NASA to Conduct Test to Prepare for Artemis I Moon Mission

NASA is targeting June 18 for the beginning of the next wet dress rehearsal test of the agency’s Space Launch System (SLS) rocket and Orion spacecraft at Kennedy Space Center with tanking operations June 20.

During the test, launch teams will rehearse operations to load propellant into the rocket’s tanks, conduct a full launch countdown, demonstrate the ability to recycle the countdown clock, and drain the tanks to give them an opportunity to practice the timelines and procedures they will use for launch.

Live coverage of tanking operations with commentary begins at 6 a.m. CDT on June 20. The target test window opens at 1:40 p.m. Coverage will air on the media channel of NASA Television, the NASA app, and the agency’s website.

NASA’s Artemis I Moon rocket returned to the spaceport’s Launch Pad 39B on June 6, after an eight-hour journey from the Vehicle Assembly Building. Teams are working to secure the SLS and Orion and connect the ground systems to the mobile launcher at the pad in preparation of the upcoming tanking test.

The rehearsal is the final test needed before launch and will begin at 4 p.m. June 18 with “call to stations,” when members of the launch control team will arrive at their consoles to start the approximately two-day countdown. On June 20, the launch director and mission management team chair decide at approximately 6 a.m. if they are “go” or “no-go” to begin tanking the rocket. The team will count down to a targeted two-hour test window that opens at 1:40 p.m. During the test, the team may hold during the countdown as necessary to verify conditions before resuming the countdown, or extend beyond the test window, if needed and resources allow.

Through Artemis missions, NASA will land the first woman and the first person of color on the Moon, paving the way for a long-term lunar presence and serving as a steppingstone to send astronauts to Mars.

The wet dress rehearsal test was also previewed in the latest edition of “This Week @ NASA.”

For updates, follow along on NASA’s Artemis blog here.

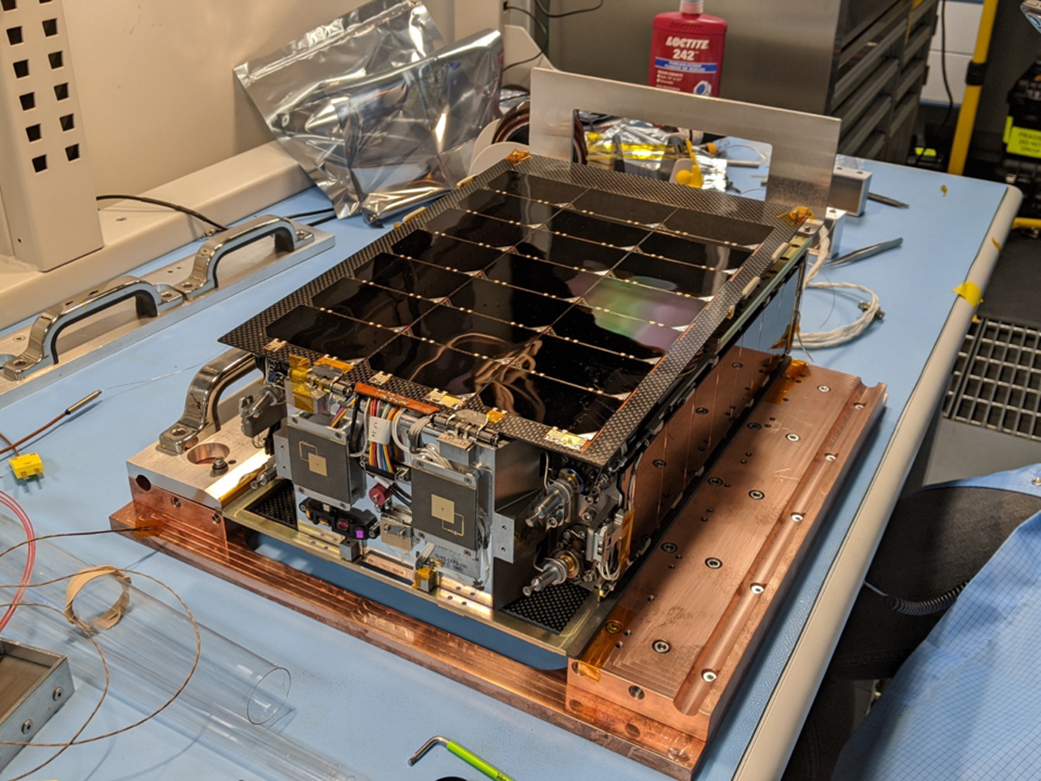

Artemis II Engine Section Moves to Final Assembly

The 212-foot core stage with its RS-25 engines will provide more than 2 million pounds of thrust at launch. With Artemis, NASA will land the first woman and the first person of color on the Moon and establish long-term exploration in preparation for missions to Mars. SLS and NASA’s Orion spacecraft, along with the commercial human landing system and the Gateway in orbit around the Moon, are NASA’s backbone for deep space exploration. SLS is the only rocket that can send Orion, astronauts, and supplies to the Moon in a single mission. Credits: NASA/Eric Bordelon

On May 24, the core stage production team moved the Space Launch System rocket engine section for Artemis II to the core stage final integration area at NASA’s Michoud Assembly Facility. While there, the engine section team is completing installation of the main propulsion systems, finishing integration of the electrical and avionics systems, and preparing for functional testing of the various systems. During final integration, the team also will install remaining internal thermal protection systems and prepare to position the engine section from vertical to horizontal so that it can be joined with the rest of the core stage. The engine section is located at the bottom of the core stage and includes the rocket’s main propulsion systems that connect to the core stage’s four RS-25 engines that will help launch the Artemis II lunar mission. This fall, the engine section will be horizontally integrated with the previously-joined forward assembly and liquid hydrogen tank to complete the core stage. NASA and core stage lead contractor Boeing are building core stages for the next three Artemis missions. The 212-foot core stage with its RS-25 engines will provide more than 2 million pounds of thrust at launch. With Artemis, NASA will land the first woman and the first person of color on the Moon and establish long-term exploration in preparation for missions to Mars. SLS and NASA’s Orion spacecraft, along with the commercial human landing system and the Gateway in orbit around the Moon, are NASA’s backbone for deep space exploration. SLS is the only rocket that can send Orion, astronauts, and supplies to the Moon in a single mission. (NASA/Eric Bordelon)

NASA Supplier Completes Manufacturing Artemis III SLS Booster Motors

Each SLS solid rocket booster has three major assemblies: forward skirt, motor, and aft skirt. The motor segments will be stored at Northrop Grumman’s Promontory, Utah, facility until they are transported to NASA’s Kennedy Space Center in Florida, where they will be integrated with the booster’s forward and aft assemblies and avionics, then stacked on the mobile launcher in the Vehicle Assembly Building for flight.

NASA and Northrop Grumman teams at Kennedy are assembling and testing booster structures and avionics for the Artemis II and Artemis III missions and preparing for the first SLS launch on the Artemis I mission. Propellant casting for the Artemis IV motor segments is in progress at Northrop’s factory in Utah. Artemis IV will be the first flight of SLS Block 1B. Testing for upgraded booster motors on Artemis IX and beyond has already begun, with the latest subscale motor test taking place June 1, 2022. Credits: Northrop Grumman

The 10 Space Launch System rocket motor segments that will help launch the Artemis III crew on their mission to land on the Moon are complete. Teams finished manufacturing the segments for the mission May 18. Each of the twin solid rocket boosters is made up of five motor segments that will be stacked with the rest of the booster parts before flight. The twin boosters supply 7.2 million pounds of thrust – more than 75% of total thrust for the first two minutes of flight. Each SLS solid rocket booster has three major assemblies: forward skirt, motor, and aft skirt. The motor segments will be stored at Northrop Grumman’s Promontory, Utah, facility until they are transported to NASA’s Kennedy Space Center, where they will be integrated with the booster’s forward and aft assemblies and avionics, then stacked on the mobile launcher in the Vehicle Assembly Building for flight. NASA and Northrop Grumman teams at Kennedy are assembling and testing booster structures and avionics for the Artemis II and Artemis III missions and preparing for the first SLS launch on the Artemis I mission. Propellant casting for the Artemis IV motor segments is in progress at Northrop’s factory in Utah. Artemis IV will be the first flight of SLS Block 1B. Testing for upgraded booster motors on Artemis IX and beyond has already begun, with the latest subscale motor test taking place June 1 at NASA’s Marshall Space Flight Center. (Northrop Grumman)

Singer Stresses Importance of Nurturing Diverse Culture During NASA’s DirectHERS Event

Jody Singer, right, director of NASA’s Marshall Space Flight Center, speaks on a panel with the agency’s three other female center directors: Marla Peréz-Davis of Glenn Research Center, second from left, Vanessa Wyche of Johnson Space Center, center, and Janet Petro of Kennedy Space Center, second from right, during the “DirectHERS – Launching Through the Glass Ceiling” event June 7 at NASA Headquarters. NASA General Counsel Sumara Thompson-King, left, moderated the panel. Singer said her technical, programmatic, and supervisory experiences have opened many doors for her, including her role as Marshall’s 14th director and first female director. She said many of her female mentors paved the way for her, most of the time through glass ceilings. “While we are going in the right direction, I believe my role is to mentor the next generation of leaders and encourage women into STEM fields,” Singer said. “My dream is that when young women of today see the first woman and the first person of color land on the Moon with NASA’s Artemis program, that they will realize the sky is not their limit.” Singer said it is important to nurture a culture of diverse groups of people, perspectives, and experiences. “Everyone needs to be welcome at the table,” she said. “I also encourage my team members and direct reports to continue to foster a culture at our center that will make top talent want to join us. By emphasizing inclusion, our most recently added NASA value, along with diversity, equity, and more – we can ensure that NASA is a place where all feel welcome and encouraged to be themselves at work.” (NASA/Aubrey Gemignani)

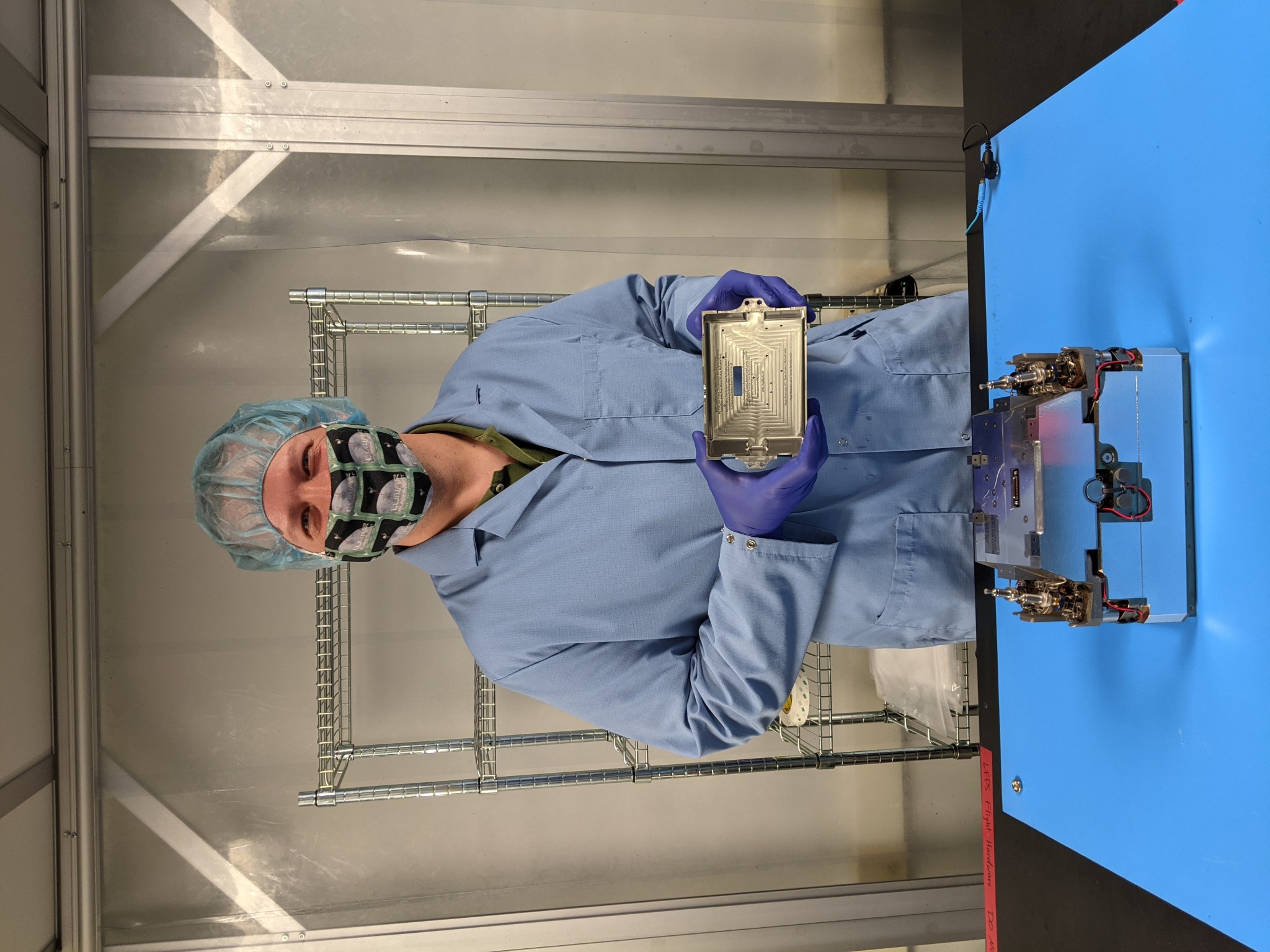

Marshall Team Delivers Tiny, Powerful ‘Lunar Flashlight’ Propulsion System

Engineers at NASA’s Marshall Space Flight Center have built some of the largest rocket engines ever to light up the icy reaches of space. Now Marshall and its commercial partners have delivered one of the smallest propulsion systems in its history, designed to help propel an upcoming NASA mission to shed new light on the Moon’s South Pole – in search of a much more useful type of ice.

Lunar Flashlight, no larger than a briefcase, is an innovative, low-cost CubeSat developed and managed by NASA’s Jet Propulsion Laboratory. As the spacecraft orbits the Moon, its near-infrared lasers will shine light onto the permanently shadowed surface of the lunar pole, while its onboard reflectometer measures surface reflection and composition to identify large ice deposits.

Expected to launch later in 2022 via a SpaceX Falcon 9 rocket, Lunar Flashlight will seek out water ice on the lunar surface, which could be collected and purified for drinking water or converted into breathable oxygen or even into rocket fuel.

NASA is seeking lunar ice deposits to answer longtime questions about the composition, quantity, and distribution of frozen water on the Moon. The mission will help determine where it exists on the surface – and whether there is enough to sustain future lunar colonies and to power advanced lunar habitats and laboratories.

The Lunar Flashlight Propulsion System was fast-tracked for design, fabrication, and testing in July 2019. “We had to scale the propulsion technology down to something that could fit into a backpack, yet with all the same challenges of larger propulsion systems,” said Daniel Cavender, manager of the project at Marshall. “This was made easier by our strategic investments in small-satellite propulsion technologies over the past few years.”

Work also benefited from new partnerships with industry and academia. Marshall led the design of the compact propulsion system and oversaw hardware development in its in-house facilities and at Plasma Processes LLC of Huntsville and Flight Works of Irvine, California. Researchers at the Georgia Institute of Technology’s Space Systems Design Lab in Atlanta built the fuel tank and electrical controller and led system integration and testing.

The tiny craft is fueled with a chemical monopropellant – a fuel capable of burning by itself without a separate oxidizer – known as Advanced Spacecraft Energetic Non-Toxic, or ASCENT. Developed by the Air Force Research Laboratory and first tested on NASA’s Green Propellant Infusion Mission, which concluded in 2020, ASCENT is a “green,” low-toxic alternative to the conventional monopropellant hydrazine.

Beyond the obvious value of finding potable water for astronauts to drink, the ability to convert lunar water ice into hydrogen and oxygen – the basic requirements to make rocket fuel – could help establish a permanent fuel depot on the Moon, enabling lunar launches of future deep space missions to Mars and other destinations.

“The mission will demonstrate our ability to use powerful, compact propulsive CubeSats for a variety of science missions at the Moon and across the solar system,” Cavender said. “That’s a game-changing capability for exploration and planetary science.”

Marshall delivered the propulsion system to Jet Propulsion Laboratory in May 2021 for spacecraft integration. Lunar Flashlight will return to Marshall for fueling before being transported to NASA’s Kennedy Space Center for launch – as a secondary payload on the same rocket as Intuitive Machines’ first mission under NASA’s Commercial Lunar Payload Services initiative. Once launched, Lunar Flashlight will take roughly six months to reach the Moon, where it will achieve a polar orbit and begin its two-month primary mission.

The Lunar Flashlight mission is funded by NASA’s Small Spacecraft Technology Program, part of the agency’s Space Technology Mission Directorate, via a NASA Small Business Innovation Research grant. Dr. Barbara Cohen, a researcher at NASA’s Goddard Space Flight Center, is its measurement lead.

Jason Hyder Clears Lines for Crew-4 Mission

By Tee Quillin

Jason Hyder helps ensure the valves, lines, and ducts on launch vehicles are ready for NASA’s SpaceX human spaceflight missions.

Hyder is a design and development engineer with Jacobs Space Exploration Group, working on the Engineering Services and Sciences Capability Augmentation contract in the Engineering Directorate at NASA’s Marshall Space Flight Center. He supports the Commercial Crew Program’s Launch Vehicle Propulsion Engineering team as the subsystem manager for the Valves, Lines, and Ducts branch.

Each component of the valve, lines, and ducts has its own unique operating environment, method of operation, and type of wear it experiences. Verifying that these parts are up to the task is critical to mission success.

Hyder provides engineering insight to the Commercial Crew Program, ensuring valves are designed in compliance with program requirements and operate at peak efficiency from testing through launch – and all over again for each booster stage’s reuse that’s assigned to a commercial crew mission. He and his team of seven engineers work with SpaceX teams to ensure all 80 design units – made up over 700 valve, line, and duct sites on the SpaceX Falcon 9 rocket – are cleared for safe launch of commercial crew missions to the International Space Station – including the Crew-4 mission that launched April 27.

“With the high level of insight and cooperation between our team and SpaceX, there is an immense sense of pride that comes with supporting the mission on console during launch,” Hyder said. “That sense of pride brings with it a personal responsibility for the crew’s safety. The focus and concentration quickly turn to pure joy once the second stage shuts down and you hear the crew has reached orbit.

“Seeing NASA astronaut Bob Hines toss around the stuffed animal zero-gravity indicator marked the culmination of our team’s hard work leading up to launch, which was especially sweet given the large effort that went into certifying the first stage booster for four flights.”

Crew-4 marked the first time that a Falcon 9 first-stage booster planned for a crew flight was certified for a fourth flight. Previously, the program had only certified boosters for reuse on up to two flights. The fourth-flight booster was assigned to Crew-4 in January, and the commercial crew launch vehicle team demonstrated its flexibility to perform within a tight time window.

Hyder was part of a group – which included NASA team members from Marshall and Kennedy Space Center, and SpaceX team members – that established an effective approach to certify the Falcon 9 first stage for multiple reuses.

“Jason brings a great energy to the team and helps ensure our astronauts have a safe ride,” said Lisa McCollum, manager of Marshall’s Commercial Crew Program support team. “For example, he set up scripts that allowed him to analyze pressure data in real time during the countdown. At the Huntsville Operations Support Center, Jason was able to quickly interpret critical data on the health of the hardware while he was on console for the launch.”

In addition to the Crew-4 mission, Hyder and his team concurrently assisted with preparations for NASA’s Boeing Orbital Flight Test-2, which launched the CST-100 Starliner spacecraft on the United Launch Alliance Atlas V rocket on May 19 from Space Launch Complex 41 at Cape Canaveral Space Force Station in Florida – about three weeks after Crew-4.

Born and raised in Johnson City, Tennessee, Hyder earned his bachelor’s degree in mechanical engineering and Master of Business Administration from Tennessee Tech University in Cookeville. In between pursuing those degrees, he worked for MAHLE Engine Components in Morristown, Tennessee, as an engineer responsible for steel machining and automated optical inspection processes. The job took him to a sister plant in Nanjing, China, for two years on assignment as a technical advisor for the ramp-up of new piston manufacturing lines. He returned to the U.S. in 2020 to begin his current position at Marshall, supporting commercial crew.

The Commercial Crew Program was formed to facilitate the development of a U.S. commercial crew space transportation capability with the goal of achieving safe, reliable, cost-effective access to and from the space station and low-Earth orbit. The program is jointly led by Kennedy and NASA’s Johnson Space Center, with support from Marshall.

The support team at Marshall consists of about 80 people supporting the commercial crew office, engineering, and mission safety. Marshall provides management support as well as engineering expertise in propulsion valves and pyrotechnics, natural environments, and vehicle structures, among others.

Quillen, a Media Fusion employee, supports Marshall’s Office of Strategic Analysis & Communications.

Marshall Hosts ‘Beautiful Expression of Hope’ to Commemorate Juneteenth

By Rick Smith

A week of clouds and rain stood down June 9, enabling NASA’s Marshall Space Flight Center team members and their Redstone Arsenal counterparts to celebrate Marshall’s first Juneteenth festival.

Gathering in the food truck “corral” at the intersection of Rideout and Martin roads to enjoy food, live music, vendor booths, and a performance by the Huntsville Community Drumline, the crowd’s mood was festive, the energy high. Marshall colleagues and guests, still recovering from two years of pandemic protocols, greeted one another with hugs and fist-bumps, laughter, and applause.

That positive spirit ran deeper than good weather and an end to lockdown, said NASA Payload Operations Director Nick Benjamin, a 14-year Marshall veteran who also co-chairs the center’s African American employee resource group.

That’s because Juneteenth, a federal holiday marking the end of slavery in the United States and officially observed each year on June 19, is less a commemoration of bitter history than “a celebration of faith and hope,” he said. As June 19 will fall on a Sunday this year, Marshall will observe the holiday June 20.

“Those words have a different meaning to a lot of [Black Americans], reaching back to a time when we communicated them through old songs and Negro spirituals,” Benjamin told festival participants. “We had faith in our ability to achieve equality. We knew that someday, somewhere, we would overcome the shadows.”

Celebrating that triumph is something everyone deserves to participate in, said Huntsville community council member Devyn Keith. “Juneteenth isn’t a story about slaves, but a story about Americans,” he told festivalgoers. “How do we celebrate it? The same way we do St. Patrick’s Day and Cinco de Mayo – as one America. We all have similar stories.”

Marshall Director Jody Singer also shared remarks on the occasion, praising her team’s dedication to unity and to NASA’s renewed equity goals.

“Every action every day makes a difference,” she said. “Our diverse workforce is changing the way NASA does business – and we’re still excellent at what we do. I thank each of you for taking care of one another, paying it forward, and being role models for all of us to follow.”

That long-term dedication is critical, said Amanda Otieno, an equal employment specialist in Marshall’s Office of Diversity and Equal Opportunity, which organized the event.

“Inclusion is not just a month out of the year, not a perfunctory annual holiday. It has to be intentionally woven into the very fabric of our culture,” Otieno said. “A great turnout at events such as this one means we continue to move steadily in the right direction. That makes me so proud.”

Benjamin agreed. “Welcome to this day of joy we have talked about for so long, celebrating a beautiful expression of hope and resistance,” he said. “Just look at us now.”

Juneteenth – an opportunity for Black Americans to celebrate their shared culture, heritage, and contributions to the American experience – is the oldest nationally celebrated event marking the end of slavery in the United States. Texas legislators were the first to make it a state holiday in 1980. The theme for the 2022 celebration is “Celebrating Culture, Cultivating Unity.”

Partners in the event included Marshall’s African American employee resource group, Team Redstone, the FBI’s Federal African American Millennials group, and Amazon’s Black Employee Network.

Marshall team members interested in joining the African American employee resource group should contact Benjamin. To learn more about diversity programs and events, visit the Office of Diversity and Equal Opportunity here.

Smith, a Manufacturing Technical Solutions employee, supports Marshall’s Office of Strategic Analysis & Communications.

Marshall Celebrates Pollinator Week With Seed Giveaway June 21

A Gulf fritillary butterfly lands on a passion vine flower in the pollinator habitat at NASA’s Marshall Space Flight Center. The Marshall Pollinator Club will celebrate Pollinator Week by giving away seed mix June 21 at the food truck corral from 11 a.m. to 1 p.m. Pollinator Week is June 20-26 in North America and is an annual celebration in support of pollinator health initiated and managed by Pollinator Partnership. To increase habitat quality and availability, Marshall established a pollinator habitat in 2019 with more than 160 plants to attract butterflies, hummingbirds, and other pollinators. The habitat also serves as an educational tool to increase understanding of pollinator health and the critical role native species play in the pollinator lifecycle. Malene McElroy, sustainability coordinator in the Environmental Engineering and Occupational Health Office at Marshall, said major threats to pollinators include habitat loss, nonnative species and diseases, pollution, and climate change. “The plants, mostly perennials, are drought tolerant and require minimal upkeep,” McElroy said of the habitat. “Many of the plants were grown from seed by Marshall Green Team members. Regional plant nurseries donated large trees and shrubs to anchor the garden. The habitat was created without any appropriated funds and is maintained by volunteers.” The habitat is certified by the North American Butterfly Association and is also an official Monarch Waystation. Additional volunteers are needed to help with general maintenance of the habitat. For more information on volunteering, contact McElroy or Lyndsey Winslette, or visit the Pollinator Club site. (NASA)

Europa Clipper Mission Completes Main Body of Spacecraft, Highlighted on ‘This Week at NASA’

An important milestone for the Europa Clipper spacecraft is featured in “This Week @NASA,” a weekly video program broadcast on NASA Television and posted online.

The main body of Europa Clipper was delivered recently to NASA’s Jet Propulsion Laboratory. Engineers and technicians there will finish assembling the spacecraft by hand, then test it to make sure it can withstand the journey to Jupiter’s icy moon Europa. Targeted for launch in October 2024, the mission will make nearly 50 flybys of the Jovian moon, which is believed to have an underground ocean that contains twice as much water as all oceans on Earth combined. The ocean on Europa may also currently have conditions suitable for supporting life.

The mission is part of the Solar System Exploration Program, which is managed by the Planetary Missions Program Office at NASA’s Marshall Space Flight Center.

View this and previous episodes at “This Week @NASA” on NASA’s YouTube page.

In This Week’s Star