, learn how Marshall uses 3-D printing, talk with astronaut TJ Creamer, enjoy live music courtesy of Marshall musicians, educational activities, food trucks and much more. (NASA/MSFC/Garrick Merrill)

With bananas and grapes, kids get a cool lesson about cryogenics on a warm day at NASA on the Square. A number of the Marshall displays had science, technology, engineering and mathematics or STEM educational aspects. (NASA/MSFC/Fred Deaton)

Volunteer to Be a Mentor: NASA GIRLS and NASA BOYS

NASA GIRLS and BOYS are virtual mentoring programs pairing middle school students with mentors across the agency. The one-on-one pairs meet through Skype, Google Hangout or FaceTime for an hour once a week for five weeks during the summer. This annual program begins July 6 and ends Aug. 7. A mentor packet is provided with lesson ideas and helpful tips. The time commitment is about 90 minutes to two hours per week with 30 minutes to an hour spent reviewing the lesson before meeting the student. The program is rewarding and flexible, with the schedule set by mentors and the students’ families. To volunteer or request information, email Mamta Nagaraja by July 1. For more information, click here. (NASA)

Ten Years After Katrina: Marshall and Michoud Prepare for Hurricane Season

When Hurricane Katrina made landfall almost 10 years ago, two NASA facilities were hit hard: Stennis Space Center and the Michoud Assembly Facility. NASA’s Marshall Space Flight Center was a leader in the recovery efforts for both facilities.

Earlier this month, Marshall and Michoud team members began their preparation for the 2015 hurricane season, which begins in June and continues until November. Meetings were held with Michoud and local leadership, tenants and local emergency personnel to review and update communication, evacuation and other plans for potential severe weather over the next few months.

“Katrina was an incredible learning experience,” said Carole Valenti, Marshall’s emergency management director. “The entire Gulf Coast region was hit hard during the storm, but thanks to preparation, resources and some amazing teamwork, both facilities were able to recover.”

In the days following Katrina, Marshall teams helped restore communications and power to both facilities, and delivered supplies to recovery teams and on-site personnel.

In the decade since Katrina, Valenti acknowledges hurricane preparedness has been greatly improved, with the emergency management teams at Michoud and Marshall continually enhancing and improving plans and systems, learning from past experiences.

Valenti’s team closely monitors weather conditions that could impact center operations every day. If severe weather happens, team members should expect announcements over the Emergency Warning System when lightning appears within a 10-mile radius of the center and via This Just In email messages or NIXLE alerts. Emergency and evacuation plans are posted in all occupied buildings and team members are encouraged to be familiar with plans and know how to react, especially when severe weather threats are in the forecast. The Emergency Management ExplorNet page offers a number of handy resources for employees, including the center’s Emergency Procedures Handbook, how to sign up for NIXLE alerts, plus preparedness tips and frequently asked questions.

Valenti also urges Marshall team members to stay weather aware this summer when away from work. “Here, we have a tendency to think that hurricanes are something we don’t need to worry about,” Valenti said, “but it’s important to remember that we all need to stay prepared for severe weather, wherever we are.”

With vacations to the beach on many Marshall team members’ calendars this summer, Valenti encourages travelers to make a plan and be ready in case of an emergency:

- Stay informed. Tune in to local television and radio stations that provide severe weather coverage, or invest in a NOAA weather radio.

- Have a communication plan. In severe weather, especially hurricanes, cellular towers can be damaged. Keep family members apprised of travel plans and make sure they know how to reach you as you travel.

- Follow instructions. If an evacuation becomes necessary, protect your family. It is better to cut a vacation short than risk injury, or worse, trying to ride out a storm.

“We want everybody to have a good time on vacation, but we also want them to come home safely and some simple preparation can do just that,” said Valenti. “Having a plan, staying informed and communicating can help keep everybody safe during severe weather.”

For more information and help to prepare for any emergency situation, visit the FEMA’s America Prepar-a-thon’s website or readyalabama.gov.

Massey, an ASRC Federal/Analytical Services employee and the Marshall Star editor, supports the Office of Strategic Analysis & Communications.

Winning Team of NASA Robot Challenge Featured On ‘This Week @NASA’

The Sample Return Robot Challenge, part of NASA’s Centennial Challenges program, was featured in the latest edition of “This Week @NASA,” a weekly video program broadcast nationwide on NASA-TV and posted online.

NASA awarded $100,000 in prize money to a team from West Virginia University for successfully completing Level 2 of the Sample Return Robot Challenge at Worcester Polytechnic Institute in Massachusetts. This was the fourth year of the event, designed to encourage innovations in autonomous navigation and robotics technologies. Teams had to demonstrate an autonomous robot that could locate samples and return them to the starting platform.

The Centennial Challenges program is part of NASA’s Space Technology Mission Directorate, which is innovating, developing, testing and flying hardware for use in NASA’s future missions.

View this and previous episodes at “This Week @NASA”.