In This Week’s Star

- NASA Acting Administrator Robert Lightfoot to Hold Marshall All-Hands Meeting Sept. 5

- Full Circle: NASA to Demonstrate Refabricator to Recycle, Reuse, Repeat

- Teams Take Home $400,000 at Second Phase of NASA’s 3-D Printed Habitat Competition

- Marshall Names New Leaders to Guide Science on Space Station

- Marshall Spinoff Provides X-Ray Vision to Scientists

- Essential to the Mission: Jeff Branting

- Safety Week 2017: ‘Sense of Fairness’ is Integral to Safety

- NASA Awards Engineering Services and Science Capability Contract

- This Week in NASA History: First Flight of Space Shuttle Discovery – Aug. 30, 1984

- Obituaries

NASA Acting Administrator Robert Lightfoot to Hold Marshall All-Hands Meeting Sept. 5

NASA Marshall Space Flight Center team members are encouraged to attend an all-hands meeting with NASA Acting Administrator Robert Lightfoot at 1 p.m. Sept. 5 in Morris Auditorium, Building 4200.

Lightfoot will be joined by Lesa Roe, NASA deputy associate administrator. The all-hands meeting is part of Lightfoot’s multi-center tour in which he is meeting with all team members at NASA centers and facilities.

Lightfoot was director of Marshall Center from 2009–2012 where he managed a broad range of propulsion, scientific and space transportation activities contributing to the nation’s space program.

Roe has had a distinguished career that includes positions at multiple NASA centers, including her most recent post as the director of NASA’s Langley Research Center from 2005-2014.

After Lightfoot’s remarks, he will answer questions during a question-and-answer session. To submit questions before the meeting, click here.

Marshall team members unable to attend can watch the all-hands meeting live on Marshall Desktop TV.

Full Circle: NASA to Demonstrate Refabricator to Recycle, Reuse, Repeat

By Bill Hubscher

In 2014, NASA made important progress toward the in-space manufacturing necessary for deep space exploration by “printing” tools in space using a 3-D printer on the International Space Station.

In 2018, the nation’s space agency will take the next step toward a sustainable in-space manufacturing capability when it launches a machine that can not only print plastic parts, but can also recycle them back into reusable raw materials to make more and/or different parts.

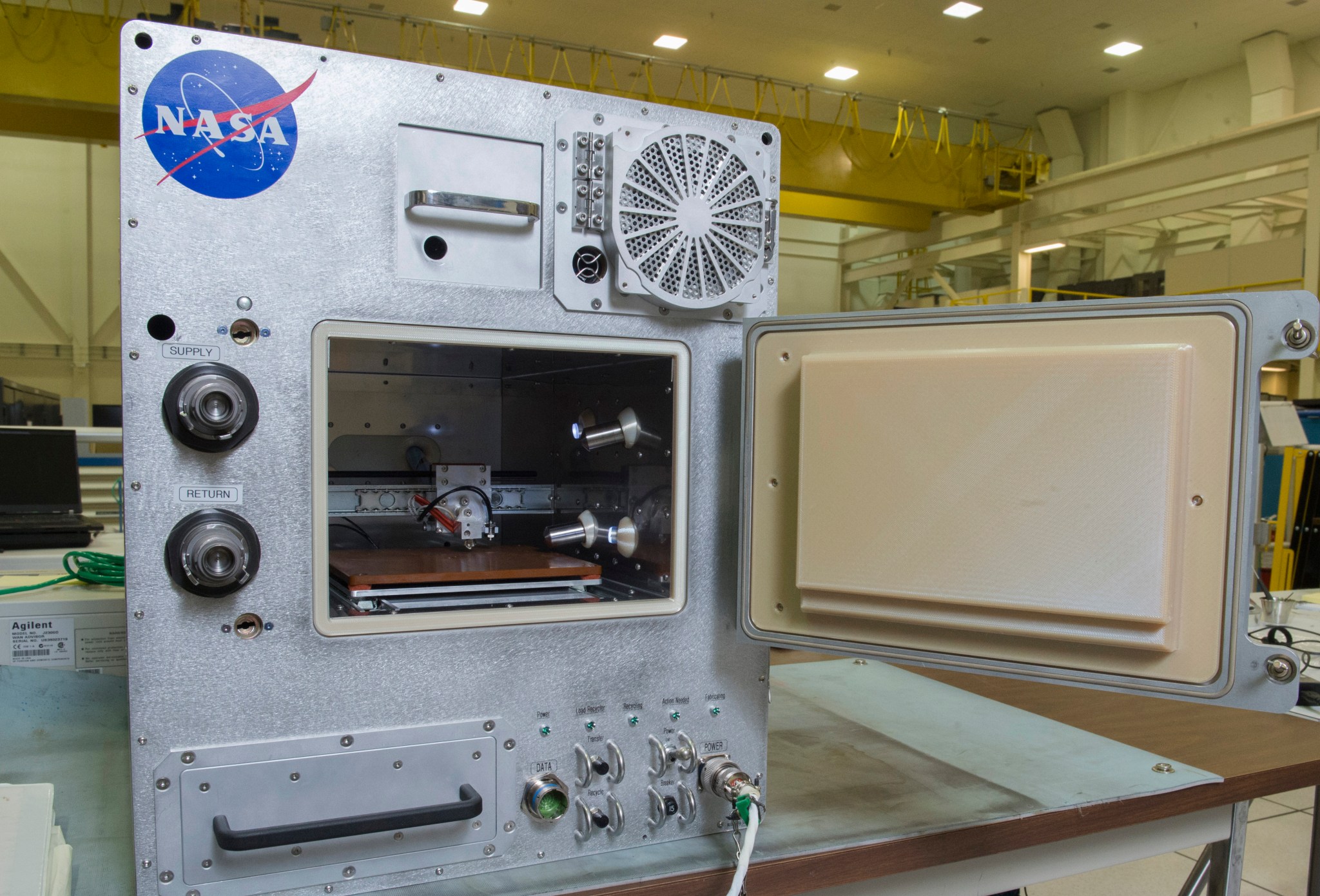

The machine, coined the Refabricator, is a device that will accept plastic materials of various sizes and shapes and turn them into the feedstock used to 3-D print items. The whole process happens in a single automated machine about the size of a compact refrigerator.

“When we begin launching humans to destinations beyond low-Earth orbit, space will be at a premium,” said Niki Werkheiser, manager of In-Space Manufacturing at NASA’s Marshall Space Flight Center, where the device will be thoroughly tested before launching to the space station. “It simply won’t be feasible to send along replacement parts or tools for everything on the spacecraft, and resupplying from Earth is cost and time prohibitive. The Refabricator will be key in demonstrating a sustainable logistics model to fabricate, recycle and reuse parts and waste materials.”

NASA awarded a Small Business Innovation Research contract valued at approximately $750,000 to Tethers Unlimited Inc. of Seattle in April 2015, to build the recycling system.

“The Refabricator demonstration is a key advancement toward our vision of implementing a truly sustainable, in-space manufacturing ecosystem,” said Rob Hoyt, CEO of Tethers Unlimited. “Astronauts could use this technology to manufacture and recycle food-safe utensils, and turn what is now inconvenient waste into feedstock to help build the next generation of space systems. We believe reusing the waste could reduce the cost and risks for NASA and private space exploration missions.”

The Refabricator will complete final flight certification testing at Marshall in late 2017 and is slated to launch to the station in April 2018. Almost all operations will be remotely commanded and controlled from Marshall’s Payload Operations Integration Center — mission control for science on the space station — and Tethers Unlimited. The ability to remotely manage the process can save astronauts time and provide greater autonomy for future spaceflight missions.

“The space station is the ideal proving ground for this important technology,” said Werkheiser. “Astronauts are already living and working in space, a mere 250 miles above Earth. Those crew members are helping make discoveries to benefit humans around the world while testing the important technology, life support systems and medical breakthroughs that will enable long-duration space exploration by humans.”

The Refabricator will be the first integrated recycler-manufacturer in orbit and may eventually be able to recycle and print, using metal as well as plastic, with very little monitoring from the station crew members. By 2020, NASA wants to create a Fabrication Laboratory, or FabLab, to test an integrated, multi-material, on-demand system.

“The FabLab would allow astronauts to select what they want or need from a catalogue of parts and then simply push a button to have it made,” said Werkheiser.

This project is an ideal example of how government and small businesses can effectively work together. In this example, NASA and Tethers Unlimited worked hand-in-hand in the rapid development of new technology for in-space applications. NASA provided guidance and insight on how to design the system to successfully meet the stringent spaceflight certification, safety and operations constraints.

NASA continues to leverage open competition, including crowd-sourcing, Small Business Innovation Research awards, Broad Agency Announcements, and challenge competitions to collaborate and meet space needs for space exploration.

Hubscher, an ASRC Federal/Analytical Services employee, supports the Office of Strategic Analysis & Communications.

Teams Take Home $400,000 at Second Phase of NASA’s 3-D Printed Habitat Competition

NASA is making progress and awarding prizes in its competition to build a 3-D printed habitat for deep space exploration.

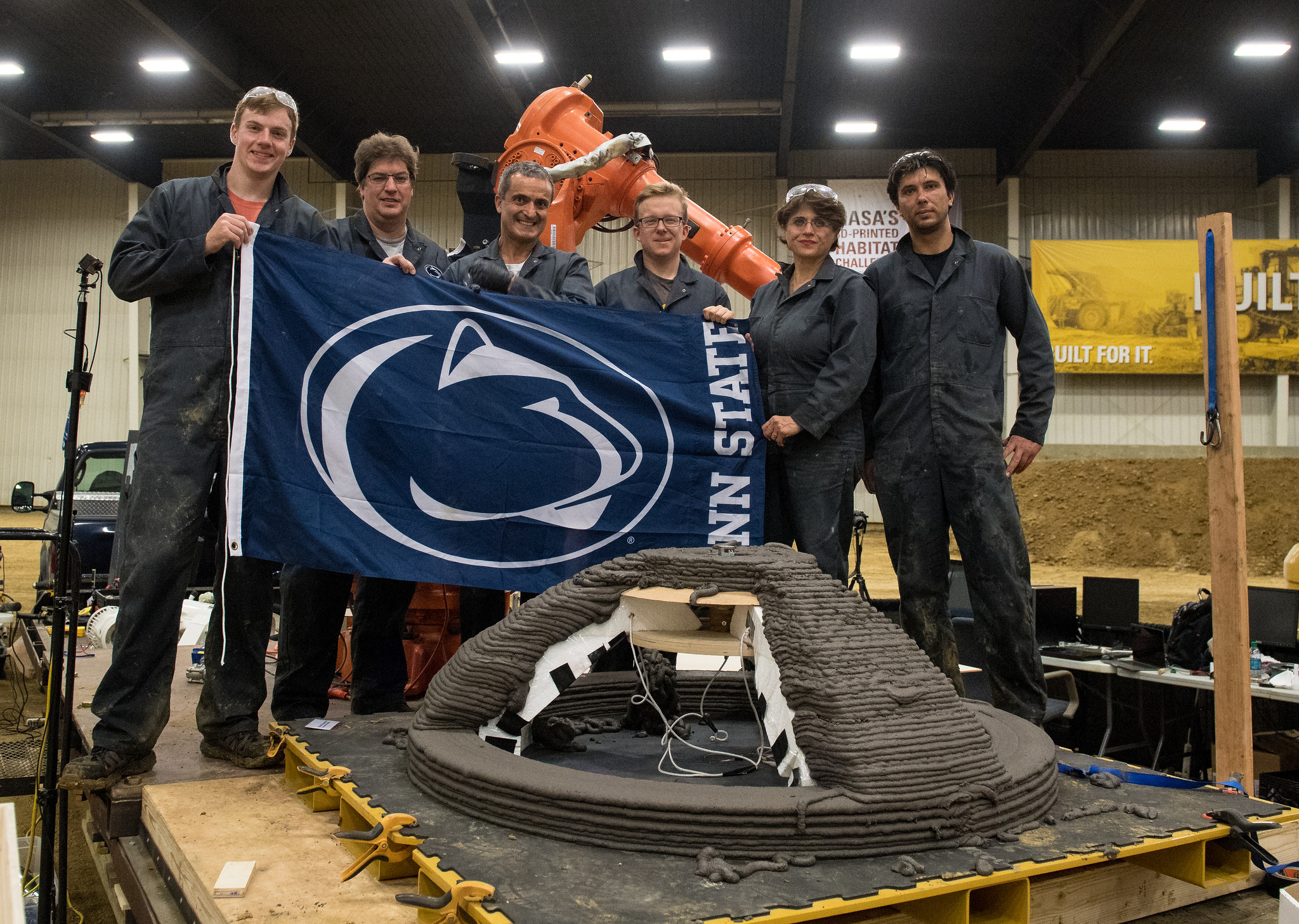

The agency awarded first place and a prize check for $250,000 to Team Foster + Partners | Branch Technology of Chattanooga, Tennessee, for successfully completing Phase 2: Level 3 of NASA’s 3-D Printed Habitat Challenge, a NASA’s Centennial Challenges prize competition. Pennsylvania State University of University Park received second place, and a check for $150,000.

Challenge activities were held Aug. 23-26 at Caterpillar’s Edwards Demonstration and Learning Center in Edwards, Illinois. Teams were presented a check at the awards ceremony on Aug. 26 by Jim Reuter, deputy associate administrator for NASA’s Space Technology Mission Directorate.

“The advancement and innovation in additive construction that we’ve seen from these teams is inspiring,” said Reuter. “Meeting the technology goals of this challenge proves that competition can push boundaries, and their work puts us that much closer to preparing the way for deep space exploration.”

The multi-phase, $2.5 million 3-D Printed Habitat Challenge is designed to advance construction technology needed to create sustainable housing solutions for Earth and beyond. Teams had to design the printer itself and construction materials. They then had to print beams, cylinders and domes that were analyzed and compressed to failure to determine scores and prize awards. Teams were encouraged to use recyclables in their printer material to earn more points. Foster + Partners | Branch Technology’s dome withstood 1694kg of pressure before breaking; Penn State’s dome held 792kg. Bradley University in Peoria, Illinois, is NASA’s 3-D Printed Habitat Challenge partner. Bradley University also partnered with sponsors Caterpillar, Bechtel and Brick & Mortar Ventures to run the competition. The Centennial Challenges program is managed at Marshall.

The competition activities were open to the public, and many industry leaders and local school groups attended the event. A gallery of photos from the challenge events can be found on the NASA Headquarters’ Flickr site.

Sudnik, an ASRC Federal/Analytical Services employee, supports the Office of Strategic Analysis & Communications.

Marshall Names New Leaders to Guide Science on Space Station

By Bill Hubscher

Every good team has a leader at the helm. Whether it’s the conductor of an orchestra, quarterback of a football team or commander of a platoon.

When it comes to guiding and managing science on the International Space Station, that leader is the payload operations director. NASA has named four new payload operations directors to join the ranks at the Payload Operations Integration Center — mission control for station science — located at NASA’s Marshall Space Flight Center.

NASA is increasing the crew complement in the U.S. segment of the station from three astronauts to four, essentially doubling the amount of science conducted on board. More science means more flight controllers are needed to help manage those investigations.

These four payload operations directors will soon begin training and certification for their new roles, joining the 24 flight controllers who help lead the large team that works with astronauts on a daily basis to conduct science in orbit.

“There was a rigorous review process of many outstanding applicants,” said Bobby Watkins, director of the Human Exploration Development & Operations Office at Marshall Center, which manages the Payload Operations Integration Center. “These four represent the best and are consummate professionals who have proven themselves as expert flight controllers for the space station.”

While all four new payload operations directors have previous flight controller experience, their journeys to lead the team are just beginning. They will soon begin the certification process, which includes training over the next six months to a year. Once officially certified, they will begin guiding the science on the station that improves life on Earth, while managing the discoveries that will help carry us to other worlds.

Here are the four newest payload operations directors:

Jessica Caudle

A Huntsville native, Caudle has held numerous flight controller roles in support of the space station program throughout her career including data management controller, in which she managed the process which allows scientists on the ground to communicate with their science experiment in orbit; as a payload rack officer, working to guide multiple investigations on the station; and as the Microgravity Science Glovebox controller, in which she monitored the contained facility on the orbiting laboratory. As a key member of the team supporting the Robotic Refueling Mission — a one-time, proof-of-concept demonstration for robotic refueling in space — she led the development of the ground command procedures. She earned a bachelor’s degree in mechanical engineering in 2008 from the University of Alabama in Huntsville, and a master’s degree in project management in 2012 from the Florida Institute of Technology in Melbourne.

Christy Kennamer

Kennamer is an accomplished flight controller who served as an operations support manager before accepting her new role, integrating new and existing science payload operations on the space station. She holds a certification as a payload communications manager, and achieved a second certification as a stowage officer, including specialized training as stowage expert for the Rodent Research team that guided that specific investigation on the space station. Prior to supporting NASA, Kennamer was employed by ADS Environmental Services in Huntsville for 15 years where she held various positions including regional data analyst manager. A native of Arab, Alabama, Kennamer earned a bachelor’s degree in civil engineering from the University of Alabama in Huntsville.

Phillippia Simmons

Simmons has a diverse and accomplished career supporting the Space Shuttle and International Space Station Programs. A native of Birmingham, Alabama, she began her career at NASA’s Johnson Space Center as a shuttle dynamics flight controller, providing trajectory planning and ground navigation support for all phases of shuttle flight. She also lived and worked in Moscow, Russia, as a liaison between U.S. and Russian flight controllers before becoming a life support engineer for the station’s life support hardware. Before accepting her new role, she served as a payload communications manager at the Marshall Center, speaking with station astronauts on a daily basis to help conduct science experiments. Simmons earned a bachelor’s degree in physics in 1994 and a master’s degree in physics in 1997, both from Alabama A&M University in Huntsville.

Christopher A. Wakefield

A native of Brilliant, Alabama, Wakefield graduated from Mississippi State University in Starkville with a bachelor’s degree in aerospace engineering in 2004. Before accepting his new role, he was an operations support manager at the Marshall Center, integrating new and existing science payloads on the space station. He is also a certified payload rack officer, supporting a series of individual experiments and investigations as a timeline, increment and real-time flight operations lead.

Stay up to date with science activities on the space station on the official Twitter feed for science on the orbiting laboratory.

Hubscher, an ASRC Federal/Analytical Services employee, supports the Office of Strategic Analysis & Communications.

Marshall Spinoff Provides X-Ray Vision to Scientists

By Will Bryan

As children, most people dream of having Superman’s X-ray vision and being able to see through walls, spy on siblings and know what is in the colorfully wrapped packages under the Christmas tree. To the dismay of our childhood selves, none of us acquired this trait.

In the early 2000s, scientists at NASA’s Marshall Space Flight Center began looking for better X-ray technology in an effort to verify the elemental composition of various spacecraft components. Traditional X-ray fluorescence devices could not easily detect elements lighter than calcium, including elements — such as aluminum and silicon — the agency needed to validate.

Marshall partnered with KeyMaster Inc., of Kennewick, Washington, now owned by Bruker AXS Inc., based in Madison, Wisconsin, to develop a hand-held device that could detect these elements. The resulting XRF scanner — recognized as a certified space technology by the Space Foundation in 2006 — is sensitive enough to detect elements heavier than neon in gas, liquid and solid form, essentially adding nine elements to the measureable range.

The key to the powerful instrument is the incorporated vacuum chamber that eliminates the problem of air resistance in detecting lower mass elements. The technology has been commercialized as the Tracer series of scanners and is used for a variety of purposes including art and history preservation and food and medicine quality control.

The basic principle of X-ray fluorescence is simple. For example, aluminum, which is widely used in spacecrafts, has 13 electrons orbiting its nucleus in three different orbits. When a high-energy particle — such as one emitted from an XRF scanner — strikes an electron in the orbit closest to the nucleus with enough energy to launch it out of that orbit, the atom becomes temporarily unstable.

The instability is remedied by an electron from a higher orbit falling into the gap left by the excited electron. The electron from the higher orbit releases energy when this happens, energy characteristic to its atom — in this case, aluminum. By measuring the energies of an object, it is possible to determine the elemental composition and abundances of that object and map the locations of those elements.

Like many good tools, Tracer scanners have found life outside of their original intent, including in the art industry. Vincent Van Gogh’s style is unique and recognizable, and his “Starry Night” is one of the most renowned paintings in the world. As it turns out, Van Gogh’s unique method of creating yellow is the key to decipher the authenticity of his paintings. Containing chromium, the yellow paint possesses a definitive signature in X-ray fluorescence. When a supposed new piece of his work is presented, the XRF tool can be used to non-destructively test and help determine if the art is truly his or a forgery. This could help save museums from making multi-million-dollar mistakes.

Used by more than 600 universities, museums and institutions worldwide, Tracer scanners not only ensure spacecraft are made of the alloys and materials they are supposed to be made of, but the scanners also help preserve history, restore art and ensure food and medicine are free of contaminants, benefitting humanity and the world for many generations to come.

If you think you have a technology that could give super powers to the average Joe, submit a New Technology Report. As Terry Taylor, manager of Marshall’s Technology Transfer Office explains, “The agency holds more than 1,400 patents and makes them available to industry through its patent licensing program. These inventions generate revenue, create jobs, save lives and show a clear return on investment for the nation’s space program.”

Bryan, an ASRC Federal/Analytical Services employee, supports the Office of Strategic Analysis & Communications.

Essential to the Mission: Jeff Branting

By Jena Rowe

Prior to beginning his career with NASA, Jeff Branting was familiar with the agency in a unique way.

“I worked with NASA a lot during my time in the Air Force,” said Branting. “As a matter of fact, I actually had the role as the custodian of the moon rocks when I was a captain. I thought they were joking when I got the assignment, but that was actually part of my duties.”

From serving in the Air Force to being hired by NASA as a security specialist seven years ago, Branting is now chief of security in the Protective Services Office at NASA’s Marshall Space Flight Center. He and his team are responsible for badging, personnel security, providing employees appropriate building access, workplace violence training, law enforcement and emergency response.

“Because of the nature of what we do, security can often feel like an inconvenience,” said Branting. “But the reality is that we keep people safe and I think feeling safe at work allows you to be a more productive employee.”

Branting and his team encourage every Marshall team member to consider safety and security as a part of their job by reporting any concerns to the Protective Services Office. Preventing something from going wrong or someone from getting hurt could be considered the definition of a good day in the world of security.

“It’s a successful day if we don’t have an event or if we’ve prevented an incident,” said Branting. “Responding to things as they happen means something is going wrong. We are prepared for that, but I’d rather prevent it than respond to it. When employees report their concerns, it allows us to prevent incidents before they happen and that is ultimately our goal.”

While the contributions of Branting and the Protective Services Office serve as the underlying backbone of safe, day-to-day operations at Marshall, their connection to the future of space exploration is not lost. “I remember planning security operations for the arrival of the Pegasus barge that transported the SLS core stage engine section earlier this year. When it finally got here and all of the planning came together, I was excited to be part of a new phase of NASA,” said Branting.

“I’ve been lucky in my life to always work for an organization that had a mission I can be proud of. I am proud that I work for NASA and realize that we contributed to the overall mission in that moment is something that I will always be proud of.”

Rowe, an ASRC Federal/Analytical Services employee, supports the Office of Strategic Analysis & Communications.

Safety Week 2017: ‘Sense of Fairness’ is Integral to Safety

Schedule of Safety Week Events: “Just Tuesday,” Sept. 26

- Just Culture panel — 9:30-11 a.m.

- Just Culture booths — 11 a.m.-1 p.m.

- Presentation: Fairness and a Practical Mindset — 1-2 p.m.

- Organizational Meetings — 1-2 p.m.

- Dedicated Housekeeping — 2-3 p.m.

By Rick Smith

Editor’s Note: NASA’s Marshall Space Flight Center will hold its first Safety Week celebration Sept. 25-29, with each day focused on a unique theme tied to team members’ health and well-being. In coming weeks, articles on each day’s theme and planned activities and presentations will appear in the Marshall Star.

On Tuesday, Sept. 26, the second day of Marshall’s Safety Week, activities will challenge team members to consider how safety and diversity intersect, and how to foster a positive, safe working environment where justice and fairness prevail. The theme for day two, “Just Tuesday,” will spotlight that critical intersection, with presentations and activities tied to the concept of fair-mindedness and the creation of a safe workplace for all team members.

“People don’t necessarily think about diversity when they think about safety, but they’re both integral to fostering the kind of culture needed to achieve NASA’s mission,” said Loucious Hires, director of Marshall’s Office of Diversity and Equal Opportunity. “An environment that celebrates equality removes a potential distraction, a mental irritant that can detract from the job at hand. That inevitably makes us safer.”

The day’s safety activities will start at 9:30 a.m. with the “Just Culture” panel in Morris Auditorium in Building 4200. This Q&A session, springing from employee feedback to Marshall’s Safety Culture Survey, will enable workers to ask questions of representatives from center organizations including the Safety and Mission Assurance Directorate, Office of Human Capital, Office of Diversity and Equal Opportunity, Office of Procurement and Office of the Chief Counsel.

Team members can anonymously email questions for the panel to sonya.dillard@nasa.gov or brandi.n.thomas@nasa.gov prior to Sept. 26. Questions also may be sent via interoffice mail to Dillard at QD12, Building 4203, Room 2317, or posted to ExplorNet.

Following the presentation, team members are encouraged to visit the lobby of Building 4203. Representatives of Marshall organizations, including the Employee Assistance Program, Protective Services, Marshall Ombudsman, Labor Relations and Marshall’s unions — the American Federation of Government Employees and Marshall Engineers and Scientists Association — will be on hand to disseminate safety information and answer additional questions.

From 1-2 p.m. in Building 4203, Room 1201, Bruce Pieper, an organization development specialist supporting the Office of Human Capital, will talk about “Fairness and a Practical Mindset.” The course will illustrate the perceptual nature of fairness, the value of self-talk — positive affirmation from one’s own inner voice — and the impact of a negative mindset on personal and professional goals.

Hires is particularly excited about Pieper’s topic. “Consider ‘Hidden Figures‘,” he said, referring to the 2016 film about female, African-American mathematicians who played crucial roles in launching NASA’s Apollo moon missions. “Talk about the practical value of embracing diversity! Equal opportunity isn’t about race or heritage. It’s about ability.”

Team members also may use time Sept. 26 to complete the safety refresher course “Orientation to NASA Safety Culture.” An alternate course, “Safety Culture for Supervisors,” will be offered for those in leadership roles. Safety Week organizers will email links to the SATERN training modules to all team members in coming weeks. Teams also should schedule at least one safety meeting by the end of Safety Week, and set aside time to address housekeeping in their offices, laboratories or shops.

Hires believes demonstrating safety in the workplace goes hand in hand with demonstrating a just and fair culture. “It’s our responsibility to model the behavior we want to see in action,” he said.

That belief underpins the motto of the Office of Diversity and Equal Opportunity: “Every Action, Every Day.”

“That’s not just the duty of our leaders and administrators, but every one of us,” he said. “Challenge your own thinking, in everything you do. Take part. Speak up. Get involved.”

Safety Week is organized by the Safety and Mission Assurance Directorate. Team members are encouraged to monitor ExplorNet for updates and additions to the Safety Week schedule.

Smith, an ASRC Federal/Analytical Services employee, supports the Office of Strategic Analysis & Communications.

NASA Awards Engineering Services and Science Capability Contract

NASA has selected Jacobs Technology of Tullahoma, Tennessee, to provide a broad spectrum of engineering and scientific support services at NASA’s Marshall Space Flight Center and the Michoud Assembly Facility.

The Engineering Services and Science Capability Augmentation contract is a cost-plus-award-fee indefinite-delivery indefinite-quantity contract that has a potential period of performance of eight years. It is a follow-on effort to the Engineering and Science Services and Skills Augmentation contract and will satisfy requirements for engineers, scientists and engineering technicians at Marshall and Michoud. The new contract begins Dec. 1, 2017, and includes a four-year base period followed by two, two-year options that may be exercised at NASA’s discretion. The maximum potential value of the contract, including all options, is approximately $1.1 billion.

Services and skills will be provided across a broad spectrum of engineering and science disciplines for the purposes of design, analysis, development and testing. Services and skills applied to hardware development will be primarily for the purpose of development and optimization of manufacturing and material processes.

Engineering and scientific support services will be provided to the to Marshall Engineering Directorate as well as other programs and projects across the center, both present and future. The contract also includes support for NASA activities and other reimbursable work for which Marshall has responsibility, including support to the Department of Defense, and other government, commercial or educational activities.

This Week in NASA History: First Flight of Space Shuttle Discovery – Aug. 30, 1984

This week in 1984, space shuttle Discovery and STS-41D launched from Kennedy Space Center. This was the maiden voyage of Discovery. The mission deployed three satellites and extended the 102-foot Office of Application and Space Technology solar wing, also known as OSAT-1 — a demonstration of large, lightweight solar arrays for future facilities in space such as the International Space Station. Here, Discovery is prepared for rollout from Kennedy’s Vehicle Assembly Building. Today, the Payload Operations Integration Center at Marshall serves as “science central” for the space station, working 24/7, 365 days a year in support of the orbiting laboratory’s scientific experiments. The NASA History Program is responsible for generating, disseminating, and preserving NASA’s remarkable history and providing a comprehensive understanding of the institutional, cultural, social, political, economic, technological, and scientific aspects of NASA’s activities in aeronautics and space. For more pictures like this one and to connect to NASA’s history, visit the Marshall History Program’s webpage. (NASA)

Obituaries

Arthur O. Boyanton Jr., 85, of Huntsville, died Aug. 20. He retired from the Marshall Center in 1987 as an engineer. He is survived by his wife, Betty Boyanton.