In This Week’s Star

- NASA Acting Administrator Lightfoot, Deputy Associate Administrator Roe meet with Marshall team

- Space Station Crew Members Return Safely to Earth

- SLS Core Stage Simulator Will Pave Way for Mission Success

- NASA Concludes Summer of Testing with Fifth Flight Controller Hot Fire

- Space Launch System Launch Vehicle Stage Adapter Ready for Thermal Insulation Application

- Orbital ATK Supports Ground Testing on CIRAS at NASA’s Langley Research Center

- Safety Week 2017: Personal Engagement is ‘Deciding Factor’ in Workplace Safety

- This Week in NASA History: STS-8 Lands at Edwards Air Force Base – Sept. 5, 1983

- RS-25 Engine Test and SLS Hardware Highlighted on ‘This Week @NASA’

- Obituaries

NASA Acting Administrator Lightfoot, Deputy Associate Administrator Roe meet with Marshall team

By Jonathan Deal

NASA Acting Administrator Robert Lightfoot and Lesa Roe, NASA deputy associate administrator, visited NASA’s Marshall Space Flight Center Sept. 5 for an all-hands meeting with members of the Marshall workforce. Team members filled Morris Auditorium in Building 4200 to listen while many more tuned in to watch on DesktopTV.

Lightfoot spoke about NASA’s recent milestones including the INSPIRE Act, which encourages young girls to study STEM fields; a call from President Donald Trump from the Oval Office to the crew of the International Space Station; the new astronaut class; re-establishment of the National Space Council; and Lightfoot’s tour of Kennedy Space Center with Vice President Mike Pence.

“The progress that Marshall continues to make is pretty phenomenal,” Lightfoot said. “From structural testing to all the software development for the Space Launch System And then of course, Payload Ops continues to step up, and more.”

The Payload Operations Integration Center, located at Marshall, manages scientific research on the station and can serve as backup mission control center, if needed. Johnson Space Center closed last week for normal operations because of flooding associated with Hurricane Harvey, which made landfall near Houston Aug. 26. While Mission Control Center Houston did not cease operations during the storm, Marshall aided the International Space Station team by temporarily routing video downlinks to ensure continuity of operations.

“These past couple of weeks have been really tough because of the hurricane. And the team here at Marshall have stepped up to help out a lot.”

Lightfoot touched on the agency’s continuity of purpose through transition and major strategic themes. NASA’s goals include making new discoveries and expanding human knowledge, pushing human presence deeper into space, strengthening global engagement and diplomacy, enhancing national security and the industrial base, catalyzing economic development and growth, addressing societal challenges and providing leadership and inspiration.

Lightfoot provided an update on the agency operating model and progress toward establishing a more efficient model that maintains critical capabilities and meets current and future mission needs. Though the agency’s operating model changes, Lightfoot stressed a few essential things that will not change. Those guiding principles include mission focus, effective and efficient services, local authority and to value the workforce.

“We will always maintain achieving mission success as our primary focus,” said Lightfoot.

The all-hands meeting was part of Lightfoot’s multi-center tour in which he is meeting with all team members at NASA centers and facilities. Roe recently announced she will retire at the end of September to become the chancellor of the University of North Texas System. The president has nominated U.S. Rep. Jim Bridenstine of Oklahoma to become the next NASA administrator, pending Senate approval.

Deal, an ASRC Federal/Analytical Services employee and the Marshall Star editor, supports the Office of Strategic Analysis & Communications.

Space Station Crew Members Return Safely to Earth

NASA astronaut Peggy Whitson, who set multiple U.S. space records during her mission on the International Space Station, safely landed back on Earth at 8:21 p.m. Sept. 2 in Kazakhstan, along with fellow crew members Jack Fischer of NASA and Fyodor Yurchikhin of Roscosmos.

While living and working aboard the world’s only orbiting laboratory, Whitson and Fischer contributed to hundreds of experiments in biology, biotechnology, physical science and Earth science. The pair of NASA astronauts welcomed several cargo spacecraft delivering tons of supplies and research experiments, and conducted a combined six spacewalks to perform maintenance and upgrades to the station.

Among their scientific exploits, Whitson and Fischer supported research into the physical changes to astronaut’s eyes caused by prolonged exposure to a microgravity environment. They also conducted a new lung tissue study that explored how stem cells work in the unique microgravity environment of the space station, which may pave the way for future stem cell research in space.

Additional research included an antibody investigation that could increase the effectiveness of chemotherapy drugs for cancer treatment, and the study of plant physiology and growth in space using an advanced plant habitat. NASA also attached the Cosmic Ray Energetics and Mass Investigation on the outside of the space station in August, which is now observing cosmic rays traveling from across the galaxy.

Whitson’s return marks the completion of a 288-day mission that began last November and spanned 122.2 million miles and 4,623 orbits of the Earth — her third long-duration mission on the station. During her latest mission, Whitson performed four spacewalks, bringing her career total to 10. With a total of 665 days in space, Whitson holds the U.S. record and places eighth on the all-time space endurance list.

Fischer, who launched in April, completed 136 days in space, during which he conducted the first and second spacewalks of his career. Yurchikhin, who launched with Fischer, now has a total of 673 days in space, putting him seventh place on the all-time endurance list.

Expedition 53 continues operating the station with NASA’s Randy Bresnik in command, and Sergey Ryazanskiy of Roscosmos and Paolo Nespoli of ESA (European Space Agency) serving as flight engineers. The three-person crew will operate the station until the arrival of NASA astronauts Mark Vande Hei and Joe Acaba, and Alexander Misurkin of Roscosmos. Vande Hei, Acaba and Misurkin are scheduled to launch Sept. 12 from Baikonur, Kazakhstan.

Breaking news, images and features from the station are available on Instagram and Twitter.

SLS Core Stage Simulator Will Pave Way for Mission Success

To reduce the risk of first-time operations with one-of-a-kind spaceflight hardware for NASA’s Space Launch System, the agency built a core stage pathfinder similar in size, shape and weight to the 212-foot-tall core stage. Like SLS, the core stage pathfinder will be doing something that’s never been done — testing new shipping and handling equipment and procedures from the manufacturing site to the test site to the launch site. Three companies helped build the pathfinder, joining more than 1,000 other American businesses that have contributed to building NASA’s deep-space rocket. North Alabama companies Radiance Technologies and Dynetics of Huntsville and G&G Steel of Russellville worked to build and assemble the core stage pathfinder. NASA core stage team members from Marshall joined the companies to see the pathfinder assembled before its shipment to Michoud. The steel simulator will travel by commercial barge from G&G Steel’s Cordova factory to NASA’s rocket factory, the Michoud Assembly Facility. Later, it will make its way on NASA’s barge Pegasus to the agency’s Stennis Space Center, and then to Kennedy Space Center. In all these NASA facilities, the core stage pathfinder will help technicians practice critical operations for handling and transporting flight hardware and enable them to fit check the hardware before the actual core stage arrives at their facilities. (NASA/MSFC)

NASA Concludes Summer of Testing with Fifth Flight Controller Hot Fire

On Aug. 30, NASA engineers closed a summer of successful hot fire testing for flight controllers on RS-25 engines that will help power NASA’s new Space Launch System rocket, being built to carry astronauts to deep space destinations. The space agency capped off summer testing with a 500-second hot fire of a fifth RS-25 engine flight controller unit on the A-1 Test Stand at NASA’s Stennis Space Center. The controller serves as the “brain” of the engine, communicating with SLS flight computers to ensure engines are performing at needed levels. NASA tested the first flight controller unit for the SLS engine in March. The agency launched a series of summer tests with a second flight controller unit hot fire at the end of May, then followed up with three additional tests. The flight controller tests are critical in preparation for upcoming SLS flights to deep space — the uncrewed Exploration Mission-1 and Exploration Mission-2. Each SLS rocket is powered at launch by four RS-25 engines firing simultaneously and working in conjunction with a pair of solid rocket boosters. The engines generate a combined 2 million pounds of thrust at liftoff. With the boosters, total thrust at liftoff will exceed 8 million pounds. The RS-25 engines designated for use on the initial SLS missions are former space shuttle main engines, modified to provide the additional power needed for the larger, heavier SLS rocket. During tests, the controllers are installed on a developmental RS-25 engine, which is then fired in the same manner and for the same amount of time that will be needed during an SLS launch. (NASA)

Space Launch System Launch Vehicle Stage Adapter Ready for Thermal Insulation Application

The largest piece of hardware for NASA’s Space Launch System built at NASA’s Marshall Space Flight Center is ready for thermal insulation. Manufacturing is complete on the launch vehicle stage adapter, and it has been moved to Building 4707, NASA’s Center for Advanced Manufacturing, for the application of the spray-on foam insulation that will surround it during its ride to space. Not only is the stage adapter the largest segment of the rocket built at Marshall, measuring 27.6 feet in diameter and 30 feet tall, it is also the largest piece of flight hardware to have insulation applied at Marshall by hand. The stage adapter connects two major sections of the upper part of SLS — the core stage and the interim cryogenic propulsion stage — for the first flight of the rocket and NASA’s Orion spacecraft. Insulation is applied to segments of rocket hardware to protect them from aerodynamic heating. When the insulation is applied, the coating will appear yellow, but as the insulation is exposed to the sun, it will turn orange. Teledyne Brown Engineering of Huntsville is the prime contractor for the adapter. (NASA/MSFC/Tyler Martin)

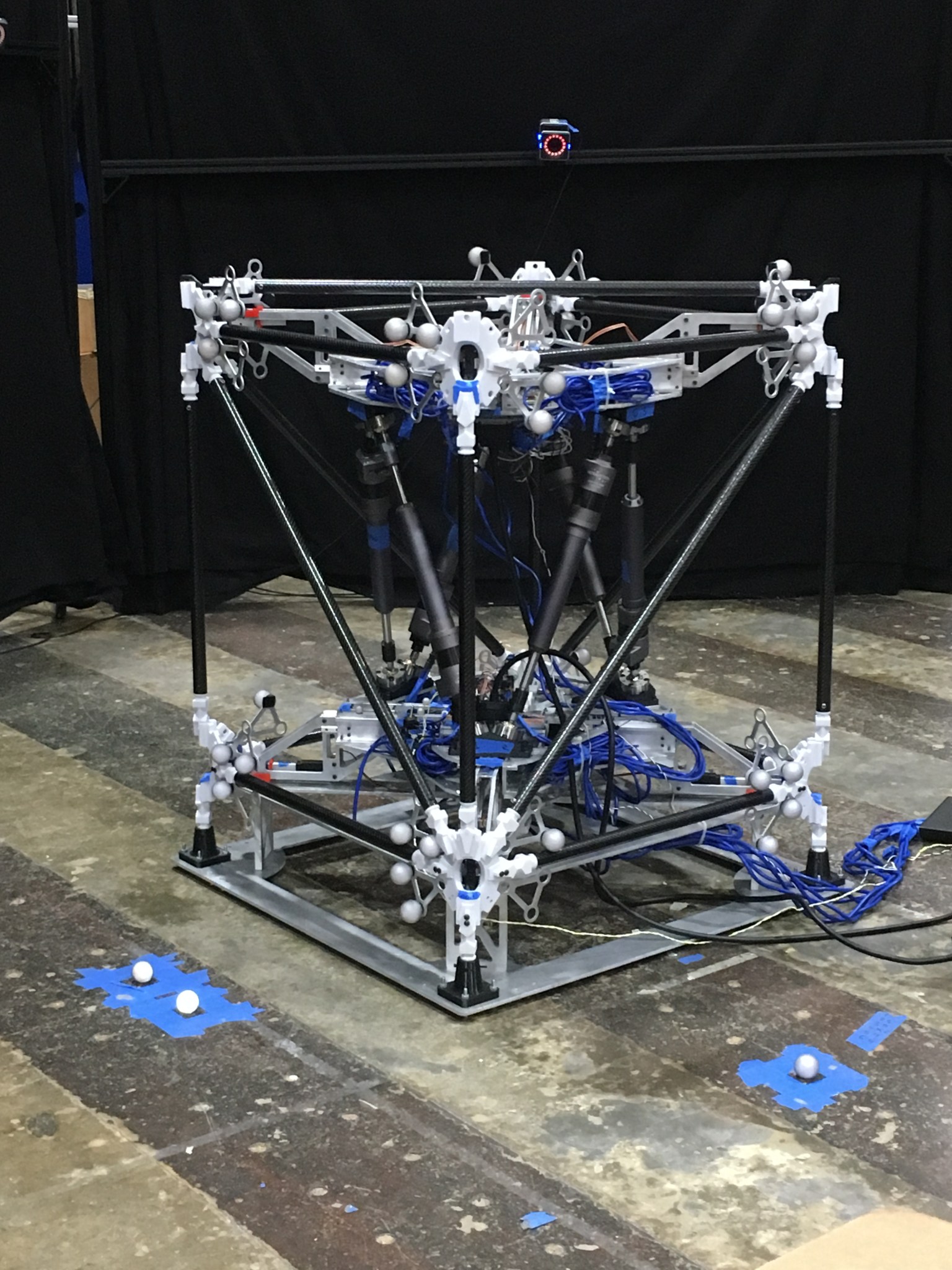

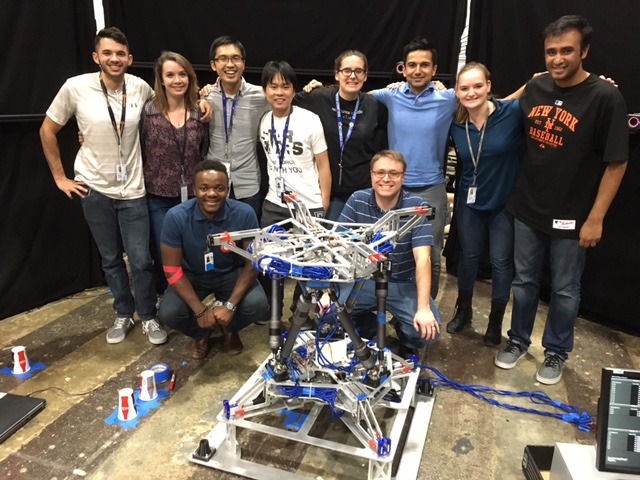

Orbital ATK Supports Ground Testing on CIRAS at NASA’s Langley Research Center

By Amanda Adams

The Commercial Infrastructure for Robotic Assembly and Services project, or CIRAS, has reached an important milestone in advancing technologies to build large structures in space.

Ground demonstration of the CIRAS component, NASA Intelligent Jigging and Assembly Robot 2.0, was conducted July 20 at NASA’s Langley Research Center.

The objective of the demonstration, in collaboration with industry partner Orbital ATK of Dulles, Virginia, was to assemble a square bay truss made of individual struts and nodes using the component, also known as NINJAR 2.0. The demonstration showcased NINJAR 2.0’s ability to position and hold the struts into a perfectly aligned square bay truss for to be permanently welded into place. In orbit, these joints will be secured by an electron beam welder.

“The NINJAR 2.0 has refined capabilities to hold pieces of framework together with very high precision to form a perfect cube,” said Dave Moore, project lead for NASA’s Technology Demonstration Missions program. “CIRAS is like a portable workshop. Once it builds the truss out, it can add capabilities such as installation of solar arrays to provide more power to the payload.”

“We are very happy with the performance of the NINJAR 2.0 during this demonstration,” said Charles Taylor, NASA project manager for CIRAS. “All 10 runs conducted were not only within the criteria of success for this demonstration, but were very close to the more stringent criteria for next year’s ground test.”

Erik Komendera, a research engineer at Langley, and his team of interns have spent the last 10 months working on taking this technology from concept to reality. Their next focus will integrate the Strut Assembly, Manufacturing, Utility & Robotic Aid into the assembly process to pass the struts to NINJAR 3.0 and will develop a state estimation system to use in orbit that will visualize where the struts are and measure the preciseness of the angles. The fully functional CIRAS robotic manufacturing system is set for ground demonstration at Langley mid-2018.

The square bay trusses built by CIRAS will serve as the backbone on which space structures are anchored. Currently, structures sent to space are limited by the size of the payload that can fit on the launch vehicle. The advent of practical, robotic in-space assembly and manufacturing will mitigate the need for deployment mechanisms which will greatly reduce the weight of the payload and enable assembly using materials delivered by multiple launch vehicles. This will lead to simplified common architectures of any size, enabling interchangeable parts and driving down costs.

CIRAS, one of three projects awarded under the NASA Technology Demonstration Missions Program’s “Utilizing Public-Private Partnerships to Advance Tipping Point Technologies” solicitation, will help NASA meet its goals for robotic in-space assembly and manufacturing by using existing NASA technologies and building on the capabilities of Orbital ATK’s first Mission Extension Vehicle, MEV-1, scheduled to launch in 2018. The final version will use NASA’s Tendon-Actuated Lightweight In-Space Manipulator — originally developed to capture asteroids — to assemble and deploy modular truss structures and install and reposition solar arrays on-orbit.

“We are excited by the progress, results and promise of a number of key technologies being developed by the CIRAS team,” said Tom Wilson, president of Space Logistics LLC, a subsidiary of Orbital ATK. “We are making significant progress on our MEV-1, and we look forward to building on to its existing capabilities with the robotic and other technologies developed in the CIRAS program.”

CIRAS is a part of the In-Space Robotic Manufacturing and Assembly project portfolio, managed by NASA’s Technology Demonstration Missions Program and sponsored by NASA’s Space Technology Mission Directorate. NASA’s Marshall Space Flight Center leads the TDM program for the agency.

The CIRAS team includes prime contractor Orbital ATK, supported by its wholly owned subsidiary, Space Logistics, LLC; along with Langley, NASA’s Glenn Research Center, NASA’s Goddard Space Flight Center, and the U.S. Naval Research Laboratory in Washington.

Adams, an ASRC Federal/Analytical Services employee, supports the Office of Strategic Analysis & Communications.

Safety Week 2017: Personal Engagement is ‘Deciding Factor’ in Workplace Safety

By Rick Smith

Schedule of Safety Week Events: “Engaged Wednesday,” Sept. 27

- Organizational Meetings — 9-10 a.m.

- Safety Engagement Activities/Safety Vendors — 9 a.m.-2 p.m.

- Presentation: Yoga for Stress Reduction — 11 a.m.-Noon

- Food Truck Vendors — 11 a.m.-1 p.m.

- Flu Shots — Noon-3 p.m.

- Presentation: Balance Training for an Aging Workforce (Session 1) — Noon-1 p.m.

- Presentation: Balance Training for an Aging Workforce (Session 2) — 1-2 p.m.

- Dedicated Housekeeping — 2-3 p.m.

Editor’s Note: NASA’s Marshall Space Flight Center will mark Safety Week Sept. 25-29, with each day focused on a unique theme tied to team members’ health and well-being. The Marshall Star is presenting a series of articles on each day’s theme and the planned activities and presentations associated with it.

Midway through Marshall’s Safety Week, on Wednesday, Sept. 27, the topic will turn to engagement — the concept that every individual must be personally invested in a culture of safety, doing his or her part to ensure the health and well-being of the entire team.

“Every workplace safety program includes rules and regulations, and seeks to drive home the importance of safety awareness via training and motivational presentations. That’s 90 percent of the formula,” said Roy Malone, director of Marshall’s Office of Center Operations. “The other 10 percent is the deciding factor — personal engagement. It’s the actions of the individual, every day, that make our workplace safe or unsafe.”

The Sept. 27 activities will kick off with safety vendor exhibits and presentations in Activities Building 4316 and the NASA Wellness Center between 9 a.m. and 2 p.m. Food truck vendors will set up outside Building 4316 from 11 a.m. to 1 p.m., with tables and seating available under a large tent on the 4316 lawn.

Teams are encouraged to stay for lunch and engage in networking and team-building activities. Marshall’s Space Launch System Program will add to the team spirit, displaying its large, inflatable SLS exhibit outside 4316 for photos and selfies.

Flu shots will be available in Building 4316 from noon to 3 p.m., and two health-focused presentations will help round out the day’s activities. From 11 a.m. until noon in Building 4315, Leah Fox, a safety and occupational health specialist in Marshall’s Safety and Mission Assurance Directorate, will lead a class on “Yoga for Stress Reduction.” Yoga is an ancient Indian discipline that combines controlled breathing, meditation techniques and precise physical control of the body. Studies have shown it can reduce stress, lower blood pressure and improve balance.

Fox, who teaches a yoga class each Wednesday at 11:15 a.m. at the Wellness Center, said, “It’s the best 45 minutes you can give to yourself. The effects linger throughout the remainder of the day.” She encourages team members to contact her for more information.

Josh Steed, a rehab and manual therapy specialist at TherapySouth of Huntsville, will present an hour-long class on “Balance Training for an Aging Workforce” at noon and 1 p.m. in Building 4315’s East Gym. Balance training teaches users the importance of maintaining balance — the body’s base of support — despite changes to one’s posture due to age or destabilizing injury or surgery.

Team members also are reminded to complete safety refresher courses in SATERN during Safety Week, and to set aside time for housekeeping in their offices, laboratories or shops.

Malone is encouraged by the progress he’s seen in making safety second nature — not just among engaged workers but Americans nationwide. “Our society has taken steps to motivate people to embrace personal safety,” he said, pointing to seat belt safety as an example. But, he noted, while seat belt use has improved dramatically nationwide — up from 14 percent in 1984 to 90 percent in 2005, according to a National Highway Transportation Safety report — it still took more than two decades to achieve that result.

“We get caught up in deadlines, always trying to get more done,” Malone said. “We look for opportunities to save time, and sometimes we cut corners. When it comes to safety, that’s not good. We must take it to heart that making unsafe choices can have a serious impact on everyone around us.”

That may take a personal wakeup call, he added. “When tempted to take a safety shortcut, stop and ask, ‘Who else am I putting at risk?’ That might make the difference.”

Safety Week is organized by the Safety and Mission Assurance Directorate. Team members are encouraged to monitor ExplorNet for Safety Week schedule updates.

Smith, an ASRC Federal/Analytical Services employee, supports the Office of Strategic Analysis & Communications.

This Week in NASA History: STS-8 Lands at Edwards Air Force Base – Sept. 5, 1983

This week in 1983, space shuttle Challenger and STS-8 landed at Edwards Air Force Base in California after a successful six-day mission. When Challenger launched on Aug. 30, Guion S. Bluford made history as he became the first African American in space. Here, Bluford assists with a medical test that required the use of a treadmill exercising device designed by the STS-8 medical doctor. Today, the Payload Operations Integration Center at Marshall serves as “science central” for the space station, working 24/7, 365 days a year in support of the orbiting laboratory’s scientific experiments. The NASA History Program is responsible for generating, disseminating and preserving NASA’s remarkable history and providing a comprehensive understanding of the institutional, cultural, social, political, economic, technological and scientific aspects of NASA’s activities in aeronautics and space. For more pictures like this one and to connect to NASA’s history, visit the Marshall History Program’s webpage. (NASA)

RS-25 Engine Test and SLS Hardware Highlighted on ‘This Week @NASA’

The latest test of the RS-25 engine for NASA’s Space Launch System, and an update of the progress made on SLS hardware are featured in the latest edition of “This Week @NASA,” a weekly video program broadcast nationwide on NASA-TV and posted online.

On Aug. 30, NASA successfully tested one of its RS-25 engines, four of which will help power the SLS rocket to deep-space destinations. Also, progress on SLS hardware continued with the largest piece of hardware for SLS built at NASA’s Marshall Space Flight Center now ready for thermal insulation.

Marshall manages the SLS program for NASA.

View this and previous episodes at “This Week @NASA” on NASA’s YouTube page.

Obituaries

Raymond P. Garcia, 81, of Huntsville, died Aug. 29. He retired from the Marshall Center in 2004 as a propulsion engineer. He is survived by his wife, Sandra Garcia.

Ronald W. Sockwell, 82, of Huntsville, died Aug. 28. He retired from the Marshall Center in 1989 as an electrical engineer. He is survived by his wife, Carolyn L. Sockwell.