Name: David Robinson

Title: Branch Head, Environmental Test Engineering and Integration Branch

Formal Job Classification: Supervisory Aerospace Engineer, Flight Systems Test

Organization: Code 549, Environmental Test Engineering and Integration Branch, Engineering and Technology Directorate

What do you do and what is most interesting about your role here at Goddard? How do you help support Goddard’s mission?

As the branch head, I run the group that integrates and tests spacecraft and instruments. We take flight hardware through a series of tests to verify it can survive what it will experience during the rocket launch and while in space. Our motto is “Test like you fly, and fly like you test.”

The most interesting thing about my job is that I am responsible for a lot of unique large scale test facilities such as the high capacity centrifuge, vibration tables, thermal-vacuum chambers, and electromagnetic labs, plus about a dozen clean rooms. Through the people in my branch, I am involved in the activities of hundreds of people working on Goddard’s flight projects.

When did you decide to become a mechanical engineer?

As a kid, I was fascinated by airplanes and read as much as I could about the adventures of fighter pilots and astronauts. I was always trying to build airplanes out of Legos. When I was about 12 years old, my mother said that since I loved airplanes and rockets so much I should be an aerospace engineer. It turns out that was all it took to give me a direction in life.

What is unusual about your education?

In 1996, I attended the International Space University (ISU) in Strasbourg, France for a master’s in space studies.

I wanted to get the big picture about space and get international experience. At ISU, I met students from all over the world and learned about different space agencies including the European Space Agency. I learned a lot about space, from science to policy, from launch vehicles to control rooms.

I was raised in Lexington, Kentucky, and went to the University of Virginia for a bachelor’s in aerospace engineering. In 1990, I started working at NASA’s Glenn Research Center in Cleveland, Ohio, as a systems safety engineer on the space station.

While at NASA Glenn, I attended Cleveland State University and earned a master’s in mechanical engineering.

How did you get to Goddard?

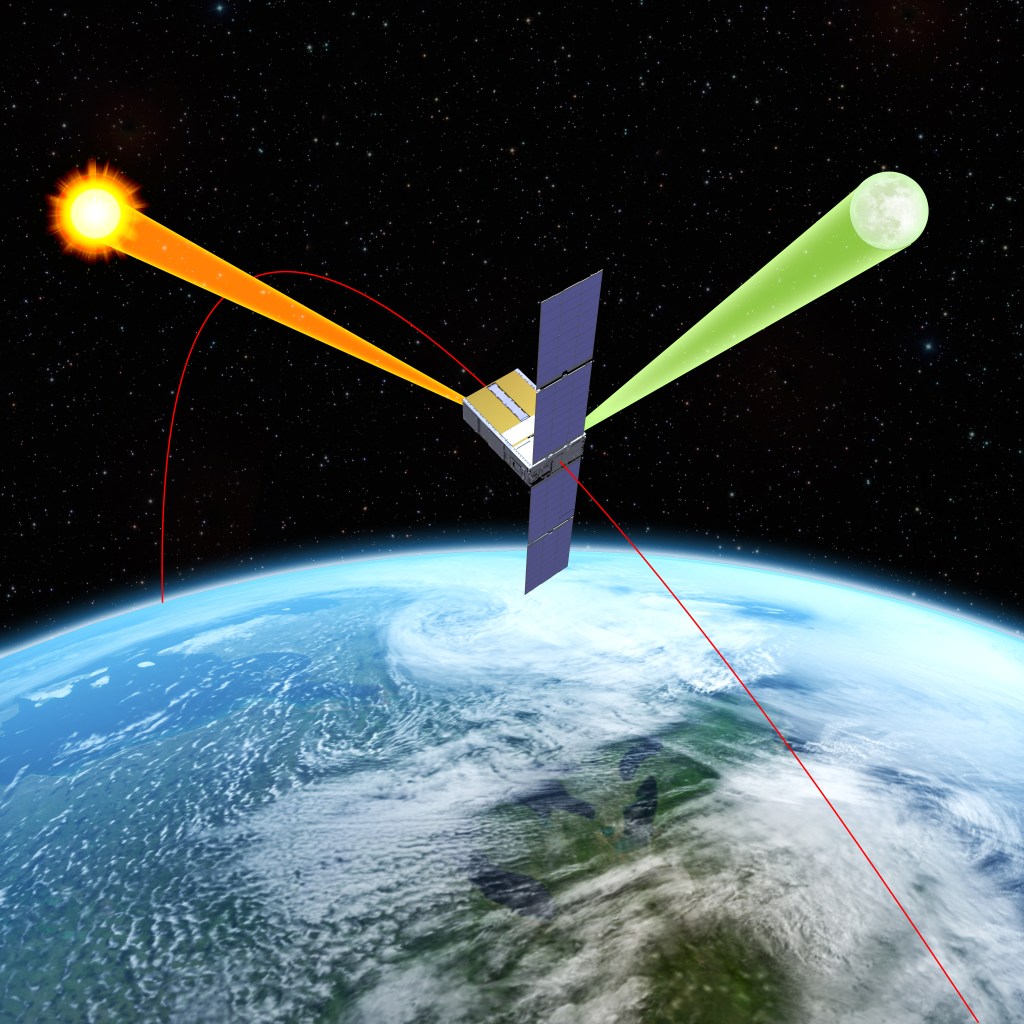

In 1997, I transferred from NASA Glenn to Goddard to work in the mechanical engineering branch designing and building spacecraft and instruments. I worked on many projects including the Burst Alert Telescope (BAT) instrument on Swift, the Solar Dynamics Observatory (SDO), the Thermal Infrared Sensor for Landsat 8, Astro-H, and concluded with the Global Ecosystem Dynamics Investigation Lidar (GEDI).

What was one of your favorite projects?

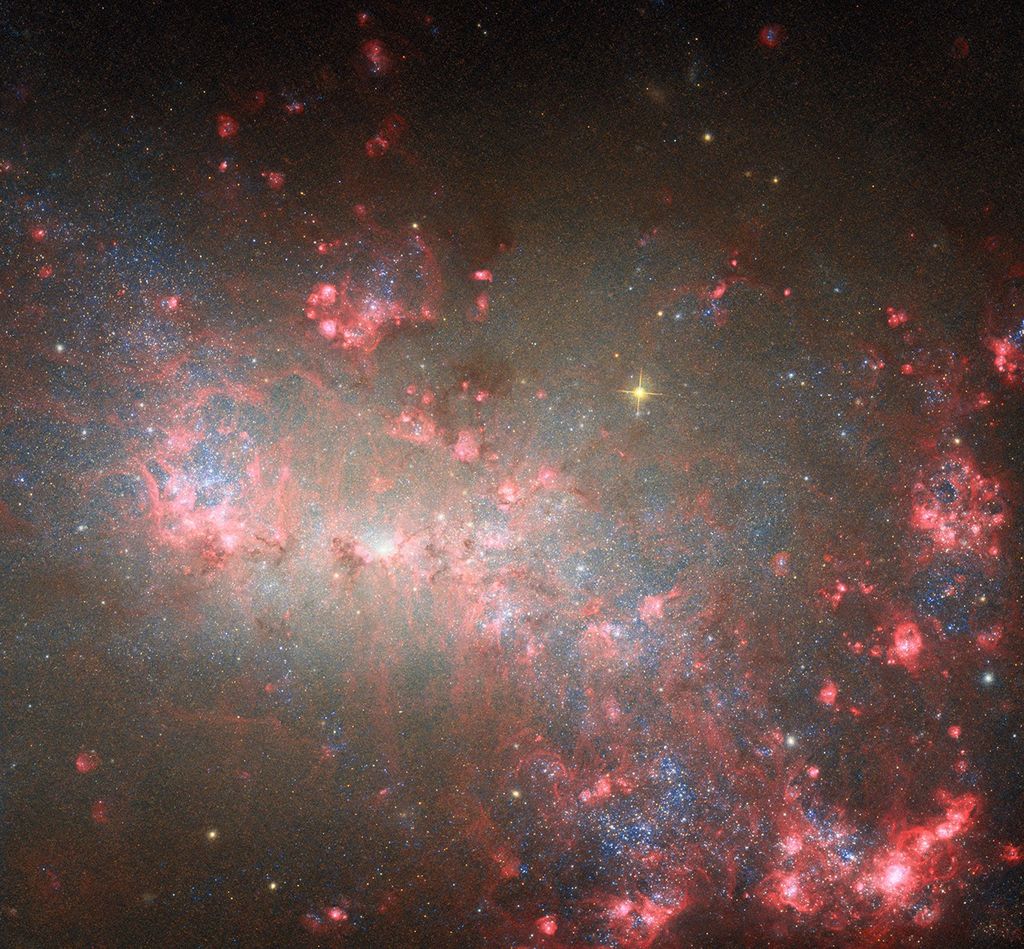

Of all the projects I worked on, one of my favorites was the Solar Dynamics Observatory (SDO). I was the lead mechanical engineer for the spacecraft bus. I got to design, build, assemble and test the spacecraft bus. I even got to see it launch.

Something that I physically put my hands on is now in space! It’s an awesome, great feeling! You put your heart and soul in something for four or five years, see it launch and then know that it is producing science for the solar science community!

How does it feel to be a manager and no longer a hands on engineer?

Now my job is all about enabling people in my branch to do good work, making sure that we have the funding, developing the people in my branch to have the right skills. I get to see the big picture. I see every mission that comes to Goddard. In the past, I worked on one project for four or five years. Now on a daily basis, I may interact with a dozen projects that are in the integration and test complex.

Also, I have a lot more personal interactions. Instead of working with a small group of people day in and day out, now I meet with people from all of the directorates at Goddard to solve problems, make plans, and set the stage for integration and testing up here in the Integration and Test Complex. So I interact with many more people than I used to as an engineer.

I now use a different part of my brain.

How do you smooth out conflicts?

Sometimes I need to smooth out conflicts between people, and balance the priorities of different Goddard teams.

I try to be a good listener and understand everybody’s point of view and motivation. I believe that at Goddard, we are all working in good faith to get missions done. When I can help people understand each other and realize that we all want to accomplish the same goal of getting the mission done and move forward together, often conflicts fall away. It is a little like being a coach of a football team or a therapist.

What do you miss most about being a project engineer? What do you enjoy most about being a manager?

I miss designing and building things and working in an intense project environment. I miss putting my hands on flight hardware.

On the other hand, as a manager, I really enjoy mentoring the young people in my branch and helping them develop their potential as test engineers. Seeing them grow brings me great joy.

You manage many cool types of facilities. Please tell us about the enormous High Capacity Centrifuge (HCC)?

We have a unique national asset, our centrifuge, technically the High Capacity Centrifuge (HCC), which has a 120-foot long rotating arm that spins up to 38 revolutions per minute. It weighs 500,000 pounds, all steel, resting on a giant bearing assembly. The “tip speed” of the HCC is about 160 mph, which generates nearly 30g of acceleration. The HCC was built in 1964. It is powered by two huge, 1,250 horsepower motors, each weighing about 5,000 pounds, which we recently refurbished.

Basically, the HCC is like a merry-go-round. If you are sitting in the center, you are not spinning as fast as when you are sitting on the edge.

We test our satellites and instruments on the HCC to make sure they can withstand the forces of a rocket launch. We are planning to test the Wide Field Infrared Survey Telescope (WFIRST). In the past, before I became branch head, we worked with the National Safety Transportation Board to test the speed at which certain SUVs would roll over. We put a two-ton vehicle on the centrifuge platform, strapped it in a special rig so it could not fall off, and spun it around until it tipped over. We are one of the few facilities in the United States with this capability.

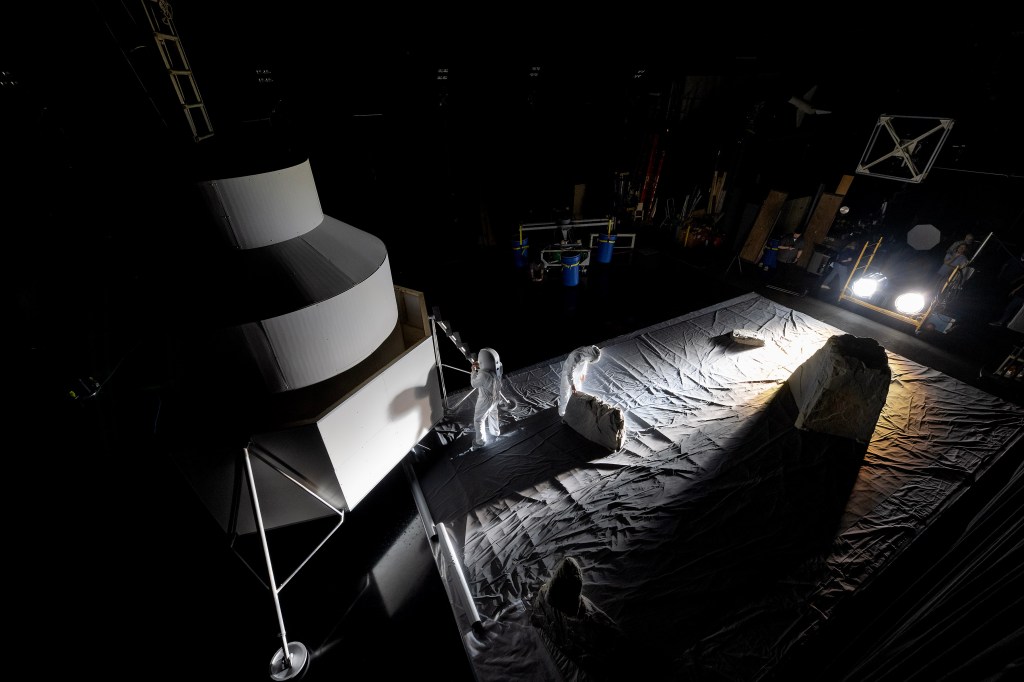

Please describe the ‘world’s largest’ clean room by volume, the Spacecraft Systems Development and Integration Facility (SSDIF)?

On center, we have over 30 clean rooms. Within the Integration and Test Complex, which I manage, we have about a dozen. Our SSDIF is a celebrity in the world of clean rooms because it is where a lot of the Hubble Space Telescope servicing mission preparation and James Webb Space Telescope (JWST) assembly work was done.

We also have the world’s largest ISO 7 clean room, the SSDIF. It is enormous; it is 10 stories tall with a volume of 1.3 million cubic feet. It has six huge, essentially aircraft propellers on the 10th floor that pull air through a massive wall of HEPA filters. The airflow through the HEPA filters can be as high as 900,000 cubic feet per minute. For a typical home, this airflow would be about one complete air exchange per second.

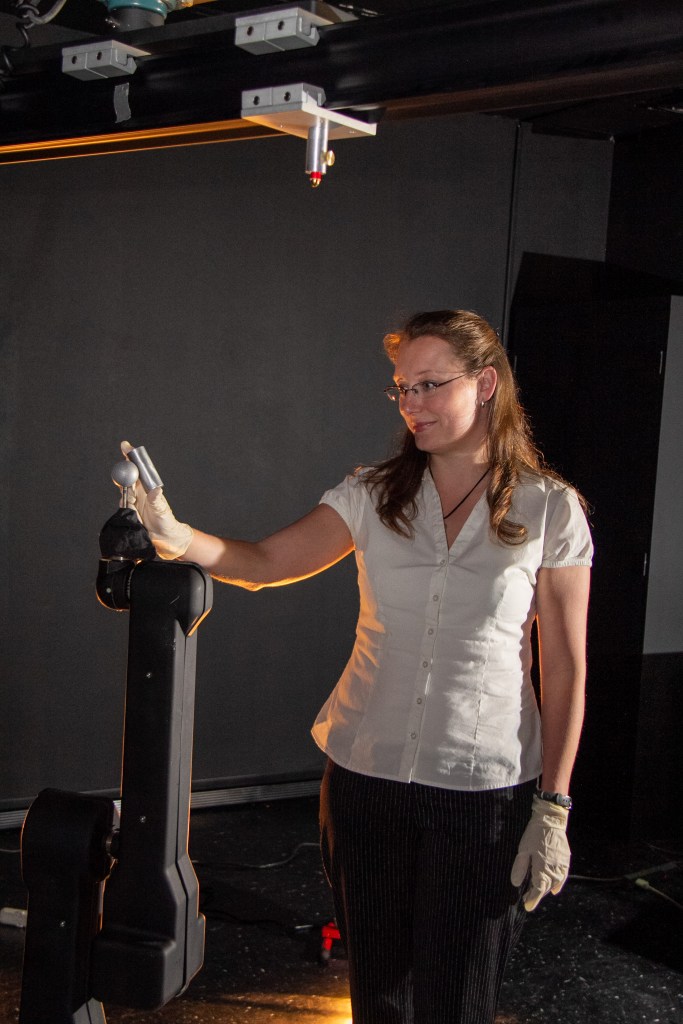

Everyone who enters has to first put on a clean room bunny suit and go through an air shower before entering. Every tool and piece of equipment that goes in has to be precision-cleaned with alcohol or other special solvents.

Please tell us about some of Goddard’s other impressive testing equipment.

We also have a lot of impressive testing equipment. Our overall group of testing equipment is sometimes called our “shake and bake” test area.

Our huge thermal vacuum chamber, the Space Environment Simulator (SES), is one of the largest in the United States; the interior is 27 feet in diameter by 40 feet tall. It is large enough that we can put an entire satellite inside it and deploy solar arrays and antennas. We can chill and heat the internal walls of the chamber to cool down a satellite as cold as minus 175 degrees Celsius (minus 283 F) and warm it up as hot as 100 degrees Celsius (212 F).

Our 900 square foot acoustics chamber can reproduce the noise of an actual rocket launch. We can go as loud as 154 decibels, which is the equivalent of standing next to an aircraft jet engine. We also have several vibration tables that shake flight hardware to make sure they can survive the vibrations of a rocket launch.

We also do extensive Electromagnetic Interference and Compatibility (EMI/EMC) testing, which checks to make sure that the avionics on a satellite do not interfere with each other and also whether the avionics can survive the electromagnetic environment in space.

In your almost 30 years of working for NASA, what are some of the international projects you have enjoyed?

In 1996, I worked on a hand-held space experiment for the U.S. astronauts that flew to the Russian Mir Space Station. I got a chance to go to Moscow and Star City to deliver the experiment and meet the American astronauts. I was fairly young, a little nervous. I thought it was the coolest thing in the world to hand deliver an experiment to an American astronaut in Star City, Russia!

From 2011-2014, for the Astro-H project, a collaboration with the Japan Aerospace Exploration Agency, I made several trips to Japan to install our part of the cryogenic instrument into their part of the instrument. We worked long, hard days to complete all the integration.

Is there something surprising about your hobbies that people do not generally know?

My wife and I have two sons. As a Boy Scout dad, we went on many camping trips and events including a two-week backpacking trip to the Philmont Scout Ranch in New Mexico. We are very proud that our two sons became Eagle Scouts, the highest Scout honor.

I also have a 120-year-old house which keeps me busy renovating. I’ve had to fix, replace, build, or paint just about everything in it, which taught me a lot about project management and engineering!

In addition, I love to garden. I have a small orchard with apples, cherries, peaches, grapes, blueberries and raspberries. I also make my own sweet apple cider if the weather behaves and I get a good harvest.