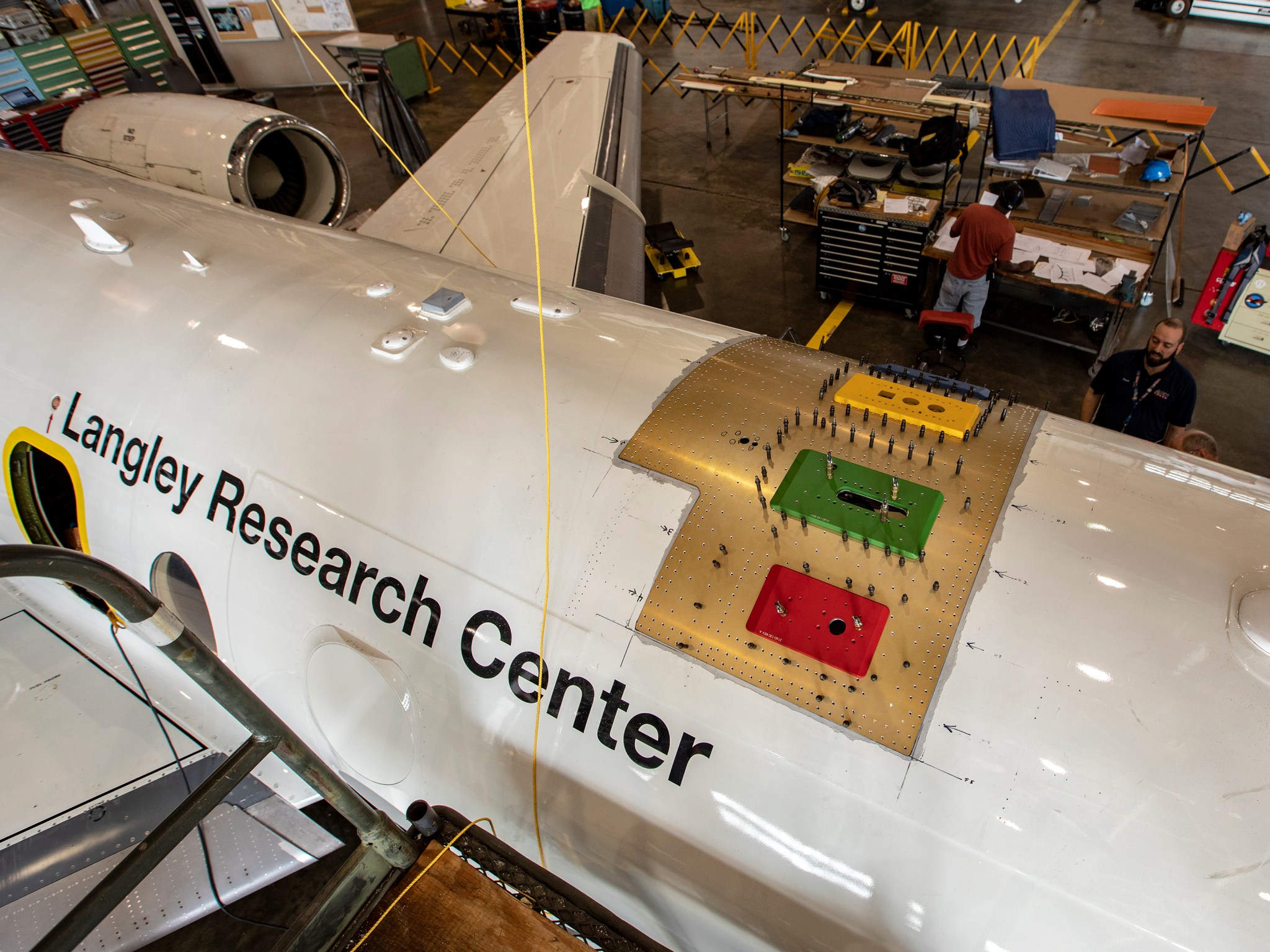

Inside the large and historic hangar at NASA’s Langley Research Center is a buzzing world of aviation. On any day you can find a multitude of aircraft being tinkered on or going on missions in support of numerous NASA projects. Projects like the X-59’s eXternal Vision System that will allow pilots to fly without a forward-facing window, or aircraft outfitted with unique sensors that characterize aerosol-cloud-meteorology interactions supporting NASA’s Aerosol Cloud Meteorology Interactions Over the Western Atlantic Experiment (ACTIVATE ) mission.

This complex system of an ever-changing fleet of aircraft requires serious ingenuity and masterful skills. Aircraft are always changing to meet the needs of the researchers who carry out NASA’s airborne campaigns.

“Some people may not realize that these guys sometimes only have about eight days to gut-out an airplane and then install everything needed for its next mission,” said Rick Yasky, NASA research pilot. “That’s a very short time to do a lot of work, which can include fabricating completely new pieces for the airplane.”

This is where NASA aerospace engineers truly shine. Their mission is to design, install and check new concepts required to support the wide variety of NASA aerial missions. The equipment recently installed in support of the ACTIVATE mission, for example, consists of four large sensors each about six to twelve inches. These sensors were arranged on top of the aircraft’s fuselage in what resembles the morning rays of a sunrise.

“The unique placement and design was completely drawn-up by the engineers,” said Yasky. “Not only did they have to create a mounting system with hundreds of precisely matching mounting points, but they also had to take aerodynamics into account with the exterior placement and mounting shape.”

Another aircraft ready for its next mission was NASA’s Beechcraft King Air UC-12B. The King Air recently finished its flying mission supporting the X-59 XVS test and in a matter of days, the team in the hangar had the plane empty and ready for its next assignment.

The engineering designs don’t just disappear though.

“Even though the exterior cameras are gone from the King Air now, the mounting system within the nose will remain within and can be used again for other tests,” said Yasky.

Not only are many aircraft constantly being outfitted for different missions, but airplanes also require many hours of scheduled maintenance to ensure they’re fit to fly. NASA crew chiefs are responsible for all safety and flight worthiness of the airplane.

“Our crew chiefs routinely inspect and repair every component of these aircraft to the most exacting standards,” said Yasky. “During maintenance you’ll find engines open, wires everywhere, and avionics being removed or installed, all to make sure the plane is safe and ready to go.”

This one-two combo of NASA engineers and crew chiefs is what turn ideas, into reality. Together, these experts ensure the aircraft in their care are ready to fly so NASA researchers and pilots safely and effectively complete their missions.

“They turn 2-D drawings into a 3-D product,” said Yasky. “They’re true artisans at their craft.”

David Meade

NASA Langley Research Center