In This Week’s Star

- Jody Singer Named Marshall Space Flight Center Acting Director

- First SLS Core Stage Flight Hardware Complete, Ready for Joining

- May Reflects on NASA Career During Retirement Reception

- Marshall Interns Develop and Release Navigation Software

- Technical Advisor George Young Reflects on 50-Year Career at Marshall

- Technology Transfer Office Announces 2018 Tech Tank Winners

- ‘Show-Me State’ Students Talk with Astronaut, Celebrate NASA Anniversaries

- This Week in NASA History: SUMI Launches – July 30, 2010

Jody Singer Named Marshall Space Flight Center Acting Director

By Amanda M. Adams

NASA has named Jody Singer acting director of NASA’s Marshall Space Flight Center as the agency seeks a permanent director. Todd May, who had served as Marshall director since February 2016, retired from the agency effective July 27, capping a 27-year career with NASA that began in 1991 as an engineer at Marshall.

“My decision to retire from NASA was a difficult one, primarily because of the truly exceptional people I got to work with every day,” said May. “With deep management experience over three decades at the project, program and center levels, I’m confident Jody Singer will continue to lead the Marshall’s critical work achieving the next wave of human exploration to the Moon, Mars and beyond.”

Singer was appointed Marshall deputy director in February 2016, assisting the director with the daily management of the center’s workforce and operations. Over her 32-year NASA career, Singer has served in numerous leadership roles overeseeing human spaceflight, technology and science flight missions programs and projects, and in 2002 was appointed to the Senior Executive Service, the personnel system covering top managerial positions in federal agencies. She began her career in 1985 as an engineer in NASA’s professional intern program.

Prior to becoming the deputy center director, Singer was the manager of the Flight Programs and Partnerships Office at Marshall from 2013 to 2016, where she held primary responsibility for the center’s work with human advanced exploration projects, science flight mission programs, technology demonstration missions, commercial crew, and International Space Station life support systems, research facilities, and payload operations. Singer also was responsible for identifying opportunities to develop and maintain partnerships with other government agencies, academia, and international and commercial partners that will help achieve NASA’s vision.

Her experience in human spaceflight includes 25 years in the Space Shuttle Program where she was responsible for the development, testing, flight readiness, safety and performance of the propulsion elements: the external tank, solid rocket boosters and main engines. Her experience also includes the Return to Flight activities following the Columbia tragedy, serving as as the first female project manager for the Reusable Solid Rocket Booster Project Office and as deputy manager in the Space Shuttle Propulsion Office as it successfully completed its mission and retirement.

From 2010 through 2012, she held deputy positions for three concurrent programs: the Space Shuttle Program, Ares, and for the start-up of the the Space Launch System. In 2012, as the deputy program manager of SLS at Marshall, she helped lead nearly 3,000 civil servants and contractors involved in the developing and testing of the vehicle — the most powerful rocket ever built, able to carry astronauts in NASA’s Orion spacecraft on deep space missions to the Moon and ultimately to Mars.

Singer has been recognized with numerous awards during her NASA career, including the NASA Outstanding Leadership Medal, the NASA Exceptional Service Medal, and two Presidential Rank of Meritorious Executive Awards, the highest honor for career federal employees.

Adams, an ASRC Federal/Analytical Services employee, supports Marshall’s Office of Strategic Analysis & Communications.

First SLS Core Stage Flight Hardware Complete, Ready for Joining

By Brian Massey

The first major piece of core stage hardware for NASA’s Space Launch System rocket has been assembled and is ready to be joined with other hardware for Exploration Mission-1, the first integrated flight of SLS and the Orion spacecraft. SLS will enable a new era of exploration beyond low-Earth orbit, launching crew and cargo on deep space exploration missions to the Moon, Mars and beyond.

The backbone of the world’s most powerful rocket, the 212-foot-tall core stage, will contain the SLS rocket’s four RS-25 rocket engines, propellant tanks, flight computers and much more. Though the smallest part of the core stage, the forward skirt will serve two critical roles. It will connect the upper part of the rocket to the core stage and house many of the flight computers, or avionics.

“Completion of the core stage forward skirt is a major step in NASA’s progress to the launch pad,” said Deborah Bagdigian, lead manager for the forward skirt at the agency’s Marshall Space Flight Center. “We’re putting into practice the steps and processes needed to assemble the largest rocket stage ever built. With the forward skirt, we are improving and refining how we’ll conduct final assembly of the rest of the rocket.”

On July 24, forward skirt assembly was wrapped up with the installation of all its parts. As part of forward skirt testing, the flight computers came to life for the first time as NASA engineers tested critical avionic systems that will control the rocket’s flight. The construction, assembly and avionics testing occurred at NASA’s Michoud Assembly Facility.

Located throughout the core stage, the avionics are the rocket’s “brains,” controlling navigation and communication during launch and flight. It is critical that each of the avionics units is installed correctly, work as expected and communicate with each other and other components, including the Orion spacecraft and ground support systems.

“It was amazing to see the computers come to life for the first time” said Lisa Espy, lead test engineer for SLS core stage avionics. “These are the computers that will control the rocket as it soars off the pad for Exploration Mission-1.”

The forward skirt test series was the first of many that will verify the rocket’s avionics will work as expected during launch. The tests show the forward skirt was built correctly, and that all components and wiring on the inside have been put together and connected properly and are sending data over the lines as expected.

The avionic computers ran “built-in tests” that Espy compares to the internal diagnostic tests performed by an automobile when first started. All of the health and data status reports came back as expected. The tests were a success and did not return any error codes. Such error codes would be similar to a check engine light on a car.

The successful tests give the team the confidence needed to move forward with avionics installations in the core stage intertank and engine section. With more hardware and more interfaces, the installation in the intertank will be more complex, and the complexity will ramp up even more as the team moves to the engine section, introducing hydraulics and other hardware needed for the rocket’s engines.

“Each piece of hardware and each test builds to the next,” Espy said. “That’s why we’re excited about the successful forward skirt tests. They lay a solid foundation as we continue to build more and more complex components and get the rocket ready for its first launch.”

The forward skirt is now ready to be joined with the rest of the rocket’s core stage. Integration of the massive core stage will take place in two joins, the forward join — including the forward skirt, liquid oxygen tank and intertank — and the aft join — including the liquid hydrogen tank and the engine section.

Engineers will perform standalone tests on each component as they are completed. Once the forward and aft joins are integrated, they will perform a final integrated function test, testing all the core stage’s avionics together.

The fully integrated core stage and its four RS-25 engines will then be fired up during a final test before launch. At NASA’s Kennedy Space Center, the core stage will be stacked with the upper part of the rocket, including Orion, and joined to the rocket’s twin solid rocket boosters, in preparation for EM-1.

Massey, an ASRC Federal/Analytical Services employee, supports Marshall’s Office of Strategic Analysis & Communications.

May Reflects on NASA Career During Retirement Reception

Todd May thanks the Marshall team during his farewell address at the reception July 25 honoring his service as he retires as director of NASA’s Marshall Space Flight Center. During his remarks, May reflected on his 27-year career with NASA and shared emotional highlights and personal memories. (NASA/Emmett Given)

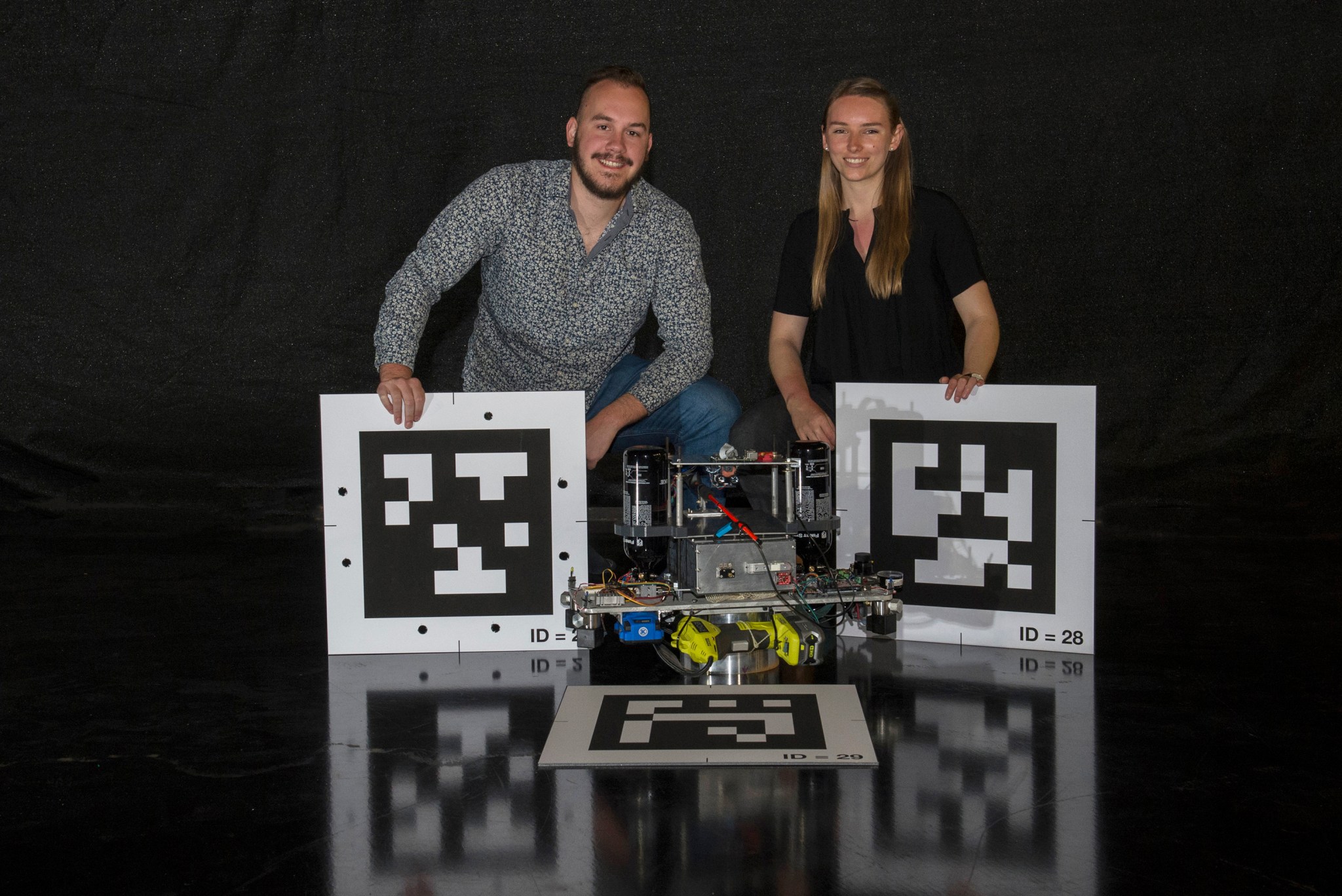

Marshall Interns Develop and Release Navigation Software

By Amanda Adams

Interning at NASA puts students at the center of innovation and discovery. For two students at NASA’s Marshall Space Flight Center, this meant having the incredible opportunity to not only leave their mark on one of NASA’s most unique testing facilities, but also release their own open source software.

Junior engineering interns Greta Studier, from Swarthmore College in Pennsylvania, and Tristan Schuler, from George Mason University in Fairfax, Virginia, developed a navigation system that mimics the star tracking navigation system that will be used in space on a small satellite, propelled by an electrostatic sail, currently in development at Marshall.

“To progress our research and development of electrostatic sails, we needed to come up with a localization navigation system to track our robotic prototype in the test lab,” said Studier. “The system we developed provides an inexpensive solution that allows us to track our robot within five centimeters of accuracy.”

Robotic Nano Air-bearing Simulators are being developed and evolved by interns under Marshall’s Technology Innovation Program to test the deployment of the electrostatic sail on Marshall’s Flat Floor Flight Robotics Lab — a state-of-the-art testing facility featuring an epoxy floor designed to allow engineers to simulate movements that help test the guidance, navigation and control systems of spacecraft.

“We’re really proud of the work these students have put into this system,” said Tom Bryan, the students’ mentor and senior engineer for the lab. “They are quite modest about their achievement, but what they’ve accomplished here has advanced the capabilities of our Flat Floor Flight Robotics Lab, and can be very valuable to others as open source software.”

The students’ invention simulates the navigation system that will direct NASA’s Heliopause Electrostatic Rapid Transit System by tracking its location based on the position of the satellite relative to the stars. The proposed HERTS E-Sail concept, a propellantless propulsion system, would harness solar wind to travel into interstellar space. This potentially revolutionary propulsion system could send spacecraft to the edge of our solar system, the heliopause, faster than ever before.

The students named AprilNAV after a 2D tag system, called AprilTAG, developed by the University of Michigan. They began by using AprilTAGs, modifying the code to fit their needs.

“At school, I used AprilTAGs on soda cans to direct a robot to go up to the can and grab it,” said Schuler. “The beauty of this system is that it tells the camera where the tag is located in relation to the camera. With this information, we can take several tags and average the coordinates together to come up with the optimum position of the camera.”

The duo had a series of 2D barcodes, resembling QR codes, printed on foam board and helped mount them at calculated intervals to the facility’s ceiling. A camera was positioned on top of the Nano Air-Bearing Simulator, a robot built by previous interns and modified by Schuler and Studier. The camera is programmed to read the barcodes as the robot floats across the Flat Floor. Then, the robot relays its position back to the students. This process simulates how HERTS will use a star tracker in space as navigation to reach the heliopause.

While AprilNAV was developed from a need and with a specific purpose in mind, it can be used in many different capacities. The students worked with the Technology Transfer Office at Marshall to release their code to the public.

“The nice thing about AprilNAV is that other users can use the navigation code to create their own control systems,” said Schuler. “For example, robotic labs could use this if they wanted to control quadcopters inside a room.”

The code for AprilNAV is available to the public at no cost on software.nasa.gov and code.nasa.gov.

Adams, an ASRC Federal/Analytical Services employee, supports Marshall’s Office of Strategic Analysis & Communications.

Technical Advisor George Young Reflects on 50-Year Career at Marshall

By Amanda Adams

From his early days as an engineer with the Science and Engineering Directorate to his current work as technical advisor in the Space Technology Development Office, George Young has seen NASA’s Marshall Space Flight Center grow and change in many ways throughout his 50-year career.

“The biggest change I’ve seen is with the culture,” said Young. “When I first came to work here, the focus was on making a machine fly. We were more concerned with the end product whereas now we focus more on process control. We work to define the processes so that we are confident of getting the end item we want.”

A native of Meridian, Mississippi, Young joined NASA in 1968 after completing a NASA graduate fellowship at Mississippi State University in Starkville. After graduation, he and his wife moved to Huntsville to start a life in the heart of the Rocket City where they raised three children and gained seven grandchildren in their 53 years of marriage. Shortly after reporting to NASA, Young was called to active duty in the U.S. Army where he served in the Army Aviation Systems Command and also in Corps of Engineers in Vietnam before returning to NASA.

Young was inspired to pursue a career in engineering at NASA by his cousin, astronaut and former NASA Administrator Richard Truly. “He is a few years older than me and I looked up to him,” said Young.

One of his most memorable experiences was working on the space shuttle Challenger accident analysis team. “Failure analysis is a really interesting task in any job,” said Young. “You’re looking at something that was designed to perform a particular task, and for some reason, it failed, and you’re looking for the why. It isn’t always clear. You seek to understand those things so you can redesign it and control it so it doesn’t happen again.”

Some of Young’s favorite projects over the years include his work on cryogenic fluid management, the early development of the space shuttle main engine, and as branch chief of the Turbomachinery and Combustion Devices Branch at Marshall. As Propulsion Lab technical assistant, he initiated the product development team for the Fastrac engine. When it evolved into the propulsion for the experimental X34 vehicle, he became chief engineer for the project. “The Fastrac engine was exciting because it was a completely new engine. Most of the time, engines evolve from an existing version and are upscaled or improved. Fastrac wasn’t like that,” Young said. “We didn’t use technology from previous engines because we wanted to depart from our current model and build a completely new, more cost-effective engine.”

“George brings so much experience about engines and their history and technological background,” said Michael Lapointe, manager of the Space Technology Development Office at Marshall. “As we move into new areas like additive manufacturing, we really rely on his expertise to understand how the new technology compares with what was previously done to the space shuttle main engine. He’s a very valuable resource for us.”

As for the future, Young doesn’t have any immediate plans to retire. “I’m not going to go home and sit down,” he said. “As long as I’m healthy and enjoying it, I’ll be here. If you enjoy your job, it’s like a hobby and it’s never a chore to come to work.”

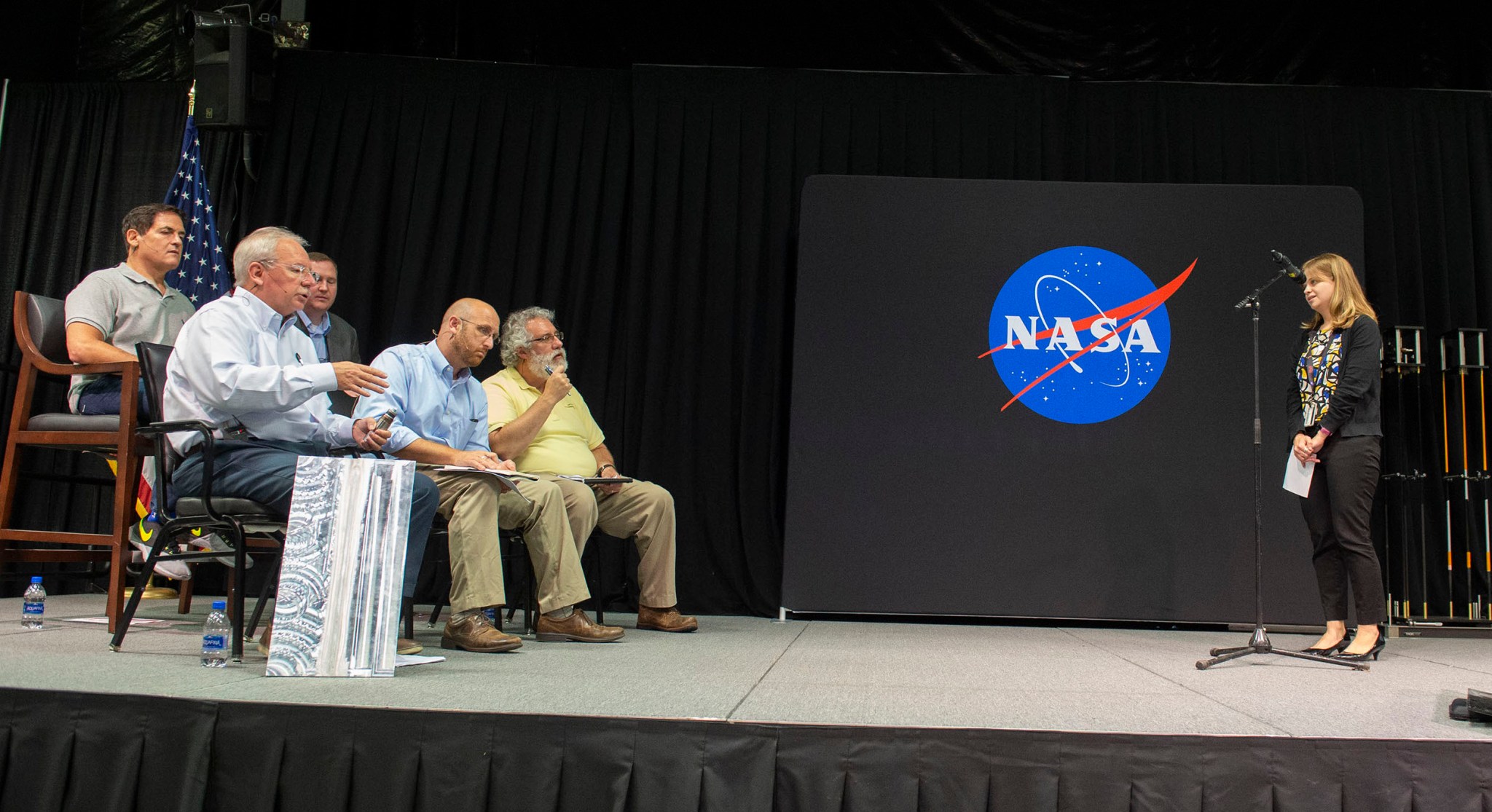

Technology Transfer Office Announces 2018 Tech Tank Winners

Tracy Prater, an engineer in NASA Marshall Space Flight Center’s Materials & Processes Laboratory, pitches her innovation, “W-Re Coatings of Friction Stir Welding Tools,” to a panel of judges at the 2018 Tech Tank. Prater’s idea was selected as one of the top three concepts at the July 19 event, which allowed Marshall team members to pitch ideas of innovation and technology. Other winners from Tech Tank were “Better, Cheaper Shock & Radiation Protection for CCAs” by John McConnell, software quality engineer in the Vehicle Systems Department; and “Biochemical Countermeasures to Radiation Exposure” by Michael Schoenfeld, an engineer in the Propulsion Systems Department. Each of the top winning innovators received a $1,000 cash prize as well as NASA funding to mature their ideas. NASA awarded eight of the 13 participants, including the three winners, a potential total of $77,600 to grow their innovations. (NASA/Emmett Given)

‘Show-Me State’ Students Talk with Astronaut, Celebrate NASA Anniversaries

By Michael Akintonwa and Christopher Blair

More than 200 students in St. Louis spoke with an astronaut aboard the International Space Station, observed Moon rocks and viewed the historic Apollo 11 lunar capsule at the St. Louis Science Center. The day-long event helped celebrate NASA’s 60th anniversary, as well as the upcoming 50th anniversary of the Apollo 11 Moon landing.

On July 18, a “long-distance” Earth-to-space video call was made connecting students with NASA astronaut Serena M. Auñón-Chancellor orbiting nearly 250 miles above Earth. This opportunity, known as an ISS education downlink, marks the first ever conducted at the St. Louis Science Center. Auñón-Chancellor, a flight engineer for Expedition 56, answered questions about living and working in space, while inspiring students to pursue careers in the STEM fields of science, technology, engineering and math.

Following a NASA career having served as a flight surgeon, an aquanaut for the NEEMO 20 undersea exploration mission, and as capsule communicator for multiple space station resupply missions, Auñón-Chancellor is a first-time crewmember aboard station.

“The students recently studied space-themed topics to prepare for this downlink, each one eager to learn more about living and working in space,” said Christian Greer, chief officer for science, education and experience at the St. Louis facility.

The science center was selected through a competitive process as part of NASA’s Year of Education on Station, a campaign providing authentic experiences to enhance student learning, performance and interest in STEM fields. In-flight education downlinks are an integral component of NASA Education’s STEM on Station activity, providing space-station-related resources and opportunities for students of all ages.

The downlink also enriched an exhibit featuring a stunning piece of American space history, the Apollo 11 lunar capsule. On display now until Sept. 3, this capsule carried astronauts Neil Armstrong, Buzz Aldrin and Michael Collins to the Moon and back. The capsule is part a traveling exhibit titled “Destination Moon: The Apollo 11 Mission” on loan from the National Air and Space Museum in Washington.

Throughout the day, NASA’s accomplishments were on display, including examples of space station research and plans for deep-space exploration on the new Space Launch System rocket. Students engaged in hands-on activities conducted by the science center staff, and an education team from local industry leader, Boeing. Additionally, students interacted with representatives from NASA’s Marshall Space Flight Center and elected officials of the Missouri legislature.

Soon, bright-eyed kids like those in St. Louis will lead scientific missions to the Moon, Mars and beyond, thanks to educational activities inspiring the next generation to advance achievements in discovery, invention and exploration.

Akintonwa, a summer intern at Marshall; and Blair, a NASA employee, both support the Office of Strategic Analysis & Communications.

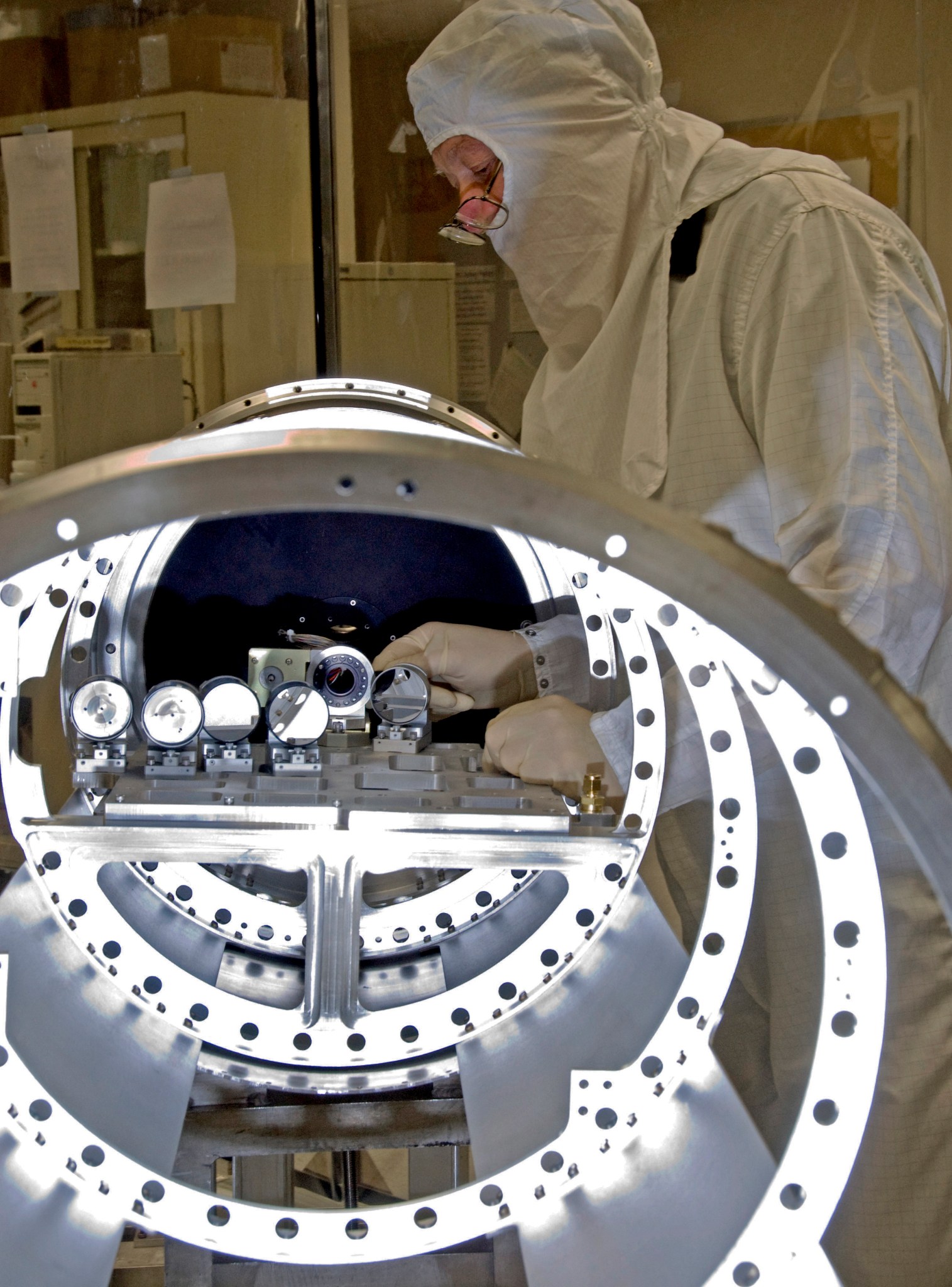

This Week in NASA History: SUMI Launches – July 30, 2010

This week in 2010, the Solar Ultraviolet Magnetograph Investigation, or SUMI, was launched aboard a sounding rocket from White Sands Missile Range. The mission was designed to determine the strength and direction of magnetic fields in a region of the Sun where magnetic fields had never been measured. SUMI successfully targeted a sun spot in the transition region and took the first measurements of the solar magnetic field in the transition region, a turbulent layer of the Sun’s atmosphere that lies between its surface and outermost level. Solar flares that erupt in this region can blast toward Earth, shorting out ground circuits and impacting humanity’s ability to expand into space. SUMI was designed and developed at NASA’s Marshall Space Flight Center. Here, Marshall scientist Ed West assembles the optical system of the SUMI telescope. The NASA History Program is responsible for generating, disseminating, and preserving NASA’s remarkable history and providing a comprehensive understanding of the institutional, cultural, social, political, economic, technological, and scientific aspects of NASA’s activities in aeronautics and space. For more pictures like this one and to connect to NASA’s history, visit the Marshall History Program’s webpage. (NASA)