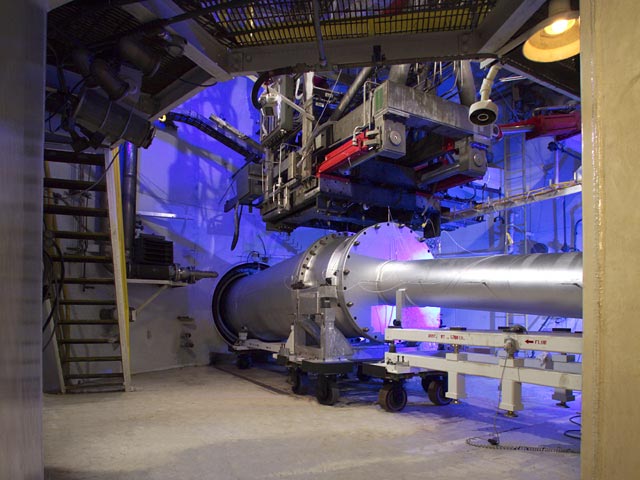

The Hypersonic Tunnel Facility (HTF) at NASA’s Neil Armstrong Test Facility in Sandusky, Ohio, was originally designed to test nuclear thermal rocket nozzles. It is a hypersonic (Mach 5, 6, and 7) blowdown, non-vitiated free jet facility that tests large-scale hypersonic air-breathing propulsion systems.

Facility Overview

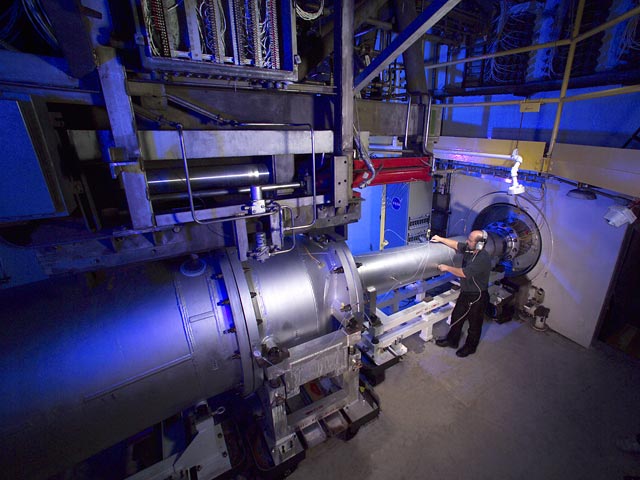

Designed to conduct research, development, and acceptance testing of hypersonic airbreathing propulsion systems, HTF is a fully self-contained facility. Its experimental infrastructure includes a shop area for fabrication of materials for facility subsystems and assembly of customer hardware. Due to the high-energy nature of the facility, it is operated remotely from a control room approximately one-quarter mile from the actual facility.

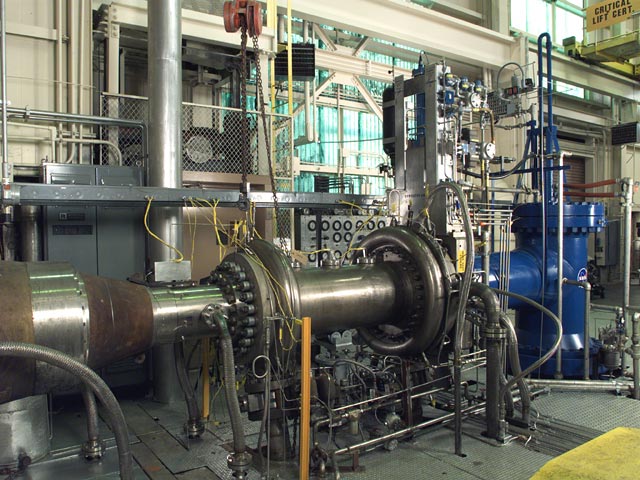

The HTF is a blow-down, non-vitiated, free jet wind tunnel that is capable of simulating Mach 5, Mach 6, and Mach 7 true enthalpy conditions. The primary performance differentiator between the HTF and other hypersonic free jet facilities is its non-vitiated (clean) flow. Whereas traditional facilities of this type use a combustion process to generate high enthalpy conditions required to simulate hypersonic flows, the HTF generates these conditions by flowing nitrogen gas through a 3-MW graphite core storage heater. This heated nitrogen is then mixed with ambient temperature oxygen and ambient temperature nitrogen to yield a flow of synthetic (true composition) air at the requisite stagnation temperature. Three interchangeable nozzles are used to establish the facility Mach number condition of 5, 6, and 7. A nominal free jet test section “characteristic dimension” is the nozzle exit diameter, 42 inches for the HTF.

However, the hypersonic core flow varies with Mach number. The test section length can be adjusted from 10 feet to 14 feet in length. Utilization of aero-appliances around test hardware is standard practice. A single stage steam ejector is used to exhaust the facility flow and provide altitude simulation.

The facility’s size and long run duration allow for full systems testing of large flight-rated structures and propulsion systems. The facility is capable of supporting both hydrogen and hydrocarbon fueled propulsion systems. In addition to free jet testing, the use of the facility to support direct connect subsonic and supersonic combustion is currently being developed. This capability would allow for the testing of large-scale combustors in a non-vitiated flow.

Quick Facts

| Hypersonic Tunnel Facility | |

|---|---|

| Mach Number | 5.0 – 7.0 |

| Test Section | 10 feet length available, expandable to 14 feet |

| Altitude | Up to 120,000 feet |

| Total Pressure | 1200 psig maximum |

| Total Temperature | 4500°R maximum |

- The HTF contains a large stand-alone experimental infrastructure that can be readily reconfigured to test a variety of ground test applications including high-energy, high-risk testing.

- In addition to free jet testing, the use of the facility to support direct connect subsonic and supersonic combustion is currently being developed.

- The HTF’s size and long run duration allow for full systems testing of large flight rated structures and propulsion systems.

- Originally designed to test nuclear thermal rocket nozzles as part of the Nuclear Engine for Rocket Vehicle Application (NERVA) program, the HTF was reconfigured as a hypersonic (Mach 5,6,7) blowdown, non-vitiated, free jet facility capable of testing large-scale hypersonic airbreathing propulsion systems.

Capabilities

Operational Features

- Blowdown, free jet tunnel

- Utilizes non-vitiated air supply

- 3-MW graphite storage heater

- Provides:

- True flight enthalpy test conditions

- Altitude simulation

- Air composition (Synthetic: GN2, GOx)

- Maximum Operating Conditions:

- 4,500°R maximum total temperature (mixed)

- 1,200 psig maximum total pressure

- 222 lbm/sec Total Flow

- Up to 120,000 ft altitude simulation

- Five-minute run time (depending on operating conditions)

- 42-inch exit diameter nozzle

- 14-foot test section length available that can be expanded to 14 feet to accommodate longer test articles

- 8,500 lbf thrust balance – single axis

Propellant Systems

- Gaseous H2

- Liquid hydrocarbons (JP7, JP10, etc.)

- Silane

- Upgrade possible for LOx and LH2

- LH2 system in standby

Control Systems

- PLC system – sequences facility systems

- Test Matrix Sequencer – sets run parameters

HTF Run Conditions, Nozzle

| Nozzle | Mach 5 | Mach 6 | Mach7 |

|---|---|---|---|

| Stagnation Pressure, psia | 410.0 70.5 |

1200.0 144.0 |

1200.0 430.0 |

| Stagnation Temperature, R | 2200 2420 |

2965 3310 |

3830 4500 |

| Mass Flow, lbs/sec | 189.0 30.9 |

222.0 25.4 |

104.0 36.2 |

| Throat Diameter, in. | 7.2 7.2 |

4.9 4.9 |

3.2 3.2 |

| Exit Diameter, in. | 42.0 42.0 |

42.0 42.0 |

42.0 42.0 |

HTF Run Conditions, Test Section

| Test Section | Mach 5 | Mach 6 | Mach 7 |

|---|---|---|---|

| Static Pressure, psia |

0.74 0.118 |

0.61 0.071 |

0.33 0.071 |

| Static Temperature, R |

384 428 |

390 451 |

412 451 |

| Altitude, ft | 68,000 108,000 |

72,000 120,000 |

93,000 120,000 |

| Run Time, sec | 103a 294b |

42a 294b |

90a 180c |

b – Limited by steam availability at 150 psig

c – Limited by mixture and diffuser temperature limits

Contact

Hypersonic Tunnel Facility (HTF)

Facility Manager: Hal Weaver

419-621-2219

Harold.F.Weaver@nasa.gov

Neil A. Armstrong Test Facility (ATF)

Deputy Director: David Taylor

419-621-2101

David.E.Taylor@nasa.gov

Using Our Facilities

NASA’s Glenn Research Center in Cleveland provides ground test facilities to industry, government, and academia. If you are considering testing in one of our facilities or would like further information about a specific facility or capability, please let us know.

/Hubble%20Space%20Telescope%20(A).png)