By Jason Costa

NASA’s John F. Kennedy Space Center

Growing up on the family farm in central Illinois, Kenneth Engeling never imagined working at NASA’s Kennedy Space Center in Florida, let alone having a career in plasma-based technologies. However, hard work, great mentors, and a burgeoning interest in plasma agriculture technology illuminated his path to the world’s premier multiuser spaceport.

After leaving the small rural community where his family has maintained a farm for four generations, Engeling attended the University of Michigan in Ann Arbor. Inspired by his high school chemistry teacher, he pursued an undergraduate degree in nuclear engineering until, one day, he registered for an elective course that would change the direction of his education and his life.

“I stumbled upon Dr. John Foster’s ‘Introduction to Plasma Physics’ course,” Engeling said. “His enthusiasm for the field and his work, combined with the widespread applications of plasma, had steered me to a new course.”

Plasma – considered the fourth state of matter, along with solid, liquid, and gas – is an electrically neutral gas comprising over 99% of the visible universe, including our Sun. NASA’s use of plasma-based technology dates to the Mercury program, as a means of recreating re-entry conditions to test the spacecraft’s heatshield. The agency’s current plasma-based technology research focuses on additional applications like 3D electronics printing, water purification, spacecraft propulsion, and waste management.

Engeling continued to pursue plasma studies through undergraduate research within Foster’s lab and went on to work with the professor throughout graduate school, choosing him as Ph.D. advisor during his doctoral program. Professor Foster kept in contact with his former colleagues from his time working at NASA’s Glenn Research Center in Ohio, and he saw an opportunity in the field of plasma technology for his enthusiastic young student.

“Dr. Foster introduced me to the Space Crop Production team at Kennedy for potential work as an intern,” Engeling said. “During this time, we also met Dr. Annie Meier, who was spearheading a one-year plasma waste gasification project and was looking for an intern with plasma knowledge.”

Fitting the description perfectly, Engeling jumped at the opportunity and soon became an intern at Kennedy’s Applied Chemistry Lab while finishing his doctoral studies. There he found another mentor in Meier and, with her and the OSCAR (Orbital Syngas / Commodity Augmentation Reactor) team, he worked on plasma waste gasification – an extreme thermal process that uses plasma to convert organic waste into energy, specifically electricity and synthetic gas that can be chemically manipulated to create useful gases such as oxygen, hydrogen, and methane.

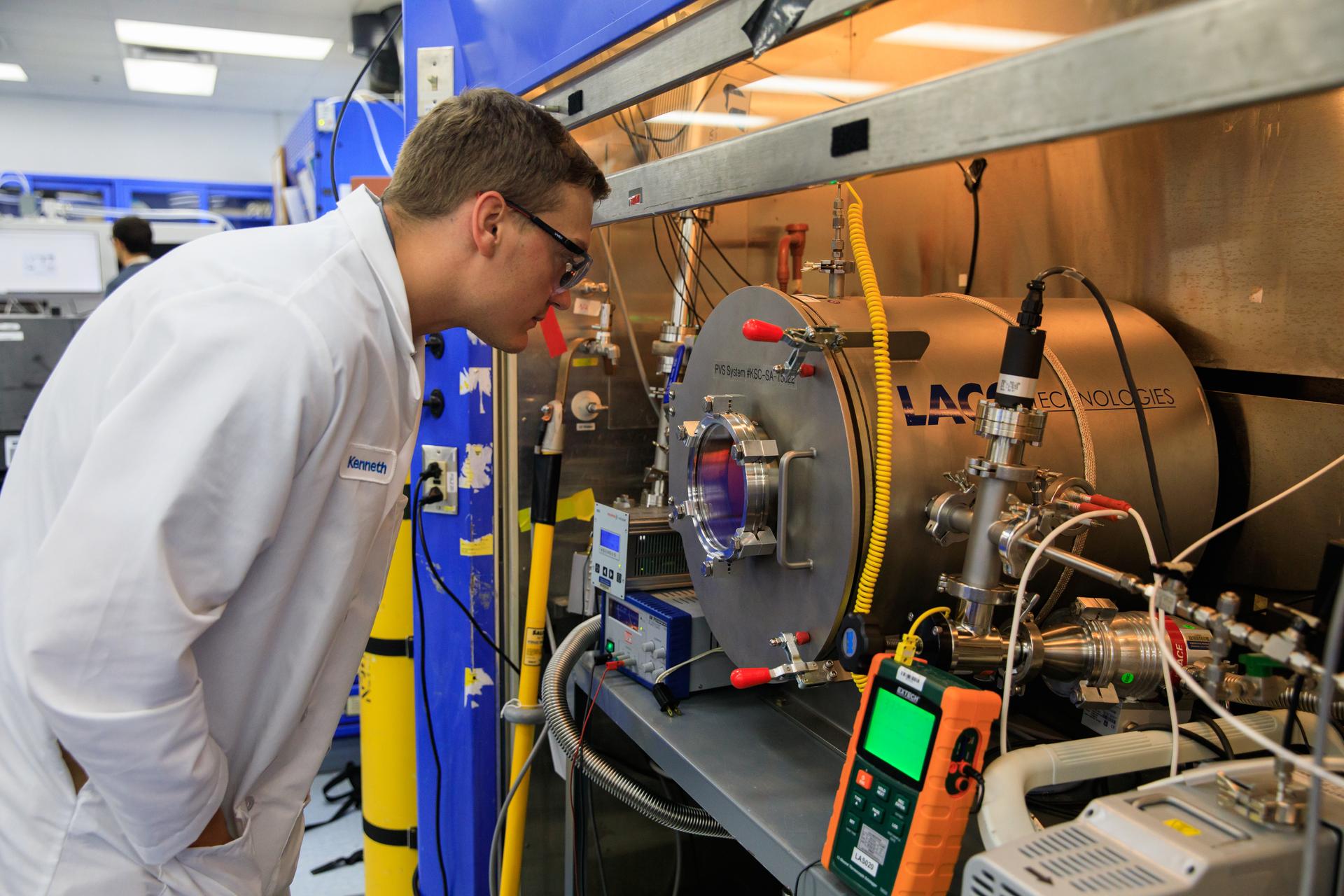

In an effort to demonstrate the use of an alternative technology, Engeling worked with a plasma torch as the thermal processing tool for waste gasification. He also worked with the Space Crop Production team, commonly referred to as the Veggie group, on ways to sterilize seeds. After graduating with his Ph.D., he took a contracting job with the Air Force, but as soon as a position opened with Meier and her team, Engeling applied, was hired, and began his fulltime career at NASA in the summer of 2020.

“My favorite part about working for NASA is the colleagues I have around me,” Engeling said. “Not only are they fantastic people but being able to ‘walk across the hall’ and have discussions with experts in chemistry, trash-to-gas systems, materials science, and space crop productions really opens up a world of possibilities.”

Engeling now spends much of his time in the lab as an agency aerospace technologist working on a handful of projects at Kennedy Space Center that may one day help support future deep space exploration. One project is molten regolith electrolysis (MRE), or melting lunar soil to extract oxygen, while another is working on plasma-produced gaseous species – reactive gases energized during plasma creation that help control chemical reactions – for sanitizing seeds, produce, and equipment. He also works to create rocket fuel from Moon rocks and treats volatile organic compounds, or toxic gases, with plasma to break apart the compounds into less harmful gases.

Though his current work has taken him a long way from the family farm, Engeling thoroughly enjoys working with plasma technology and is reminded regularly by the lab team’s successes – and failures – just how useful their work is in shaping the future of long-duration human exploration of space.

“A fun aspect of normal workdays is that I am surrounded by people with an interest in new technologies and ideas that allow us to create new processes or concepts as we pursue technological goals such as waste management or plasma assisted space crop production,” Engeling said. “Having those around you that are eager to learn and discover new methods really makes NASA a unique and enjoyable place to work.”